3

Table of Contents:

Aerator Equipment ........................................................................................................................ 4

Electrical/PCCInstallation ............................................................................................................. 4-5

Timer Operation............................................................................................................................. 5

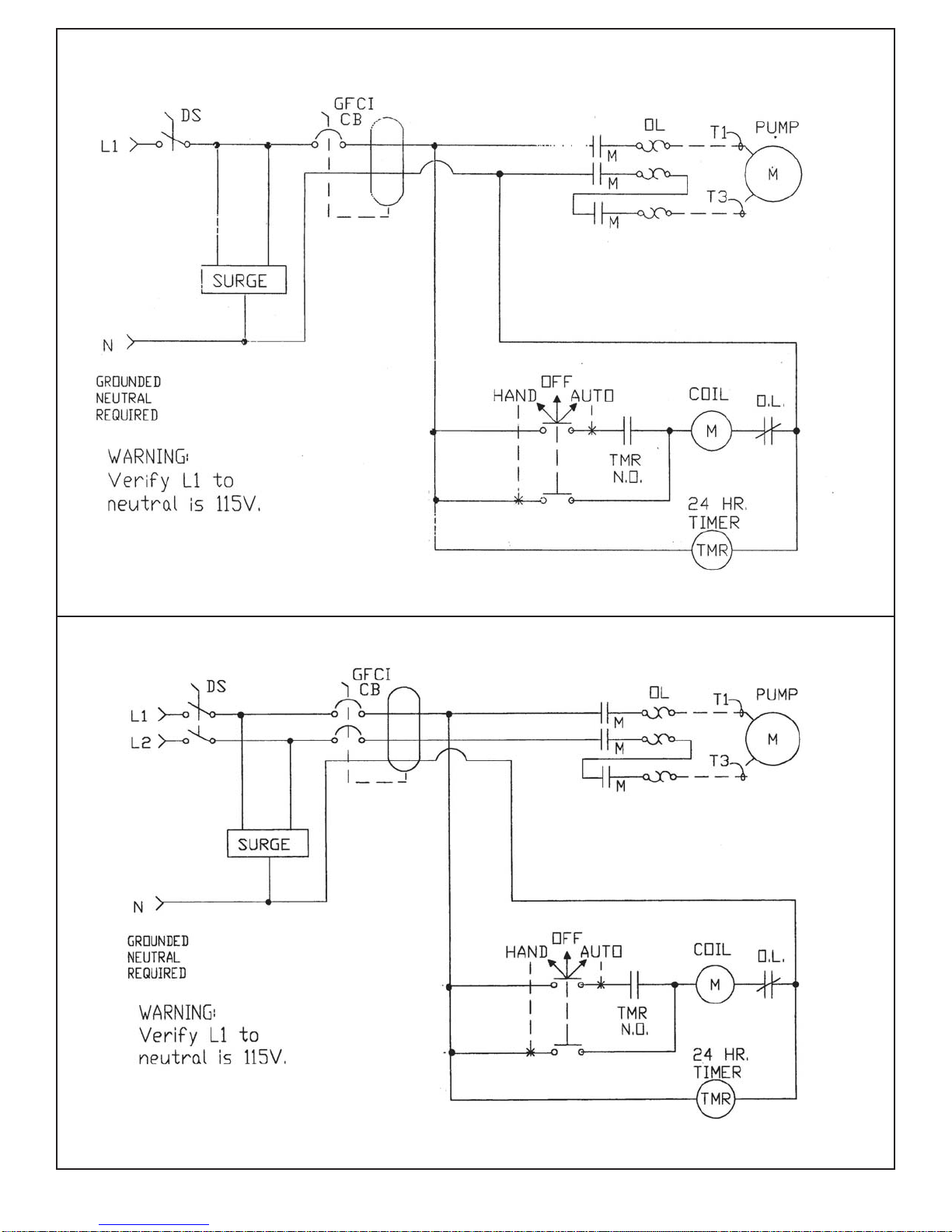

Power Control Center Schematics ................................................................................................. 6-8

