OTIS OI-6900-X-X-T-2B User manual

CAUTION

CAUTION: FOR SAFETY REASONS, THIS EQUIPMENT MUST BE OPERATED AND

SERVICED BY QUALIFIED PERSONNEL ONLY. READ AND UNDERSTAND THE

INSTRUCTION MANUAL COMPLETELY BEFORE OPERATING OR SERVICING.

DANGER

DANGER: OTIS INSTRUMENTS INC. OI-6900-X-X-T-2B IS AN AMBIENT AIR TOXIC GAS

SENSOR ASSEMBLY AND ONLY MONITORS IN THE IMMEDIATE VICINITY OF THE

SENSOR HOUSING. A SITE SURVEY IS REQUIRED IN ORDER TO DETERMINE THE BEST

PLACEMENT AND QUANTITY OF SENSOR ASSEMBLIES. IMPROPER INSTALLATION

CAN LEAD TO AN UNDETECTABLE GAS LEAK WHICH COULD RESULT IN PERSONAL

INJURY OR LOSS OF LIFE.

TABLE OF CONTENTS

OI-6900-X-X-T-2B OPS GUIDE_REV 1.1 i

TABLE OF CONTENTS

1PRODUCT OVERVIEW..........................................................................................................................................1

1.1 INTRODUCTION ....................................................................................................................................................1

1.2 PRODUCT SPECIFICATIONS ...............................................................................................................................2

1.3SYSTEM DIAGRAMS.............................................................................................................................................3

1.3.1 EXTERNAL SYSTEM DIAGRAM ...........................................................................................................................3

1.3.2 INTERNAL SYSTEM DIAGRAM.............................................................................................................................4

1.3.3 ASSEMBLY DIAGRAM...........................................................................................................................................5

2INSTALLATION AND START-UP..........................................................................................................................6

2.1 PRODUCT PLACEMENT .......................................................................................................................................6

2.2 PRODUCT MOUNTING .........................................................................................................................................7

2.3 WIRING CONFIGURATIONS.................................................................................................................................7

2.3.1 OPENING THE ENCLOSURE................................................................................................................................8

2.3.2 CONNECTING THE BATTERIES...........................................................................................................................8

2.3.3 CLOSING THE ENCLOSURE ................................................................................................................................9

2.4 SYSTEM START-UP ..............................................................................................................................................9

2.5 NORMAL OPERATING MODE.............................................................................................................................10

3PRODUCT SETTINGS AND CONFIGURATION .................................................................................................11

3.1 RELAY TEST........................................................................................................................................................11

3.1.1 PERFORMING THE RELAY TEST ......................................................................................................................12

3.2 NETWORK ID.......................................................................................................................................................12

3.3 SYSTEM INFORMATION.....................................................................................................................................13

3.4 NULL/CALIBRATION TIMER INFORMATION .....................................................................................................13

3.5 UNIT INFORMATION ...........................................................................................................................................14

3.6 BACKGROUND SETTING....................................................................................................................................14

3.7 CALIBRATION METHOD .....................................................................................................................................15

3.8 DISPLAY SCREEN CONTRAST SETTING .........................................................................................................16

3.9 RETURN TO FACTORY DEFAULT SETTINGS ..................................................................................................17

4OPERATION SETTINGS .....................................................................................................................................19

4.1 POWERING THE DEVICE ...................................................................................................................................19

4.1.1 POWERING ON ...................................................................................................................................................19

4.1.2 POWERING OFF..................................................................................................................................................19

4.2 SENSOR CALIBRATION......................................................................................................................................20

4.2.1 NULLING THE SENSOR (AUTO NULL) ..............................................................................................................20

4.2.2 CALIBRATING THE SENSOR (MANUAL CAL) ...................................................................................................22

4.2.3 CALIBRATING THE SENSOR (AUTO CAL) ........................................................................................................23

4.3 SENSOR RADIO ADDRESS................................................................................................................................25

4.3.1 SENSOR RADIO ADDRESS SETTING ...............................................................................................................25

5PRODUCT MAINTENANCE.................................................................................................................................26

5.1 SCHEDULED MAINTENANCE.............................................................................................................................26

5.2 SENSOR REPLACEMENT...................................................................................................................................27

5.3 BATTERY REPLACEMENT .................................................................................................................................28

5.4 PRODUCT TROUBLESHOOTING.......................................................................................................................30

5.5 PRODUCT REPLACEMENT PARTS AND ACCESSORIES................................................................................31

