OSF EUROTRONIK-20 User manual

Installation and Operating Instructions

-20

R

Art.No. 3104811211

Function

The electronic backwash controller EUROTRONIK-20 switches the filtration pump of a swimming-pool on

and off at programmable times and controls the backwashing and clear rinsing cycles for cleaning the

filter. The EUROTRONIK, which is mounted on the 6-way valve with a protected quick coupling,

automatically moves the valve into the correct position and operates the filter pump. The time of the

backwashing and clear rinsing cycles is adjustable and can be seen in the LCD display.

The backwashing cycle can be carried out both on a time-control (by way of the integrated digital switch

clock) as well as pressure-dependent basis. The adjustable pressure switch (art. no. 2000599015) is not

included in the delivery package. It is also possible to start the backwashing cycle manually with a key in

the housing cover.

A connection for a 230 V motor-operated valve enables withdrawal of the water needed for the

backwashing cycle directly from the swimming pool instead of from the overflow collecting tank and

replenishment of fresh water during backwashing. An additional floating relay contact can be used

during backwashing to operate a second pump (backwash pump or blower).

A connection for an external temperature regulator provides the possibility of heating the pool during the

filtration times. An internal latch makes sure that the heater will only be enabled when the pump is running.

To empty the swimming pool, the 6-way valve can be moved into the position Empty. The key for this is

also located in the housing cover. For maintenance purposes the valve can also be moved into the

position Closed with a further key.

The respective valve position and position changes can be read on an LCD display in the housing cover

without having to open the housing. The valve disk is lifted before turning to protect the star seal. The

pump is switched off during this time.

Technical specifications

Dimensions:

245mm x 140mm x 95mm

Power supply:

230V/50Hz

Power consumption of the controler:

approx.10VA

Breaking capacity:

max. 1,1 kW (AC3)

Motor-operated valve:

230V

System of protection:

IP 54

Ambient conditions:

0-40°C, max. 95% r.H. non condensing

Usable valves:

Praher 1½" and 2"

Speck 1½" and 2"

Midas 1½" and 2"

Astral 1½"

With appropriate adapter

Astral 2"

Hayward 1½"

Static water pressure:

max.0,3bar

Water column above the valve:

max. 3,0m

The specified valve variants are guide values. Since the design and geometry of the valves can change

and these sometimes show significant sample variations, compatibility with the EUROTRONIK may need

to be requested from the valve manufacturer.

Operating instructions EUROTRONIK-20 Page: 2

Table of contents

Seiten

Function 1

Technical specifications 1

Mounting 3

Preparation of the 6-way valve 3

Preparation of the controller 3

Mounting on an Astral 2" valve 4

Mounting on Astral, Midas and Hayward valves 4

Mounting of the EUROTRONIK 4

Electrical connection 5

Operating elements 6

LCD display 6

Switching the controller on/off 7

Manual control of the filter pump 7

Setting the time 7

Programming the timer (backwashing and clear rinsing times) 8

Programming the timer (filtration times) 8

Backwashing (manual) 9

Emptying the swimming pool 9

Closing the valve 9

DIP switch on the upper circuit board 10

Intermittent backwashing 10

Fortnightly backwashing 10

Service terminal (only for service personnel) 11

Operating cycles of the backwash controller 11

Input signals 11

Microswitch 11

Light scanners 11

Heater 11

Filter pump 12

Auxiliary pump 12

Motor-operated valve 12

Servomotor 13

Operating instructions EUROTRONIK-20 Page: 3

Mounting

The controller must be mounted in accordance with its system of protection so that it is protected against

moisture. The ambient temperature should lie between 0° C and + 40° C and should be as constant as

possible. The relative humidity should not exceed 95% and no condensation should occur. Direct

incidence of heat or sunlight on the device must be avoided.

The power supply to the device must be connected via an all-polar main switch with a contact gap width of

at least 3mm. The device must be switched off before the housing is opened.

Preparation of the 6-way valve

Before mounting the EUROTRONIK it must be ensured that the

valve moves easily and is free of dirt.

The 6-way valve must be in the position Filter when mounting

the controller. In this position the handle of the valve must be

removed by driving the fastening pin out of the valve shaft. Then

insert the shorter osf pin delivered with the device in the middle of

the hole in the valve shaft. If the pin is too loose in the hole, it can

be fastened with a little adhesive or grease to facilitate mounting of

the controller. For later operation of the system it is immaterial

whether the pin is loose because it is centred by the housing of the

controller.