Aerator Placement ......................................................................................................................... 9

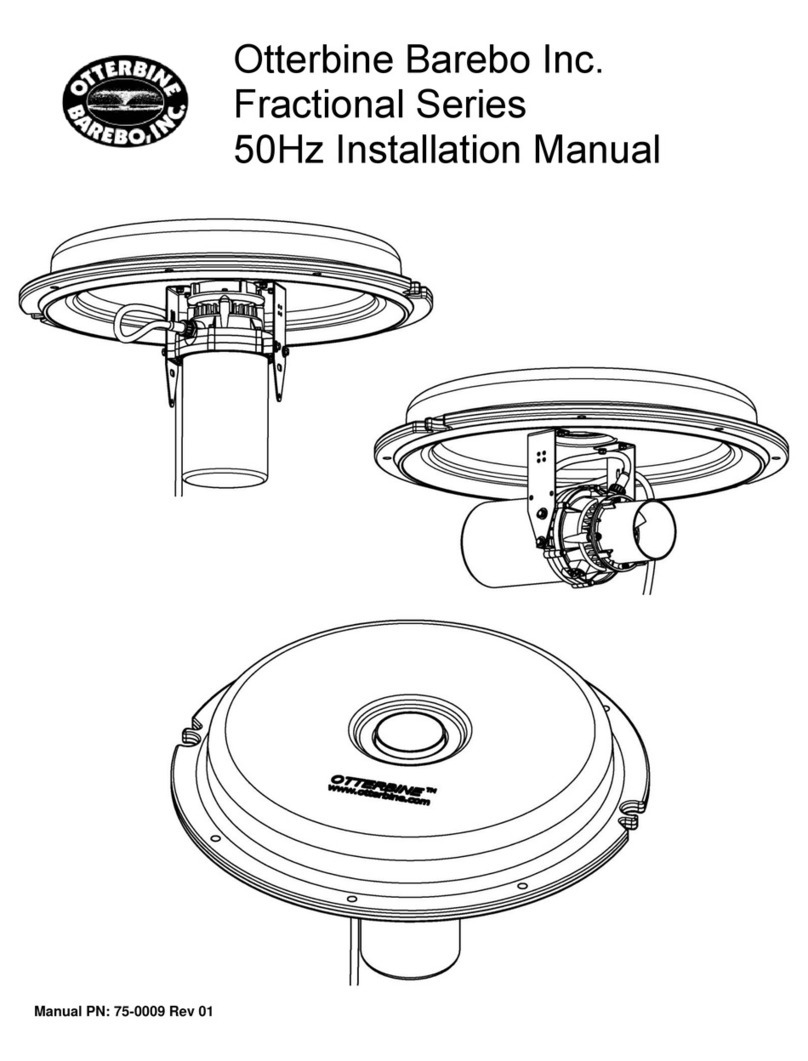

MountingtheFloat/SupplementalFloattotheUnit ............................................................................ 10

Comet Stabilizer Plates Mounting ................................................................................................. 11

PhysicalInstallation........................................................................................................................ 12-13

Mooring ......................................................................................................................................... 14

Anchoring ...................................................................................................................................... 15

ElectricalTests............................................................................................................................... 16

Open Throat Pump Chambers Parts List ....................................................................................... 17

SunburstPumpChamber/AssemblyInstructions ........................................................................... 18

GeminiPumpChamber/AssemblyInstructions .............................................................................. 19

SaturnPumpChamber/Assembly Instructions ............................................................................... 20

Decorative Pump Chambers Parts List .......................................................................................... 21

RocketPumpChamber/AssemblyInstructions.............................................................................. 22

PhoenixPumpChamber/AssemblyInstructions............................................................................. 23

Tri-StarPumpChamber/AssemblyInstructions ................................................................................ 24