TABLE OF CONTENTS

ii OI-6900-X-X-T-2B OPS GUIDE_REV 1.1

APPENDIX A: PRODUCT WARRANTY STATEMENT.............................................................................................................33

APPENDIX B: INFORMATION ABOUT RMA SERVICE REPAIRS .........................................................................................35

APPENDIX C: INFORMATION ABOUT RMA RETURNS FOR CREDIT..................................................................................37

PRODUCT OVERVIEW

OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1 1

1 PRODUCT OVERVIEW

1.1 INTRODUCTION

The Otis Instruments, Inc. (Otis) GEN II Model OI-6900-X-X-T-2B (OI-6900) Non-Explosion-Proof Ambient Air Toxic

Gas Detector is designed to detect a wide range of toxic gases in many environments. The OI-6900 features non-

intrusive magnetic switches that allow for complete system configuration, regular calibration, and product

maintenance to be performed in the field, without opening the enclosure and breaking the seal of the enclosure. Non-

intrusive interface with the OI-6900 is made possible by use of the Otis Magnetic Tool included in the purchase of

the device.

The OI-6900 continuously monitors the gas level of the surrounding environment and reports once every minute, the

reporting rate will increase to once every five seconds when the detected gas is above the Background Gas set-

point. This set-point is adjustable to account for sites that may have a constant low level of gas always present

allowing the OI-6900 to maintain a long battery life. When the gas level drops below the set-point the reporting rate

will return to once every minute. The OI-6900 display screen will always show the present concentration of gas being

detected by the sensor assembly. More information about the Background Gas Set-point is found later in this manual.

This document is an operation manual containing diagrams and step-by-step instructions for the proper and safe

installation, start-up, configuration and settings, normal operation, and product maintenance of the OI-6900.

In this manual, the instructions reference the use of push-buttons, located on the front panel of the device. In certain

environments, the activation of the non-intrusive magnetic switches, through the use of the Otis Magnetic Tool, will

replace the directive of the button-press actions. To apply the Otis Magnetic Tool, hold the tool to the side of the

device enclosure adjacent to the push-button that you wish to activate. When the magnetic switch is toggled, an on-

screen indicator will appear on the display screen, signifying that a connection was made.

NOTICE

This document should be read in its entirety before the initial operation of the product.

Should a question arise during the use of the product, this document will serve as a first reference for the end-user.

For inquiries beyond the information and instructions provided within this manual, contact the sales representative

of this product for assistance.

PRODUCT OVERVIEW

2 OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1

1.2 PRODUCT SPECIFICATIONS

System Specifications

Operating Voltage

3.6 VDC 19Ah each, 38 Ah total Lithium-Thionyl (Li-SOCl2) Battery

Estimated Battery Life

Electrochemical Sensor - 2 Years Maximum

Photo Ionization Detector Sensor –14 Days Maximum

Operating Temperature Range

-20⁰C to +54⁰C

Humidity Range

0% to 98% Relative Humidity, Noncondensing

Measurement Range

Varies based on gas type

Response Time

Varies based on gas type

WireFree Radio Option

GEN II 900 MHz –52 Networks, 255 Sensors per Network

GEN II 2.4 GHz –78 Networks, 255 Sensors per Network

RF Connection

N-Female Radio Frequency (RF) Connector

Display

Transflective (sunlight-readable)

102x64 LCD Screen

LED Back-Light

Interface

3 Push-Buttons (MENU, ADD, SUB)

3 Magnetic Switches for Non-Intrusive Calibration

Mechanical Specifications

Enclosure Materials

Aluminum Device Enclosure with Plastic Lid

Sensor Housing Material

Black Polypropylene Plastic with Stainless Steel Mesh Screen

Product Dimensions

5.37" L x 5.11" W x 15.76" H (Maximum w/ Attachments)

Product Weight

3.25 lbs

PRODUCT OVERVIEW

OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1 3

1.3 SYSTEM DIAGRAMS

Refer to the following diagrams for identification of the external and internal system components that may be referred

to in this manual.

