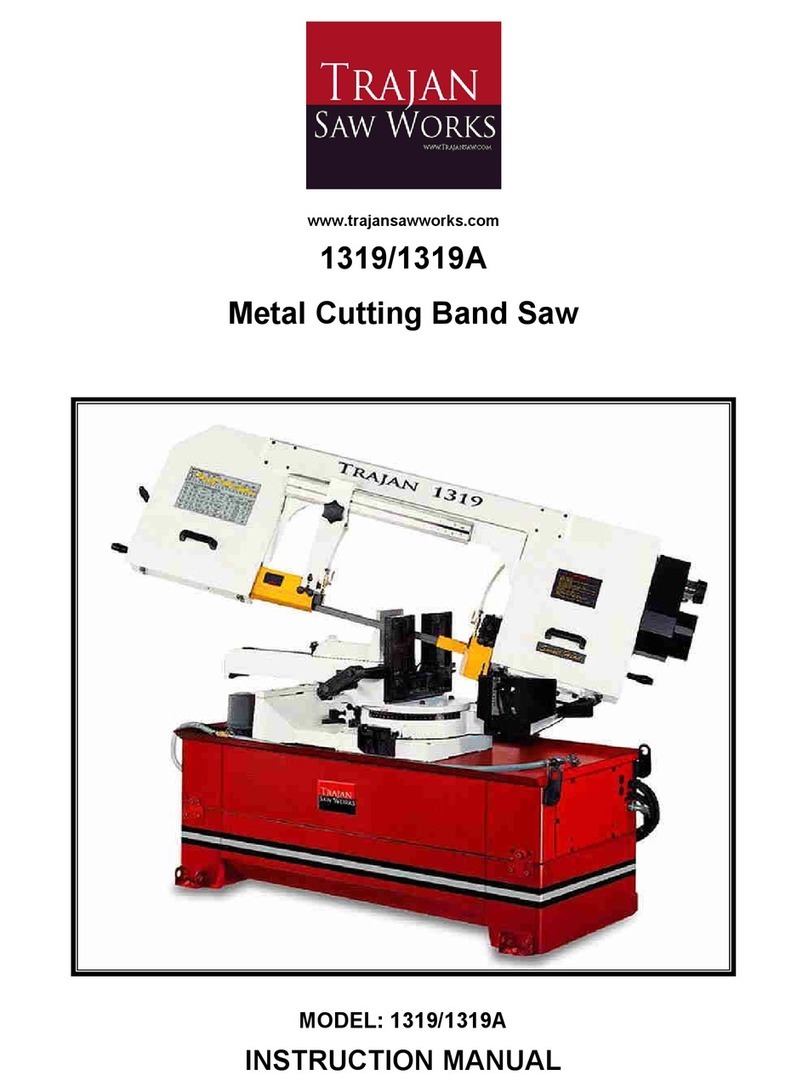

Osaki XTRA-PLUS MCS14-2000 User manual

METAL CUT-OFF SAW

OPERATORS MANUAL

MCS14-2000 Order Code OSA-279-4600K

OPERATING

OPERATING

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

1. Saw head

2. Handle

3. Adjustable guard for the cutting-off wheel

4. Adjustable clamping face

5. Spindle

6. Hand crank

7. Stationary clamping face

8. Carry handle

9. Shaft lock

11. Cutting-off wheel

12. Table

13. Chain

14. Hinged nut

15. Vice

16. Lock screw

17. Lock screw

Intems suplied

Before putting the machine into operation

which may have occurred in transit.

a work bench.

the machine is switched on.

parts run smoothly.

sure the data on the rating plate is the same as that for your

mains electricity supply.

Assembly

wheel (11) reaches the clamping face (7) of the vice (15).

and unhook the chain (13).

Caution! the resetting spring lifts the saw head (1)

automatically. Therefore, do not simply let go of the handle (2)

after cutting, but allow the saw head (1) to rise slowly by applying

slight counter pressure.

the chain (13) to anchor the saw head (1) again in

its lower position.

easier to transport.

Vice (See gures. 3 & 4)

Every work piece has to be fastened in the vice (15) before it is cut.

Pull out the spindle (5) far enough for the work piece to be

Note:

pulled out or pushed in to the exact amount required.

face (4) touches the work piece.

(5) and both halves of the nut engage with each other.

in the vice (15).

