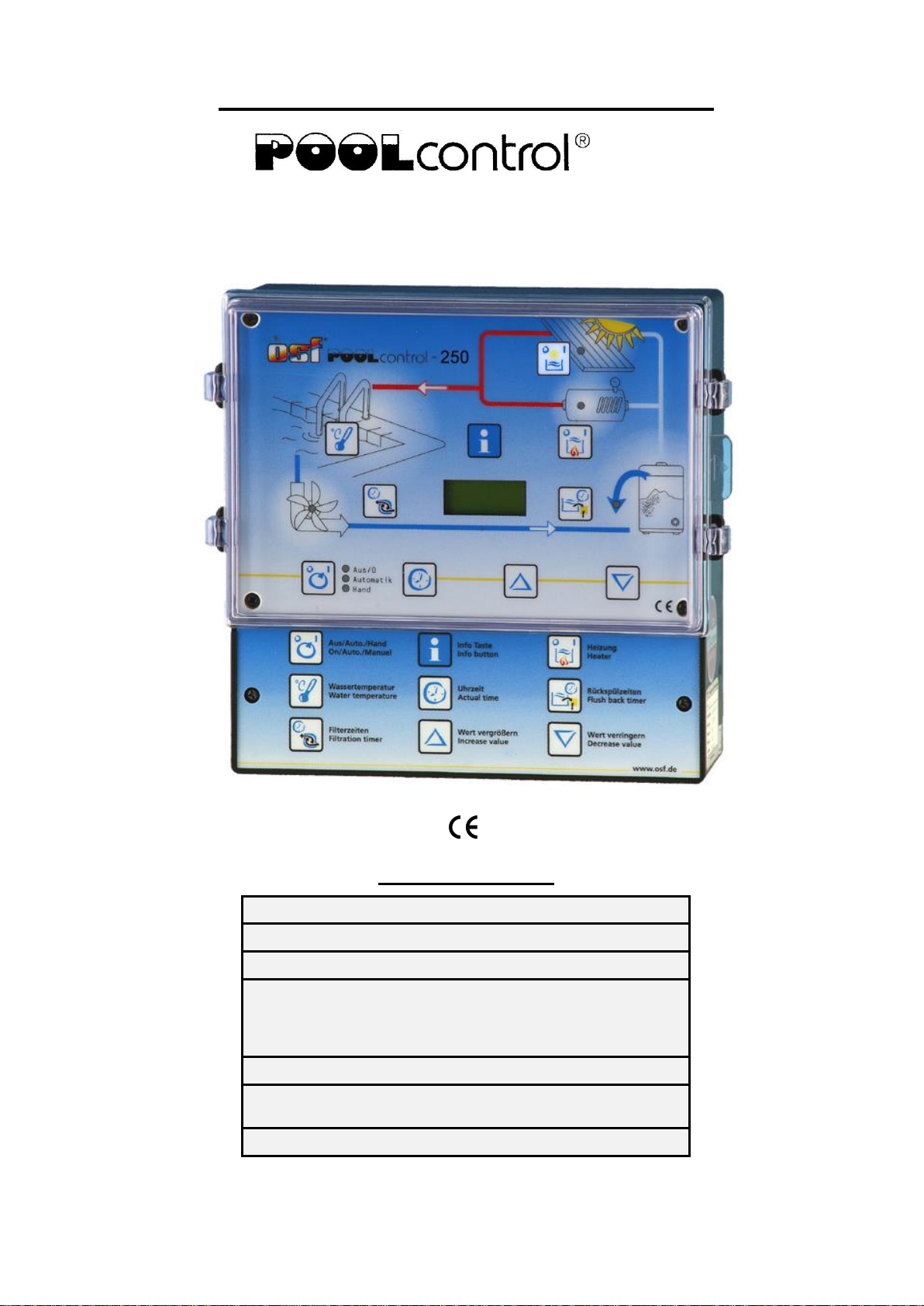

OSF POOL-Control-250 User manual

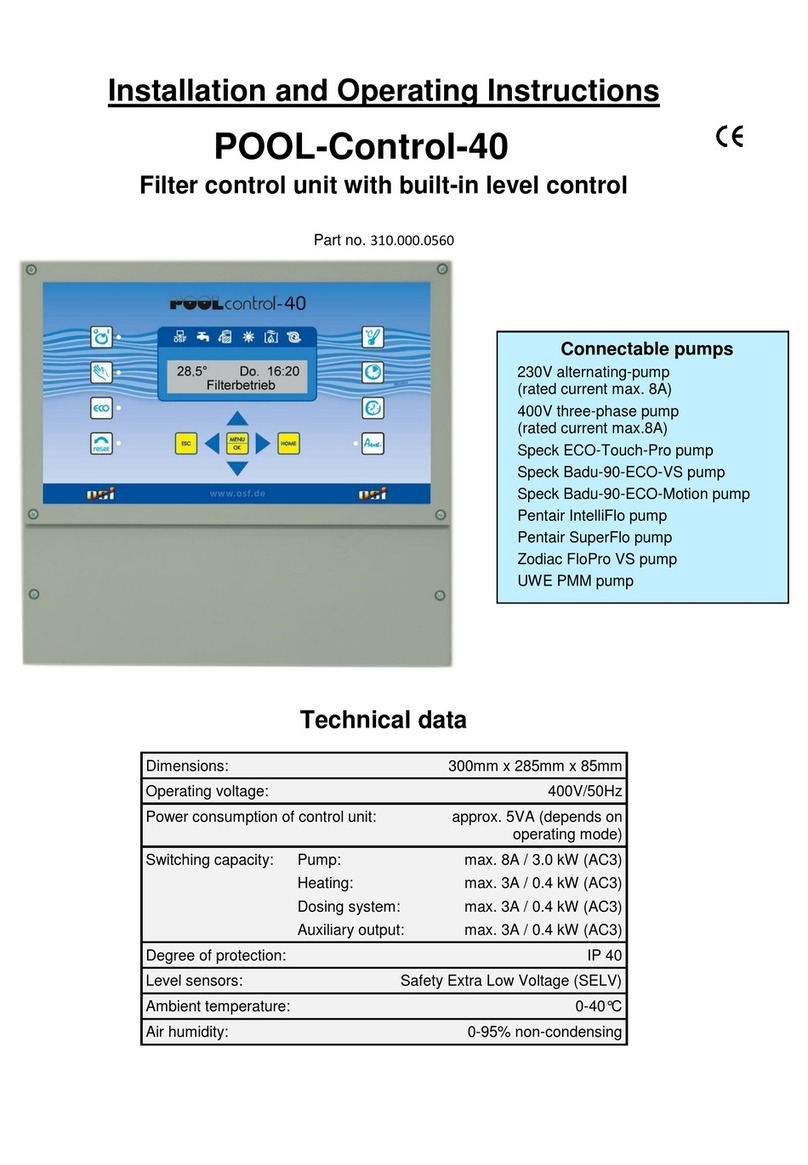

Installation and operating manual

-250

400V filter control unit

Item No.: 3100000440

Specifications:

Dimensions:

220mm x 220mm x 100mm

Operational voltage:

400V/50Hz

Control system power consumption:

ca. 10VA

Switching capacity:

Pump:

max. 3.0 kW (AC3)

Heater:

max. 2A

Dosing system:

max. 8A

Protection class:

IP 40

Surrounding

temperature

0-40°C

Humidity:

max. 80% rel. F., non-condensing!