Preparation of the controller

The controller must be in the position Filter (position on delivery).

To equalise height differences of the valve shafts, it is necessary in the case of some valves to stick one

or more of the self-adhesive spacer disks delivered with the device under the housing of the controller.

Proceed as follows to determine whether one or more spacer disks are needed:

Move the 6-way valve into the position Filter.

Mount the EUROTRONIK-10 on the valve without spacer disk.

See "Mounting of the EUROTRONIK".

Push the feeler gauge delivered with the device between the

EUROTRONIK and valve.

If the feeler gauge fits between the EUROTRONIK and valve

exactly, the gap is optimal.

If the EUROTRONIK wobbles on the valve, one or more spacer

disks must be stuck under the EUROTRONIK (see sketch below).

Thereafter the EUROTRONIK must be mounted again and the

test with the feeler gauge repeated.

After mounting the feeler gauge has to be removed. The resultant

play has no negative influence on the operation of the system.

Insert

feeler

gauge

Shorter osf-pin

Guide groove

Operating instructions EUROTRONIK-20 Page: 4

Mounting on an Astral 2" valve

A special adapter is needed for mounting on an Astral 2"

valve. This adapter is placed on the valve in such a way that:

•the screws point downwards and catch in the recesses in

the valve.

•the two recesses on the side point to the words "Filter" and

"Backwash".

These adapters are obtainable from under the article

number 1200299200.

Mounting on Astral, Midas and Hayward valves

Since the guide grooves in the valve bonnets of Midas, Astral

and Hayward valves are narrower, the two yellow slides on the

bottom of the controller must be replaced by the red slides

delivered with the device when using these types of valve.

It’s not allowable to use an Astral-Valve with bayonet lock!

Replace slides if necessary

Stick on spacer

disks if necessary

Mounting of the EUROTRONIK

Press the two slides (yellow or red) in completely at the same

time.

Place the controller on the valve carefully so that the coupling

of the controller encompasses the valve shaft and the pin

slides into the slot of the coupling.

Make sure that the coupling is not pushed into the

housing of the controller when doing so. Since the coupling

does not always fit on the valve shaft easily because of

dimensional tolerances in the case of some valves, the

housing cover should be closed during mounting.

Then turn the actuator completely to the right (approx. 45°).

The slides must then catch in the guide grooves of the valve

when released. The valve shaft may not be turned with the

device when clipping on the controller.

The osf pin in the valve shaft must now be caught in the slot of

the coupling.

