OSD Audio OSD024T1983-38 User manual

OSD DISPLAYS

12124 High Tech Av. Ste. 100

Orlando, FL 32817

Phone: 407-629-0500

Fax: 407-645-5376

www.osddisplays.com

Customer:

Model Number: OSD024T1983-38

Specification Number:

Date: 09/09/2010

Version: 1.1

For Customer’s Acceptance

Approved by Comments

Approved by Reviewed by Prepared by

P.2

REVISIONRECORD

REVNO. REVDATE CONTENTS REMARKS

0.1 2009-12-23 Firstrelease Preliminary

1.0 2010-1-13 Fullspec /

1.1 2010-9-9 Updatethedrawing P.5

P.3

CONTENTS

GENERALINFORMATION

EXTERNALDIMENSIONS

ABSOLUTEMAXIMUM RATINGS

ELECTRICALCHARACTERISTICS

BACKLIGHTCHARACTERISTICS

ELECTRO-OPTICALCHARACTERISTICS

INTERFACEDESCRIPTION

REFERENCE APPLICATIONCIRCUIT

RELIABILITY TESTCONDITIONS

INSPECTIONCRITERION

PRECAUTIONSFORUSINGLCDMODULES

PACKINGSPECIFICATION

PRIOR CONSULTMATTER

FACTORY CONTACTINFORMATION

WRITTENBY CHECKEDBY APPROVEDBY

HUANGYANXUE ZHAO ZHIWEI ZHANG SHUHANG

P.4

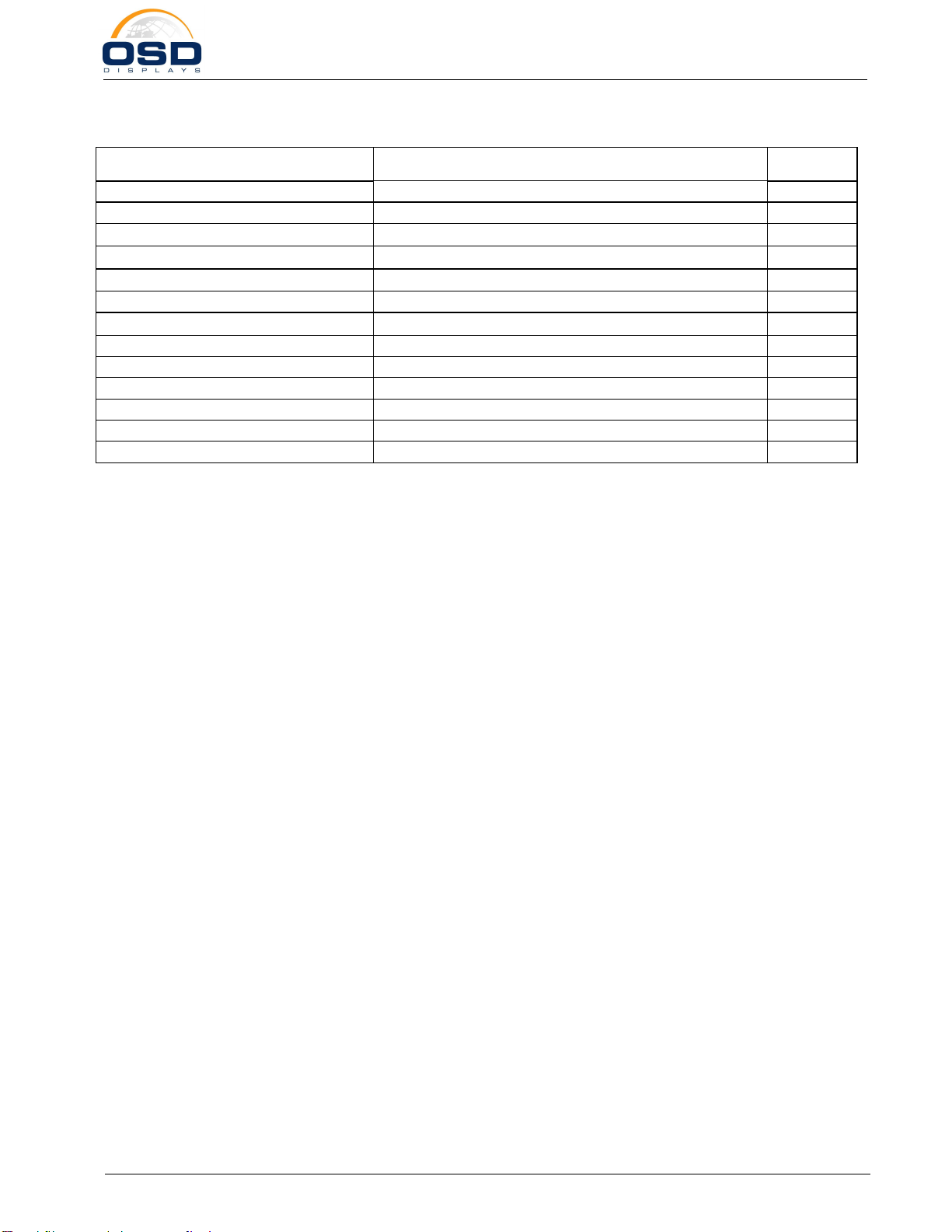

nGENERALINFORMATION

ItemContents Unit

LCDtype TFT/TRANSMISSIVE /

Viewing direction Fullviewingangle O Clock

Modulearea(W ´H ´T) 42.72×60.26×2.20 mm3

Viewing area(W´H) 38.32×50.56 mm2

Activearea(W´H) 36.72×48.96 mm2

NumberofDots 240RGB×320 /

Pixelpitch(W ´H) 0.153×0.153 mm2

DriverIC R61526 /

InterfaceType MPU/SPI+RGB /

Inputvoltage 2.8 V

ModulePowerconsumption 279 mw

Colors 262K /

BacklightType LED /

P.5

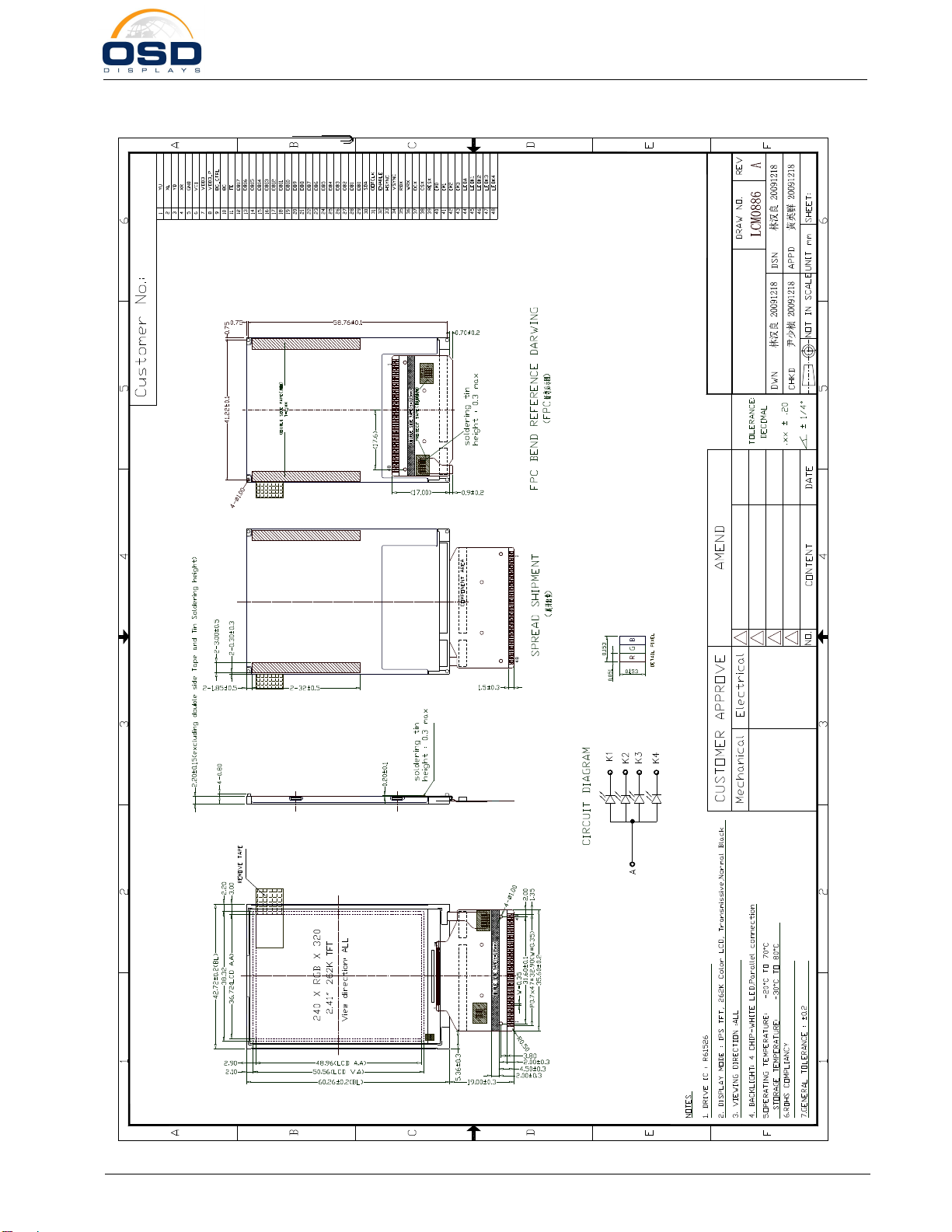

nEXTERNALDIMENSIONS

1/1

K4

K3

K2

K1

A

K4

K3

K2

K1

A

P.6

nABSOLUTEMAXIMUM RATINGS

Parameter Symbol Min Max Unit

Supplyvoltageforlogic VDD3/VCI -0.3 4.6 V

InputvoltageVIN -0.3 VDD3+0.3 V

Operating temperatureTop -20 70 °C

StoragetemperatureTST -30 80 °C

HumidityRH - 90%(Max60 °C) RH

nELECTRICALCHARACTERISTICS

DC CHARACTERISTICS

ParameterSymbol Min Typ Max Unit

Supplyvoltageforlogic VCI 2.5 2.8 3.3 V

I/O powersupply VDD3 1.65 1.8/2.8 3.3 V

InputCurrent Idd - 10.03 20.06 mA

Inputvoltage'H'level VIH 0.8VDD3 - VDD3 V

Inputvoltage'L'level VIL 0 - 0.2VDD3

V