1.3.1 EXTERNAL SYSTEM DIAGRAM

1Antenna

2Antenna Fitting

3MENU Button

4Enclosure

5Front Panel Thumbscrew

6SUB Button

7Sensor Housing Base

8Sensor Housing Cap

9ADD Button

10 LCD Display Screen

11 Enclosure Lid

12 Otis Magnetic Tool

13 Cal Adapter Kit

⑫

⑪

⑬

PRODUCT OVERVIEW

4 OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1

1.3.2 INTERNAL SYSTEM DIAGRAM

1Sensor Housing Connector

2Sensor Housing Plug

3Batteries

4Radio Module

5Battery Connectors

6Antenna Fitting Connector

7Battery Spring Clips

PRODUCT OVERVIEW

OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1 5

1.3.3 ASSEMBLY DIAGRAM

1Enclosure Lid

2Internal System

3Antenna Fitting Connector

4Enclosure

5Antenna Fitting

6900 MHz Antenna

OR

72.4 GHz Antenna

8Sensor Housing Base

9Sensor Element

10 Sensor Housing Cap

11 Sensor Housing Plug

INSTALLATION AND STARTUP

6 OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1

2 INSTALLATION AND START-UP

2.1 PRODUCT PLACEMENT

The installation instructions, and any other information supplied by Otis, provide only basic guidelines relating to the

properties of toxic gas and the effects of environmental conditions on the OI-6900 device. Sensor placement should

be determined in consultation with the site safety personnel, as well as those knowledgeable of: (1) the site/facility

where the equipment is being installed and (2) the potentially present gas types and their dispersion. Otis strongly

recommends that the end-user consults with the appropriate third party Health, Safety and Environmental (HSE) and

Industrial Hygiene (IH) professionals to determine the final quantity and placement of your gas detection devices.

The primary purpose of the OI-6900 is to provide an early warning of the accumulation of toxic gas, in order to

minimize hazards to people and property. Proper placement of the device is paramount to achieving this goal.

The following general guidelines should be considered when determining the placement of the OI-6900:

The unit should be placed greater than 6.5 Feet/2 Meters away from a monitor in order to ensure reliable

communications

The unit shall be placed such that the position of the sensor housing is pointing downward to the ground.

Avoid installing the unit in a location where airborne particles could cover or coat the sensor head.

The unit should be placed in an area that will produce the highest gas concentration. Enclosed corners and

stopping points of moving devices are two areas susceptible to a buildup of toxic gas.

In order to provide an accurate representative sample of a room, care should be taken to avoid locating the

unit near a room entrance, fresh air intake vent, or vehicle/generator exhaust point.

The unit should be placed as close as physically possible to the source of the potential toxic gas leak.

Consider placing the unit in a seldom used area, such as a warehouse, storage area, or other unfrequented

location.

Consider accessibility for regular calibration and other required maintenance.

When monitoring a ventilated gas cylinder storage area, the unit should be placed near the air return vent.

When monitoring an outdoor or open-air area, the unit should be placed near the air intake of the HVAC

system of the building.

When monitoring for the potential presence of multiple toxic gas types, the unit should be calibrated for the

least cross-sensitive toxic gas.

NOTICE

These guidelines are ONLY intended as a general directive for the placement of the OI-6900. This information

should NOT serve as a complete list when considering all potential parameters for the proper location of the unit.

It is STRONGLY advised that a third party Certified Industrial Hygienist, or other Certified Safety Professional,

conduct a site survey and annotate the location and quantity of detection devices that should be installed for

EVERY installation of EVERY site.

INSTALLATION AND STARTUP

OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1 7

2.2 PRODUCT MOUNTING

It is recommended to mount the unit to a solid structure (such as a concrete wall, steel column, or angle iron) where

a minimum of vibration will be transmitted to the unit. Alternately, a pole may be used along with a strap or a U-bolt,

as long as it is rigid and of sufficient strength. Wooden structures are not recommended for mounting, as they trap

moisture (which could affect sensor performance) and their mounting rigidity degrades over time (screws/bolts

weaken and fall out or corrode).

Any style of bolt or screw may be used as long as it is steel and meets or exceeds the following:

Maximum ¼"-20 bolt or ؼ" screw (length varies with user need)

Flat washers for bolts/nuts/screws

Minimum Grade 5 (or better)

Corrosion protection for all hardware (paint, galvanize, zinc plating, etc.)

2.3 WIRING CONFIGURATIONS

The OI-6900 is powered by dual 3.6V/19AH Lithium-Thionyl batteries. The batteries should be replaced in pairs and

you should not mix old and new batteries.

CAUTION

The internal components can be static sensitive. Use caution when opening the enclosure and handling

internal components.

DO NOT use any metal objects or tools to remove the terminal board from the internal system.

DO NOT mix old and new batteries.

WARNING

When securing the lid onto the device, tighten the enclosure lid by hand ONLY. Overtightening of the lid by

use of hand-tools could result in damage to the O-ring, potentially compromising the moisture seal, resulting

in an unsafe environment.

