OSF Pool control PC-400-ES User manual

.

Installation- and Operating Instructions

PC-400-ES

Art. No.: 3002700105

Functioning:

The filter control system PC-400-ES enables time-controlled connection and

disconnection of a 400V A.C. filter pump. Setting of the daytime and the individual response

times can be noted from the corresponding operating instructions of the automatic switch

which is enclosed. By means of the selector switch in the front cover it is possible to:

a)

Switch on and off the functioning of the unit. Attention, the control system is thus not

disconnected from the mains supply at all poles!

b)

to switch the unit to permanent operation or automatic operation (automatic switch) of the

filter pump.

Also during the working time of the filter pump, the heating of the pool is regulated by the

electronic temperature control. During interruptions of the filtering process, the heating is

automatically switched off by the internal locking device. The requested temperature of the

pool water may be chosen or the heating may be switched off by an adjuster on the front

plate.

Operation of the filter pump and the heating is displayed by indicator lamps in the front cover -

controlling is therefore possible at any time.

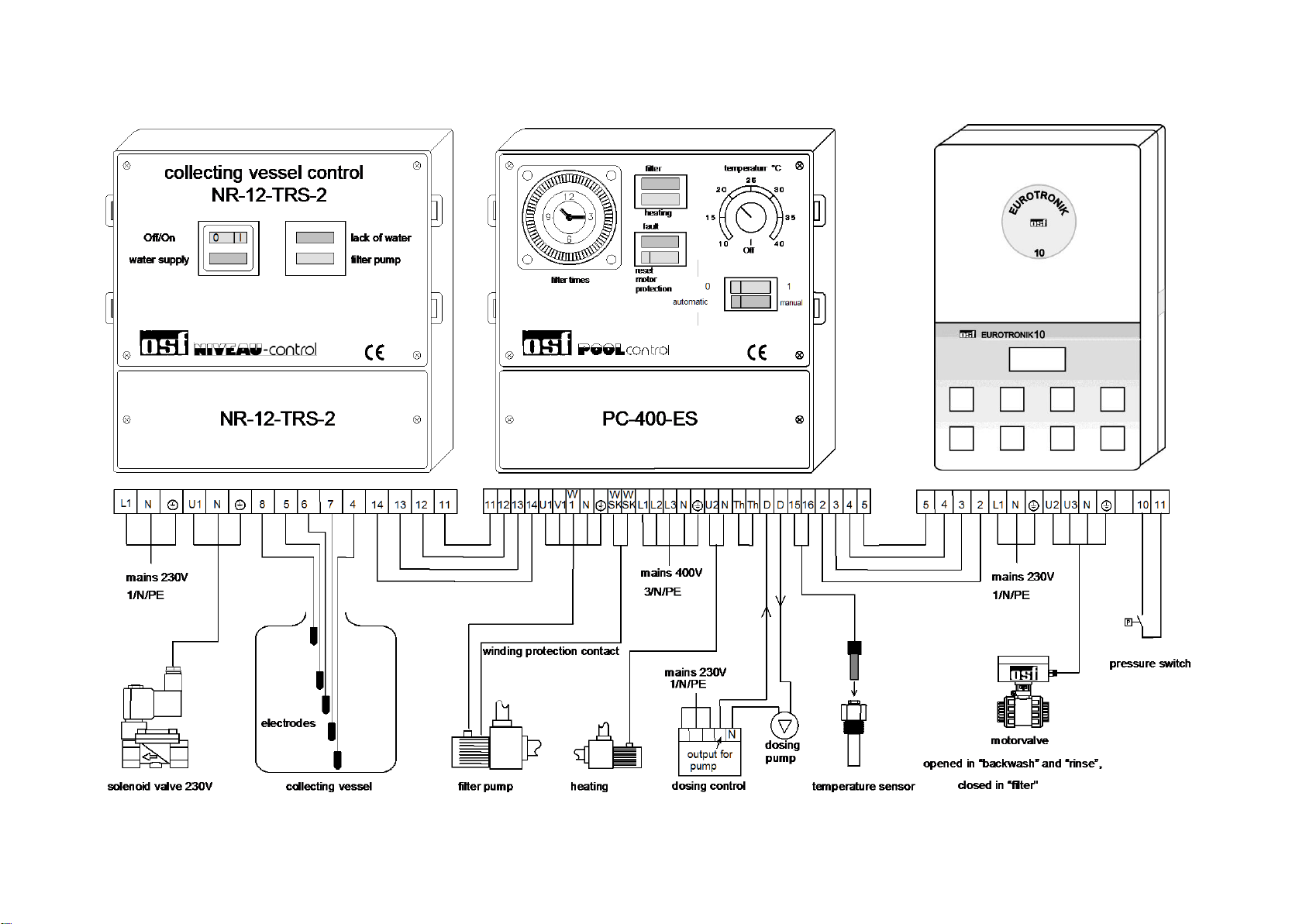

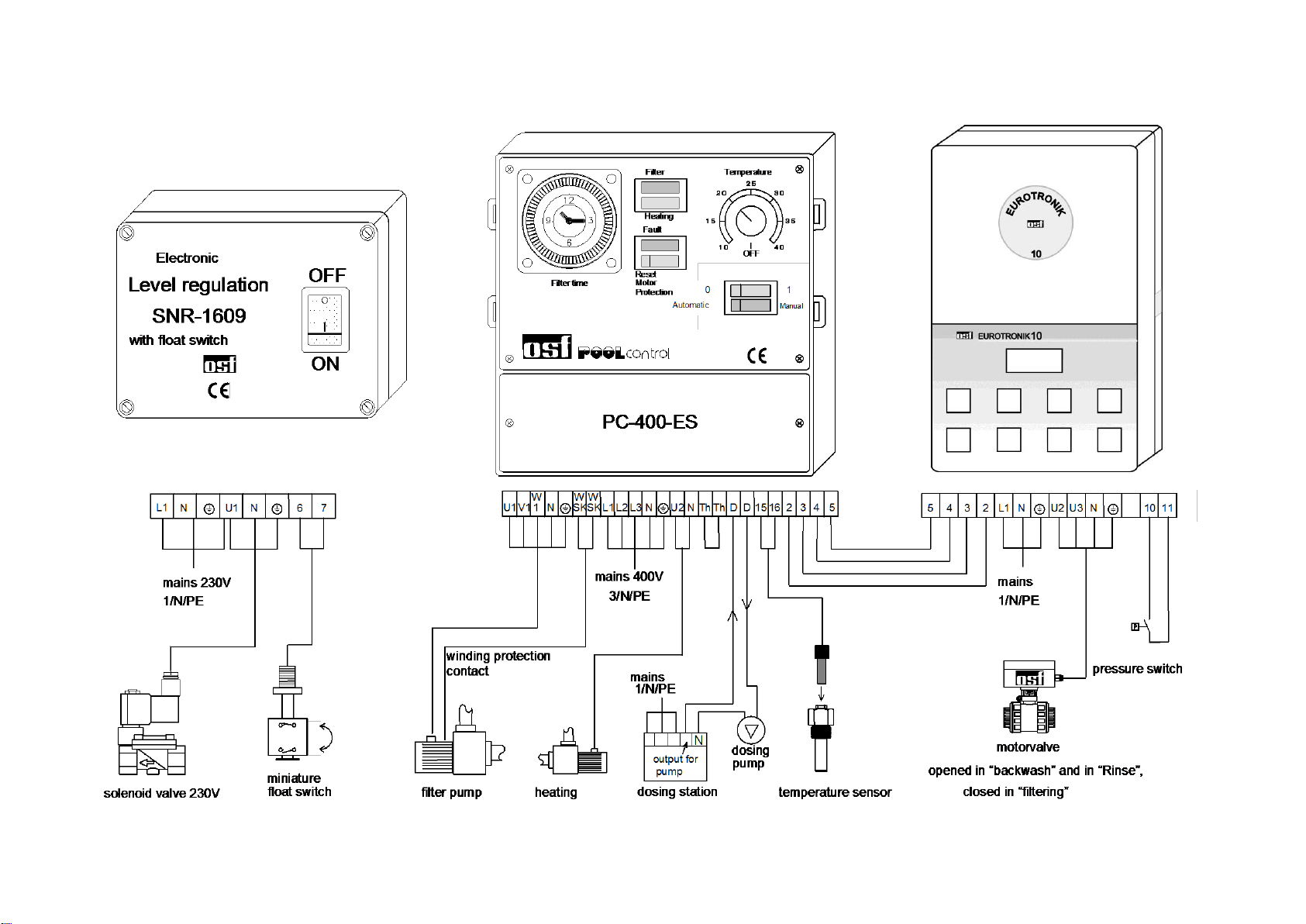

Connection terminals for an electronic level control -NR-12-TRS-2 or NR-12-TRS-3 ensure

a comfortable automatic control of the water level in the pool. Additionally, the filter pump is

protected against damage which may arise due to operation of the filter unit without water.

Connection terminals for an -EUROTRONIK-10 (Art.No. 3104800201) ensure an