1

1

2

3

Operating instructions EUROTRONIK-20 Page: 5

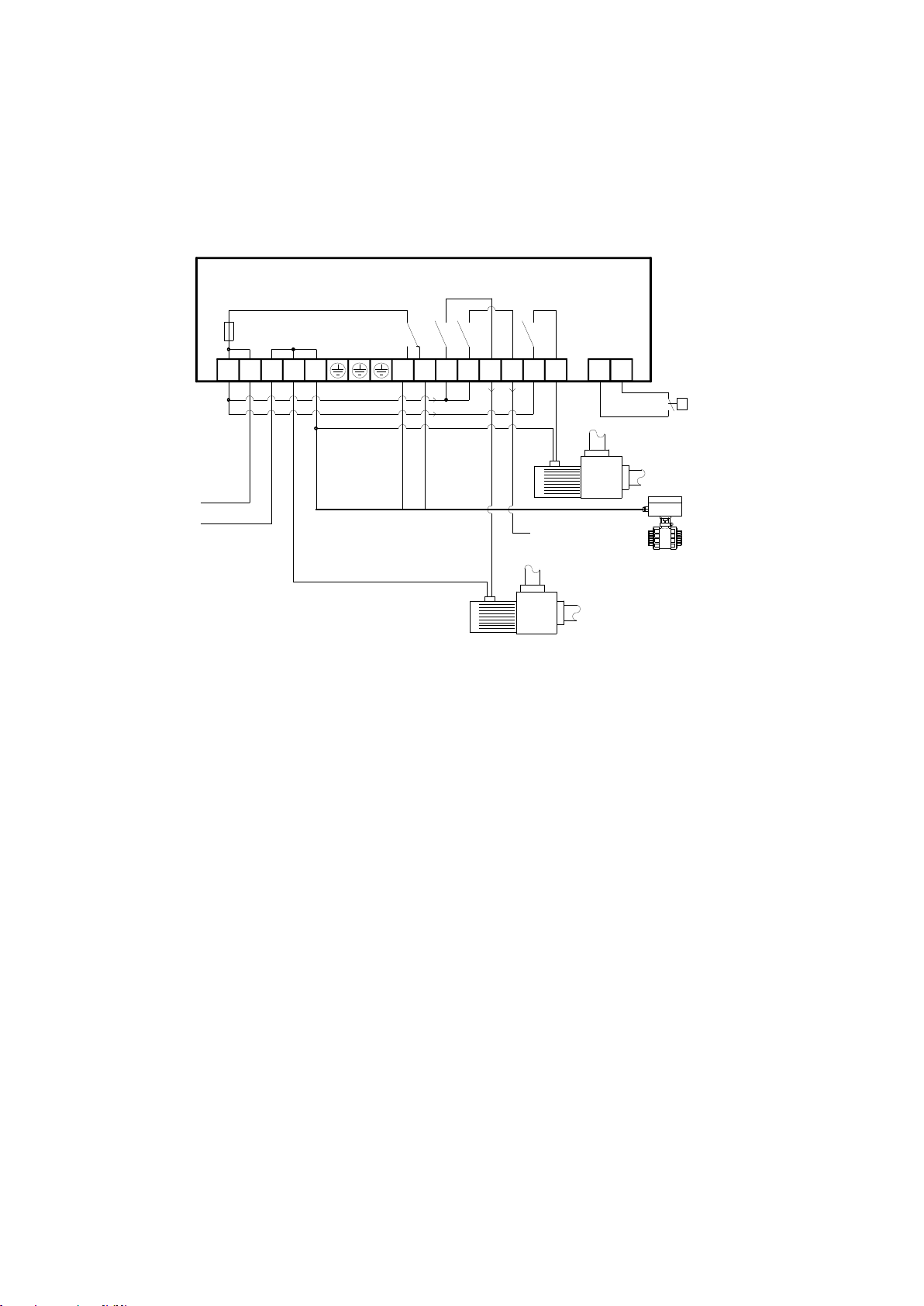

Electrical connection

Only authorised electricians may carry out electrical connection, balancing and service work! The

following connection diagrams and all valid safety regulations must be followed. When working on

the open housing precautions must be taken to protect the electronic components against

electrostatic discharges.

NL1L1 65N 7U3U2 432 1110N

Mains

P

T2A

230V/50Hz

EUROTRONIK-20

K1 K2 K3 K4

Pressure switch

Backwash pump

230V/max.1,1kW

Motor-operated valve

Temperature-

regulator

230V/max.100W

Filter pump

230V/max.1,1kW

All conductive components must be integrated in the local equipotential bonding system.

The terminals L1 and 2, L1 and 3 as well as L1 and 6 have to be connected.

The contact K2 in the EUROTRONIK is closed when the valve has reached one of its final positions. This

prevents the filter pump from being switched on by the filter controller during the adjusting process. In teh

position Filter this contact is only closed during filtration-time.

The contact K3 in the EUROTRONIK is only closed when the valve is in the final position Filter and the

filter pump is running. An external temperature regulator can be connected to terminal 5 which is only

supplied with power during filtration time.

The contact K1 in the EUROTRONIK supplies the terminal U2 with power during backwashing, clear

rinsing and emptying, while for the rest of the time the terminal U3 is live. A motor-operated valve (230 V)

can be connected to these terminals to replenish the water lost during the rinsing cycles.

The contact K4 in the EUROTRONIK is only closed when the valve is in the final position Backwash and

can be used to operate an additional backwash pump.

The osf pressure switch (art. no. 2000599015) can be connected to the terminals 10 and 11. It is screwed

into the manometer connection in the 6-way valve. The metal body of the pressure switch must be

grounded. This switch triggers a backwashing cycle when the pressure limit that has been set is exceeded

irrespective of how the switch clock in the EUROTRONIK has been programmed.

Operating instructions EUROTRONIK-20 Page: 6

Operating elements

LCD display

Controller ON/OFF

Set time

Backwash (manual)

Program timer

Close valve

Empty swimming pool

Change values

(Backwash and clear rinsing times)

Manual control of pump Program timer

(Filtration times)

LCD display

Thu8:46

Filter

Normal operating display during filter time showing the current time and valve position.

