Installation and operating manual for WATERFRIEND oxygen MRD-1 page 3 (42)

Set the dosing plan............................................................................................................................................18

Set the delivery rate of the pump ......................................................................................................................19

Set the power-on delay of the controller............................................................................................................19

Set the temperature compensation...................................................................................................................20

Calibration...............................................................................................................................................................20

Buffer solution....................................................................................................................................................20

Electrodes..........................................................................................................................................................20

Calibrating the pH electrode..............................................................................................................................21

Calibrating the upper value (pH 7) ....................................................................................................................21

Setting the lower value (pH 4)...........................................................................................................................21

pH calibration errors ..........................................................................................................................................22

Service settings ......................................................................................................................................................22

Time and date....................................................................................................................................................22

Selecting the language......................................................................................................................................22

Operating hours after the last calibration ..........................................................................................................23

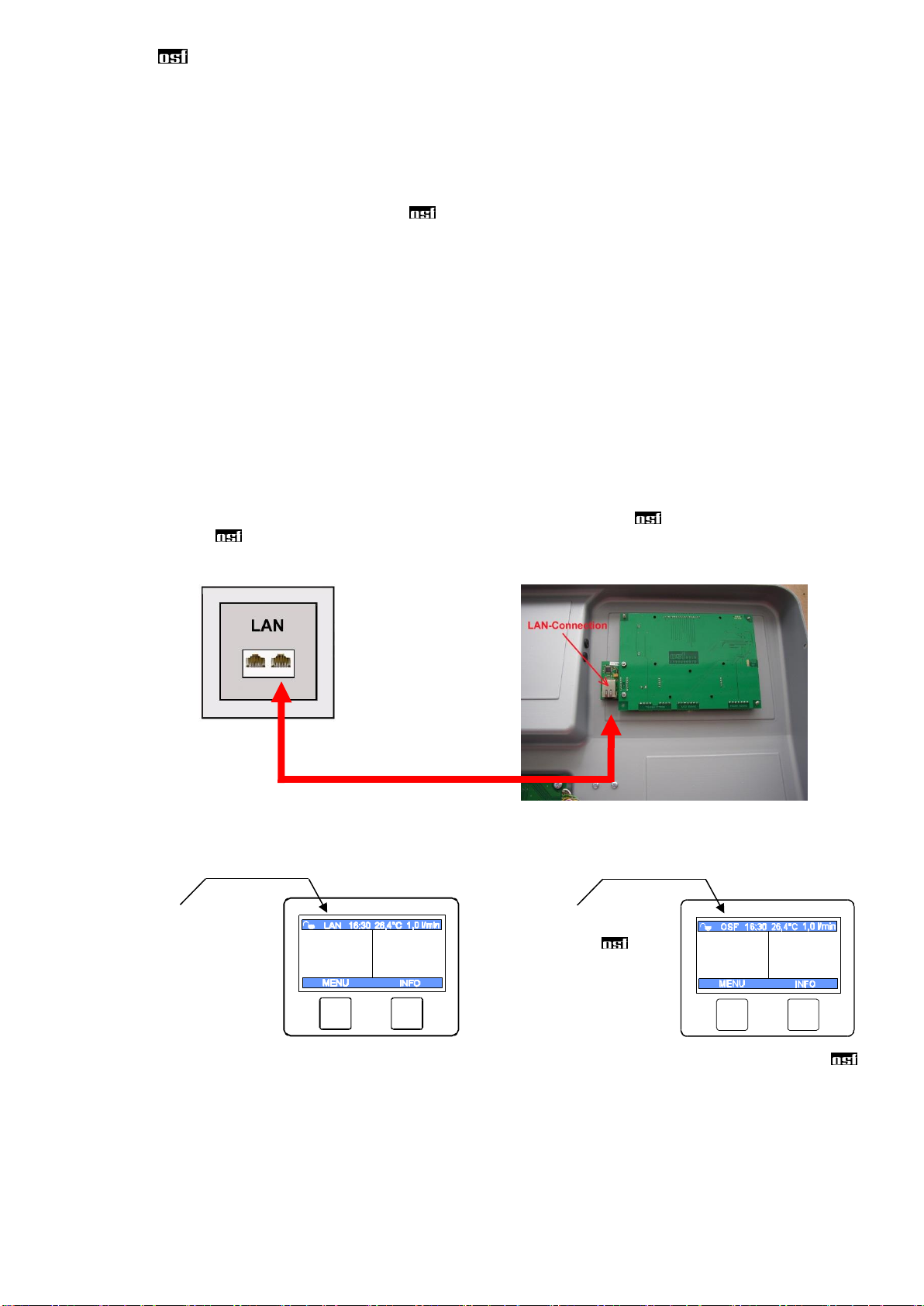

LAN settings ......................................................................................................................................................24

Access control (PIN numbers)...........................................................................................................................24

Reset all settings to factory settings..................................................................................................................24

Adjustment of temperature display....................................................................................................................25

Acoustic error message.....................................................................................................................................25

Increase pH <=> decrease pH ..........................................................................................................................26