PC-250 Filter control unit operating manual Page: 2 (24

Contents

Function:...............................................................................................................................................4

Front panel displays and controls:.......................................................................................................5

LCD display.....................................................................................................................................................5

Selecting operating mode ...............................................................................................................................5

Pump indicator lamp......................................................................................................................................6

Heater indicator lamp.....................................................................................................................................6

Solar heater......................................................................................................................................................6

Backflushing process indicator lamp............................................................................................................6

Selecting the temperature...............................................................................................................................6

Switching on frost protection mode ..............................................................................................................6

Setting the time................................................................................................................................................7

Programming the timer..................................................................................................................................7

Delete rinsing time:........................................................................................................................................................ 7

Programming backflushing............................................................................................................................8

Deleting switching times:............................................................................................................................................... 8

Start backflushing process manually............................................................................................................8

Info key.............................................................................................................................................................8

Installation ............................................................................................................................................9

Electrical power supply.........................................................................................................................9

Mains connection when using 400V 3-phase pump:..................................................................................10

Mains connection when using 230 V AC pump:........................................................................................10

Heater connection .........................................................................................................................................10

Level regulation and backflushing control.................................................................................................11

Dosing system connection.............................................................................................................................12

Temperature sensor connection...................................................................................................................12

Setting motor protection .....................................................................................................................12

Starting the backflushing process ......................................................................................................12

Balancing the temperature controller................................................................................................13

Temperature sensor resistance...........................................................................................................13

Fuses....................................................................................................................................................13

Service terminal............................................................................................................................13

Filter unit operating mode ...........................................................................................................................14

Heater operating mode.................................................................................................................................14

Water temperature .......................................................................................................................................15

Additional heater...........................................................................................................................................15

Solar................................................................................................................................................................15

Water..............................................................................................................................................................15

PC-250 Filter control unit operating manual Page: 3 (24

Set temperature.............................................................................................................................................15

Current...........................................................................................................................................................15

Motor protection...........................................................................................................................................15

Solar difference .............................................................................................................................................15

Solar additional temperature.......................................................................................................................16

Limit temperature.........................................................................................................................................16

Additional heater minimum time (hysteresis)............................................................................................16

Solar heater minimum time (hysteresis).....................................................................................................17

Filter pump run-on time...............................................................................................................................17

Heater priority circuit ..................................................................................................................................18

Solar heater priority circuit.........................................................................................................................18

Frost protection.............................................................................................................................................19

Pump time......................................................................................................................................................19

heater time.....................................................................................................................................................19

Solar time.......................................................................................................................................................19

Motor defect ..................................................................................................................................................19

Phase fields ....................................................................................................................................................19

Int. backflushing (intern) .............................................................................................................................19

Ext. Backflushing (extern)............................................................................................................................19

Forced switch-on of NR-12-TRS-2..............................................................................................................19

EUROTRONIK backflushing signal...........................................................................................................20

Interlocking....................................................................................................................................................20

Filter pump....................................................................................................................................................20

Solar operation..............................................................................................................................................20

Heater.............................................................................................................................................................21

Dosing unit.....................................................................................................................................................21

Backflushing valve........................................................................................................................................21

Rinsing valve..................................................................................................................................................22

Language........................................................................................................................................................22

Combination of PC-250 with NR-12-TRS-2 and Eurotronik-10......................................................23

PC-250 Filter control unit operating manual Page: 4 (24

Function:

The PC-250 filter control unit enables

time-dependent switching on and off of a

400 V three-phase current pump or a 230

V alternating current filter pump in

accordance with a freely programmable

switching program.

Backflushing can be carried out both with

bar valves and with the

EUROTRONIK-10 backflushing control

system and 6-way valves.

heater of the swimming pool is controlled

by the electronic temperature regulation

system while the filter pump is running.

The heater is automatically switched off by

the internal interlock during filter pauses.

The required swimming pool water

temperature can be selected on the front

panel, or the heater can be switched off. A

floating contact (terminals 22 + 23) and a

voltage-carrying output (terminal U2) are

available for connecting the heater.

The microprocessor automatically

activates the solar temperature regulation

through the connection of a solar

temperature sensor (Art. No.

3100000030). Free solar energy will

therefore be given priority in heater the

swimming pool. The additional heater

(terminals U2 and N) will only be switched

on automatically if the solar unit is not

supplying any energy. The solar heater

and, simultaneously, the filter pump will

also start if solar energy is available

outside filter running times (timer off). The

solar temperature sensor is suitable for

operating solar absorbers through which

the swimming pool water flows directly.

This controller is not usable for other types

of solar collector.

Terminals for electronic level regulation

NR-12-TRS-2 (Art. No. 3030075020)

enable convenient automatic regulation of

the swimming pool water level. The filter

pump is also additionally protected against

damage which could be caused by filter

unit operation without water.

The INFO key on the front panel enables

reading out of various operating

parameters in addition to language

changeover.

Extra terminals enable the connection of

additional devices such as a dosing

system. Terminals 20 + 21 are floating,

and can therefore be used individually.

The relay contact between terminals 20

and 21 remains closed during the filter

periods, the relay contact is opened

outside these periods. This contact can be

loaded with a voltage of maximum 230 V

and a current of maximum 8 A.

The terminals for the coil earthing contact

enable the connection of a coil earthing

contact switch which is integrated in the

filter pump motor windings. If this contact

opens, for example due to excessive

motor winding warming, the filter pump will

be switched off automatically, and with it

the heater and dosing system. As soon as

the coil earthing contact closes once the

motor windings have cooled down, the

units will be started up again automatically.

Manual resetting is not necessary. The

terminals for the coil earthing contact are

provided with 230 V.

Operation of filter pump and heater is

displayed by indicator lamps in the front

panel, which means that checks can be

made at any time.

The filter pump is protected by an

electronic motor protection system (current

range infinitely variable up to 8A) against

overloading.

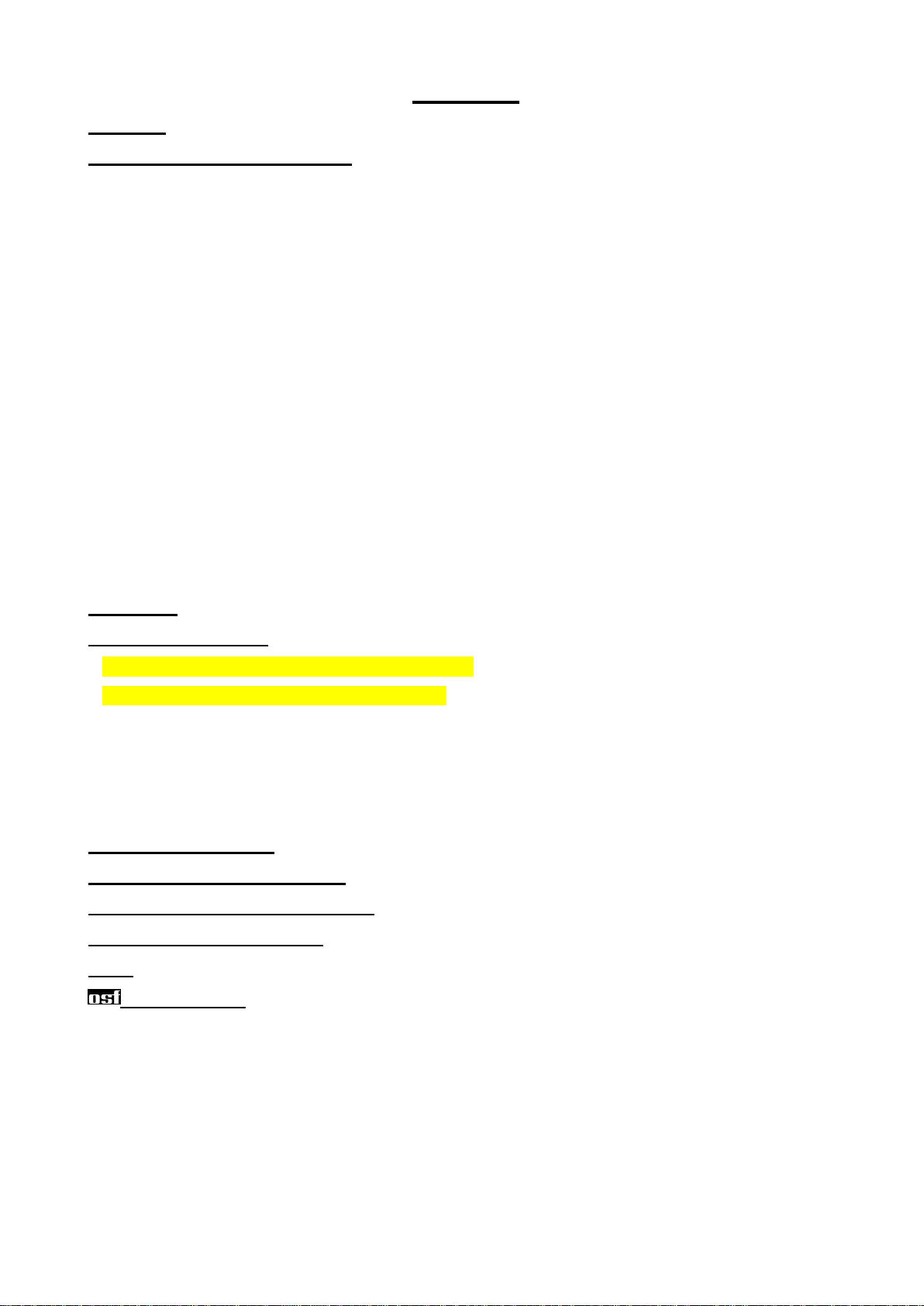

Front panel displays and controls:

solar button ON/OFF

adjust temperature

adjust switching times

control light filter pump

select operating mode

control lights operating mode

art

set time

adjust backflushing

control light solar heating

control light heating

heating ON/OFF

LCD

adjustment buttons

info Button

control light backflushing

LCD display

LCD display

23,4

14:46

°C

Normal operating display with current water temperature and time.