Thu9:18

Pause

Normal operating display without filtration showing the current time.

Thu6:32

Manually

Normal operating display with manually activated filter pump showing the current time.

Lift

Backwash

The backwashing cycle has been started. The valve disk is first lifted.

Rotate

Backwash

The valve disk is turned into the position Backwash.

Lower

Backwash

The valve disk is lowered into the position Backwash.

4:39

Backwash

The backwashing cycle is running. The remaining backwash time is displayed (in

min.:sec.).

Lift

Cl.Rinse

After backwashing the valve disk is lifted again.

Rotate

Cl.Rinse

The valve disk is turned into the position Clear Rinse.

Lower

Cl.Rinse

The valve disk is lowered into the position Clear Rinse.

0:10

Cl.Rinse

The clear rinsing cycle is running. The remaining rinsing time is displayed (in

min.:sec.).

Lift

Filter

The valve disk is lifted to be turned into the position Filter.

Rotate

Filter

The valve disk is turned back into the position Filter.

Lower

Filter

The valve disk is lowered into the position Filter.

Lift

Empty

The valve disk is lifted to be turned into the position Empty.

Operating instructions EUROTRONIK-20 Page: 7

Rotate

Empty

The valve disk is turned into the position Empty.

Lower

Empty

The valve disk is lowered into the position Empty.

Pumpon

Empty

The valve is in the position Empty. The filter pump is on.

Lift

Closed

The valve disk is lifted to be turned into the position Closed.

Rotate

Closed

The valve disk is turned into the position Closed.

Lower

Closed

The valve disk is lowered into the position Closed.

Valve

Closed

The valve is in the position Closed. The filter pump is disabled.

Lift

Off

The EUROTRONIK has been switched off. The valve disk is lifted to be turned into the

position Filter (home position).

Rotate

Off

The valve disk is turned into the position Filter (home position).

Lower

Off

The valve disk is lowered into the position Filter (home position).

Machine

is off

The EUROTRONIK is off. The valve is in the position Filter.

Switch

defect

The bottom final position of the valve disk has not been detected. The microswitch in

the bottom part of the housing is possibly damaged. When the fault has been repaired,

the controller can be switched off and back on again with the key .

Switching the controller on/off

The controller is switched on and off with the key . Note! This does not switch off the

power supply to the device! If the valve is not in the position Filter when the controller is

switched off, it is turned there automatically.

Manual control of the filter pump

The can be switched on manually with the key .

Setting the time

The time and weekday are set with the key :

1. Press the key

Mon 8:46

time

appears in the display.

2. The time can then be set with the keys and .

To save the time, press the key again. If, during setting, more than 10 seconds pass

without a key being pressed, the last time displayed is saved automatically and the normal

operating display appears again.

Operating instructions EUROTRONIK-20 Page: 8

Programming the timer (backwashing and clear rinsing times)

The integrated weekly timer for automatic backwashing and clear rinsing is programmed with

the key :

1. Press the key

Duration

120

Back:

appears in the display.

2. The desired duration of backwashing (in seconds) can then be set with the keys and

. The maximum backwashing time that can be set is 900 seconds (15 minutes). If a

backwashing time of 0 seconds is set, the timer is inoperative.

3. Press the key again

Duration

10

Clear

appears in the display.

4. The desired duration of clear rinsing (in seconds) can then be set with the keys and .

The maximum clear rinsing time that can be set is 120 seconds (2 minutes).

5. Press the key again

--------

1.Rinse

appears in the display.

6. The desired point in time for backwashing can then be set with the keys and .

7. Further backwashing cycles can then be programmed as described in points 5 and 6. A

total of 15 backwashing cycles per week can be programmed.

8. To save the switch times, press the key again. If, during setting, more than 10 seconds

pass without a key being pressed, the last switch time displayed is saved automatically

and the normal operating display appears again.

If backwashing times have already been programmed, they can be deleted with the key :

1. Press the key repeatedly until the backwashing time that is to be deleted appears in

the display

Wed 9:00

2. Rinse

2. Set the backwash time on

--------

2. Rinse

with the keys and (between Sun. 23:59

and Mon. 0:00).