enlargement of the filter control to an automatic filter- and re-flushing control.

Another terminal connection enables the connection of additional devices, e.g. dosing

technology. The terminals D/D are potential-free and can therefore be used individually. The

relay contact between terminals D/D is closed during the filter times; this relay contact is open

outside of the filter times. This contact can be used with a maximum voltage of 230V and a

maximum load of 400W (cos φ = 1).

The connection terminals for the winding protection contact (WSK) enable the connection of a

winding protection contact switch, which is integrated in the motor winding of the filter pump. If

this contact opens, e.g. due to excessive heating of the motor winding, the filter pump and with

it the heating and dosing technology are automatically switched off. As soon as the winding

protection contact closes after the motor winding has cooled down, the units switches on

again automatically. A manual reset is not required. The "WSK" connection terminals carry

230V.

Operation of the filter pump and the heating is displayed by indicator lamps in the front cover -

controlling is therefore possible at any time.

The filter pump is protected against overload by an electronic motor protection (current range

continuously adjustable up to 8A).

Operating manual PC-400-ES page: 2

Technical Data:

Dimensions:

220mm x 220mm x 100mm

Operating voltage:

400V/50Hz

Power consumption of the control system:

abt.1,5VA

Capacity:

Pump:

max. 3,0 kW (AC3)

Heating:

max. 0,4 kW (AC1)

Type of protection:

IP 40

Installation:

The control unit must be mounted such that it is protected from moisture in accordance with its degree of

protection. The ambient temperature must lie between 0°C and + 40°C and should vary as little as possible. The

relative humidity at the installation position must not exceed 95% and there must not be any condensation. Avoid

exposing the unit to direct heat or sunlight.

The swimming pool is to be constructed in such a way that a possible technical defect, a power failure or a

defective control cannot cause any consequential damage.

Electrical connection:

The power supply for the unit must be provided via an all-pole disconnection switch with a minimum contact gap of

3mm and via a residual-current circuit breaker with a fault current IFN ≤30mA.

Always disconnect the unit from the power supply before opening the case. All electrical wiring and calibration and

servicing work must be performed solely by an approved electrician. The attached wiring diagrams and all

applicable safety regulations must be observed.

Low voltage lines:

Low-voltage lines must not be laid along with three-phase or AC power cables in the same cable conduit. In

general, always avoid routing low-voltage lines close to three-phase or AC power cables.

When using a 400V three-phase pump:

When using a 230V AC pump:

Operating manual PC-400-ES page: 3

This control is not suitable for connecting a filter pump with speed control. We have other

controls in our delivery program for such pumps.

The bridge which is installed by the manufacturer between the two terminals designated as Th

has to be removed if a safety temperature limiter is connected. If the latter is not connected,

the bridge has to remain in place.