Outputvoltage'H'level VOH 0.8VDD3 - - V

Outputvoltage'L'level VOL - - 0.2VDD3

V

nBACKLIGHTCHARACTERISTICS

ItemSymbol Min.

Typ. Max. Unit Condition

ForwardvoltageVf 2.9 3.1 3.4 V

LuminanceLv 39004300 4700 cd/m2

If=72mA

Ta=25℃

NumberofLED- - 4 - Piece -

ConnectionmodeP - Parallel

- - -

Using condition:constantcurrentdrivingmethodIf=72mA(+/-10%).

P.7

nELECTRO-OPTICALCHARACTERISTICS

ItemSymbol Condition Min Typ Max Unit

Remark

Note

Responsetime

Tr+Tf - 26 39 ms Fig.1 4

Contrastratio

Cr 300 842 - --- FIG2. 1

Luminance

uniformitydWHITE 85 94 - % FIG2. 3

Surface

LuminanceLv

θ=0°

Æ=0°

Ta=25

209 261 - cd/m2

FIG2. 2

Æ=90°70 80 - deg FIG3.

Æ=270°70 80 - deg FIG3.

Æ=0°70 80 - deg FIG3.

Viewing angle

rangeq

Æ=180°70 80 - deg FIG3.

6

Redx 0.5918

0.6418

0.6918

-

Redy 0.2804

0.3304

0.3804

-

Greenx 0.2555

0.3055

0.3555

-

Greeny 0.5186

0.5686

0.6186

-

Bluex 0.0930

0.1430

0.1930

-

Bluey --- 0.0382

0.0882

-

Whitex 0.2207

0.2807

0.3407

-

CIE(x,y)

chromaticity

Whitey

θ=0°

Æ=0°

Ta=25℃

0.2288

0.2888

0.3488

-

FIG2. 5

Note1. ContrastRatio(CR)isdefinedmathematicallybythefollowingformula.Formore

informationseeFIG2.:

(

)

( )

AverageSurface Luminance with all white

pixels P1,P2,P3,P4,P5

ContrastRatio = AverageSurfaceLuminance withall black

pixelsP1,P2,P3,P4,P5

Note2. SurfaceluminanceistheLCDsurface from thesurfacewithallpixelsdisplaying white.

FormoreinformationseeFIG2.

Lv=AverageSurfaceLuminancewithallwhitepixels(P1,P2, P3,P4,P5)

Note3. Theuniformityinsurfaceluminance(dWHITE)isdeterminedbymeasuringluminanceat

eachtestposition1through5,andthendividing themaximumluminanceof5pointsluminanceby

minimumluminanceof5pointsluminance.Formoreinformationsee FIG2.

,

,

SurfaceLuminancewithallwhitepixels

(,,,)

WHITE= MaxiSurfaceLuminancewithallwhitepix

els(,,,)

d

12345

12345

MinimumPPPPP

mumPPPPP

Note4. ResponsetimeisthetimerequiredforthedisplaytotransitionfromWhitetoblack(Rise

Time,Tr) andfromblacktowhite(DecayTime,Tf).ForadditionalinformationseeFIG1..