Use ONLY Otis supplied batteries in this device.

INSTALLATION AND STARTUP

8 OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1

2.3.1 OPENING THE ENCLOSURE

To prepare the OI-6900 for installation, you must first open the device, exposing the control board and its

components to connect the batteries.

1. Remove the enclosure lid, unscrewing it from the device enclosure. Set aside.

2. Gripping the front panel thumbscrews, lift the internal system out of the enclosure and rest it against

the rim of the enclosure opening.

NOTICE

Disconnecting the sensor connector plug from the sensor housing connector and the antenna fitting

cable will allow for the complete removal of the internal system from the device enclosure.

Disconnecting the internal system may provide ease in accessing the control board terminals for

connecting the battery plug into the battery connectors. If this step is performed, it is essential that all

connections are rejoined before returning the internal system back into the enclosure.

2.3.2 CONNECTING THE BATTERIES

To provide power to the OI-6900 you will need to connect the battery connectors to the OI-6900 battery

terminals located on the control board. Refer to the following instructions for how to connect the batteries

to your device:

On the GEN II Model OI-6900 Detector:

1. Plug the battery on the bottom of the radio board into the closer 2-pin battery terminal.

2. Plug the battery on the top of the radio board into the other available 2-pin battery terminal.

INSTALLATION AND STARTUP

OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1 9

2.3.3 CLOSING THE ENCLOSURE

1. Place the internal system back into the device enclosure, matching each mounting post to its

corresponding eyelet anchored within the base of the enclosure.

2. Using the thumbscrews, gently push to seat the internal system into the mounting posts.

NOTICE

The thumbscrews on the OI-6900 function ONLY as thumb-holds for ease in removal of the internal

system from the base of the enclosure. Do NOT attempt to loosen or tighten the thumbscrews when

opening or closing the enclosure.

3. Verify that the sealing ring, seated at the threaded opening of the device enclosure, is correctly in

place.

4. Affix the enclosure lid back onto the device, rotating the lid until it is tightly screwed into place.

2.4 SYSTEM START-UP

After power is applied, the unit will enter into OFF mode. Once the enclosure is properly closed you may turn the unit

ON and begin its 1-minute warmup period. During warmup, the display will show a countdown of the time remaining

until the system start-up is complete. The Otis logo and the unit information will also flash on the display screen

during start-up.

At the end of the countdown, the device will be in normal operating mode.

INSTALLATION AND STARTUP

10 OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1

2.5 NORMAL OPERATING MODE

During normal operating mode, the OI-6900 continuously samples the air and updates the measured concentration

of the target gas on the display screen. The display, when in normal operation, appears as shown below.

1Measured gas concentration (reading)

2Gas concentration unit of measure

3Sensor element gas type

In the event of a device failure, the unit will alternate between the normal operating screen and a fault screen on the

display, in 5 second intervals, until the fault has been cleared, or is corrected. The fault code, located in the bottom-

left corner of the display, appears on both screens. The unit continuously registers that the system is in fault, so that

even with at-a-glance instrument checks in the field, it can be seen. When the fault is corrected, the unit will return

to normal operating mode.

For a list of the fault codes and warning symbols of the OI-6900, and their associated meaning, refer to the Product

Troubleshooting section of this manual.

Both system menus are accessible from the normal operating mode. To access the product settings and

configuration menu, press and hold the MENU button, for approximately 6 seconds, until the menu is activated and

open on the display screen. To access the operation settings menu from the normal operating screen, press the

MENU button once and the menu will open and show on the display.

NOTICE

After 5 minutes of no interaction with the device, the unit will automatically return to normal operating mode.

PRODUCT SETTINGS AND CONFIGURATION

OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1 11

3 PRODUCT SETTINGS AND CONFIGURATION

The product settings and configuration menu allows the end-user to tailor the device settings to meet their required

specifications and/or site conditions.

The product settings and configuration menu consist of the following screens:

Relay Test

Network ID

System Information

Null/Calibration Timers

Unit Info

Background Setting

Calibration Method

Display Screen Contrast Setting

Return to Factory Default Settings

While the device is in normal operating mode, press and hold the MENU button, for approximately 6 seconds, until the

product settings and configuration menu is activated and open on the display screen.

3.1 RELAY TEST

The relay test simulates a gas level reading, indicating the presence of a toxic gas at the sensor. The relay test is

used to ensure the proper functionality of the relay settings on the monitor. The test can also be used to simulate

emergency/safety drills onsite.