Auffang-

behälter

The filter pump is switched on by the NR-12-TRS-2 level regulation system.

6-Wege

Spülung

The filter pump is switched on by the EUROTRONIK-10 backflushing

control system.

Pumpe

gesperrt

The filter pump is switched off by the EUROTRONIK-10 or the NR-12-TRS-

2 level regulation system.

Rück-

spülen

The filter pump is switched on because backflushing is taking place using

the bar valve connected.

Klar-

spülen

The filter pump is switched on because rinsing is taking place using the bar

valve connected.

Motor-

schutz

The filter pump has been switched off by the electronic motor protection

system. Once the pump has cooled down and the cause of overloading has

been rectified, it can be switched on again using the key.

Phase

fehlt

The filter pump is switched off because current is not flowing in all 3 phases

of the 3-phase current network. It can be switched on again using the key

once the error has been rectified.

Selecting operating mode

The control system can be switched off or you can select between manual

and automatic operating mode using the key. Caution! This does not

mean that the control system has been switched to voltage-free! The

operating mode selected is displayed using the indicator lamps next to the

key.

PC-250 Filter control unit operating manual Page: 6 (24

Pump indicator lamp

This indicator lamp displays filter pump operation. You can see the pump

operating mode from the lamp colour:

Off: the filter pump is switched off

Green: the filter pump is in operation

Red: the pump has been temporarily switched off by the NR-12-TRS-2

level regulation system or the EUROTRONIK-10 backflushing system, the

motor protection has triggered or it was switched off by phase fields.

Heater indicator lamp

This indicator lamp displays heater operation. You can see the heater

operating mode from the lamp colour:

Off: the heater is off

Green: the heater is in operation

Red: the additional heater is blocked.

Use the key to block or release the heater. The solar heater is not

switched using this key.

Solar heater

If a solar sensor has been connected to the control system, this indicator

lamp is used to show the current operating status of the solar heater.

Backflushing process indicator lamp

This indicator lamp always illuminates if backflushing or rinsing using the

bar valve is taking place.

Selecting the temperature

Use the key to select the swimming pool water temperature.

1. Press the key the display shows

2. Use the and keys to set the required temperature between 0 °C and

40 °C.

3. Press the key again to save the required temperature. If no key is

pressed for more than 10 seconds during temperature setting, the last

temperature selected is saved automatically and the normal operating

display will be shown again.

Switching on frost protection mode

If you press the , and keys simultaneously, frost protection mode is

selected and the display shows

1. Use the and keys to switch frost protection mode on or off.

2. Press the key again to save the required operating mode . If frost

protection mode has been switched on, the display will show:

24,5

Wasser:

°C

aus

Frost.

utz mode

Frostsch

PC-250 Filter control unit operating manual Page: 7 (24

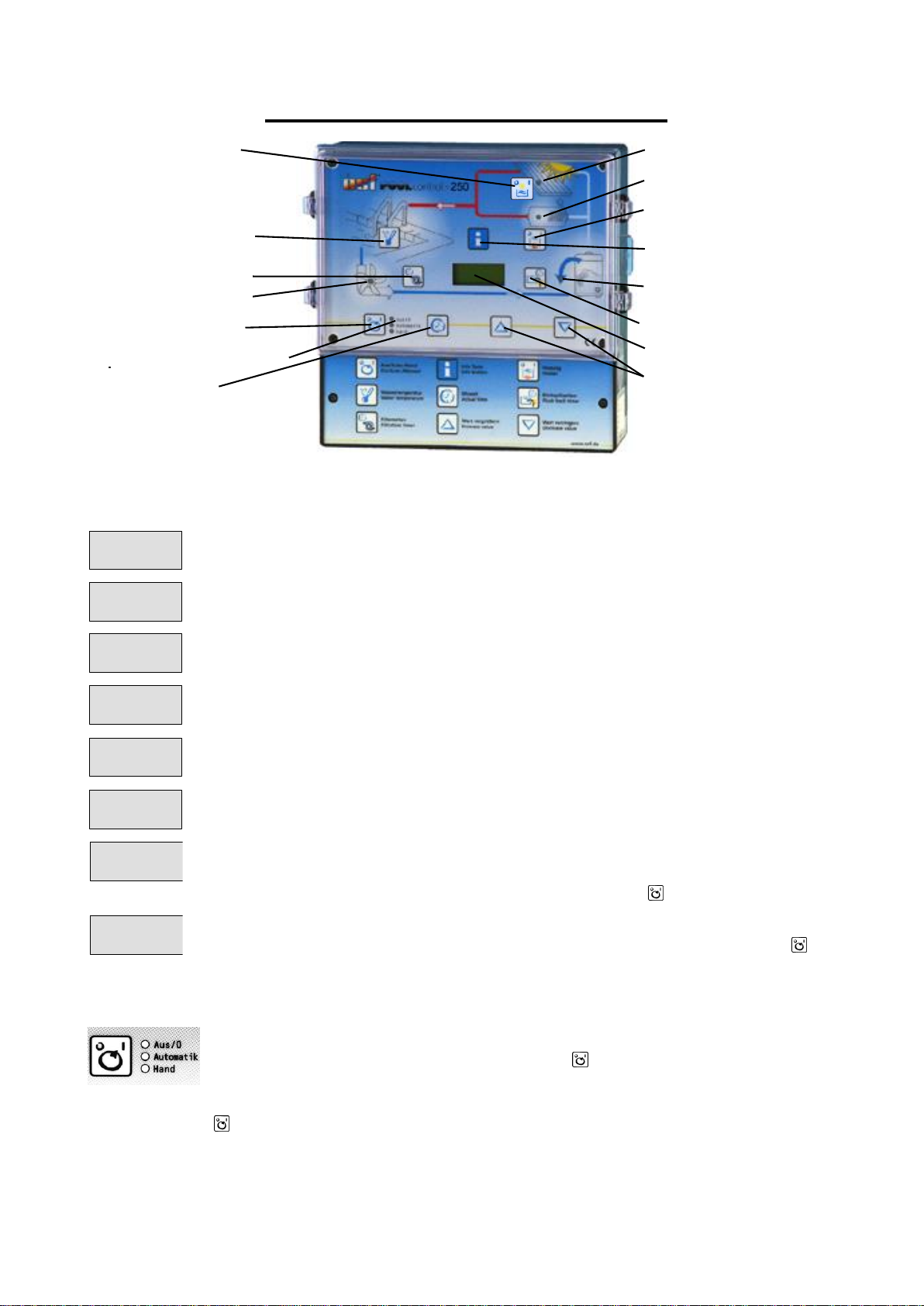

Setting the time

Use the key to set the current time:

1. Press the key the display shows

Sa 14:46

Uhrzeit

, the minute display

blinks.

2. You can now use the and keys to set the minutes.

3. Press the key the hour display blinks.

4. You can now use the and keys to set the hours.

5. Press the key the weekday display blinks.

6. You can now use the and keys to set the weekday.

Press the key again to save the time. If no key is pressed for more than

10 seconds during setting, the last time displayed is saved automatically

and the normal operating display will be shown again.

Programming the timer

Use the key to program the built-in timer, whereby the switch-on time and

the associated switch-off time must always be entered as pairs.

1. Press the key the display shows

-----

1.

if no switching time

has yet been programmed.

2. If you press one of the or keys, or if a switching time has already

been programmed, the display shows

0:00

0:00

1.

, the minute display of

the top time (switch-on time) blinks. Note: if you press the key, the

current time will be taken over.

3. You can now use the and keys to set the required switch-on time

minutes.

4. Press the key again the hours in the switch-on time blink

5. You can now use the and keys to set the required switch-on time

hours.

6. Press the key again the minutes in the switch-off time blink

7. You can now use the and keys to set the required switch-off time

minutes. Note: if you press the key, the current time can be taken

over, if you press the and keys simultaneously the switch-on time

set previously will be taken over.

8. Press the key again the hours in the switch-off time blink

9. You can now use the and keys to set the required switch-off time

hours.

10.Further switching times can now be programmed as in points 1-9.

11.Press the key again to save the switching time. If no key is pressed

for more than 10 seconds during setting, the last switching time

displayed is saved automatically and the normal operating display will

be shown again.