Note5. CIE(x,y)chromaticity,Thex,yvalueisdeterminedbyscreenactiveareaposition5.For

moreinformationseeFIG2.

Note6. Viewingangleistheangleatwhichthecontrastratioisgreaterthan2.ForTFTmodulethe

conrastratioisgreaterthan10.Theanglesaredeterminedforthehorizontalorxaxisandthe

verticaloryaxiswithrespecttothezaxiswhichisnormaltotheLCDsurface.Formore

informationseeFIG3.

Note7. ForViewingangleandresponsetimetesting,thetestingdataisbaseonAutronic-Melchers s

ConoScope.SeriesInstruments.Forcontrastratio,Surface Luminance,Luminanceuniformityand

CIE,thetestingdataisbaseonTOPCON sBM-5photodetector.

Note8. ForTFT module, Grayscalereverseoccursinthedirectionofpanelviewing angle

P.8

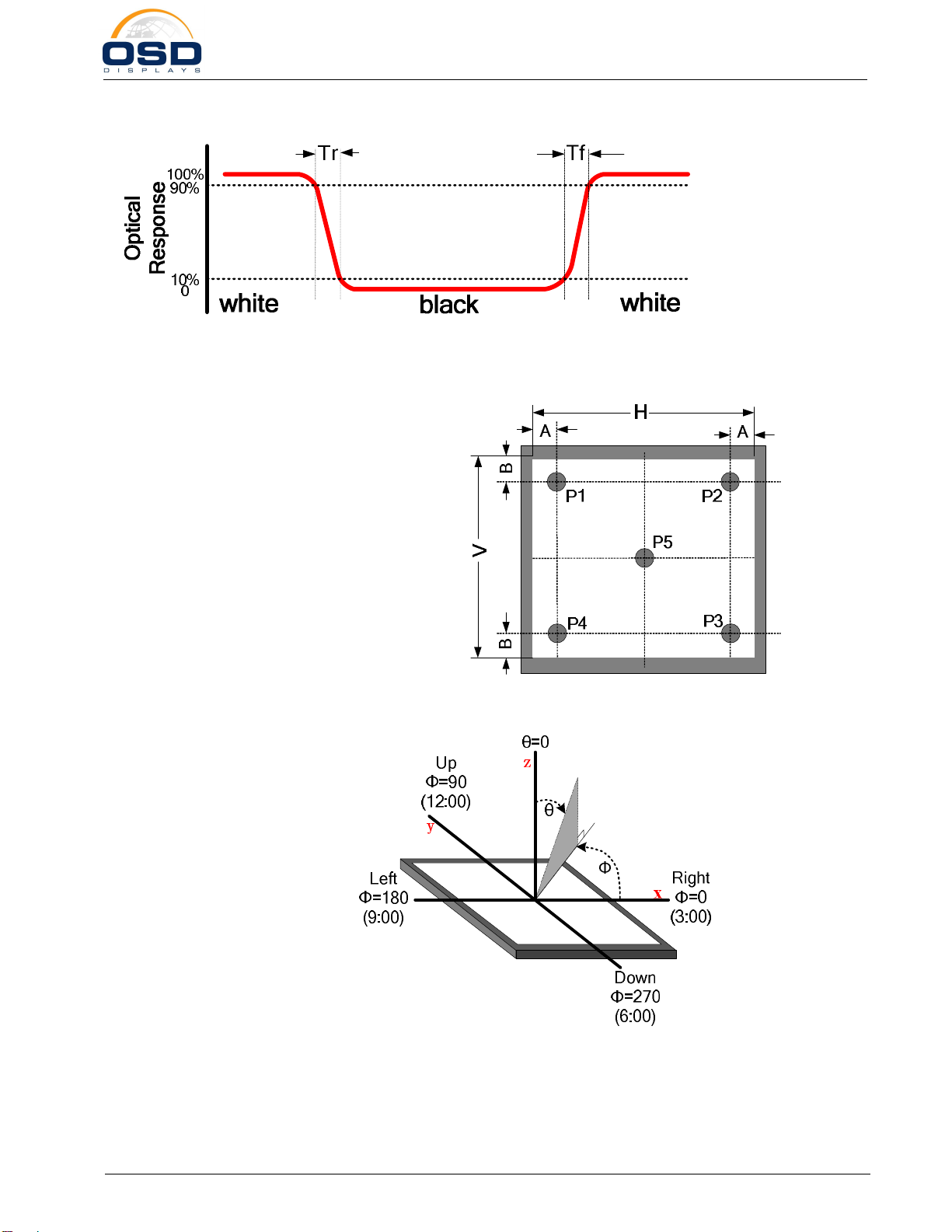

FIG.1. ThedefinitionofResponseTime

FIG.2. MeasuringmethodforContrastratio,surfaceluminance, Luminanceuniformity,CIE (x,

y)chromaticity

FIG.3. Thedefinitionofviewingangle

A:5mm

B:5mm

H,V:ActiveArea

Lightspotsize Æ=5mm, 500mm distance fromthe

LCDsurface todetectorlens

measurementinstrumentisTOPCON sluminance

meterBM-5

P.9

nINTERFACEDESCRIPTION

Pin

NO.

Symbol I/Oor

connectto Description Whennot

inuse

1 YU NC NC -

2 XL NC NC -

3 YD NC NC -

4 XR NC NC -

5 GND Powersupply Ground -

6 VCI Powersupply Powersupplyforliquidcrystalanalogcircuit.

AMP:2.5V~3.3V,TYPE:2.8V -

7 VDD3 Powersupply Powersupplytointerface pinsandthelogic.

AMP:1.65V~3.3V,TYPE:2.8V -

8 VDD3_P Powersupply

PowersupplytoLEDPWM.

Supplyavoltageaccording toLEDdriverinput.

ThisshouldbeconnectedtoVDD3evenwhen

LEDPWM isnotused.

VDD3

9 BC_CTRL

10 BC

O

ThesepinsareLEDPWMforthismodule.Control

signalforbrightnessofLEDbacklight.PWM

signal swidthisselectedfrom 256 values

between0%(Low)and100%(High)byVDD3_P

amplitude.LEDPWMcanbeusedasasignalto

turnLEDon/offwhenthebacklightcontrol

functionisnotused.

Open

11 TE O

Hostprocessor

TearingEffectoutputsignal.Leaveopenwhen

notused. Open

12~

29 DB[17:0] I/O

Hostprocessor

18-bitbi-directionaldatabusinDBITypeB

operation.

8-bitinterface:UseDB[7:0]

9-bitinterface:UseDB[8:0]

16-bitinterface:UseDB[15:0]

18-bitinterface:UseDB[17:0]

Abnormalcurrent(throughcurrent)isnot

conductedwhenCSXisHigh andthedatabusis

Hi-z.