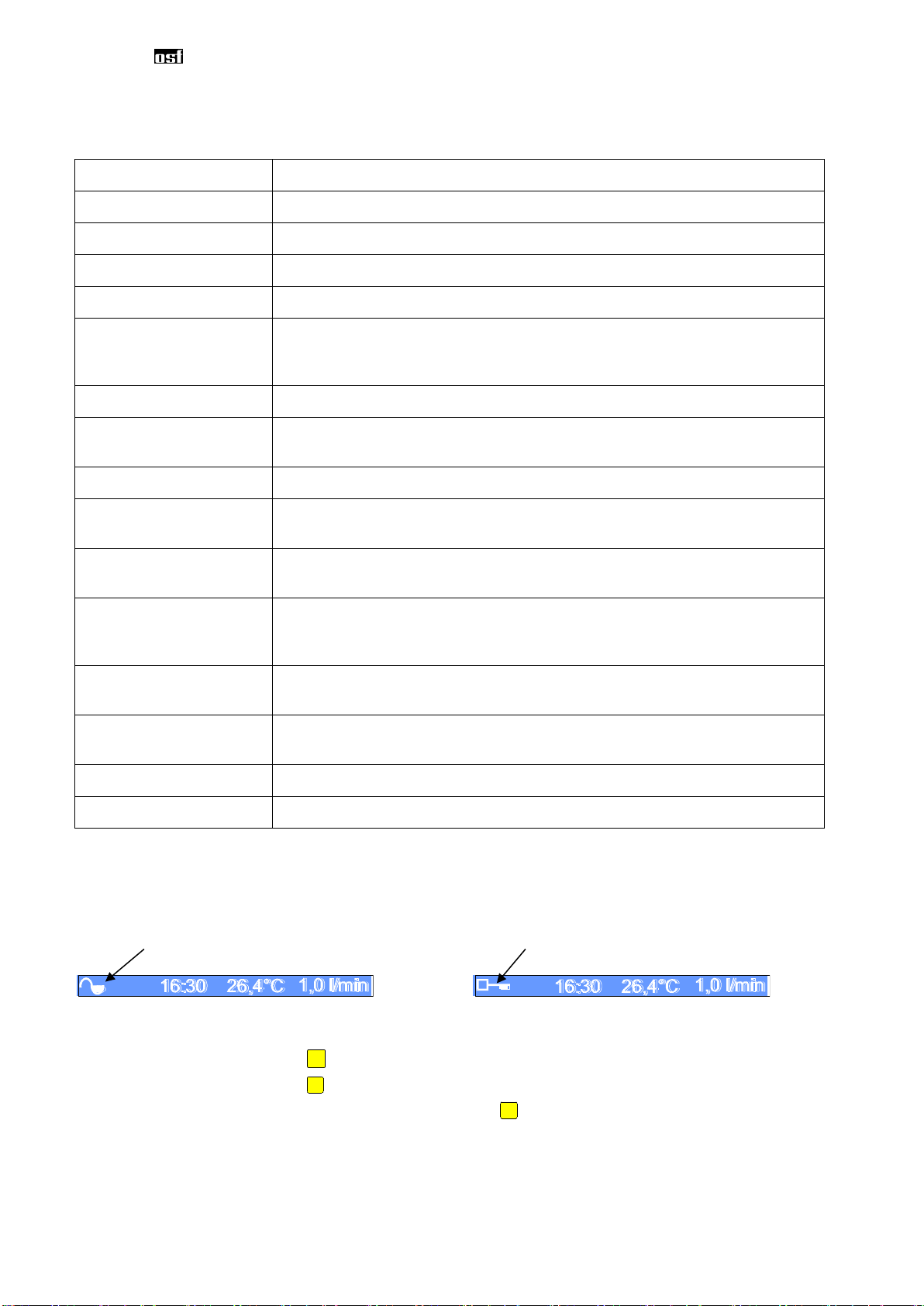

Alarm / error message............................................................................................................................................26

Acknowledging an error message.....................................................................................................................26

Measuring chamber colors....................................................................................................................................26

Meaning of the individual colors........................................................................................................................27

Using the osf communication server ...................................................................................................................27

Communication server for pool owners...........................................................................................................28

Registering a new device with the server..........................................................................................................28

Communication server for pool installers........................................................................................................30

Registering a new control unit with the server ..................................................................................................30

Communication server with technical view .....................................................................................................32

Registering a new device with the server..........................................................................................................32

Read device ID on the display of the dosing control.........................................................................................34

Changing the PIN (password)............................................................................................................................35

Assigning a new PIN .........................................................................................................................................35

Naming the unit...................................................................................................................................................35

Entering an e-mail address................................................................................................................................35

Entering an e-mail address ...............................................................................................................................35

Assigning a name..............................................................................................................................................35

Update......................................................................................................................................................................36

Checking for updates .........................................................................................................................................36

Explanations ...........................................................................................................................................................37

Storage, Transport.............................................................................................................................................37

Maintenance............................................................................................................................................................37

6-monthly service ...................................................................................................................................................37

Sealtightness.....................................................................................................................................................37

Dirt filter .............................................................................................................................................................37

Injection valves..................................................................................................................................................37