Delete rinsing time:

If switching times have already been programmed, you can use the key

PC-250 Filter control unit operating manual Page: 8 (24

to delete them.

1. Press the key as often as required until the switching time to be

deleted is displayed

10:00

16:00

3.

2. The switching time is deleted if you press the and keys

simultaneously.

Note:

If you press the key, the current time is taken over.

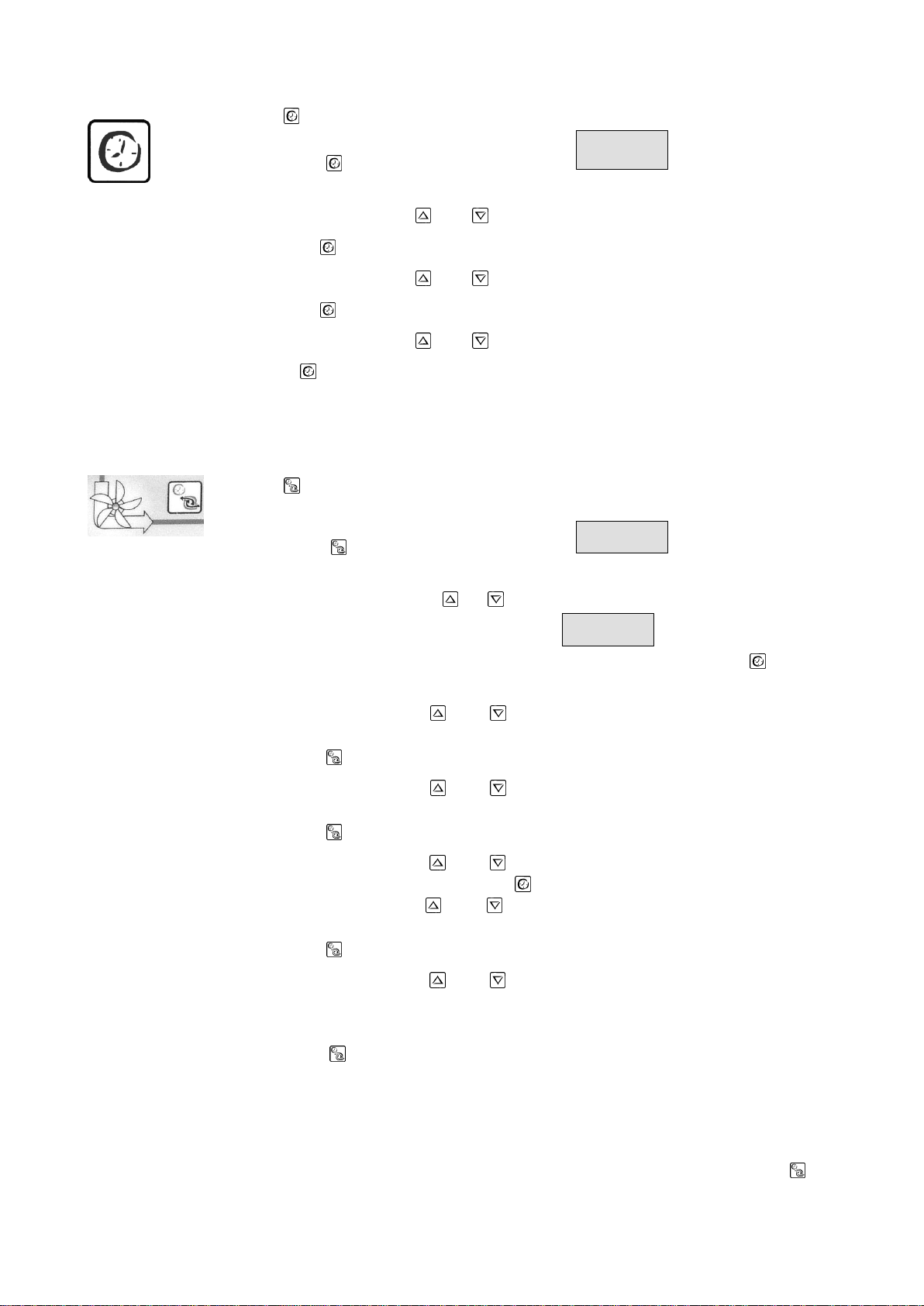

Programming backflushing

Use the key to control backflushing using the bar valve.

1. Once the key has been pressed the first time, you can use the and

keys to set the backflushing duration

10 Sek.

Rückspül

.

2. Once the key has been pressed the next time, you can use the and

keys to set the rinsing duration

10 Sek.

Klarspül

.

3. Once the key has been pressed again, you can set the time of the

rinsing process

Mo 16:00

1. Start

.

In the first stage, the and keys are used to set the minutes.

If you press the key, the current time is taken over.

4. Press the key again the hours in the switch-on time blink

You can now use the and keys to set the hours.

5. Press the key again the switch-on time weekday blinks.

You can now use the and keys to set the weekday.

6. Further start times can be programmed in the same manner as

described in points 1 to 5.

Deleting switching times:

If you press the and keys simultaneously, the rinsing time shown in the

display will be deleted.

Note:

If you press the key, the current time is taken over.

Start backflushing process manually

If the backflushing key is pressed for 3 seconds without interruption, the

backflushing process will start. Backflushing will not start unless a

backflushing duration has been entered.

Info key

If you press the INFO key, the program version number will be displayed

:

If the info key is pressed several times successively, the following information

can be called up.

1) Language

PC250

ver.1.xx

PC-250 Filter control unit operating manual Page: 9 (24

The current language is displayed. If you press the and keys, you can

switch between the German and English languages. The language

displayed will be saved automatically.

2) Solar temperature

3) Water temperature

4) Filter pump operating status

5) Additional heater operating status

6) Solar heater operating status

7) Filter pump operating hours counter

8) Additional heater operating hours counter

9) Solar heater operating hours counter

10) Motor protection

The trigger current set for the motor protection system is visible in the

display.

2 facilities are available for setting the motor protection system.

a) The current motor current is accepted and saved if the filter pump is

running and the and keys are pressed simultaneously. (The starting

current delay factor is automatically declared.)

b) If you press the or keys, the filter pump current consumption

can be set manually. The current displayed will be saved automatically.

11) Quit info mode

To quit the information mode, press the Info key for 3 seconds without

interruption.

If the Info key is not pressed for a longer period, the device switches back

to the normal operating display automatically.

Installation

The controller must be protected against moisture in accordance with its protection class,

and the fixed to a plain, fireproof support with suitable loading capacity and must be out of

the reach of children. You should avoid direct sunlight, UV radiation and formation of

condensate due to temperature variations. The device must be powered via a multi-pole

main switch with a contact opening width of at least 3mm and a residual current circuit

breaker with IFN30mA . The device must be isolated before opening the housing.

Electrical power supply

Electrical power supply connections, in addition to alignment and service work, may only be

carried out by approved electricians. The attached circuit diagrams and all applicable safety

regulations must be observed. All conductive components must be included in the

equipotential bonding.

