- Tighten the lock nut to make sure that the position does not

change.

OPERATION AND USE

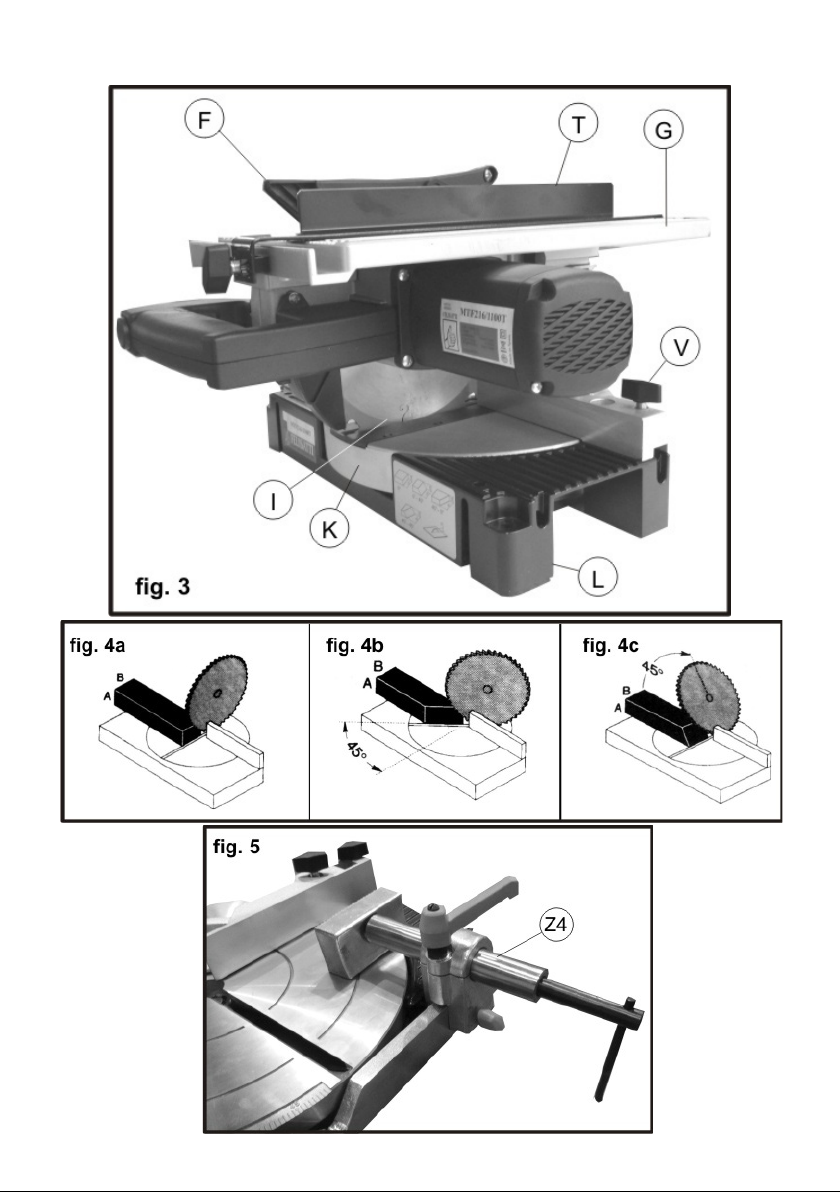

1. CUTTING WITH THE BLADE AT 90º AND TURNTA-BLE

TURNED

- Unlock the turntable K(Fig.1) by turning lever Yto the left.

- Turn the turntable with the handle, selecting the cutting

angle required using the graduated scale R2 and index R

(Fig.1), and lock again by turning lever Y(Fig.1) to the right.

Note: there are pre-set cutting angles (0º, ±15º, ±22º30’, ±30º,

±45º) on which the turntable may easily be locked.

2. CUTTING WITH THE BLADE INCLINED AND TURNTABLE

AT 0º (Fig.6) (Optional accessory)

- Move guide Xoutwards, in the direction of the arrow, or

even out of the machine for better operation. - R e l e a s e

the motor unit by loosening lever O(Fig.1).

