Operating instructions for POOL-Control-45 exclusiv filter control unit Page 3 (44)

How level control works for balancing tanks.............................................................................................14

Pool with skimmer ...........................................................................................................................................15

Level measurement in the standpipe ..............................................................................................................15

Use without level control .................................................................................................................................15

Solenoid valve for topping up the water level..................................................................................................15

Display ...............................................................................................................................16

Operation...........................................................................................................................16

Switching on the PC-45 exclusiv.....................................................................................................................16

Switching off the PC-45 exclusiv.....................................................................................................................17

Operating mode selection ...............................................................................................................................17

Child safety lock ..............................................................................................................................................17

Pro mode (Service engineer level)..................................................................................................................17

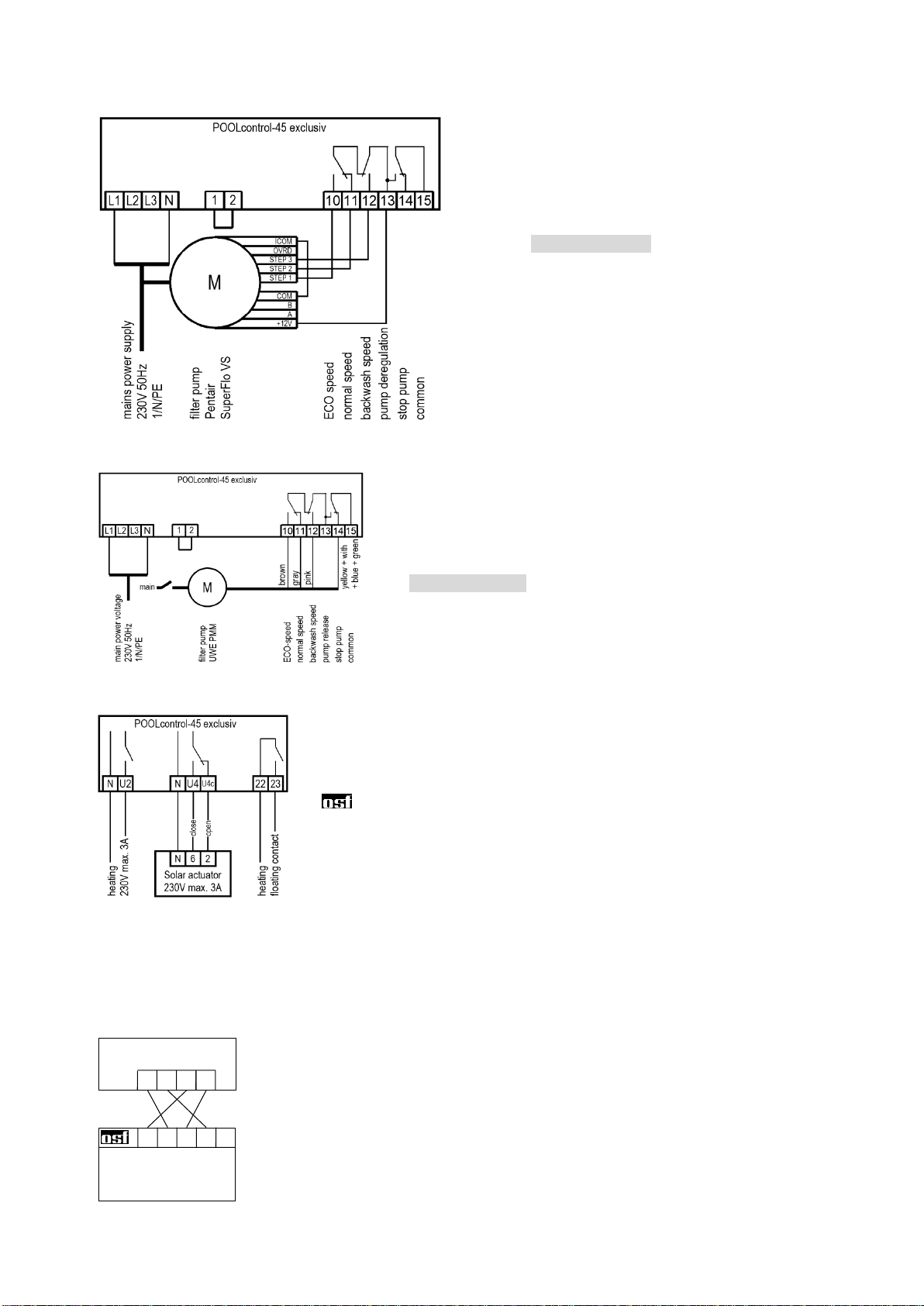

Heater settings ................................................................................................................................................18

Setting the water temperature...................................................................................................................18

Temperature reduction in Eco mode.........................................................................................................18

Switching the heating on/off......................................................................................................................18

Frost protection .........................................................................................................................................18

Settings for the filtration system......................................................................................................................18

Automatic –Continuous running –Off......................................................................................................19

Programming the filtration timer................................................................................................................19

Deleting a timer setting .............................................................................................................................19

Checking the timer settings.......................................................................................................................20

Setting the ECO filtration times.......................................................................................................................20