18-bitinputdatabusinDPIoperation.

16-bitinterface:UseDB[15:0]

18-bitinterface:UseDB[17:0]

VDD3

orGND

orOPEN

30 SDA I/O

Hostprocessor

Serialdatainput/outputpininDBITypeC

operation.Dataisinputontherisingedgeof

signalSCL. Dataisoutputonthefallingedgeof

SCLwhenserialdataoutputpinisselected.

VDD3or

GND

31 DOTCLK I

Hostprocessor

Pixelclocksignal.Thedatainputtiming isseton

therisingedge.LeaveopenwhenDPIisnot

selected.Connecttohostprocessorandinputan

IOVCC1/GND signalalwayswhenDPIis

selected.

VDD3or

GND

32 ENABLE I

Hostprocessor

DataenablesignalinDPIoperation.

Low:Select(Accessible)

High:Notselect(Inaccessible)Leaveopenwhen

DPIisnotselected.Connecttohostprocessorand

inputanIOVCC1/GND signalalwayswhenDPI

isselected.

VDD3or

GND

p,

P.10

33 HSYNC I

Hostprocessor

Linesynchronoussignal. Lowactive.

LeaveopenwhenDPIIsnotselected.

Connecttohostprocessorandinputan

IOVCC1/GND signalalwayswhenDPIis

selected.

VDD3or

GND

34 VSYNC I

Hostprocessor

Framesynchronoussignal. Lowactive.

LeaveopenwhenDPIisnotselected.

Connecttohostprocessorandinputan

IOVCC1/GND

signalalwayswhenDPIisselected.

VDD3or

GND

35 RDX I

Hostprocessor

Readstrobesignal.DataarereadwhenRDXis

low. VDD3

36 WRX I

Hostprocessor

WritestrobesignalinDBITypeBoperation.

DataarewrittenwhenWRXisLow.

SynchronousclocksignalinDBITypeC

operation.

-

37 DCX I

Hostprocessor

Command/dataselectsignal

Low:Command

High:Data

Command/dataselectsignalinDBITypeC

operation(Option3).

-

38 CSX I

Hostprocessor

Systembusselectsignal.

Low:Select(Accessible)High:Notselect

(Inaccessible)

Makesuretoconnecttohostprocessor.Follow

ACtiming

tocontrolthesignal.ChipenablesignalinDBI

TypeCoperation(Option3).

-

39 RESX

I

HostProcessor

orexternalRC

oscillator

Resetpin.TheModuleisinitializedwhenRESX

isLow.Makesuretoexecutepower-onresetwhen

turning thepowersupplyon.

-

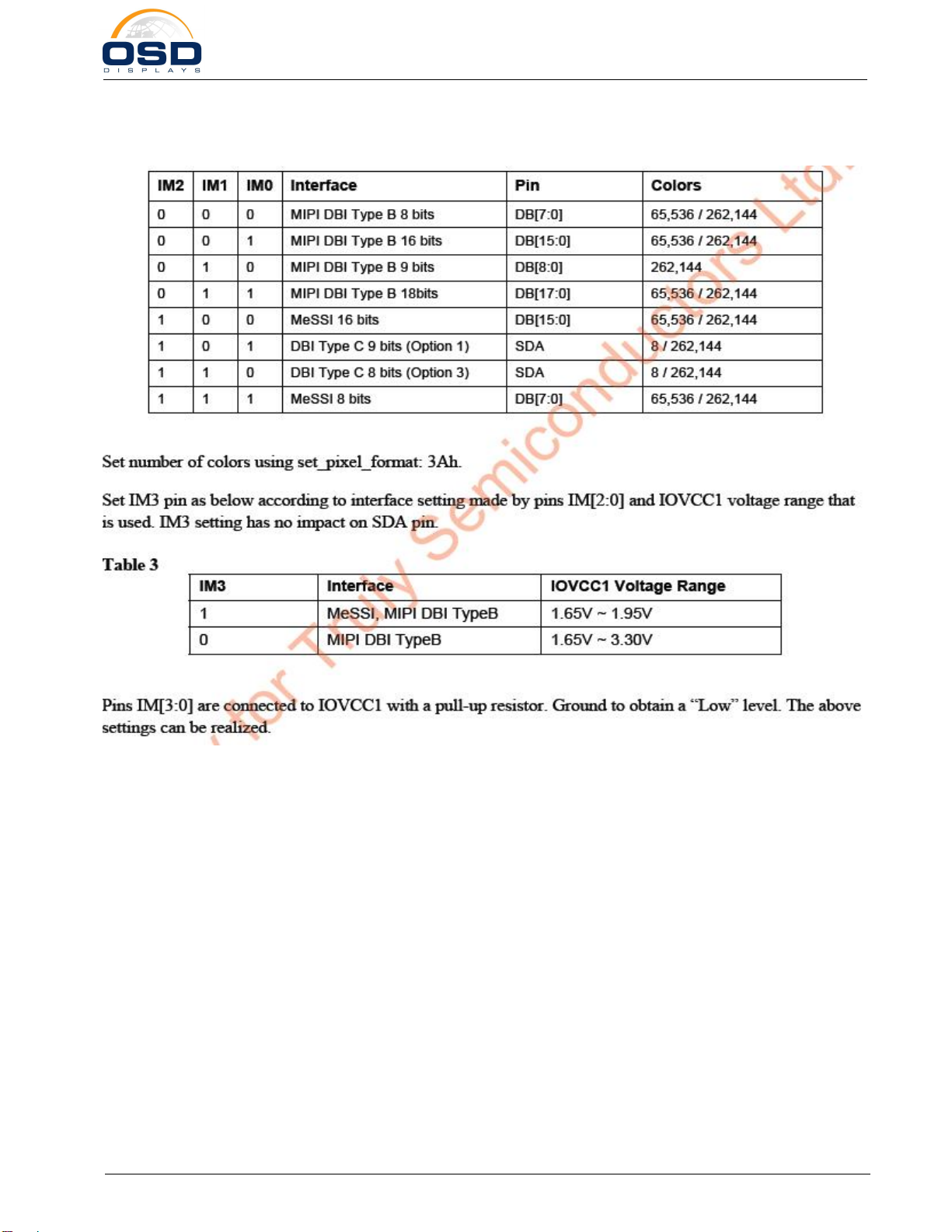

40 IM0 -

41 IM1 -

42 IM2 -

43 IM3

I

Hostprocessor

Interfaceselectingsignal.UsedtoswitchDBI

TypeB(18/16/9/8bits)andTypeC

(Option1/Option3).

Internallyconnectedtoapull-up resistor.Ground

ifnecessary.Forthedetails,pleasereferto

NOTE1.