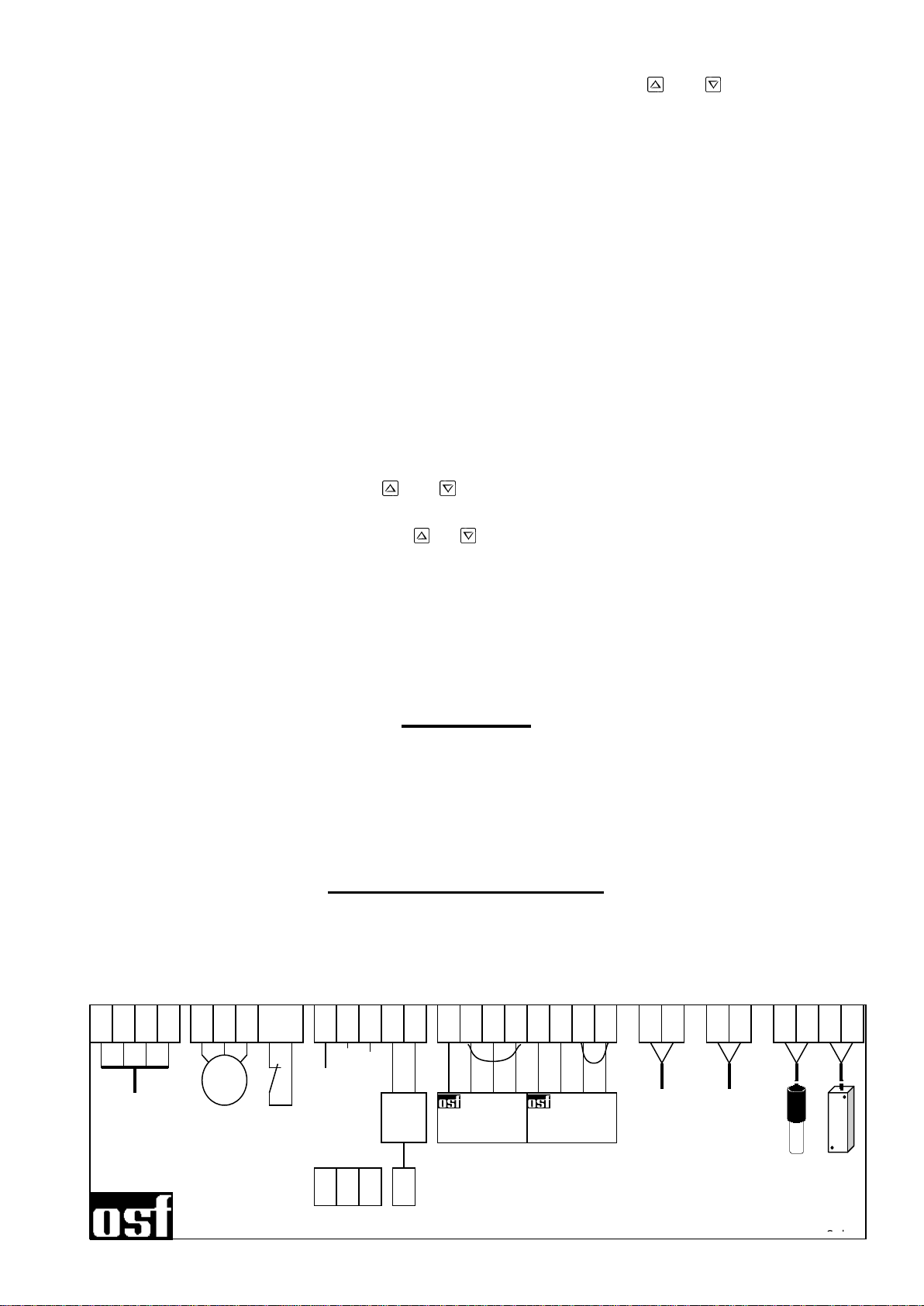

NTC

sensor

Water

temp.

PC-250

Filter pump

400V

max. 8A

Solar

Actuator

Aktive

NTC

sensor

Solar

temp.

Dosing system

floating

max. 8A

L1

L2

L3

N

Mains

3 / N / PE

400V 50Hz

30

31

32

33

U1

W1

V1

WSK

U2

U3

U4

U5

U6

2

3

4

5

11

12

13

14

20

21

22

23

Heater floating

max. 8A

M

3~

Winding

protection

contact

N

N

N

N

EUROTRONIK-

10

Level regulation

NR-12-TRS-2

Heater 230V 2A

Backflushing 230V 2A

Rinsing230V 2A

*Remove bridge if

connecting NR-12-TRS-2 or

Eurotronik-10

!

*

*

All components must be included in the equipotential bonding!

PC-250 Filter control unit operating manual Page: 10 (24

Mains connection when using 400V 3-phase pump:

Pool-Control-250

Wicklungs-

3M

W1V1U1L1 L3L2 NWSK

FI-Schalter schutz-

max. B16A

Vorsicherungen

400V max. 8A

Filterpumpe

Netz 3/N/

400/230V 50Hz

25A/0,03A kontakt

The bridge fitted in the works between the terminals labelled WSK must be removed if a

pump with coil earthing contact is connected. If no such connection is made, it must remain

fitted. These terminals carry mains voltage!

Mains connection when using 230 V AC pump:

Pool-Control-250

Wicklungs-

1

M

W1V1U1L3L2L1 NWSK

schutz-

230V max. 8A

Filterpumpe

max. B16A

Vorsicherung

FI-Schalter

Netz 1/N/

230V 50Hz

25A/0,03A

N

kontakt

The bridge fitted in the works between the terminals labelled WSK must be removed if a

pump with coil earthing contact is connected. If no such connection is made, it must remain

fitted. These terminals carry mains voltage!

The motor current must be fed using all 3 switching contacts in the filter control unit so that

the electronic motor protection works correctly (terminals L2 and L3 in addition to U1 and

V1 bridged, pump connected to W1).

Heater connection

Floating contact (e.g. for

boiler control)

230V heater (e.g. circulation

pump)

Solar heater

PC-250

max. 8A

22

23

Heizung

potentialfrei

PC250

max. 2A

U2

Heizung 230V

N

PC-250

U5

N

6

2

3

U6

Stellantrieb 230V

Solar-

PC-250 Filter control unit operating manual Page: 11 (24

The floating relay contact between terminals 22 and 23 can be loaded with a voltage of

maximum 230 V and a current of maximum 8 A.

If the heater requires 230 V, it can be connected to terminal U2. Terminals are also

available for the heater N connection.

A 230 V solar actuating drive can be connected to terminals U5 and U6 for operating

the solar heater. When operating solar heater, terminal U5 carries the mains voltage and

terminal U6 is voltage-free. If the solar heater is not being operated, terminal U5 remains

voltage-free and terminal U6 carries the mains voltage. These contacts may the loaded

with a maximum 230 V/1.5A.

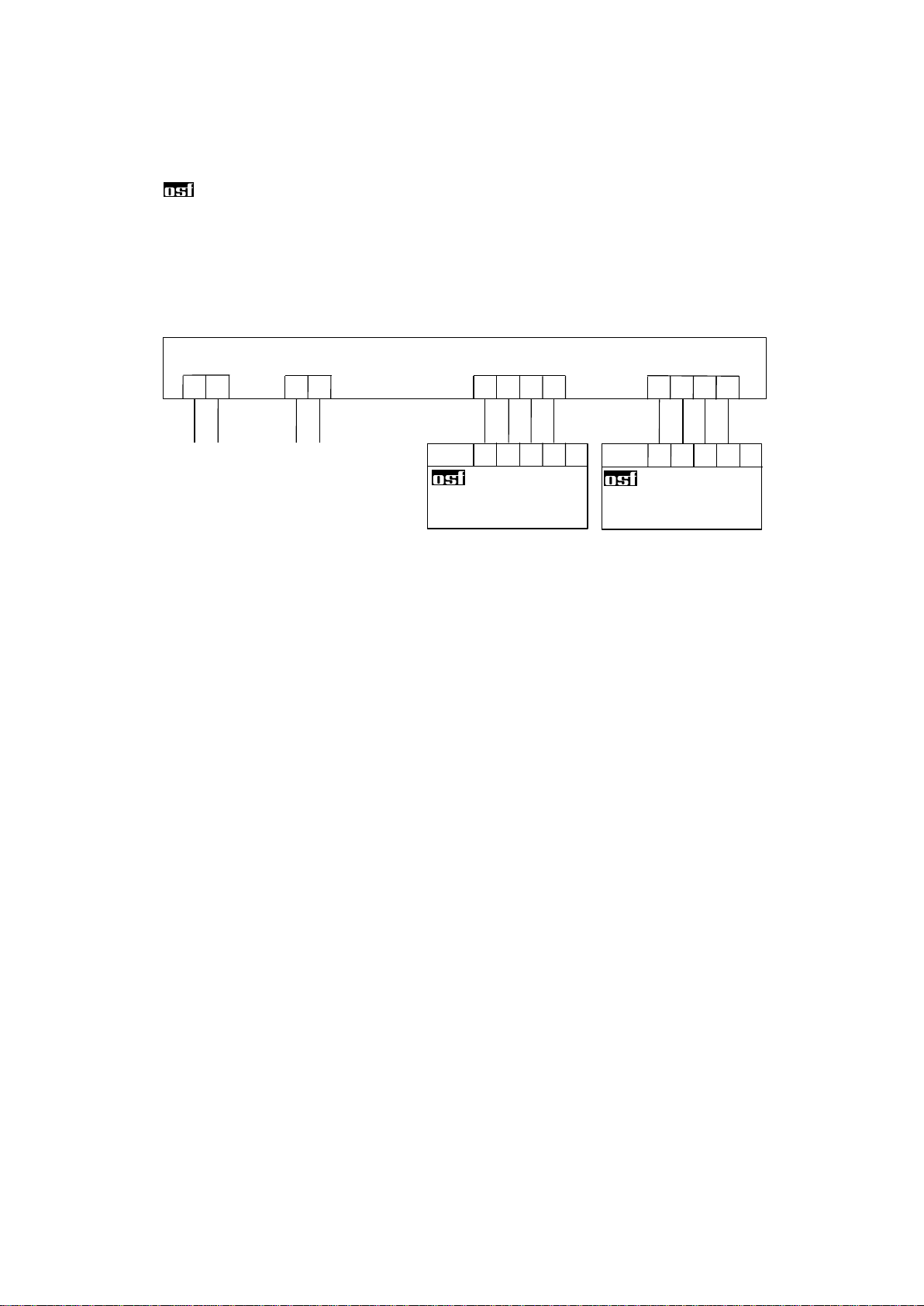

Level regulation and backflushing control

Filtersteuerung PC-30

NR-12-TRS-2

steuerung

Auffangbehälter-

11

12

13

14

11

12

13

14

U3

N

Rückspülventil

230V

max.2A

EUROTRONIK-10

2

3

4

5

2

3

4

5

Rückspülsteuerung

U4

N

Klarspülventil

230V

max.2A

A 230 V bar valve for backflushing can be connected to terminals U3 and N.