Automatic –Continuous running –Off......................................................................................................21

Entering, editing and deleting ECO timer settings....................................................................................21

Backwash using slide valves...........................................................................................................................21

Manual backwash .....................................................................................................................................21

Programming the backwash timer settings...............................................................................................21

Setting up Party mode.....................................................................................................................................22

Fault indicators / Information page..................................................................................................................23

“Pump disabled” fault indicator .................................................................................................................23

Resetting any fault indicators....................................................................................................................23

Log ............................................................................................................................................................23

Operating hours counter ...........................................................................................................................23

Acoustic alarm...........................................................................................................................................23

Service settings.................................................................................................................24

Set the date and time................................................................................................................................24

Add a new device......................................................................................................................................24

Perform factory reset.................................................................................................................................24

Network settings........................................................................................................................................24

Alarm settings ...........................................................................................................................................24

Set the level-control parameters...............................................................................................................24

Set motor protection..................................................................................................................................24

Set the pump startup time.........................................................................................................................24

Set the backwash duration........................................................................................................................24

Set the rinse duration................................................................................................................................24

Set the temperature-control parameters...................................................................................................24

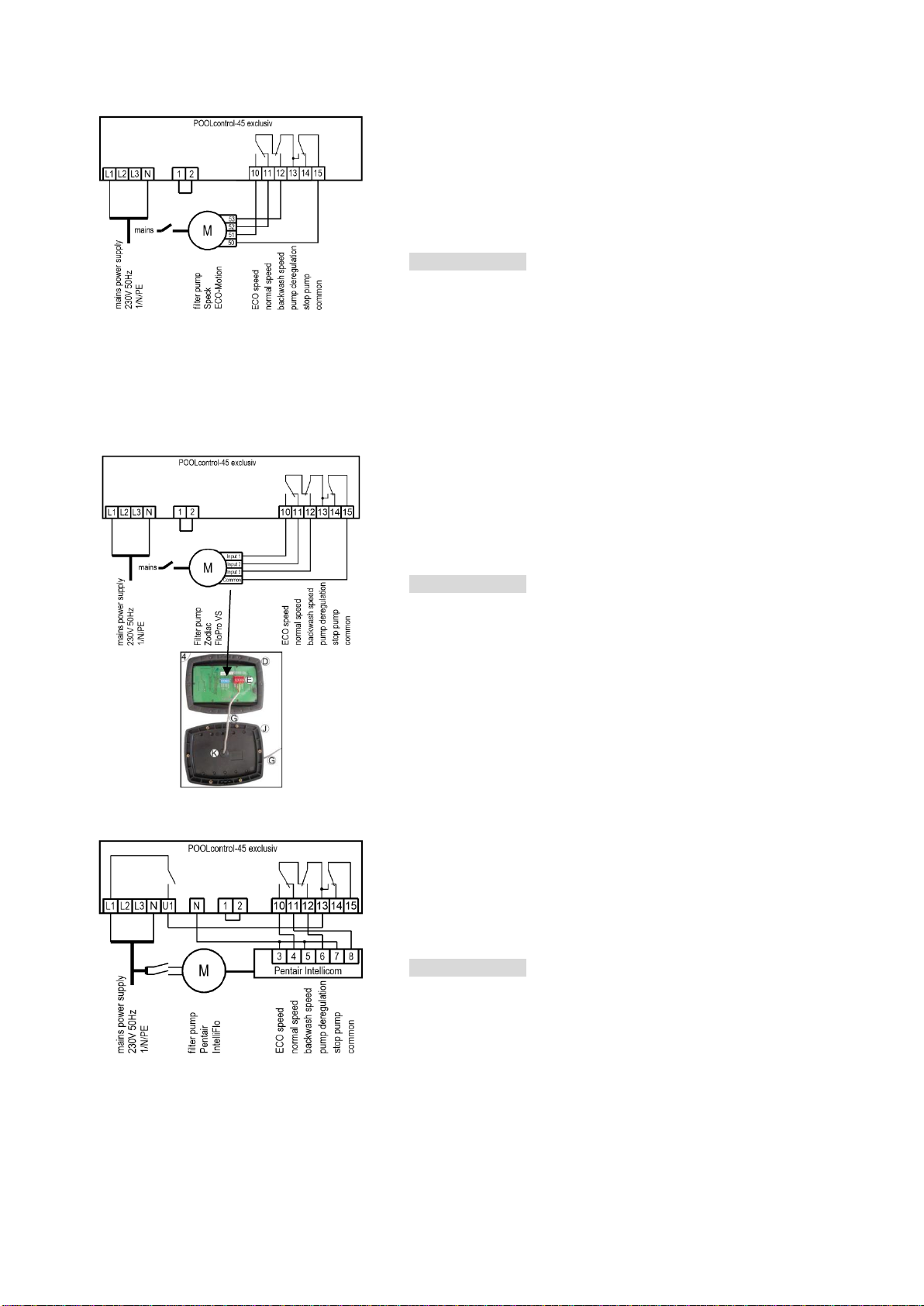

Configuring the control unit.............................................................................................25

Pro mode ...........................................................................................................................25