-

44 LEDA LEDdriver LEDANODE -

45 LEDK1 LEDdriver LEDK1(CATHODE ) -

46 LEDK2 LEDdriver LEDK2(CATHODE ) -

47 LEDK3 LEDdriver LEDK3(CATHODE ) -

48 LEDK4 LEDdriver LEDK4(CATHODE ) -

P.11

Note1

nREFERENCEAPPLICATIONCIRCUIT

Pleaseconsult ourtechnicaldepartmentfordetailinformation.

P.12

nRELIABILITYTESTCONDITIONS

No. TestItem TestCondition Inspectionafter test

1 HighTemperatureStorage80±2℃/200hours

2 LowTemperatureStorage-30±2℃/200hours

3 HighTemperatureOperating

70±2℃/120hours

4 LowTemperatureOperating

-20±2℃/120hours

5 TemperatureCycle-20±2℃~25~70±2℃×10cycles

(30min.)(5min.)(30min.)

6 DampProofTest50℃±5℃×90%RH/120hours

7 VibrationTest

Frequency:10Hz~55Hz~10Hz

Amplitude:1.5mm,X,Y,Zdirection

fortotal3hours(Packing condition)

8 Dropping test

Droptothegroundfrom1mheight,

onetime,everysideofcarton.

(Packingcondition)

9 ESDtestVoltage:±8KVR:330ΩC:150pF

Airdischarge, 10time

Inspectionafter

2~4hoursstorageat

roomtemperature, the

sampleshallbefreefrom

defects:

1.AirbubbleintheLCD;

2.Sealleak;

3.Non-display;

4.missingsegments;

5.Glasscrack;

6.CurrentIddistwice

higherthaninitialvalue.

Remark:

1.Thetestsamplesshouldbeappliedtoonlyonetestitem.

2.Samplesizeforeachtestitemis5~10pcs.

3.ForDampProofTest,Purewater(Resistance>10MΩ)shouldbeused.

4.IncaseofmalfunctiondefectcausedbyESDdamage,ifitwouldberecoveredtonormalstateafter

resetting, itwouldbejudgedasagoodpart.

5.ELevaluationshouldbeexceptedfromreliabilitytestwithhumidityandtemperature:Somedefects

suchasblackspot/blemishcanhappenbynaturalchemicalreactionwithhumidityandFluorescence EL

has.

6.FailureJudgmentCriterion:BasicSpecification,ElectricalCharacteristic,MechanicalCharacteristic,

OpticalCharacteristic.

P.13

nINSPECTIONCRITERION

OUTGOING QUALITYSTANDARD PAGE1OF4

TITLE:FUNCTIONALTEST&INSPECTION CRITERIA MDSProduct

Thisspecificationismadetobeusedasthestandardacceptance/rejectioncriteriaforColormobile

phoneLCM.

1Sampleplan

SamplingplanaccordingtoGB/T2828.1-2003/ISO2859-1:1999andANSI/ASQCZ1.4-1993,

normallevel2andbasedon:

Majordefect:AQL0.65

Minordefect:AQL1.5

2. Inspectioncondition

Viewing distanceforcosmeticinspectionisabout30cmwithbareeyes,andunderan

environmentof20~40Wlightintensity,alldirectionsforinspecting thesampleshouldbewithin

45°againstperpendicularline.

3.DefinitionofinspectionzoneinLCD.

ZoneA:character/Digitarea

ZoneB:viewing areaexceptZoneA(ZoneA+ZoneB=minimumViewing area)

ZoneC:Outsideviewing area (invisibleareaafterassemblyincustomer sproduct)

Fig.1InspectionzonesinanLCD.

Note:Asageneralrule,visualdefectsinZoneCarepermissible, whenitisnotroublefor

qualityandassemblyofcustomer sproduct.

C

B

A

P.14

OUTGOING QUALITYSTANDARD PAGE2OF4

TITLE:FUNCTIONALTEST&INSPECTION CRITERIA MDSProduct

4.Inspectionstandards

4.1MajorDefect

Item

No

Itemstobe

inspected InspectionStandard Classification

ofdefects

4.1.1

All

functional

defects

1)Nodisplay

2)Displayabnormally

3)Missingvertical,horizontalsegment

4)Shortcircuit

5)Back-lightno lighting,flickering and abnormallighting.

4.1.2Missing Missingcomponent

4.1.3

Outline

dimension

Overalloutlinedimensionbeyondthedrawing isnotallowed.