A 230 V bar valve for rinsing can be connected to terminals U4 and N.

Both valves will be controlled by the internal backflushing controller.

Heater and dosing systems are blocked during the backflushing and rinsing processes.

Either bar valves or a EUROTRONIK-10 can be used for backflushing or rinsing.

The bridge fitted in the works between terminals 13 and 14 must be removed if level

regulation system NR-12-TRS-2 is connected. The bridge can remain between these

terminals if no level regulation system is connected. Terminals 11 and 12 remain unused in

this case. These terminals carry mains voltage!

The bridge fitted in the works between terminals 3and 5must be removed if a

EUROTRONIK-10 system is connected. The bridge can remain between these terminals if

no EUROTRONIK-10 system is connected. Terminals 2and 4remain unused in this case.

These terminals carry mains voltage!

Opening any of the contacts between terminals 13 and 14 or 3 and 5 causes filter pump,

dosing systems and heater to be turned off immediately.

Closing any of the contacts between terminals 2 and 4 or 11 and 12 causes forced

switching on of the filter pump, whereas heater and dosing systems are switched off.

PC-250 Filter control unit operating manual Page: 12 (24

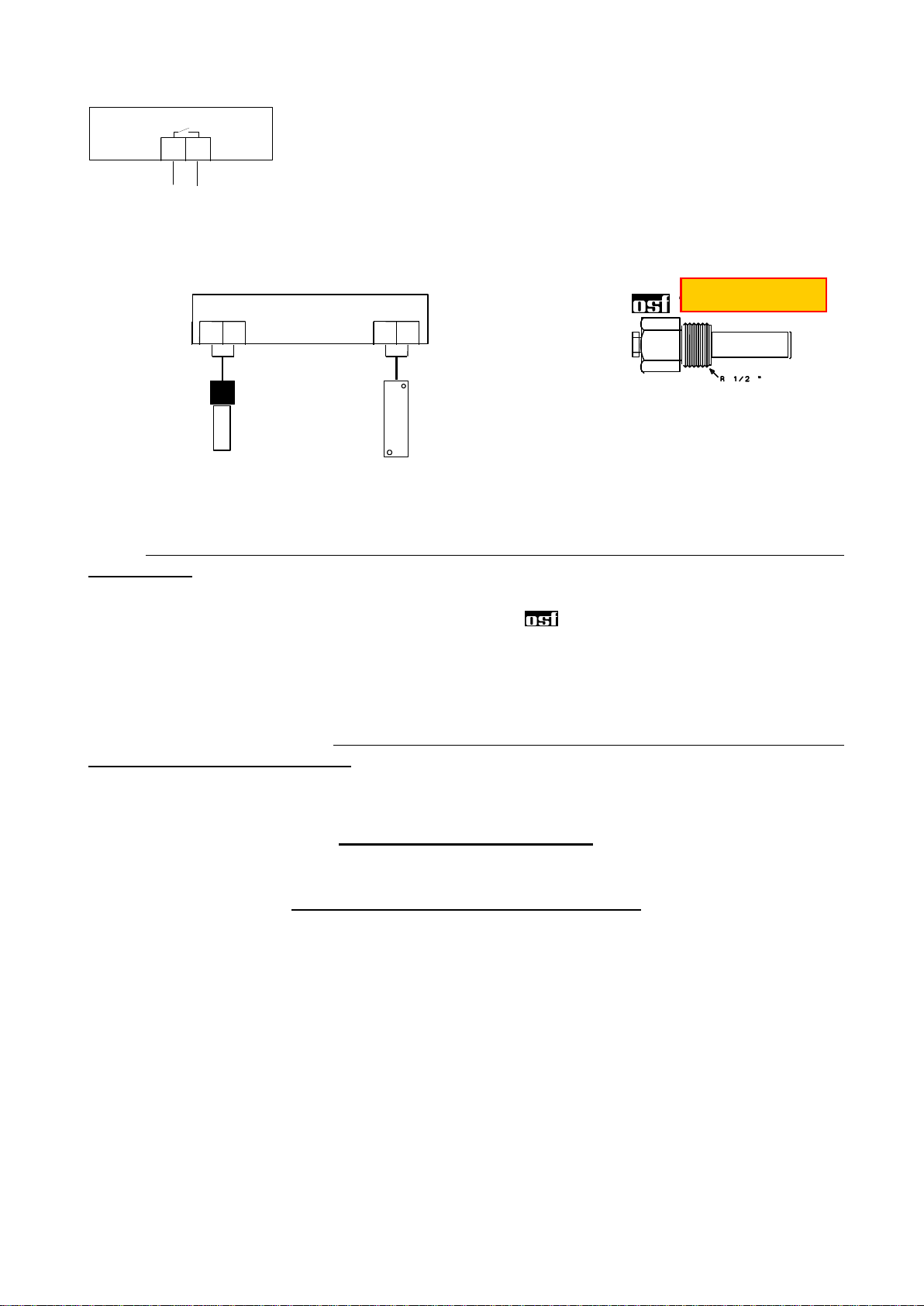

Dosing system connection

PC-250

20

21

Dosiertechnik

(potentialfrei)

max. 230V / 8A

There is a floating relay contact between terminals 20

and 21. This can, for example, be used for activation of

the dosing system (the contact remains closed during

filter operation).

This contact can be loaded with a maximum of 230 V/8A.

Temperature sensor connection

Schwimmbad

Temperaturfühler

30

31

Fühler

Solar-

32

33

Filtersteuerung PC-250

-Tauchhülse

The swimming pool temperature sensor is connected to terminals 30 and 31. The

temperature sensor is supplied with a cable length of 1.5 m as standard. If required, this

can be lengthened to maximum 20 m (cross-section minimum 0.5 mm²) with a 2-core

cable. You should avoid routing the sensor cable near power cables to prevent possible

interference.

Since precise temperature control can only be achieved with good heat transfer between

temperature sensor and swimming pool water, an immersed sleeve R ½" (Art. No.

3200200003) should be built into the piping system. The sensor polarity is as required.

A solar temperature sensor (Art. No. 3100000030) can be additionally connected to

terminals 32 and 33. The temperature sensor is supplied with a cable length of 20 m as

standard. If required, this can be lengthened to maximum 50 m (cross-section minimum

0.5mm²) with a 2-core cable. You should avoid routing the sensor cable near power cables

to prevent possible interference. The solar temperature sensor should be connected at the

solar collector output and must have good heat contact to the returning water flow. The

temperature at the temperature sensor installation site may not exceed 80 °C.

Setting motor protection

Please see the Info key information in menu command 10.

Starting the backflushing process

If the backflushing key is pressed for 3 seconds without interruption, the backflushing

process will start. Backflushing will not start unless a backflushing duration has been

entered.

Submerged sleeve

PC-250 Filter control unit operating manual Page: 13 (24

Balancing the temperature controller

The electronic temperature regulator and the temperature

centre are balanced with one another in the works. If one of

the sensors is replaced, or if a sensor cable is extended, a

new balance must be carried out if necessary using the

potentiometers in the controller. Turning the water

temperature sensor potentiometer clockwise causes an

increase in the water temperature displayed. If the solar

sensor potentiometer is turned clockwise, a higher collector

temperature is displayed. Since the solar temperature

regulation only works correctly with precisely balanced

sensors, this balance should only be carried out by a trained

service technician.

Temperature sensor resistance

Both temperature sensors have the resistance

values listed to the right.