- Turn the motor unit, selecting the required inclination using

the graduated scale R1 (Fig.1) and lock lever Oonce more.

3. USE OF THE MITRE SAW

WARNING–MakesurethatthelockbuttonE(Fig.1)isinthe

releaseposition.

- Set the upper bench to the maximum height.

- Always start with the motor unit in rest position (raised with

the safety hook tted)

- Fix the material to be cut rmly to the cutting plane.

- Start and wait for the blade to reach maximum revolutions.

- Press the button releasing the motor unit.

- Gradually lower the motor unit and cut.

4. BLADE START AND STOP

WARNING – make sure that the moving protector is in the correct

position when the blade is at rest (raised).

The machine is provided with a switch C(Fig.1) with push button,

which is used to start and stop the blade. It is possible to block

the switch ‘ON’ by pressing the lock button E(Fig.1)

WARNING – engaging the lock button disables the safety

device provided by the manufacturer and enables push-

buttonstart.Itisrecommendedthatthisdevicebeusedwith

theutmostcautionandONLYwhenusingthemachineasa

circularsaw.

To release the switch again, it is only necessary to press the

button and release.

5. USE OF THE CLAMP (OPTIONALACCESSORY)

- Raise the saw to be able to place the wood board or the

aluminium pipe on the bench for cutting and in position with

respect to guide M (Fig.1).

- Fit the clamp Z4 (Fig.5) if it is not already tted, and turn the

bolt until the clamp press rmly on the piece to be cut, making

sure that it do not move, to avoid any accident.

- Once the operation is complete, loosen the clamp to release

the piece and change the position for the next job.

6. USE OF THE UPPER BENCH

To use the upper plane, proceed as follows:

- Make sure that the lock button E (Fig.1) is released

(standing out).

- Lower the blade unit completely and lock with pin P (Fig.1a).

- Release handles H (Fig.2) and select the height of the

upper plane, proceeding to lock the handles once more.

7. USE OF THE STOP GUIDE FOR THE UPPER BENCH (Fig.7)

Use as follows:

- Insert guide Tin the upper bench.

- Select the cutting width.

- Lock guide T by tightening buttery U followed by buttery

S.

8. MISCELLANEOUS ACCESSORIES

The machine is supplied with the uptake nozzle included B

(Fig.1) and may therefore be connected easily to any vacuum

cleaner.

9. MISUSE

The functions and use of the tool that you have bought are only

as indicated in this manual.

Any other use of the tool is entirely prohibited.

• Do not cut aluminium or steel on the upper plane.

• Always use sharp blades suitable for the cut to be made.

• Do not use the machine without the described protection.

• Not suitable for foodstuffs.

• Use the machine only for cutting wood, aluminium proles,

PVC tubes, steel pipes and only with the right blade.

The cutting of any other material is entirely prohib-ited.

MAINTENANCE

WARNING-beforeanymaintenanceoperation,unplugthe

machine.

1. LUBRICATION

The mitre saw is delivered with in all moving parts of the motor

and gearbox entirely lubricated and needs no further lubrication

operations.

Regular lubrication is recommended of the joints of the moving

controls.

2. ORDINARY CLEANING

WARNING-avoidtouchingthehandlewithhandsdirtywith

oilorgrease.Insuchanevent,cleanimmediately.

- Carefully clean the machine after use with dry com-pressed

air.

3. DISPOSAL

When the life of the machine is at an end or when it can no

longer be repaired, make sure that the scrap is disposed of in

observance of current regulations in the country of use and that

the operation is undertaken by specialised personnel authorised

in the matter.

PART REPLACEMENT

WARNING – before carrying out any replacement, unplug

themachine.

1. REPLACING THE SAW BLADE I (Fig.1)

Replace as follows:

- Set the head to fully open (Fig.1)

- Raise the upper bench as far as is allowed.

- Release the moving protection Q(Fig.2) working on button

Q1 (Fig.1a) and raise completely.

- Fit the spanner provided in the holes of the clamp, keeping

the shaft locked with another tubular spanner supplied by the

manufacturer, and unscrew the left bolt until the saw blade is