Major

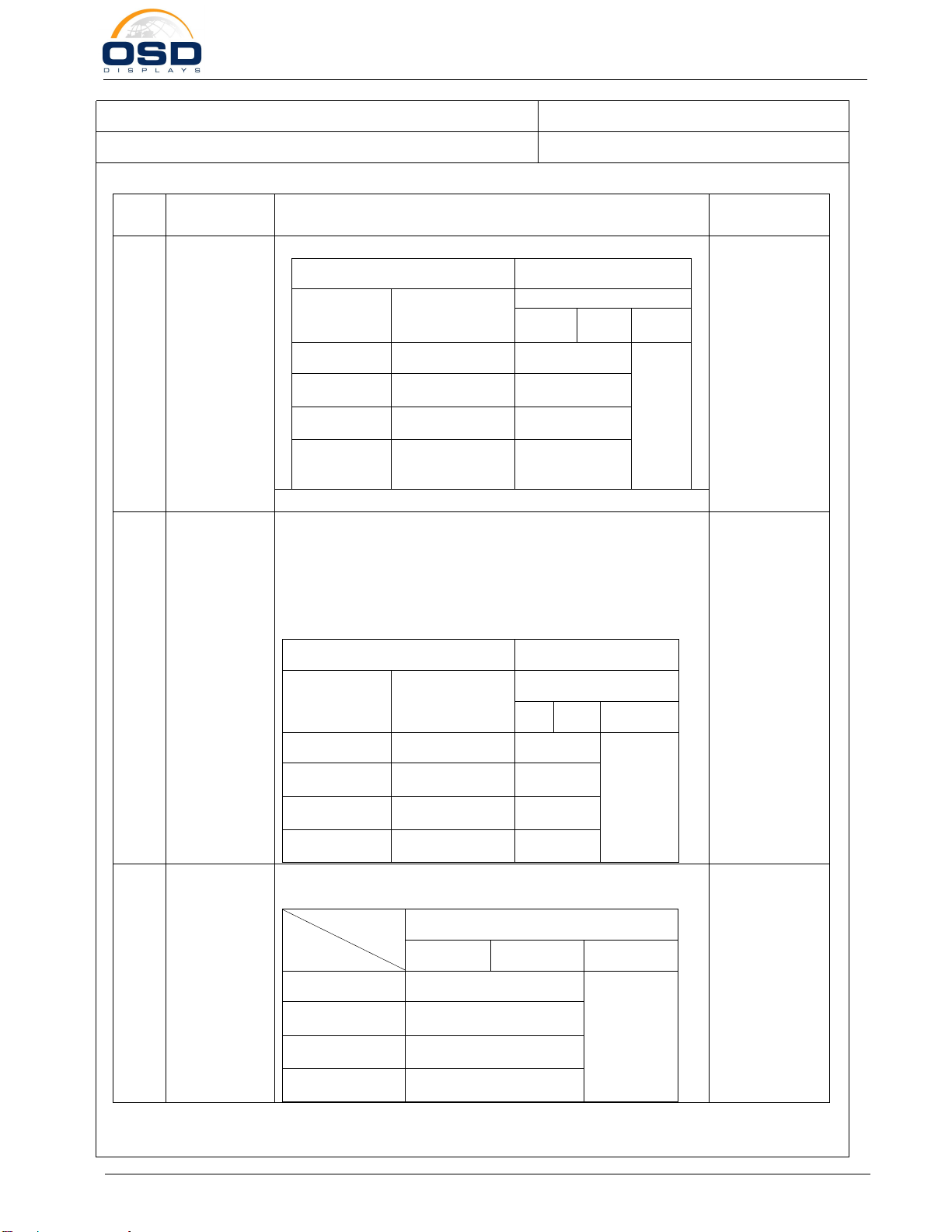

4.2CosmeticDefect

Item

No

Itemstobe

inspected InspectionStandard Classification of

defects

Fordark/whitespot, sizeΦis definedy

as Φ=

2

)( yx +x

1.

AcceptableQty

Zone

Size(mm) A B C

Φ≤0.10 Ignore

0.10<Φ≤0.15 2

0.15<Φ≤0.20 1

Clear

Spots

Blackand

whiteSpot

defect

Pinhole,

Foreign

Particle,

Dirtunder

polarizer

Φ>0.20 0

Ignore

Minor

4.2.1

DimSpots

Circle

shapedand

dimedged

defects

2.

AcceptableQty2. Zone

Size(mm) A B C

Φ≤0.2 Ignore

0.20<Φ≤0.40 3

0.40<Φ≤0.60 2

0.60<Φ≤0.80 1

Ignore

0.80<Φ0

Minor

P.15

OUTGOING QUALITYSTANDARD PAGE3OF4

TITLE:FUNCTIONALTEST&INSPECTION CRITERIA MDSProduct

4.2. CosmeticDefect

Item

No

Items tobe

inspected Inspection Standard Classification

ofdefects

Size(mm) AcceptableQty

Zone

L(Length) W(Width) A B C

Ignore W≤0.02 Ignore

L≤3.0 0.02<W≤0.03 2

L≤2.0 0.03<W≤0.05 1

0.05<W Defineas spot

defect

Ignore

4.2.2

Linedefect

Blackline,

Whiteline,

Foreign

material

under

polarizer,

Minor

4.2.3

Polarizer

scratch

If thePolarizerscratchcanbeseenaftermobilephone

coverassembling orintheoperatingcondition,judgeby

thelinedefectof4.2.2.

If thePolarizerscratchcanbeseenonlyinnon-operating

conditionorsomespecialangle, judgebythefollowing.

Size(mm) AcceptableQty

Zone

L(Length) W(Width)