NOTICE

The triggering of relays from the detector will also simulate low and high level alarm relays at the monitor. Monitors

cannot distinguish between real and simulated data received. When the monitor relays are triggered, alarming

devices will perform as intended, initiating emergency procedures as if a harmful or toxic gas was actually present.

To prevent this from occurring, set the monitor to calibration mode before performing the relay test. Calibration

mode of the monitor will allow the transmission of the data, without the activation of the monitor relays. Consult

the Sensor Calibration section of this manual for instructions on how to perform this procedure.

It is recommended that a relay test be conducted EVERY 30 days, alongside the maintenance and calibration of the

detector.

PRODUCT SETTINGS AND CONFIGURATION

12 OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1

3.1.1 PERFORMING THE RELAY TEST

The relay test gas level reading can be increased or decreased in increments of 5% of the sensor scale,

up to 100% of the sensor scale.

1. Press the ADD button until the low and high alarm levels are reached and the relay(s) are triggered

to light all visual alarm(s) and sound all audio alarm(s) on the monitor.

2. Once all relays have been tested and the test is complete, press the SUB button to return the relay

test reading back to zero and to deactivate the monitor alarm(s).

3. Press the MENU button to advance to the Network ID screen.

3.2 NETWORK ID

The Network ID is used to synchronize the communication between the Otis Monitor and Sensor Assembly:

There are 52 networks available with the GEN II 900 MHz radio.

There are 78 networks available with the GEN II 2.4 GHz radio.

The monitor and sensor assembly must have the same Network ID in order to communicate.

1. Press the ADD or SUB button until the Network ID matches the value being used on the Primary

Monitor.

2. Press the MENU button to advance to the System Information screen.

PRODUCT SETTINGS AND CONFIGURATION

OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1 13

3.3 SYSTEM INFORMATION

The system information screen allows the end-user to view the following information:

The connection status to the Primary Otis Monitor.

The scale of the sensor element.

The battery voltage of the device.

The voltage value the sensor was reading when nulled in Volts.

The current voltage value the sensor element is reading in Volts.

This screen is for informational purposes only.

1. Press the MENU button to advance to the Null/Calibration Time Information screen.

3.4 NULL/CALIBRATION TIMER INFORMATION

The null/calibration time information screen allows the end-user to view the following information:

The days since the sensor assembly was last nulled, only updates while the unit is turned on.

The days since the sensor assembly was last calibrated, only updates while the unit is turned on.

The calibration number of the sensor, used for diagnostic purposes.

This screen is for informational purposes only.

1. Press the MENU button to advance to the Unit Information screen.

PRODUCT SETTINGS AND CONFIGURATION

14 OI-6900-X-X-T-2B OPS_GUIDE_REV 1.1

3.5 UNIT INFORMATION

The unit information screen allows the end-user to view the following information:

The number of times the radio has transmitted and not received an acknowledgement.

The date of manufacture of the sensor assembly.

The serial number of the sensor assembly.

This screen is for informational purposes only.

1. Press the MENU button to advance to the Background Setting screen.

3.6 BACKGROUND SETTING

The background setting is the gas reading at which the radio transmission changes from once every minute to once

every five seconds. The background setting is adjustable so that if there is a consistent level of gas always present

the sensor will not increase the radio transmission rate, this leads to longer battery life on sites where a consistent

low level of gas is always present in the background.

The default background level is 4% of the sensor element scale.

The minimum that the background can be set to is 1% of the sensor element scale.

The maximum that the background can be set to is 10% of the sensor element scale.