ConstellationPumpChamber/AssemblyInstructions ......................................................................... 25

CometPumpChamber/AssemblyInstructions .................................................................................. 26

GenesisPumpChamber/AssemblyInstructions................................................................................. 27

EquinoxPumpChamber/AssemblyInstructions ................................................................................ 28

PowerUnitPartsList....................................................................................................................... 29

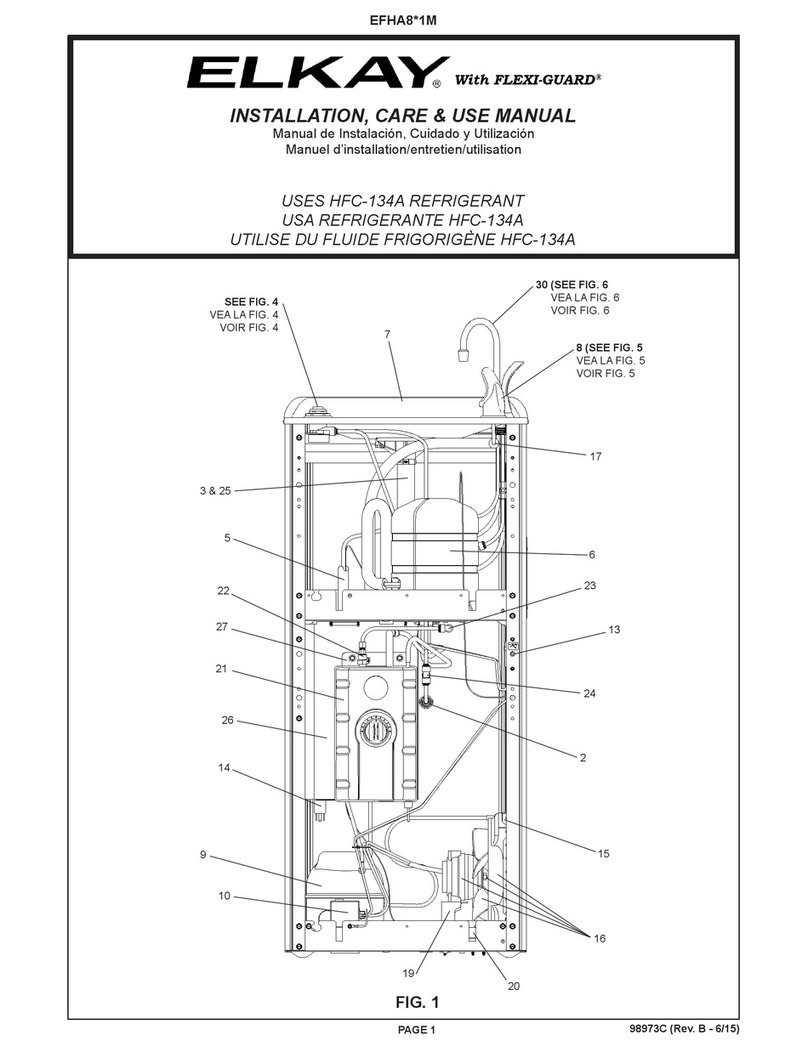

PowerUnitDiagram ........................................................................................................................ 30

ScreenInstallation............................................................................................................................ 31

TroubleShooting ............................................................................................................................. 32

TechnicalData-Domestic ............................................................................................................... 33-34

TechnicalData-International........................................................................................................... 35-36

MaximumCableLengths ................................................................................................................. 37

Maintenance .................................................................................................................................... 37

WinterizationandSpecialWarnings.................................................................................................. 38

OtterbineWarranty.......................................................................................................................... 39

Revised11/06/2008

WARNING: PHYSICALLY disconnect the unit and lights from their

electrical source before entering, wading or swimming in the water in

which they are installed. Only factory approved power cord is to be

used. Do not splice or repair the cord, replacement is necessary if

damage occurs.