3. To delete the switch time, press the key again.

Programming the timer (filtration times)

The integrated weekly timer for the filter pump is programmed with the key :

1. Press the key

--------

1. ON

appears in the display.

2. The desired beginning of the first filtration time can then be set with the keys and .

3. Press the key again

Mon0:00

1. OFF

appears in the display.

4. The desired end of the first filtration time can then be set with the keys and .

5. Taste erneut drücken in der Anzeige erscheint

--------

2. EIN

6. Further filtration times can then be programmed as described in points 2-5. A total of 15

filtration times per week can be programmed.

7. To save the switch times, press the key again. If, during setting, more than 10 seconds

pass without a key being pressed, the last switch time displayed is saved automatically

and the normal operating display appears again.

If filtration times have already been programmed, they can be deleted with the key :

1. Press the key repeatedly until the filtration time that is to be deleted appears in the

Operating instructions EUROTRONIK-20 Page: 9

display

Wed 7:30

3. ON

2. Set the filtration time on

--------

3. ON

with the keys and (between Sun. 23:59 and

Mon. 0:00).

3. To delete the switch time, press the key again.

Backwashing (manual)

A backwashing cycle can be started manually at any time –irrespective of how the timer has

been programmed –with the key . The duration of the backwashing cycle is the same as

that entered during programming of the timer.

This key can also be used to end a backwashing cycle already in progress.

Emptying the swimming pool

When the key is pressed for longer than 5 seconds, the valve is turned into the

position Empty and the filter pump switched on. Emptying can be stopped by pressing this

key again.

Closing the valve

The key is used to turn the valve into the position Closed for service purposes. In this

valve position the filter pump is disabled. The valve is turned back into the position Filter by

pressing this key again.

