EIN-CP-VCOM-2

Rev. 1.0 © 3/9/01

3

© 2001 by Orenco Systems, Inc. All

rights reserved. No part of this

publication may be reproduced or

distributed in any form or by any

means, without the prior written

permission of the publisher.

Table of Contents

Introduction.......................................................................................2

HyperTerminal..................................................................................4

To Create a New Connection................................................................. 4

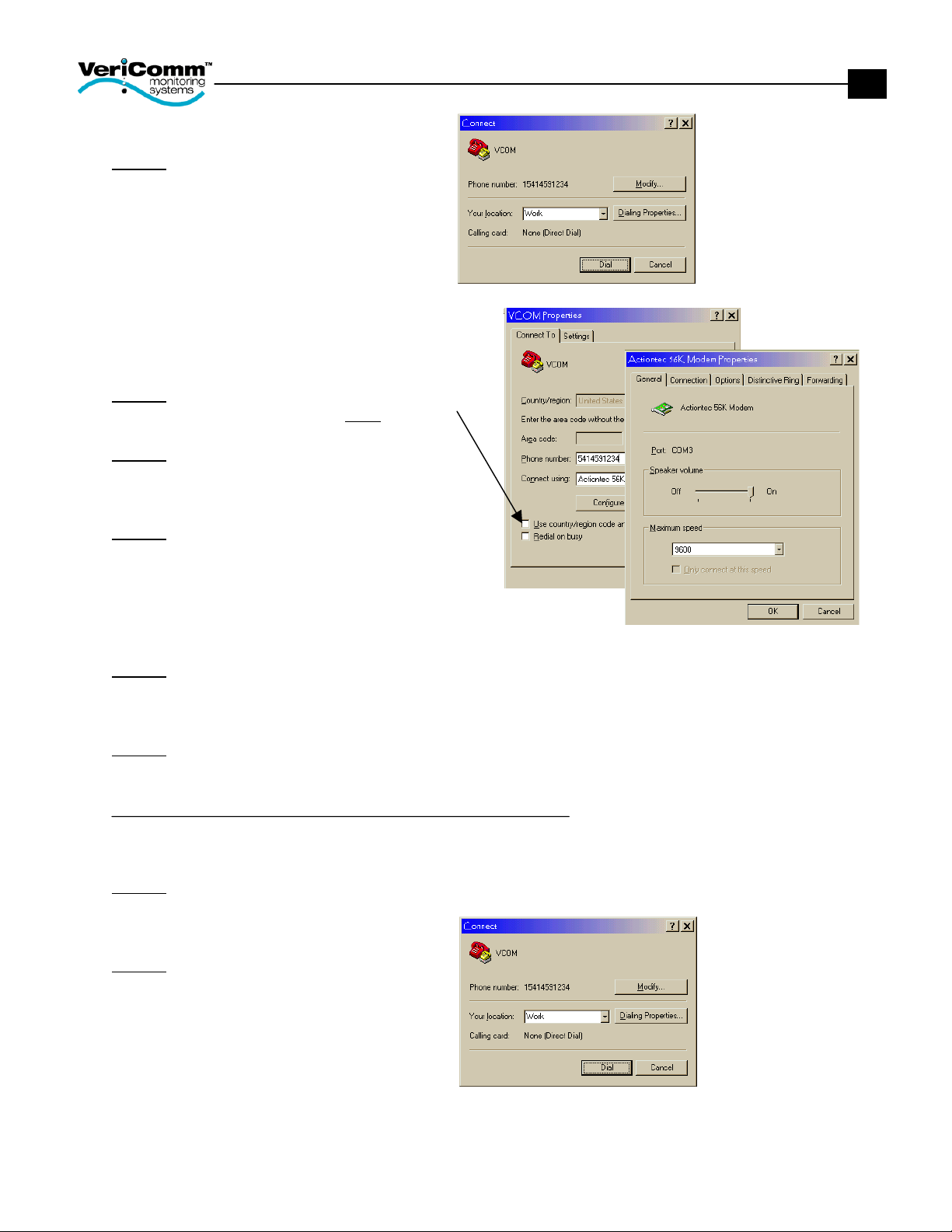

To Connect Remotely to a Custom VCOM Panel................................. 5

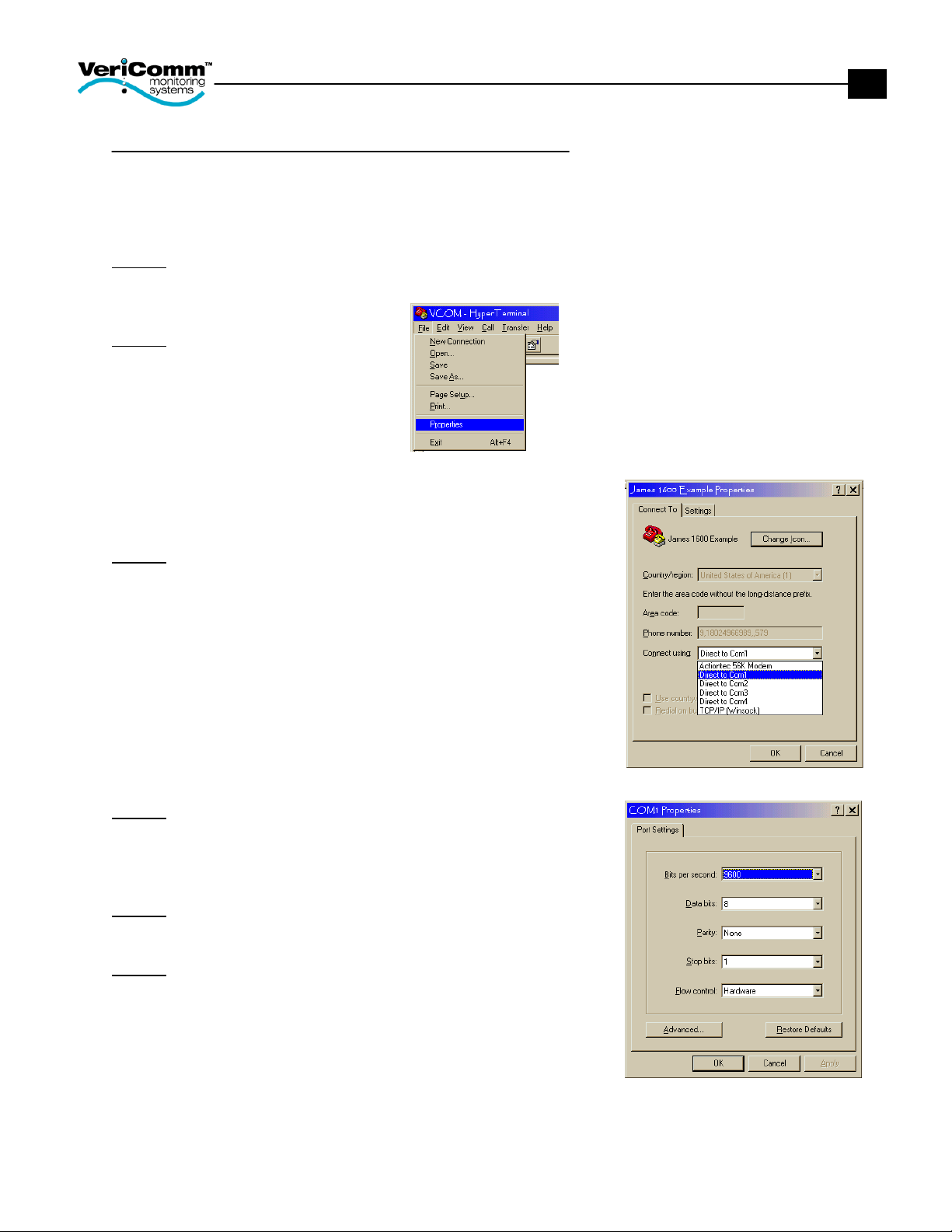

To Connect Directly to a Custom VCOM Panel ................................... 6

Login Screen.....................................................................................7

Login Procedure .................................................................................... 7

Run Mode Menu...............................................................................8

1. System Status Displays..................................................................... 8

2. Maintenance Log Entry .................................................................... 8

3. Maintenance Log Report.................................................................. 8

4. Expanded Report Menu.................................................................... 8

5. Enter a Password .............................................................................. 8

6. Initiate a Call Back........................................................................... 8

P. TRINET Program Mode Menu ........................................................ 8

C. MODEM OFF-LINE (Hang Up) ..................................................... 8

Page Select Menu ............................................................................9

System Status Page................................................................................ 9

Individual Status Page(s)....................................................................... 9

Settings.................................................................................................. 9

Flow Data Page(s) ............................................................................... 10

Log Parameters.................................................................................... 10

Inputs & Outputs ................................................................................. 10

Page Definition & Layout................................................................10

1. Page Description............................................................................. 10

2. PT# ................................................................................................. 10

3. Description ..................................................................................... 10

4. Value .............................................................................................. 10

5. Sts................................................................................................... 11

6. CurTm ............................................................................................ 11

7. PrevTime ........................................................................................ 11

8. Why? .............................................................................................. 11

9. Choices........................................................................................... 11

Adjusting Point Settings..................................................................11

To Force a Digital Point On ................................................................ 12

To Force a Digital Point Off................................................................ 13

To Override a Numeric Point Value.................................................... 14

To Override a Point for a Specified Time............................................ 15

System Status Menu ......................................................................16

To View Details of a Specified Point.................................................. 16

Explain the Point Value (A) ................................................................ 17

Rule Display (F).................................................................................. 17

Change Time/Date (I).......................................................................... 18

Input & Output Displays (K-N)........................................................... 18

Logs (Q,S,U) ....................................................................................... 19

Maintenance Log............................................................................20

Entering Maintenance Notes................................................................ 20

Viewing the Maintenance Log Report................................................. 21

Retrieving Logs...............................................................................22

To Retrieve a Log................................................................................ 22