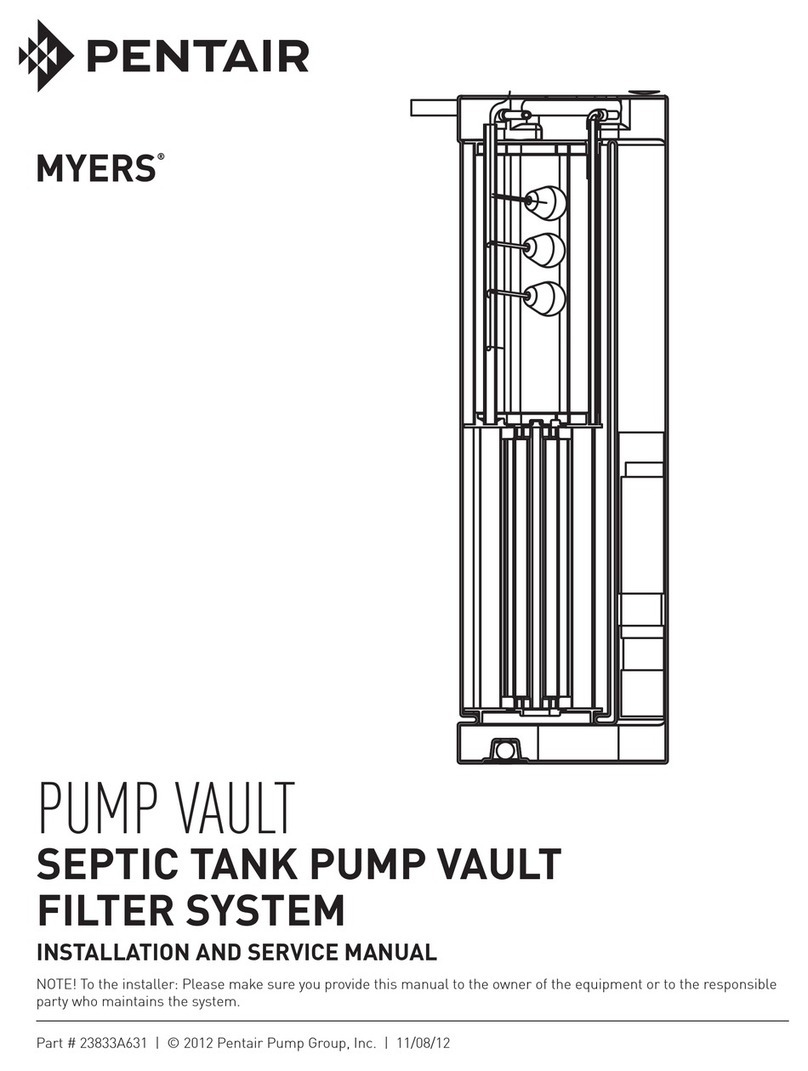

QL3B 2FC5 and QL3B 2FC5-S

Operating Weight: 7 lbs (3.2 kgs)

QL3B 4FC5

Operating Weight: 8 lbs (3.7 kgs)

QL3B 7FC5

Operating Weight: 9 lbs (4.0 kgs)

Inlet

Inlet

Inlet

Outlet

Outlet

Outlet

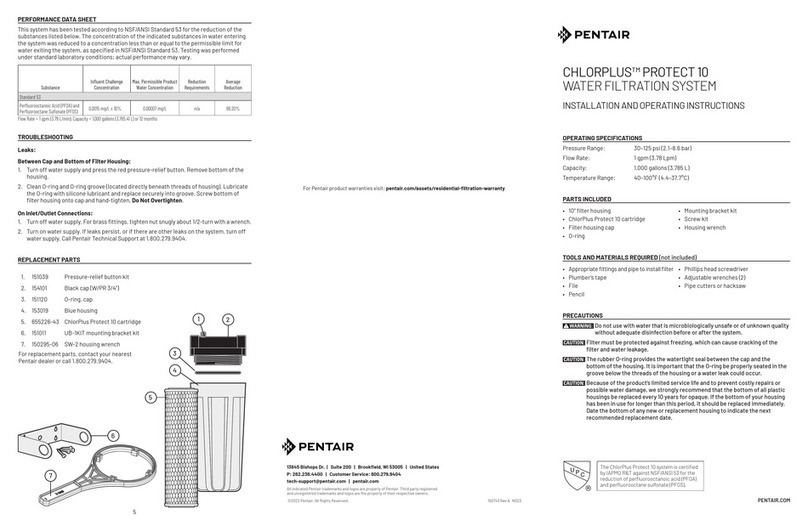

MOUNTING AND CONNECTION CONSIDERATIONS

Give consideration to the following when selecting a suitable mounting location for the system.

• Height and width dimensions

•

•

•

•

installation and when replacing the cartridge(s).

•

removal and replacement.

INSTALLATION PRECAUTIONS

•

recommended.

• If water hammer is evident, install a water hammer arrestor

before the Pentair® Everpure® system.

•

Use two (2) or three (3) wraps of PTFE thread sealant tape.

•

components.

NOTE:

reverse osmosis system, plumb-in between the RO water outlet

and in front of the equipment water inlet.

INSTALLATION PROCEDURE

IMPORTANT:

not in use. The water supply to equipment will be shut off during

installation.

NOTE: For installations in Australia and New Zealand product must

AS/NZS 3500 and AS/NZS 2845.1.

1. Locate the feed water supply shut-off valve and turn off.

NOTE: If not available, we recommend the installation of a

Pentair Everpure system. This will allow the system to be

serviced without shutting off the main water supply. (It will not

2.

must be mounted in a vertical position.

3.

the inlet connection of the system.

4.

A.

B. Turn cartridge to right (1/4 turn) until rotation stops.

5. Select the appropriate size supply line for the equipment

being served and connect it to the outlet port of the system.

to connection.

6. With the system inlet shut-off valve in the closed/off position

(see illustration on page 3), slowly open the feed water supply

the system inlet connection.

7. Hold the unconnected equipment supply line over a bucket or

When air is purged and water runs clear, close the system inlet

valve.

8. Connect the outlet supply line to equipment served as required.

9. Open the inlet valve and check for leaks.

10. If no leaks, the installation is complete.

11. Inform the manager and or owner/operator that the equipment

serviced can now be turned on and checked for normal operation.

Leave this installation, operation, and maintenance manual

with the establishment for future reference.

WARNING: FOR CORRECT OPERATION OF THIS APPLIANCE IT IS

ESSENTIAL TO OBSERVE THE MANUFACTURER’S INSTRUCTIONS.

2 • PENTAIR® EVERPURE® QL3B FC SERIES WATER FILTRATION SYSTEMS INSTALLATION, OPERATION & MAINTENANCE GUIDE