1. Press the ADD or SUB button until the Background is set to the desired level.

2. Press the MENU button to advance to the Calibration Method screen.

Table of contents

Other OTIS Other manuals

Popular Other manuals by other brands

Artist Guitars

Artist Guitars RoboWinder user guide

Billet Specialties

Billet Specialties V-Trac V4120 installation manual

Auvidea

Auvidea J120 Technical reference manual

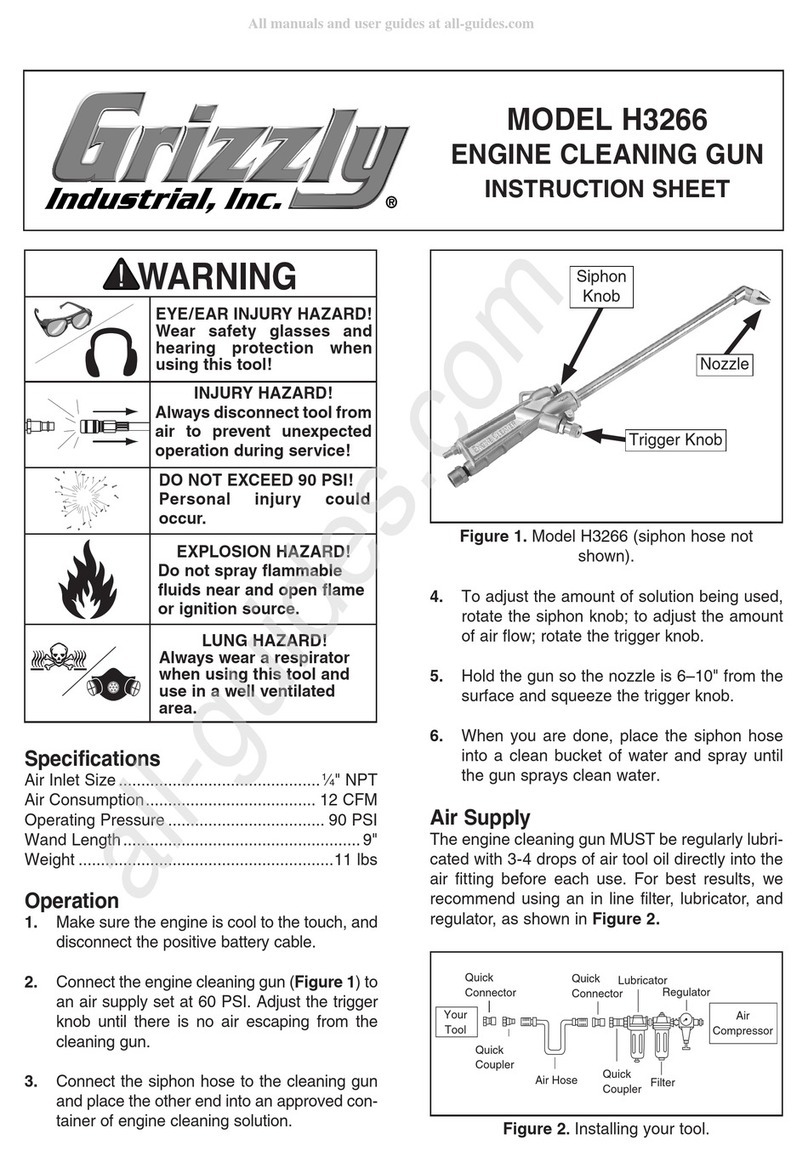

Grizzly

Grizzly H3266 instruction sheet

Horizon Fitness

Horizon Fitness Titan XP90 quick start guide

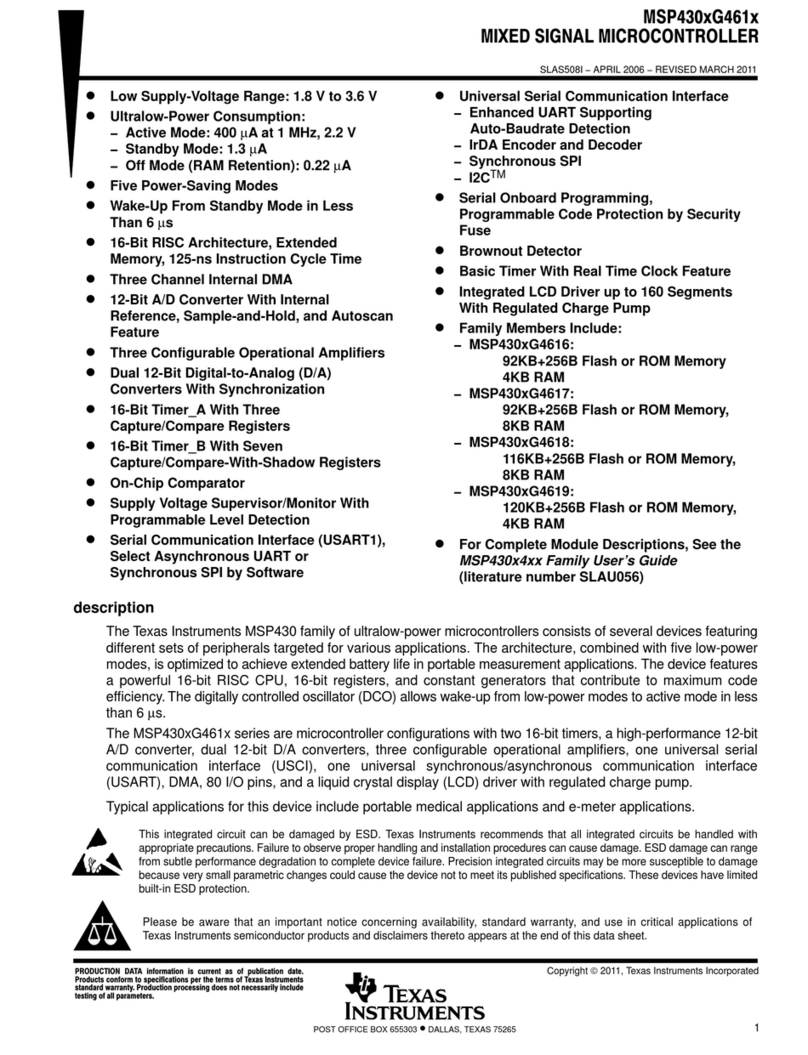

Texas Instruments

Texas Instruments MSP430FG4616IPZ manual

Meaco

Meaco 12L-AH Dehumidifier instruction manual

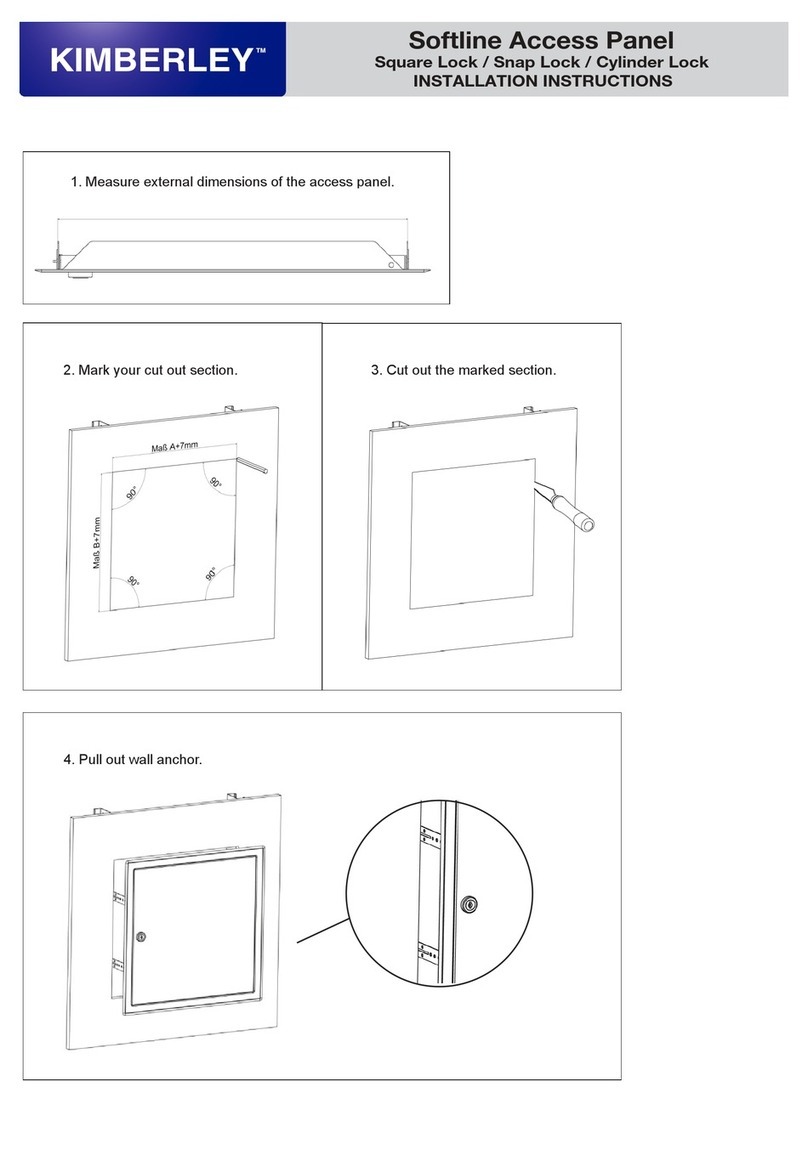

