Osaki OSA-279-8000K User manual

150mm (6”) BENCH GRINDER-250W

ORDER CODE

OSA-279-8000K

OPERATOR S MANUAL

P ease retain this information for future reference.

WAR I G:

THE SAFETY I FORMATIO GIVE I SIDE MUST BE READ

A D U DERSTOOD BY A Y PERSO USI G, I STALLI G, REPAIRI G OR

MAI TAI I G THIS PRODUCT.

•Suitable for DIY & hobby use

•Powerful 250W smooth running motor,

230-240V/50Hz supply

•Spark deflectors/eye shields

•Adjustable work supports

- Supplied with:

150 x 20 x 36 grit wheel

150 x 20 x 60 grit wheel

QUALITY GUARANTEE & WARRANTY

O AKI POWER TOOL carry a one year manufacturer’s warranty.

O AKI POWER TOOL are designed & produced to the highest standards & specifications.

O AKI POWER TOOL are fully guaranteed against faulty materials & workmanship.

Should they be found to be defective, they will either be repaired or replaced free of charge

(fair wear and tear and/or misuse excepted). This does not affect your legal rights.

Please retain supplier invoice as proof of purchase.

OSA I POWER TOOLS are designed for DIY and hobby use only.

They are not covered by an industrial warranty. Industrial use will invalidate this guarantee.

Specifications may change without prior notice. E&EO

THE ENVIRONMENT

DECLARATION OF CONFORMITY

We hereby certify that the

OSAKI 150MM (6”) BE CH GRI DER - 250W

(ORDER CODE: OSA-279-8000K)

complies with all the relevant provisions of the

Machinery Directive 2006/42/EC

Standards Applied: EN 61029-1:2009/A11:2010, EN 61029-2-4:2011

EMC Electromagnetic Compatibility Directive 2014/30/EU

Standards Applied: EN 55014-1:2006/A2:2011, EN 55014-2:1997/A2:2008, EN 61000-3-2:2014, EN 61000-3-3:2013

RoHS2 Restriction of Hazardous Substances Directive 2011/65/EU

Standards Applied: EN 50581-1:2012

igned:

Date: 29th November 2017

Name: eith Read

Position: HSQE Manager

Official Agent

KENNEDY TOOLS

Wigston, Leicester, England, LE18 2F .

www.kennedy-tools.co.uk

Always dispose of unwanted tools, accessories and packaging materials in an environmentally

friendly manner.

In observance of European Directive 2012/19/EU on Waste Electrical and Electronic Equipment

(WEEE) and its implementation in accordance with national law, electrical goods that have

reached the end of their life must be collected separately and returned to an environmentally

compatible recycling facility.

Do not dispose of electrical goods with domestic waste materials as inappropriate disposal may

cause potential hazards to the environment and human health.

For further information, please contact your local authority or the retailer from whom you

purchased the product.

This product does not contain any restricted substances in concentrations and applications

which are banned by the European RoHS2 Directive.

© The Kennedy Group Ltd. 11/17

THE KE EDY GROUP LTD, Wigston, Leicester, England, LE18 2FS.

Osaki Power Too s are committed to the production of a range of qua ity power too s

that are designed for high performance and ong service ife. By fo owing the

recommended safety and maintenance procedures they wi ast for many years.

WORK AREA CAUTION

PERSONAL SAFETY

1.

Keep your work area clean and well lit. Cluttered

benches and dark areas will invite accidents.

2. Do not operate power tools in explosive

environments. for example; in presence of

flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or

fumes.

3. tore tools out of reach of children or other

untrained persons. Tools are dangerous in the

hands of untrained users.

4. Keep bystanders and children away while

operating the power tool. Distraction can

cause you to loose control.

WARNING!

Grinding dust becomes a potential health problem when

airborne. Breathing these particles may cause allergic respiratory symptoms,

mucosal & non-allergic respiratory symptoms & cancer.

1. ALWAY wear the approved eye, ear and respiratory protection during operation.

Use safety glasses or goggles which conform to BSEN136 or CE equivalent that

provide protection from the front and side. It is always the user’s responsibility for

following accepted eye, face, respiratory, hearing and body protection.

2. Dress appropriately. Always ensure that all long hair and loose clothing, ties,

scarves, jewellery, etc., are secured or removed.

3. TAY ALERT! Watch what you are doing and use common sense when operating a

grinder. Do not use the tool while tired or under the influence of drugs, alcohol, or

medication. Loss of concentration while operating power tools may result in serious

personal injury.

4. To avoid accidental starting be sure the power switch is in the ‘off ’ position before plugging in.

Plugging in tools that have the switch on is very dangerous.

5. Remove wrenches before turning the grinder ‘on’. A wrench that is left attached to a rotating part

of the tool may result in personal injury.

6. Never use the grinder without the safety guards in position and operating correctly.

2

NOTES

3

6

ELECTRICAL AFETY

A RCCB (Residual Current Circuit Breaker) should be fitted in the mains

electricity distribution board.

PLUG FITTING

A moulded U 3 pin plug with ASTA/BS approval is already fitted for your

safety. If it becomes damaged, and needs replacing, cut off the plug and

prepare the wires. Use the following instructions:

a) Connect the GREEN/YELLOW earth wire to the earth terminal marked

either ‘E’ or with the earth symbol ‘ ’.

b) Connect the BROWN live wire to the live terminal marked ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal marked ‘N’.

d) After wiring, check there are no bare wires, that all wires have been correctly connected, that the cable

external insulation extends beyond the cable restraint and that the restraint is tight.