Operating instructions EUROTRONIK-20 Page: 10

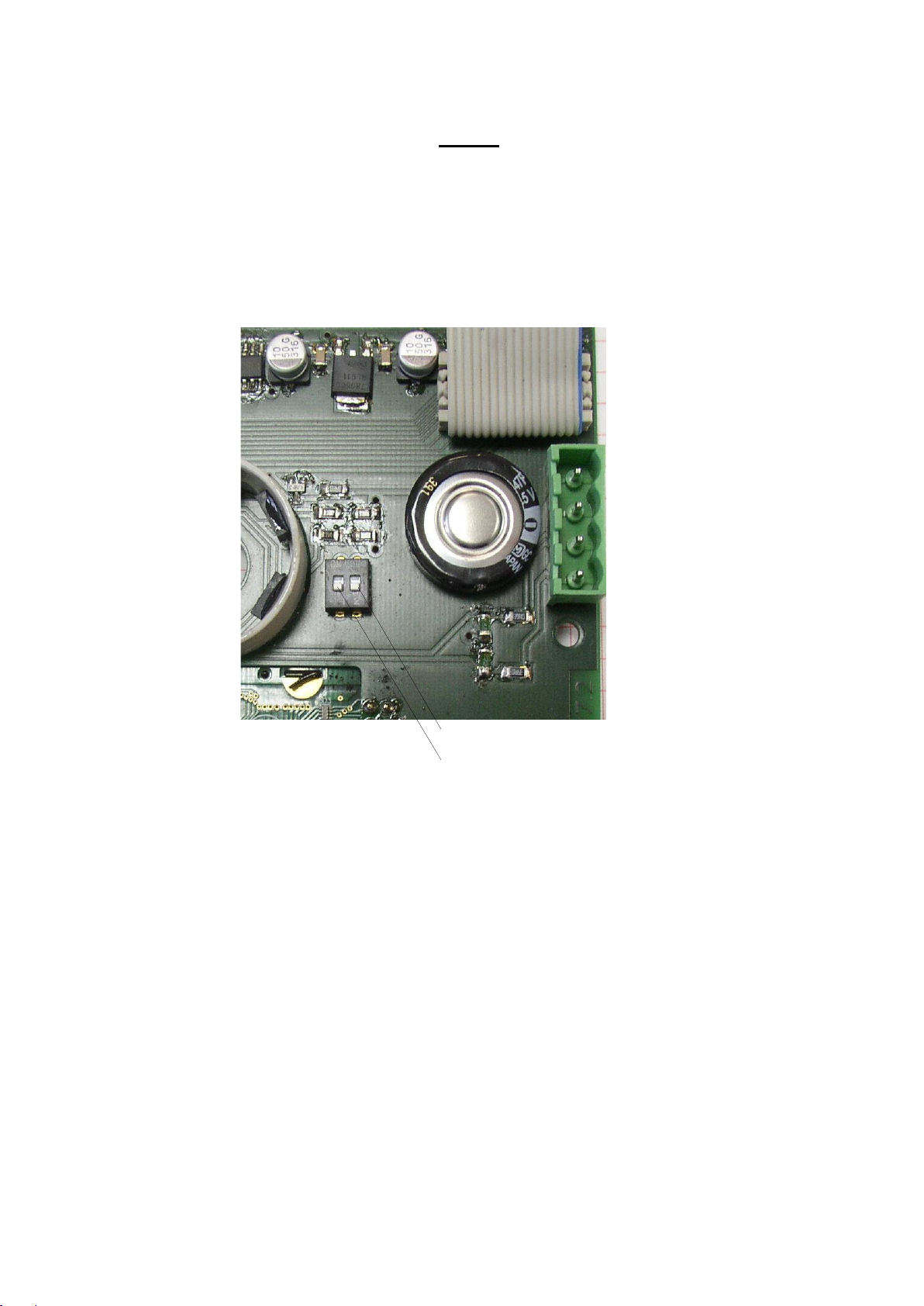

DIP switch on the upper circuit board

Intermittent backwashing and fortnightly backwashing can be activated with a DIP switch on the upper

circuit board inside the EUROTRONIK. The housing has to be opened to access these operating

elements.

The power supply to the device must be switched off first! Since the interior of the EUROTRONIK

contains electronic components that react sensitively to the discharging of static electricity, the

tools used must first be discharged by touching a grounded metal part. The electronic

components should not be touched as far as possible.

Intermittent backwashing

The EUROTRONIK-10 offers two possibilities of controlling the filter pump during backwashing:

a) Constant backwashing with continuous operation of the filter pump during the complete backwashing

time.

b) Intermittent backwashing with repeated switching on and off of the pump during the backwashing time

for better loosening of the filter sand.

The right switch in the DIP switch is used to switch between intermittent backwashing and constant

backwashing. The bottom switch position is for constant backwashing (factory setting) and the top switch

position for intermittent backwashing.

Fortnightly backwashing

If, in the case of pools subject to little use, a backwashing cycle is only to be started every second week,

the left switch in the DIP switch must be switched into the top switch position. If it is in the bottom switch

position (factory setting), every switch command of the switch clock is carried out. In the top switch

position only one backwashing cycle per week can be programmed with the switch clock. This backwash

command is only carried out every second week.

Fortnightly backwashing

Intermittent backwashing

Operating instructions EUROTRONIK-20 Page: 11

Service terminal (only for service personnel)

An osf service terminal (art. no. 3010000900) can be connected to

this controller for optimum adjustment of the controller to the

different types of swimming pool and to facilitate commissioning

and fault diagnosis. The connector for this is mounted on the circuit

board inside the device. The power supply to the controller

must be switched off before opening the housing and

plugging in the service terminal! Plugging the service

connector in or out when the device is on can destroy the

device! The operating time meter appears in the display of the

service terminal after switching on the controller, e.g.:

Operating hours:

switched on 156

total: 238

Filt.-pump 26

Further pages can be called up with the keys and . If necessary, the values in the top line can be

changed after pressing the key .

Operating cycles of the backwash controller

The following counter statuses are shown:

Backwash

Number of completely carried-out backwash cycles.

Empty

Number of emptying cycles.

Close

Number of closing cycles.

Input signals

The current input signals of the EUROTRONIK are shown in this line:

Pressure switch:

Switch status of a pressure switch connected to terminals 10 and 11.

B. fortnightly:

Switch position of the left DIP switch (backwash fortnightly).

B. interval:

Switch position of the right DIP switch (intermittent backwashing).

Microswitch

The current status of the microswitch in the bottom part of the housing, which is used by the controller to

detect whether the valve disk has been lowered, is shown on this page.

Light scanners

The measured values of the light scanners, which are used by the controller to detect the valve positions,

are shown on this page. Two values are shown for each of the five light scanners. The value in brackets

should be between 30 and 70. The other value should be more than 700 when the housing is open and

should fall notably on approaching a reflecting object.