MITRE cuts (See g. 5)

The vice can be swiveled from 0° to 45° in order to

make miter cuts.

Clamping face (4) will automatically swing into the correct position

and align itself with the work piece in order to ensure that the work

piece is safely fastened.

OPERATING INSTRUCTIONS

Adjusting the stop screw (See g. 6)

The downward movement of the cutting-off wheel can be adjusted

with the stop screw (18). This is necessary to compensate wheel

wear -as the cutting-off wheel becomes smaller in diameter it

would no longer be able to cut right through the work piece.

wheel (11) reaches the clamping face (7) of the vice (15).

.

Replacing the cutting-off wheel

(See gures. 7&8)

(21) for the cutting-off wheel to the rear.

wheel (11) slowly with the other hand until the shaft lock (9)

engages.

screw (22) in counterclockwise direction.

worn cutting-off wheel (11).

Important!

mounting the cutting-off wheel.

care to tighten the shaft screw (22) just enough to hold the

wheel (11) securely in place and prevent it from spinning. Over

tightening the shaft screw (11) may damage the cutting-off wheel.

front and fasten in place with the thumb screw (20).

Using the cutting-off machine ON/OFF switch

(See g. 9)

The MCS14-2000 metal cutting-off machine is equipped with a

safety switch to prevent accidental starting.

switch (10).

(10).

Making a cut (See g. 10 & 11)

reach its top speed.

the cutting-off wheel makes slight contact with the work piece.

to jump or chatter. This will only result in cuts of poor quality

or a broken wheel.

cutting operation.

formation of a burr, you should not reduce the cutting speed at

the end of the cutting operation.

Note: The number of cuts per cutting-off wheel and their quality

cuts may accelerate wheel wear, but they also prevent discoloring

of the work piece and the formation of a burr.

Maintenance

Caution!

Ordering replacement parts

Please provide the following information on all orders for replace-

Osaki Power Tools are committed to the Production of Quality Power Tools that are designed for

high performance and long service life. By following the recommended safety and maintenance

procedures they will last for many years

GENERAL SAFETY

The MCS14-2000 metal cutting-off machine is designed for cutting

The machine is to be used only for its prescribed purpose.

Any other use is deemed to be a case of misuse. The user/operator

and not the manufacturer will be held liable for damage and/or

injuries of any kind that result from such misuse. The machine is to

be operated only with suitable cutting-off wheels. It is prohibited

to use any kind of saw blade made of HSS, HM, CV, etc. To use the

machine properly you must also observe the safety regulations,

the assembly instructions and the operating instructions to be

found in this manual.

All persons who use and service the machine have to be acquainted

with this manual and must be informed about the machines

-

vention regulations in force in your area. The same applies for the

general rules of occupational health and safety. The manufacturer

shall not be liable for any changes made to the machine nor for

any damage resulting from such changes.

Even when the machine is used as prescribed it is still impossible to

(injuries through cutting).

Important information

Please read the directions for use carefully and observe the

information provided. It is important to consult these instructions

in order to acquaint yourself with the machine, its proper use and

safety precautions.

Safety information

Please read the directions for use carefully and observe the

information provided. It is important to consult these instructions

in order to acquaint yourself with the machine, its proper use and

safety precautions.

following basic safety precautions in order to reduce the risk of

with the cutting-off machine.

working on dusty jobs

on, make sure that all keys and wrenches have been removed

from the tool.

accidents.

damp or wet locations, and never expose them to rain. Keep

your place of work.

children, to touch the electric tool or its cables. Keep them

away from your work area.

Man, earth and tne Universe

am forces that create an

immovable centre of balance..,

the

balance of power

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

and safer when used within their quoted capacity range.

work for which they were not intended.

are recommended. Wear a hair net if you have long hair.

piece securely. This is safer than using your hand.

regulations and the instructions for changing cutting-off

extension cables regularly and replace them if damaged. Keep

handles dry and free from oil and grease.

using the electric tool, prior to maintenance, and when

changing attachments such as cutting-off wheels.

dangerous to use unsuitable accessories.

cause an injury.

the electric tool, carefully check that the safety devices or any

slightly damaged parts are working as intended. Check that

the moving parts are in good working order, that they do not

jam, and that no parts are damaged. All parts must be

correctly assembled and meet all the conditions required to

stated in the operating instructions, damaged safety devices

service centre. Have damaged switches replaced by a customer

cannot be turned on and off.

points toward the work piece.