Yellow & Green = Earth wire

Brown = Live wire

Blue = Neutral wire

Cable restraint

UK

ONLY

ELECTRONIC INFORMATION

13amp

fuse

SPECIFICATIONS

Order code OSA-279-8000K

Motor input capacity 250W

Motor supply voltage 230V-240V/50Hz

No load speed 2950RPM

Wheel size 150 x 20 x 12.7mm

Size inc. guards (HxWxD) 250 x 320 x 230mm

Net weight 7.5kg

WHEEL REPLACEMENT

When the distance between the outer diameter of the grinding

wheel and the edge of the work support is greater than 5mm,

the grinding wheel needs to be replaced.

Checking New Grinding Wheels

New grinding wheels must be tested using a “ringing test”

method. A light tap on the grinding wheel with a light non-

metallic implement or knocking the grinding wheel against a

surface, will produce a clear ringing sound which will indicate

that it is intact.

Changing A Grinding Wheel

1. Loosen the three screws.

2. Remove the outer covering plate.

3. Remove the holding nut, flange and grinding wheel.

4. Insure that the second flange remains on the shaft.

5. Put the replacement grinding wheel onto the shaft.

6. Replace the flange and the nut.

7. Secure the nut fully but do not over tighten.

8. Remount the covering plate with the three screws.

9. Adjust the spark deflector and work support to a 2mm gap.

A certain oscillation of the wheel is normal, up to 0.3mm in radial and 0.5mm in axial direction

measured at the circumference of the wheel.

ELECTRICAL SAFETY

1. Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adaptor plugs with earthed (grounded)

power tools. Matching plugs and outlets will

reduce risk of electric shock.

2. Avoid body contact with grounded surfaces

such as pipes, r a d i a t o r s , r a n g e s and

refrigerators. There is an increased risk of

electric shock if your body is grounded.

3. DO NOT expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

4. DO NOT abuse the cord. Never use the cord to

pull the plug from an outlet. eep the cord

away from heat, oil, sharp edges or moving

parts. Damaged cords should be replaced

immediately by qualified repair personnel.

Damaged cords will increase the risk of

electric shock.

5. When o p e r a t i n g the grinder in a d a m p

location or outside, use a heavy duty

extension cord in conjunction with a residual

current device (RCD) rated at 30mA or less.

4 5

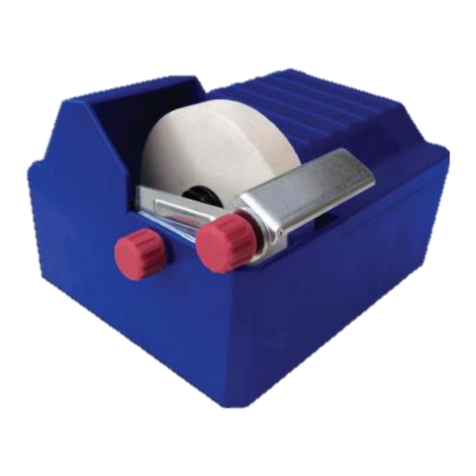

IDENTIFICATION

This tool has been designed for metal grinding applications. Please read its instructions to familiarise

yourself with the major components of this tool before using it.

Eye Shield

Spark deflector

Motor Housing

Work Support

Adjusting nob

On/Off switch

Fixing hole 8mm

Adjusting Screw

Coarse

36 Grit

Medium

60 Grit

Wheel

guard

cover

Outer

Flange

Inner

Flange

ASSEMBLY

<2mm

<2mm

All the following components must be fitted correctly before

using the bench grinder.

• Spark Deflectors - These are provided to prevent sparks

from re-entering the grinding wheel assembly. The gap

between the spark deflector and the face of grinding wheel

is adjustable and should be kept at a distance of 2mm.

Fitted in two parts, the mounting bracket and the deflector.

Firstly, screw the mounting bracket to the wheel guard as

shown in Fig.2 then fix the deflector to the mounting

bracket, setting it at a distance of 2mm from the grinding

wheel. see Fig.3

INSTALLATION

The bench grinder must be placed on a flat, horizontal and stable surface. The bench grinder should be

fixed to something heavy enough, so that it will not move whilst in use.

Attach the bench grinder using screws or nuts and bolts using the four 8mm fixing holes provided at the

base of the unit.

When using the bench grinder for the first time, it should be allowed to run for at least five minutes

before it is used to grind a work piece.

OPERATION

Remember to wear the appropriate personal protective equipment.

Check that the machine is assembled and adjusted correctly then switch on the machine.

The machine must reach full speed before any grinding work commences.

For best results use the coarse grinding wheel first followed by the medium grinding wheel.

Rest the workpiece on the Work Support to eliminate chatter then add a small amount of pressure to

grind away to the desired amount.

Grinding Wheel Handling and torage

All grinding wheels can be easily damaged by mishandling that results in the wheel being subjected to any

shock loading. This can occur by inadvertently dropping, knocking or banging against any other object.

Any grinding wheel subjected to such mishandling should be carefully examined for signs of damage.

If in doubt do not use.

During storage, grinding wheels must not be subjected to:

Humidity, water or other liquids. Freezing temperatures. Any temperature low enough to cause the

formation of condensation.

• Eye Shields - Protect from grinding

debris which is thrown out at a

high velocity and can damage

your eyes. The eyeshields are

fitted to the top of the spark

deflectors using a 50mm Cross

Head Cap Screw, nut and

washers.

Before changing an eye shield

ensure that the machine is

switched off. Always ensure that

eyeshields are undamaged and

fitted securely before operating

the machine.

• Work Supports - Used to provide a firm and stable support to rest

the work piece on. The distance between the work support and

grinding wheel is adjustable, checked frequently and should be

kept at a distance of 2mm.

Fig.3

Fig.1

Fig.2

Fig.4

Fig.5

Other Osaki Grinder manuals