The following lines enable the service technician to check the output relays of the controller.

Heater

This line shows whether the relay K3 is on. This relay is used to activate the heater while the filter pump is

on.

The following displays are possible:

Heater: OFF

The relay contact between terminals 3 and 5 (K3) is open, the heater is

disabled.

Heater: On

The relay contact between terminals 3 and 5 (K3) is closed, operation of the

heater is enabled.

When the heater is shown in the top line of the service terminal, it can be switched on or off:

connector for service terminal

Operating instructions EUROTRONIK-20 Page: 12

1. The following display appears after pressing the key :

Heater: OFF

Manual control

of contact betw.

terminals 3+5.

2. The heater can be enabled with the key (K3 closed) and disabled again with the key (K3 open).

3. The normal diagnostics display reappears when the key is pressed again.

Filter pump

This line shows whether the relay K2 is on. This relay is used to switch the filter pump on or off.

The following displays are possible:

Filtration: OFF

The filter pump is switched off (K2 open)

Filtration: ON

The filter pump is switched on (K2 closed)

When the filter pump is shown in the top line of the service terminal, it can be switched on or off:

1. The following display appears after pressing the key :

Filtration: OFF

Manual control

of contact betw.

terminals 2+4.

2. The filter pump can be switched on with the key (K2 closed) and switched off again with the key

(K2 open).

3. The normal diagnostics display reappears when the key is pressed again.

Auxiliary pump

This line shows whether the EUROTRONIK switches on an auxiliary backwash pump with the help of the

contact K4.

The following displays are possible:

Backw.pump: OFF

The pump is off (K4 open).

Backw.pump: ON

The pump is on (K4 closed).

When the auxiliary backwash pump is shown in the top line of the service terminal, it can be switched on

or off:

1. The following display appears after pressing the key :

Backw.pump: OFF

Manual control

of contact betw.

terminals 6+7.

2. The backwash pump can be switched on with the key (K4 closed) and switched off again with the

key (K4 open).

3. The normal diagnostics display reappears when the key is pressed again.

Motor-operated valve

This line shows whether a motor-operated valve is opened or closed by the relay contact K1.

The following displays are possible:

Motor valve:SHUT

The motor-operated valve is closed, terminal U3 is live with mains power.

Motor valve:OPEN

The motor-operated valve is open, terminal U2 is live with mains power.

When the motor-operated valve is shown in the top line of the service terminal, it can be opened or

closed:

1. The following display appears after pressing the key :

Motor valve:SHUT

Manual control

of motorvalve on

terminals U2+U3

2. The motor-operated valve can be opened with the key and closed again with the key .

3. The normal diagnostics display reappears when the key is pressed again.

Operating instructions EUROTRONIK-20 Page: 13

Servomotor

This line shows whether the servomotor in the EUROTRONIK to turn the 6-way valve is on or off.

The following displays are possible:

Act.motor: OFF

The servomotor is off.

Act.motor: UP

The servomotor lifts the valve disk or turns it into the next position.

Act.motor: DOWN

The servomotor lowers the valve disk.

When the servomotor is shown in the top line of the service terminal, it can be switched on or off:

1. The following display appears after pressing the key :

Act.motor: OFF

Manual control

of drive

(6-way-valve)

2. The valve disk can be lifted and turned with the key . Renewed pressing of the key switches the

servomotor off again.

3. The valve disk can be lowered into one of the valve positions with the key . The motor is switched off

when the bottom final position is reached or the key is pressed again.

4. The normal diagnostics display reappears when the key is pressed again.

Note!

The drain of the swimming pool must be installed in such a way that the pipe is

higher than the water level at least at one point. A suitable ventilation valve must

be installed at the highest point. The function of this ventilation valve is to

ventilate the drain pipe whenever the filter pump is not in operation. This then

prevents unnecessary water loss in the event of a leaking multiple-way valve.

These installation and operating instructions must be observed.

We wish you lots of fun and relaxation in your swimming pool.

Further information can be found on the Internet at the following address:

https://osf.de/download/documents/documents.php?device=Eurotronik-20

Hansjürgen Meier

Elektrotechnik und Elektronik GmbH & Co KG

Eichendorffstraße 6

D-32339 Espelkamp

E-Mail: info@osf.de

Internet: www.osf.de Subject to changes 04/2021

This manual suits for next models

1

Table of contents