A B C

Ignore W≤0.03 Ignore

5.0<L≤10.0

0.03<W≤0.05 2

L≤5.0 0.05<W≤0.08 1

0.08<W 0

Ignore

Minor

4.2.4

Polarize

Airbubble

Airbubbles betweenglass &polarizer

AcceptableQty2.Zone

Size(mm) A B C

Φ≤0.2 Ignore

0.20<Φ≤0.30 2

0.30<Φ≤0.50 1

0.50<Φ0

Ignore

Minor

P.16

OUTGOING QUALITYSTANDARD PAGE4OF4

TITLE:FUNCTIONALTEST&INSPECTION CRITERIA MDSProduct

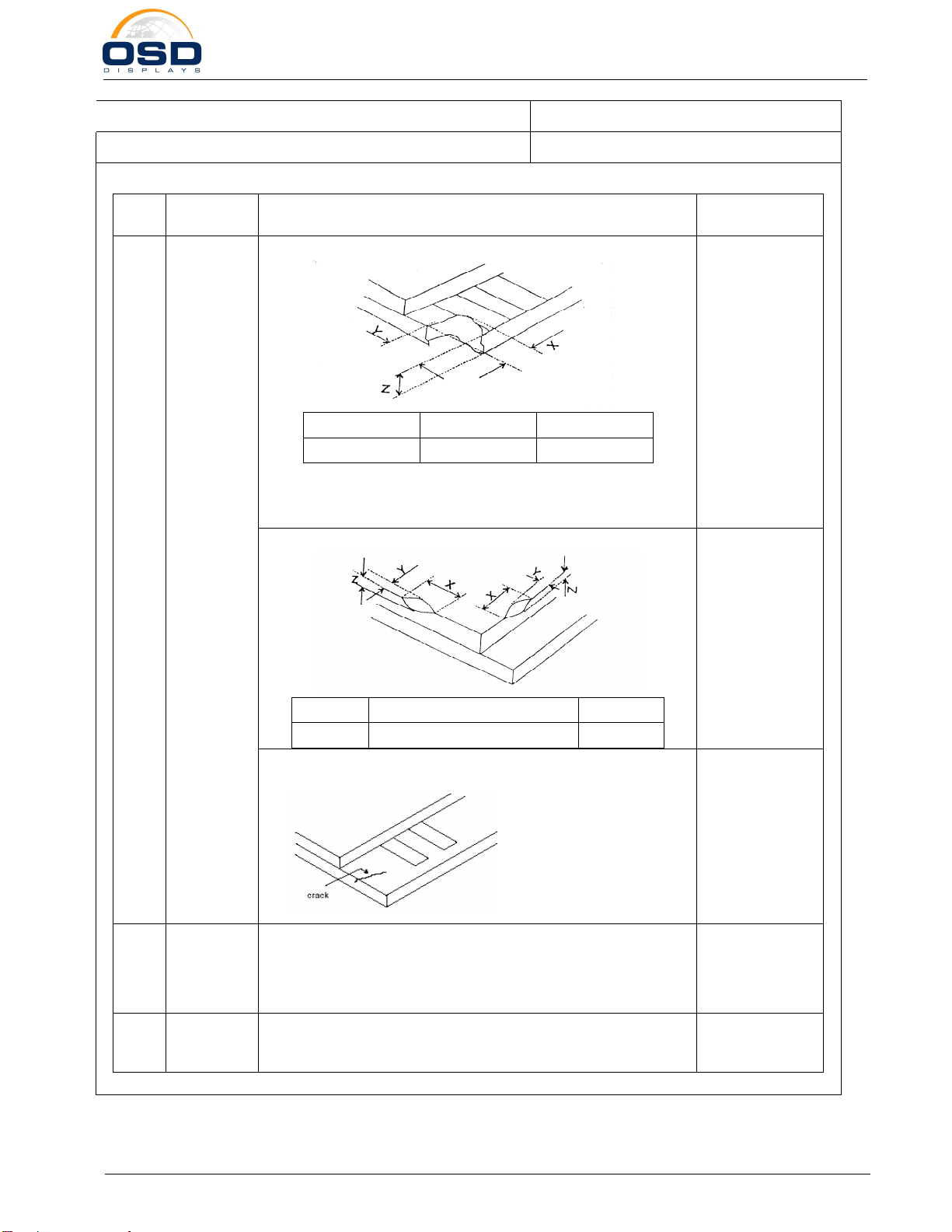

4.3. CosmeticDefect

Item

No

Itemstobe

inspected InspectionStandard Classificationof

defects

(i)Chips on corner

Notes:S=contactpadlength

Chipson thecornerofterminalshall notbeallowedtoextend

intotheITOpadorexposeperimeterseal.

X Y Z

≤2.0 ≤S Disregard

Minor

(ii)Usualsurfacecracks

X Y Z

≤3.0 <Innerborderlineoftheseal Disregard

Minor

4.3.5

Glass

defect

(iii)Crack

Crackstend tobreakarenotallowed.

Major

4.3.6

Parts

alignment

1) NotallowICand FPC/heat-sealleadwidthismorethan50%

beyondleadpattern.

2)Notallowchiporsoldercomponentisoff centermorethan

50% ofthepadoutline.

Minor

4.3.7

SMT

According tothe<Acceptabilityofelectronicassemblies>

IPC-A-610Cclass 2standard.Componentmissingorfunction

defectareMajordefect, theothersareMinordefect.

P.17

nPRECAUTIONSFORUSINGLCDMODULES

1HandingPrecautions

1.1 Thedisplaypanelismadeofglassandpolarizer.Asglass isfragile.Ittendstobecomeor

chippedduring handling especiallyontheedges.Pleaseavoiddroppingorjarring.Donot

subjectittoamechanicalshockbydropping itorimpact.

1.2 Ifthedisplaypanelisdamagedandtheliquidcrystalsubstanceleaksout,besurenottogetany

inyourmouth.If thesubstancecontactsyourskinorclothes,washitoffusing soapandwater.

1.3 Donotapplyexcessiveforcetothedisplaysurfaceortheadjoiningareassincethismaycause

thecolortonetovary.Donottouchthedisplaywithbarehands.Thiswill stainthedisplayarea

anddegradedinsulationbetweenterminals(somecosmeticsaredeterminedtothepolarizer).

1.4 Thepolarizercoveringthedisplaysurface oftheLCDmoduleissoftandeasilyscratched.

Handlethispolarizercarefully.Donottouch, pushorrubtheexposedpolarizerswithanything

harderthananHBpencillead(glass,tweezers,etc.).Donotputorattachanythingonthe

displayareatoavoidleavingmarksonit.Condensationonthesurfaceandcontactwith

terminalsduetocoldwilldamage,stainordirtythepolarizer.Afterproductsaretestedatlow

temperaturetheymustbewarmedupinacontainerbeforecoming intocontactwithroom

temperatureair.

1.5 Ifthedisplaysurface becomescontaminated,breatheonthesurfaceandgentlywipeitwitha

softdrycloth. If itisheavilycontaminated,moistenclothwithoneofthefollowingsolvents

-Isopropylalcohol

-Ethylalcohol

Donotscrubhardtoavoiddamagingthedisplaysurface.

1.6 Solventsotherthanthoseabove-mentionedmaydamagethepolarizer.Especially,donotuse

thefollowing.

-Water

-Ketone

-Aromaticsolvents

Wipeoffsalivaorwaterdropsimmediately,contactwithwateroveralongperiodoftime

maycausedeformationorcolorfading.Avoidcontactwithoilandfats.

1.7 Exercisecaretominimizecorrosionoftheelectrode.Corrosionoftheelectrodesisaccelerated

bywaterdroplets, moisturecondensationoracurrentflowinahigh-humidityenvironment.

1.8 InstalltheLCDModulebyusing themounting holes.WhenmountingtheLCDmodulemake

sureitisfree oftwisting,warpinganddistortion.Inparticular,donotforciblypull orbendthe

I/Ocableorthebacklightcable.

1.9 Donotattempttodisassembleorprocess theLCDmodule.

1.10 NCterminalshouldbeopen. Donotconnectanything.

1.11 Ifthelogiccircuitpowerisoff, donotapplytheinputsignals.

1.12 Electro-StaticDischargeControl,SincethismoduleusesaCMOSLSI,thesamecareful

attentionshouldbepaidtoelectrostaticdischargeasforanordinaryCMOSIC.Toprevent

destructionoftheelementsbystaticelectricity,becarefultomaintainanoptimum work

environment.

-BeforeremovingLCMfromitspackingcaseorincorporating itintoaset,besure

themoduleandyourbodyhavethesameelectricpotential. Besuretogroundthebodywhen

handling theLCDmodules.

-Toolsrequiredforassembling, suchassoldering irons,mustbeproperlygrounded.

MakecertaintheACpowersource forthesoldering irondoesnotleak.Whenusingan

electricscrewdrivertoattachLCM,thescrewdrivershouldbeofgroundpotentialityto

minimize asmuchaspossibleanytransmissionofelectromagneticwavesproducedsparks

comingfromthecommutatorofthemotor.

-Toreducetheamountofstaticelectricitygenerated,donotconductassembling

P.18

andotherworkunderdryconditions.Toreducethegenerationofstaticelectricitybecareful

thattheairintheworkisnottoodry.Arelativehumidityof50%-60%isrecommended.As

faraspossiblemaketheelectricpotentialofyourworkclothesandthatoftheworkbench

thegroundpotential.

-TheLCDmoduleiscoatedwithafilmtoprotectthedisplaysurface. Exercisecare

whenpeeling offthisprotectivefilmsincestaticelectricitymaybegenerated.

1.13 SinceLCMhasbeenassembledandadjustedwithahigh degree ofprecision,avoidapplying

excessiveshockstothemoduleormaking anyalterationsormodificationstoit.

-Donotalter, modifyorchangetheshapeofthetabonthemetalframe.

-Donotmakeextraholesontheprintedcircuitboard,modifyitsshapeorchangethe

positionsofcomponentstobeattached.

-Donotdamageormodifythepatternwritingontheprintedcircuitboard.

-Absolutelydonotmodifythezebrarubberstrip(conductiverubber)orheatseal

connector.