Kimberley

Kimberley Softline Access Panel installation instructions

3M

3M DBI SALA 8518581 User instruction manual

Bosch

Bosch BEA 950 Original instructions

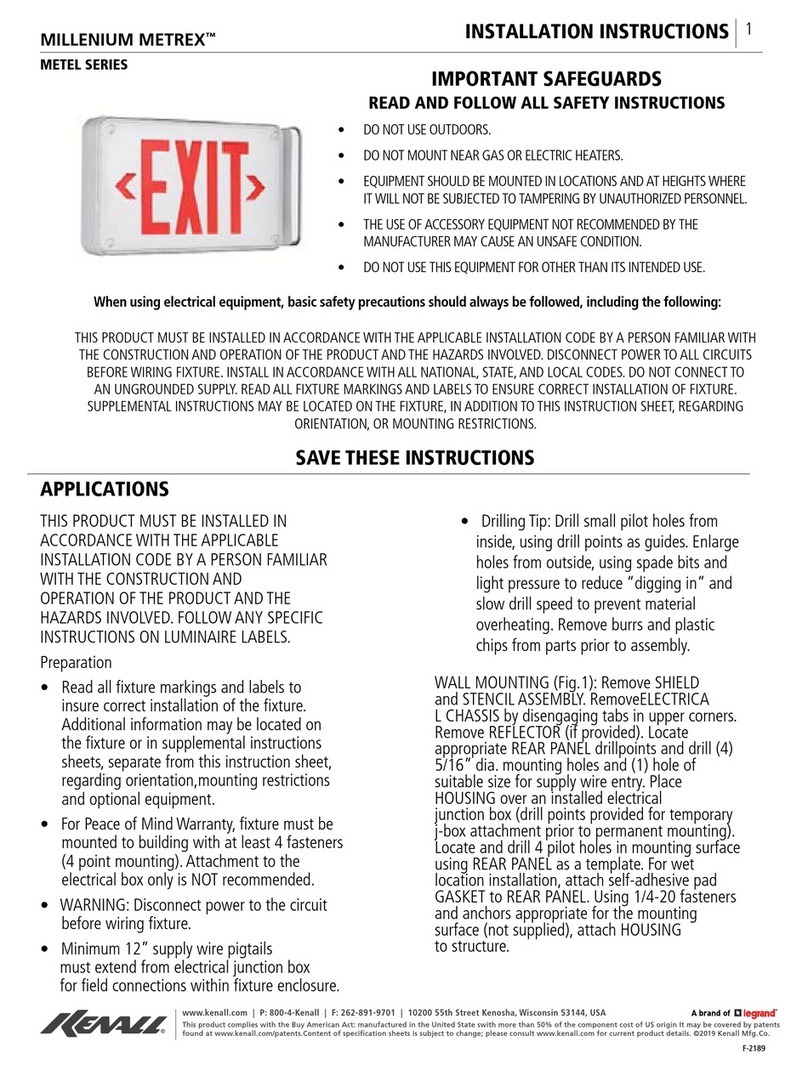

LEGRAND

LEGRAND KENALL MILLENIUM METREX METEL Series installation instructions

LAMBORGHINI

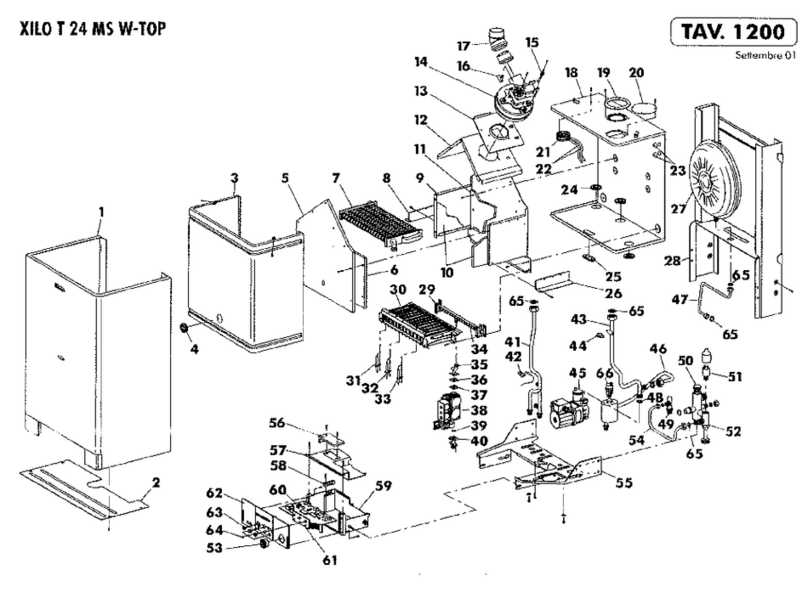

LAMBORGHINI XILO T 24 MS W-TOP - SCHEMA manual