The bridge which is installed by the manufacturer between the terminals 13 and 14 has to be

removed if a level control unit NR-12-TRS-2 is connected. If a level control unit is not

connected, the bridge has to remain bolted between these terminals. In this case, the

terminals 11 and 12 shall not be used.

The bridge which is installed by the manufacturer between the terminals 5and 3 has to be

removed, if an EUROTRONIK-10 is connected. If an EUROTRONIK-10 is not connected,

the bridge between these terminals has to remain in place. In this case, the terminals 2and 4

shall not be used.

The factory-fitted bridge between the two terminals marked WSK must be removed when

connecting a winding protection contact. If no winding protection contact is available, it must

remain screwed in.

Opening one of the contacts between terminals 13 and 14 or 3 and 5 causes the filter pump,

dosing technology and heating to be switched off immediately.

Closing one of the contacts between terminals 2 and 4 or 11 and 12 forces the filter pump to

be switched on.

The electronic control is protected together with the EUROTRONIK-10, the level control and

the heating by a 3.15A fine-wire fuse inside the device.

Electronic motor protection:

The 3-phase filter pump is protected from

damage resulting from overload by an

electronic motor protection. To do so the motor

protection needs to be set to the nominal

current of the filter pump (see name plate of

the pump). If the nominal current of the filter

pump is not known, the motor protection can

be set using the following procedure:

1. Turn the adjustment screw of the motor

protection in the terminal box clockwise up

to the stop.

2. Switch the pump on

3. Turn the adjustment screw slowly counter

clockwise until the motor protection trips

and the red fault message comes on.

4. Turn the adjustment screw clockwise by

some degrees (approx. 10%).

5. Release the motor protection with the black

key: the fault message goes off and the

filter pump runs.

Adjust motor protection

Operating manual PC-400-ES page: 4

Temperature control:

The electronic temperature control and the

temperature detector have been aligned to

each other at the factory. If the detector is

replaced, a new alignment can be made using

a potentiometer inside the equipment. If, due

to an unsuitable installation position of the

temperature detector, the water temperature

does not match the desired temperature, this

can also be adjusted using the same

potentiometer.

The table below can be used to check the temperature sensor.

Resistance values of the temperature

sensor:

Temperature Resistance

20°C 5800 Ohms

25°C 4600 Ohms

30°C 3700 Ohms

The temperature detector is supplied with a 1.5m cable as standard. If required this can be

extended up to 20m. To rule out interference avoid installing the detector cable in the vicinity

of supply cables.

Since an exact temperature control is only performed when

there is good heat transfer between temperature detector and

swimming pool water, an osf immersion sleeve R 1/2 "

(product code 3200200001) must be installed in the pipe

system.

Adjust temperature sensor

Operating manual PC-400-ES page: 5

Operation of the timer

Setting the time

Setting the switching times

Operating manual PC-400-ES page: 6

Combination PC-400-ES with NR-12-TRS-2 and Eurotronik-10

Operating manual PC-400-ES page: 7

PC-400-ES with SNR-1609 and Eurotronik-10

Operating manual PC-400-ES page: 8

osf Hansjürgen Meier

Elektrotechnik und Elektronik GmbH & Co KG

Eichendorffstraße 6

D-32339 Espelkamp

E-Mail: [email protected]

Internet: www.osf.de

Subject to change without notice! 3/22

Further information can be found on the Internet at the following address::

https://osf.de/download/documents/doclist.php?device=PC-400-ES&subdir=none

This manual suits for next models

1

Table of contents

Other OSF Control System manuals

Popular Control System manuals by other brands

Crestron

Crestron Green Light GL-IPAC-SW8 product manual

Studio Technologies

Studio Technologies 236 user guide

Rowe

Rowe HASCP Operation manual

TSI Instruments

TSI Instruments DICKEY-john INTELLIAG ISO6 Operator's manual

Mitsubishi Electric

Mitsubishi Electric MELDAS 60 Series Programming manual

Hypertherm

Hypertherm ArcGlide THC instruction manual