-Exceptforsolderingtheinterface,donotmakeanyalterationsormodificationswitha

soldering iron.

-Donotdrop,bend ortwisttheLCM.

P.19

2HandlingprecautionforLCM

2.1 LCMiseasytobedamaged.Pleasenotebelowandbecarefulforhandling.

2.2 Correcthandling:

2.3 Incorrecthandling:

Asabove picture, please handlewithanti

-

stati

cglovesaroundLCMedges.

Pleasedon tholdthe surface ofpanel.

Pleasedon ttouchICdirectly.

Pleasedon tstackLCM.

Pleasedon toperatewithsharpsticksuchas

pens.

Pleasedon tstretchinterfaceofoutput,such

asFPCcable.

Pleasedon tholdthe surface ofIC.

P.20

3StoragePrecautions

3.1 WhenstoringtheLCDmodules,thefollowing precautionarenecessary.

3.1.1 Storetheminasealedpolyethylenebag.If properlysealed,thereisnoneedforthe

desiccant.

3.1.2 Storetheminadarkplace.Donotexposetosunlightorfluorescentlight,keepthe

temperaturebetween0°Cand35°C,andkeeptherelativehumiditybetween40%RHand

60%RH.

3.1.3 Thepolarizersurface shouldnotcomeincontactwithanyotherobjects(Weadviseyouto

storethemintheanti-staticelectricitycontainerinwhichtheywereshipped).

3.2 Others 它

3.2.1 Liquidcrystalssolidifyunderlowtemperature(belowthestoragetemperaturerange)

leadingtodefectiveorientationorthegenerationofairbubbles(blackorwhite).Air

bubblesmayalsobegeneratedifthemoduleissubjecttoalowtemperature.

3.2.2 If theLCDmoduleshavebeenoperating foralongtimeshowingthesamedisplay

patterns,thedisplaypatternsmayremainonthescreenasghostimagesandaslight

contrastirregularitymayalsoappear.Anormaloperatingstatuscanberegainedby

suspending useforsometime.Itshouldbenotedthatthisphenomenondoesnotadversely

affectperformance reliability.

3.2.3 Tominimize theperformancedegradationoftheLCDmodulesresultingfrom destruction

causedbystaticelectricityetc., exercisecaretoavoidholdingthefollowingsectionswhen

handling themodules.

3.2.3.1 -Exposedareaoftheprintedcircuitboard.

3.2.3.2 -Terminalelectrodesections.

4USINGLCD MODULES

4.1 InstallingLCDModules

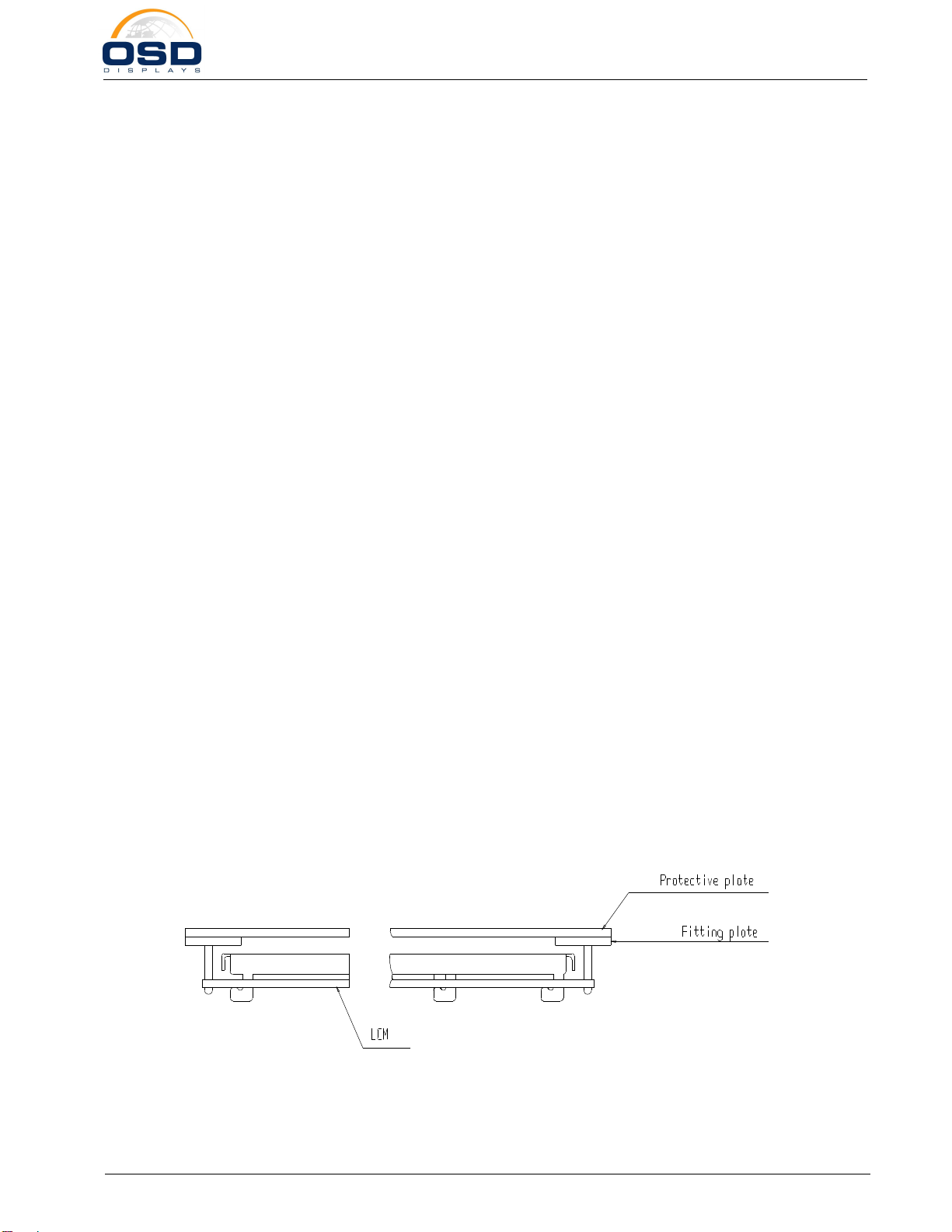

TheholeintheprintedcircuitboardisusedtofixLCMasshowninthepicturebelow.

Attendtothefollowing itemswheninstalling theLCM.

4.1.1 CoverthesurfacewithatransparentprotectiveplatetoprotectthepolarizerandLCcell.

4.1.2 Whenassembling theLCMintootherequipment,thespacertothebitbetweentheLCM

andthefittingplateshouldhaveenough heighttoavoidcausingstresstothemodule

surface,refertotheindividualspecificationsformeasurements.Themeasurement

toleranceshouldbe ±0.1mm.

Table of contents