Table of Contents

1 OFS -2000FW OVERVIEW.......................................................................................................................... 1

1.1 Theory of Operation .............................................................................................................................. 1

1.2 OFS -2000FW Specifications ................................................................................................................ 2

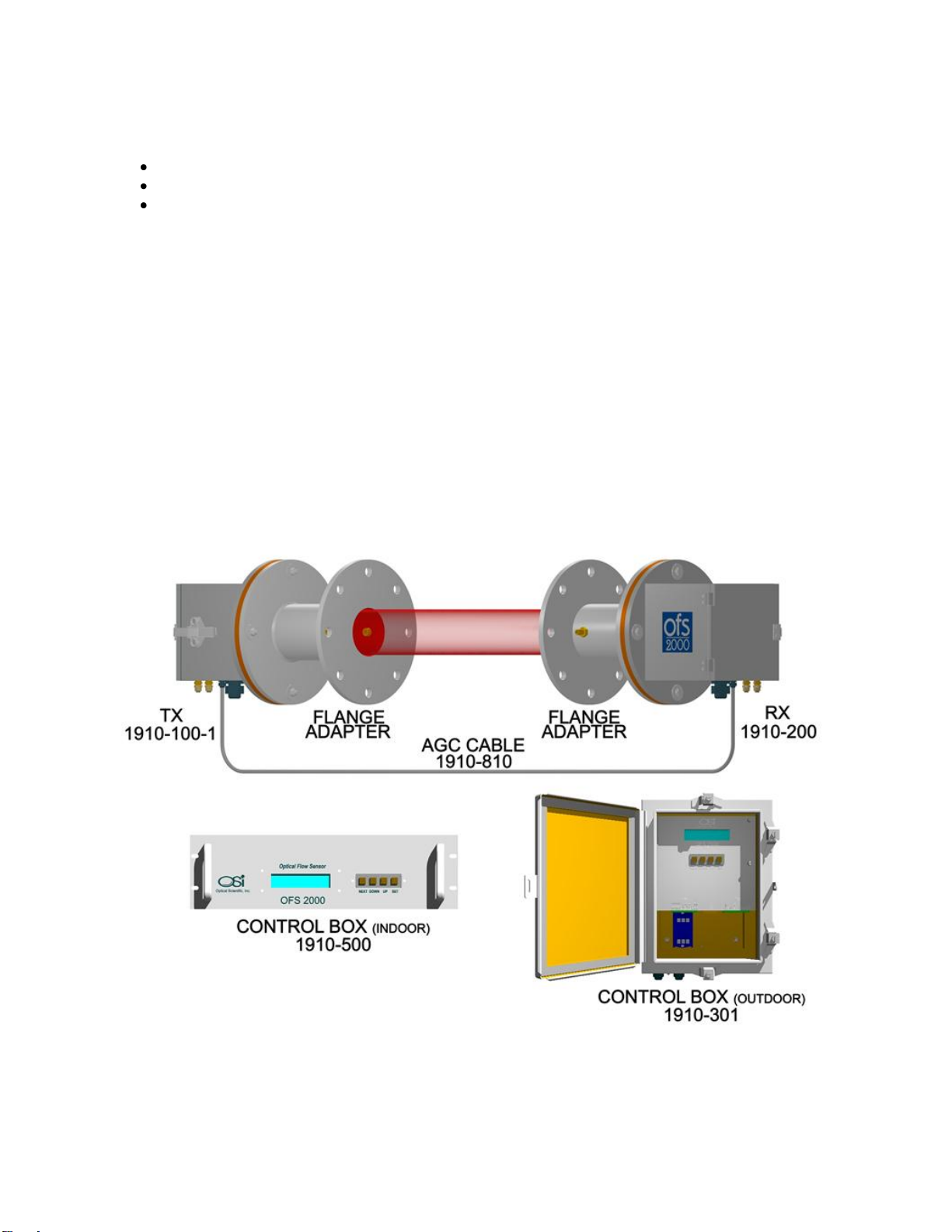

1.3 Description of Units............................................................................................................................... 3

1.4 Transmitter (TX) Unit............................................................................................................................. 4

1.5 OFS 2000FW Receiver (RX) Unit.......................................................................................................... 5

1.6 Control Box(es) Indoor And Outdoor...................................................................................................... 6

1.6.1 Outdoor Control Box ....................................................................................................................... 6

1.6.2 Indoor Control Box.......................................................................................................................... 7

2 Pre –Installation.......................................................................................................................................... 8

2.1 OFS Placement..................................................................................................................................... 8

2.2 Flange Alignment Guidelines................................................................................................................. 9

2.3 Flange Mounting Examples..................................................................................................................10

2.4 Flange Pipe Extension..........................................................................................................................11

2.5 Flange Pipe Mounting ..........................................................................................................................12

3 Installation..................................................................................................................................................13

3.1 Required at Transmitter or Receiver Location.......................................................................................13

3.2 Required at Control Unit Location.........................................................................................................13

3.3 Mechanical...........................................................................................................................................14

3.3.1 TX/RX Units...................................................................................................................................14

3.3.2 Control Units..................................................................................................................................16

3.4 Purge Air..............................................................................................................................................17

3.5 OFS in Hazardous or High Temperature Applications...........................................................................19

3.6 Pressurization Air (Z-Purge Air)............................................................................................................20

3.6.1 Unit Tubing Instructions .................................................................................................................22

3.6.2 Pressurization Unit Set Up.............................................................................................................22

3.6.3 Pressurization Unit Operation.........................................................................................................23

3.7 AC Power Connections........................................................................................................................24

3.7.1 Transmitter Unit.............................................................................................................................24

3.7.2 Control Boxes................................................................................................................................24

3.8 User Interface Connections..................................................................................................................25

3.9 OFS 2000FW Interconnecting Cables...................................................................................................26

3.10 AGC Cable Connections for OFS 2000FW Models.............................................................................27

3.11 OFS Receiver Cable ..........................................................................................................................27

3.12 4-20 mA Current Loop And Relay Connections...................................................................................28

3.13 RS-232 Connections..........................................................................................................................29

3.13.1 Limited Distance Modem (LDM) Connections...............................................................................29

3.13.2 Fiber Optic Modem (FOM) Connections.......................................................................................30

3.14 Computer Connection.........................................................................................................................31

4 Poll Commands & Data Output...................................................................................................................32

4.1 "A" Poll (Short Data String) Output .......................................................................................................32

4.1.1 "A" Poll Response Bytes................................................................................................................32

4.2 "C" Poll (Long Data String) Format.......................................................................................................32

4.2.1 “C” Poll Response Bytes ................................................................................................................33

4.2.2 Description of Status Indicator Codes (Bytes 29-32).......................................................................34

4.3 Reading The Output Data.....................................................................................................................35

5 Data Collection...........................................................................................................................................36

5.1 Using “C” Poll.......................................................................................................................................37

5.2 Using Continuous Polling .....................................................................................................................37

6 Optical Alignment .......................................................................................................................................38

6.1 Receiver Setup.....................................................................................................................................38

6.2 Transmitter Setup.................................................................................................................................39

6.2.1 Transmitter Aiming Considerations.................................................................................................40

6.2.2 Avoiding Receiver Saturation.........................................................................................................42

7 Correlation..................................................................................................................................................43

8 Initial Check and Start-Up...........................................................................................................................44

8.1 Initial Check.........................................................................................................................................44