Fuses

The electronic control system is protected by a 0.25A fine-wire

fuse on the PCB in the inside of the device. The short-circuit

protection for the filter pump must be provided by a backup

fuse of maximum 16A on site.

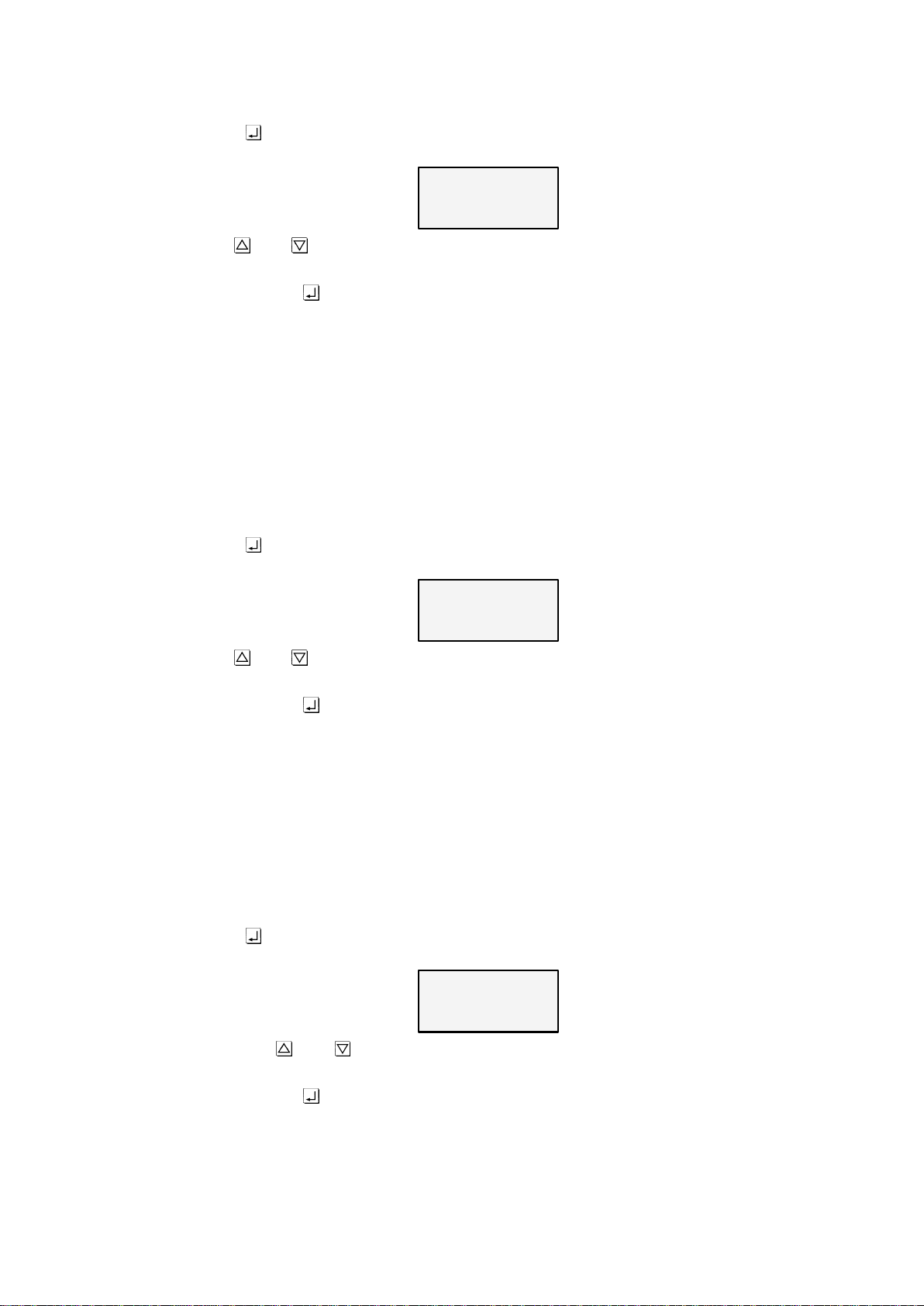

Service terminal

An osf service terminal (Art. No. 3010000900) can be

connected to this control system for optimum control system

settings for a wide range of swimming pool equipment and for

assisting in initial startup and fault diagnosis. The socket for

this is located on the rear of the top PCB inside the device.

Before opening the housing and plugging in the service

terminal, you must ensure that the control system has

been isolated from the mains! Once the control system has

been switched on, the service terminal display shows the first

4 lines of the diagnosis text, e.g.:

Filterbetrieb

Temp. erreicht

Wasser: 23,0°

Solar: 38,4°

Betriebsart der Filteranlage

Betriebsart der Heizung

gemessene Wassertemperatur

gemessene Kollektortemperatur

Temperature Resistance

20°C 5800 Ohm

25°C 4600 Ohm

30°C 3700 Ohm

PC-250 Filter control unit operating manual Page: 14 (24

Further lines can be called up using the and keys. Values in the top line can be

changed by pressing the key if necessary.

Filter unit operating mode

This line displays the current filter unit operating mode.

The following displays are possible:

Control system off

Use the key to switch the control system off.

Filter unit off

The filter unit is switched off.

Filter operation

The filter unit is switched on using the timer or the key

on the front cover.

Run-on time

The filter pump continues running when the heater is

switched off.

Forced switching

The filter pump is either switched on by the

EUROTRONIK-10 backflushing controller or the NR-12-

TRS-2 level regulation system.

Priority circuit

Outside the set filter times, the filter pump is switched on

by the temperature regulation system because this works

in the priority circuit.

Pump blocked

The filter pump is switched off temporarily by the

EUROTRONIK-10 or the NR-12-TRS-2 level regulation

system.

Backflushing

The filter pump is switched on because backflushing is

taking place using the bar valve.

Rinsing

The filter pump is switched on because rinsing is taking

place using the bar valve.

Frost protection

mode

The filter pump is in frost protection operating mode.

Heater operating mode

This line displays the current temperature regulation operating mode.

The following displays are possible:

Controller off

Use the key to switch the heater off.

Add. heater off

The heater is switched off outside the filter times.

Heater blocked

The heater is switched off because the EUROTRONIK forced

switching has occurred.

Temp. reached

The heater is switched off because the set temperature has

been reached.

Add. heater on

The heater is switched on because the water temperature is

below the set temperature.

Solar heater on

The solar heater is switched on because the water

temperature is below the set temperature and the collector is

warmer than the swimming pool water.

Frost hazard

The heater is switched on in frost protection operating mode.

Water temperature

The current water temperature is

displayed in this line. If the display

does not agree with the actual

temperature, it can be readjusted

using the adjuster on the printed

circuit board (see temperature

regulation section). Turn the adjuster

in a clockwise direction to increase

the displayed value. "Sensor break"

will be displayed if the temperature

sensor is defective. Caution: If both

temperature sensors are at the

same temperature, the solar

sensor must never display a

higher value than the water

temperature sensor otherwise the

solar heater will not switch off.

Solar temperature

The current collector temperature is

displayed in this line. If the display

does not agree with the actual

temperature, it can be readjusted

using the adjuster on the printed

circuit board (see temperature

regulation section). Turn the adjuster

in a clockwise direction to increase

the displayed value. "-----" will be

displayed if the temperature sensor is

defective. Caution: If both

temperature sensors are at the

same temperature, the solar

sensor must never display a

higher value than the water

temperature sensor otherwise the

solar heater will not switch off.

Additional heater

The additional heater operating status is displayed in this line.

Solar

The solar heater temperature is displayed in this line.

Water

The temperature at the water temperature sensor is displayed in this line.

Set temperature

The set temperature is displayed in this line, and this is set using the key in the

front cover.

Current

The filter pump current consumption for each phase is displayed in this line.

Motor protection

The triggering current for the motor protection is displayed in this line.

Solar difference

This line displays how much warmer the solar collector needs to be than the

swimming pool water before the solar heater is switched on.

Solar-

differenz

Kollektortemperatur

Wassertemperatur

Solarheizung aus

Solarh. ein

Solarheizung aus

Solarh. ein

Solar-

differenz

This value can be adjusted to meet the requirements of the relevant solar equipment

if it is displayed in the top line of the service terminal.

PC-250 Filter control unit operating manual Page: 16 (24

1. Once the key has been pressed, the filter unit is switched off and the display

shows the following:

Solardiff.: °

Differenztemp.

zwischen Wasser

und Kollektor

3

2. Now use the and keys to change the temperature difference. The smallest

adjustable value is 0.5°, the largest 10°.