Always switch off your electric tool before leaving it. Wait until

the tool stops moving completely.

conductor may only be connected to a matching socket-outlet.

liquids or gases.

components.

being used it should be kept in a dry, closed place out of

connecting up a dust extraction and collection system, make

sure that such a system is connected and in use.

cable to pull the plug out of the socket-outlet. Protect cables

from heat, oil and sharp edges.

squarely and keep your balance at all times.

when inserting the plug in the socket-outlet.

approved for outdoor use and which are marked accordingly.

distracted.

CAUTION! The use of mounted attachments and accessories

other than those intended may put you at risk of injury.

replacement parts. If not, the user may suffer an accident.

Additional safety rules for cutting-off machines

CAUTION!

unless it is fully

assembled and installed as described in this manual.

safety shoes, long tight sleeves and gloves.

beginning your work.

they are in good working order.

OPERATING INSTRUCTIONS

in a straight position in order to prevent it from moving and

skewing while the cut is being made.

you remove the work piece, clamp in a new work piece, or

adjust the angle.

screw (22) just enough to hold the wheel in place and prevent

it from spinning. Over tightening the shaft screw may damage

3700rpm or higher and are marked accordingly.

immediately.

machine.

does not touch the machine.

until it comes into contact with the work piece. Then carry out a

smooth cut. Avoid causing the cutting-off wheel to jump or

chatter. This will only lead to premature wear and result in

poor cuts or a broken cutting-off wheel.

cutting-off wheel is kept as small a possible.

cuts may accelerate wheel wear, but they also prevent

requires particular attention when cutting thin walled tubes.

but cut right through to the end with full power. This will help

to prevent the material from overheating and forming a burr.

or gases.

locations, and never expose it to rain.

on this machine.

approximately one minute before you begin cutting. If the

cutting-off wheel has an invisible fracture or defect, it will

break in less than one minute.

work.

be sure to observe the recommend values for thickness and

hole diameter.

Environment

Should your machine need replacement after extended use,

do not put in the domestic waste but dispose of it in an environ-

mentally safe way.

Waste electrical products should not be disposed

of with household waste. please recycle where

facilities exist. Check with your Local Authority

or retailer for recycling advice.

AC motor

2000 watts

3700 min-1

ø 355 x ø 25.4 x 3 mm

445 x 245 mm

0 - 45° mm

0 - 240 mm

ø 100 / 70x170 mm

100x70 mm

20 kg

SPECIFICATIONS MCS14-2000

A comprehensive in house repair and

service facility is available through your

local agent.

SERVICE & REPAIR

OTHER OSAKI PRODUCTS

AVAILABLE FROM YOUR DISTRIBUTOR

E C LOW VOLTAGE DIRECTIVE (LVD) 2006/95/EEC

E C ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (EMC) 2004/108/EEC

E C MACHINE DIRECTIVE 98/37/EEC

E C ROHS DIRECTIVE 2002/95/EEC

E C WEEE DIRECTIVE 2002/96/EEC

DECLARATION OF CONFORMITY

We hereby certify that OSAKI MSC14-2000 Metal cut-off machine

complies with all the relevant provisions of the

EC Directives 2006/95/EEC, 2004/108EEC, 98/37EC, 2002/95/EEC, 2002/96/EEC

Harmonised Standards Applied: EN61029-1:2000, * IEC61029-2-10 : 1.0:1998, EN55014-

1:2006, EN55014-2:1997, EN61000-3-2:2006, EN61000-3-3:1995

OSAKI POWER TOOLS carry one years manufacturers warranty.

OSAKI POWERTOOLS are designed & produced to the highest standards &

specications OSAKI POWERTOOLS are fully guaranteed against faulty

materials & workmanship Should they be found to be defective, they will either

be repaired or replaced free of charge (fair wear and tear and/or misuse excepted).

Please retain supplier invoice as proof of purchase.

Osaki Power Tools are designed for DIY and hobby use only. They are not covered

by an industrial warranty. Industrial use will invalidate this guarantee.

Date: 27/11/2008 Name: Martin Cooke Position: Director, The Kennedy Group Ltd.

Osaki continually strives to improve it products, specications may change without prior notice.

The Kennedy Group Ltd. 11/08

QUALITY GUARANTEE & WARRANTY

This manual suits for next models

1

Table of contents