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate. The adjusted value will be saved automatically.

A temperature difference of 3° is set at the works.

Solar additional temperature

This line displays by how much the swimming pool set temperature may be

exceeded during solar heating in order to make optimal use of solar energy during

the day. This value can be adjusted to meet the requirements of the relevant

swimming pool if it is displayed in the top line of the service terminal.

1. Once the key has been pressed, the filter unit is switched off and the display

shows the following:

Solar-Zus.: °

Überheizen

des Wassers

bei Solarbetrieb

5,0

2. Now use the and keys to change the temperature difference. The smallest

adjustable value is 0°, the largest 15°.

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate. The adjusted value will be saved automatically.

A temperature difference of 5° is set at the works.

Limit temperature

This line displays at which maximum temperature the solar heater is to be switched

off automatically for safety reasons independent of the nominal value set. This value

can be adjusted to meet the requirements of the relevant swimming pool if it is

displayed in the top line of the service terminal.

1. Once the key has been pressed, the filter unit is switched off and the display

shows the following:

Grenztemp.: °

Maximal mögliche

Wassertemperatur

bei Solarbetrieb

40,0

2. Now use the and keys to change the limit temperature. The smallest

adjustable value is 30°, the largest 50°.

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate. The adjusted value will be saved automatically.

A temperature difference of 40° is set at the works. This limit temperature influences

the solar heater only.

Additional heater minimum time (hysteresis)

This line displays the minimum switching on or off durations for the additional heater

by the temperature regulation to avoid too short switching periods. This value can be

PC-250 Filter control unit operating manual Page: 17 (24

adjusted to meet the requirements of the relevant heater equipment if it is displayed

in the top line:

1. Once the key has been pressed, the filter unit is switched off and the display

shows the following:

Min.Heizen: s

Minimale

Einschaltzeit

der Heizung

120

2. Use the and keys to change the minimum time in stages of 10s. The smallest

adjustable value is 10s, the largest 1800s

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate. The adjusted value will be saved automatically.

The time set here only influences the temperature regulator behaviour. If the filter

pump is switched off, the additional heater is switched off without delays irrespective

of the holding time set. A minimum duration of 2 minutes is set at the works.

Solar heater minimum time (hysteresis)

This line displays the minimum switching on or off durations for the solar heater by

the temperature regulation to avoid too short switching periods. This value can be

adjusted to meet the requirements of the relevant solar equipment if it is displayed in

the top line:

1. Once the key has been pressed, the filter unit is switched off and the display

shows the following:

Min. Solar: s

Minimale

Einschaltzeit

der Solarheizung

120

2. Use the and keys to change the minimum time in stages of 10s. The smallest

adjustable value is 10s, the largest 1800s

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate. The adjusted value will be saved automatically.

The time set here only influences the temperature regulator behaviour. If the filter

pump is switched off, the heater is switched off without delays irrespective of the

holding time set. A minimum duration of 2 minutes is set at the works.

Filter pump run-on time

This line displays for how long the filter pump runs on after the additional heater has

been switched off. This value can be adjusted to meet the requirements of the

relevant filter unit if it is displayed in the top line:

1. Once the key has been pressed, the filter unit is switched off and the display

shows the following:

Nachlauf: s

Nachlaufzeit der

Filterpumpe nach

d. Zusatzheizung

10

2. Now use the and keys to change the warm-up time. The smallest adjustable

value is 0s, the largest 1800s

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate. The adjusted value will be saved automatically.

Filter pump run-on is switched off at the works (run-on time = 0).

PC-250 Filter control unit operating manual Page: 18 (24

Heater priority circuit

This line displays whether the temperature regulation system has priority over the

filter time settings. Using the priority circuit, the filter pump can be switched on by the

temperature regulation system even outside the set filter times. The temperature

regulation only works during the filter times without the priority circuit.

The following displays are possible:

Priority OFF

The additional heater only works during the filter times.

Priority ON

The temperature regulation also works outside the filter

times. If the water temperature falls below the set

temperature, the filter pump and the additional heater are

switched on automatically .

If the priority circuit is displayed in the top line of the service terminal it can be

switched on or off.

1. Once the key has been pressed, the filter unit is switched off and the display

shows the following:

Vorrang: AUS

Vorrangschaltung

der Zusatz-

heizung

2. Use the key to switch the priority circuit on, and the key to switch it off.

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate.

The additional heater priority is switched off at the works.

Solar heater priority circuit

This line displays whether the solar heater has priority over the filter time settings.

Using the priority circuit, the filter pump can be switched on by the temperature

regulation system even outside the set filter times. The temperature regulation only

works during the filter times without the priority circuit.

The following displays are possible:

Prior.Solar OFF

The solar heater only works during the filter times.

Prior. Solar ON

The solar heater also works outside the filter times. The

filter pump and solar heater are switched on automatically

in sunshine.

If the priority circuit is displayed in the top line of the service terminal it can be

switched on or off.

1. Once the key has been pressed, the filter unit is switched off and the display

shows the following:

Vorr. Solar EIN

Vorrangschaltung

der Solar-

heizung

2. Use the key to switch the priority circuit on, and the key to switch it off.

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate.

The solar heater priority is switched on at the works.

PC-250 Filter control unit operating manual Page: 19 (24

The following lines are used for manual activation of the output relay.

Frost protection

This line displays the current frost protection function switch-on temperature. This

value can be adjusted to meet the requirements of the relevant filter unit if it is

displayed in the top line:

1. Once the key has been pressed, the filter unit is switched off and the display

shows the following:

Frostsch.:

Einschalttemp.

des Frost-

schutzes

°C

2. Now use the and keys to change the temperature. The smallest adjustable

value is -3°, the largest 5°.

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate. The adjusted value will be saved automatically.

4. A switch-on temperature of 0° is set at the works.

Pump time

This line displays the total operating hours for the filter pump.

heater time

This line displays the total operating hours for the additional heater.

Solar time

This line displays the total operating hours for the solar heater.

Motor defect

This line displays the number of "motor protection" error messages.

Phase fields

This line displays the number of "phase fields" error messages.

Int. backflushing (intern)

This line displays how often a backflushing process has been started by bar valves.

Ext. Backflushing (extern)

This line displays how often a backflushing process has been started by the

EUROTRONIK-10.

The following lines enable the service technician to carry out an examination of the input

signals and filter control unit output relay.

Forced switch-on of NR-12-TRS-2

This line displays whether the NR-12-TRS-2 level regulation system is subject to

forced switch-on.

The following displays are possible:

Forced switch-

onOFF

No forced switch-on, or terminals 11 and 12 not

connected.

PC-250 Filter control unit operating manual Page: 20 (24

Forced switch-on ON

Forced switch-on requested, or terminals 11 and 12

connected.

EUROTRONIK backflushing signal

This line displays whether the EUROTRONIK-10 switches the filter pump on during

backflushing or rinsing.

The following displays are possible:

EUROTRONIK OFF

no switch-on command from EUROTRONIK

EUROTRONIK ON

The EUROTRONIK has switched the filter pump on

EUROTRONIK OFF

The EUROTRONIK has switched the filter pump off

Interlocking

This line displays whether the filter unit has been switched off either by the

EUROTRONIK, NR-12-TRS-2 or the coil earthing contact.

The following displays are possible:

Interlock OFF

The pump is switched off (one of the contacts is open).

Interlock ON

Pump operation has been enabled (all interlock contacts

are closed)

Filter pump

When the filter pump operating status is displayed in the top line of the service

terminal, the pump can be switched on or off manually.

1. Once the key has been pressed, the filter unit is switched off and the the

following is displayed:

Filterpumpe: AUS

Pumpe kann von

Hand geschaltet

werden!

2. Use the key to switch the filter pump on, and the key to switch it off. Caution!

the electronic motor protection does not function in this operating mode!

3. If you press the key again, the normal diagnosis display appears and the filter

unit continues to operate.

Solar operation

When the solar heater operating status is displayed in the top line of the service

terminal, it can be switched on or off manually.

1. Once the key has been pressed, the filter unit is switched off and the the

following is displayed:

Solaranlage

HANDBETRIEB

Stellantrieb: AUS

Pumpe: AUS

2. Use the key to switch the solar heater on, and the key to switch it off. When

the solar heater is switched on, the following is displayed:

Solaranlage

HANDBETRIEB

Stellantrieb: EIN

Pumpe: AUS

Table of contents

Other OSF Control Unit manuals