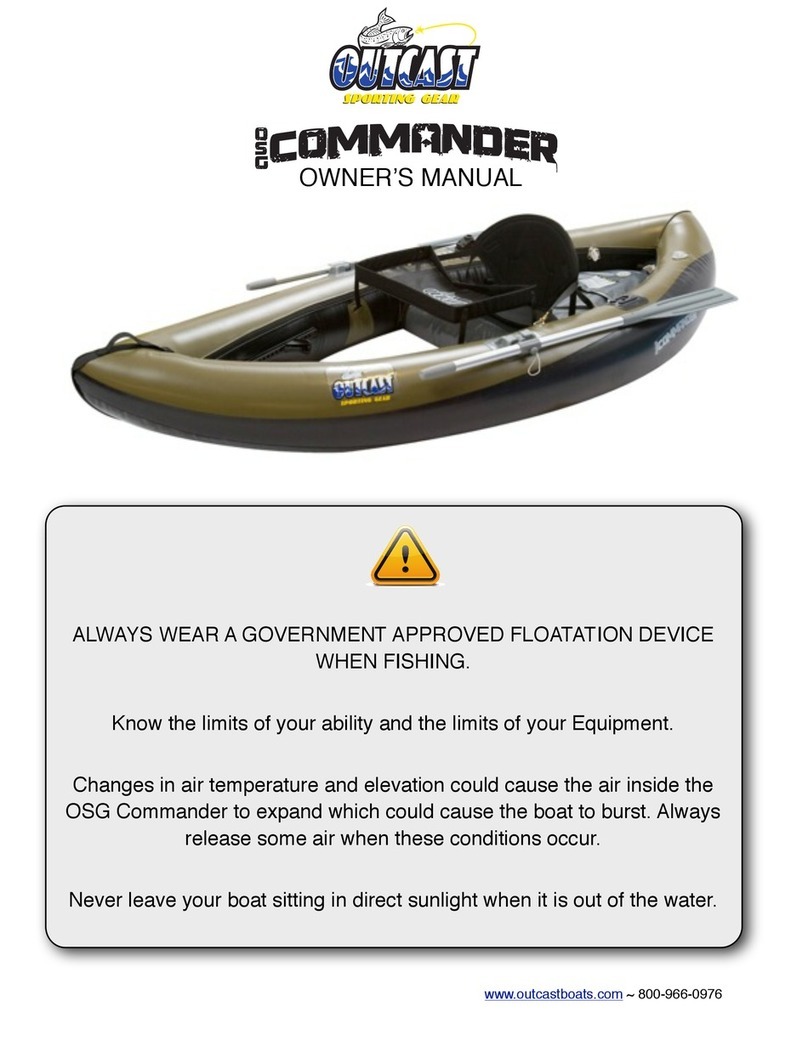

1. Valve does not retain air when pump is removed.

•Make sure that the valve stem is in the up and closed position.

•Clear any debris that might be preventing the valve from sealing. This can be accomplished by either pumping quick bursts of air

into the valve or removing the core valve assembly and cleaning the edge of the rubber diaphragm with a cotton swab and

denatured alcohol.

•Make sure that the core valve assembly is tight. Tighten valve if necessary.

2. Tube becomes soft after inflation process.

•Determine which air chamber is soft. Make sure the valve is functioning correctly, with no signs of leaking.

•Find the hole in the AIREcell and patch with the Tear Aid patch.

3. Tube is puckered or shows a void when inflated.

•The AIREcell might be misaligned. Deflate the tube(s) and as they are brought back up to pressure, manipulate the tube(s) to

free the AIREcell as it inflates. If this does not fix the problem, deflate the boat, open the zipper and adjust the AIREcell.

4. Zipper is difficult to operate.

•Use a combination of soap, water and an old toothbrush to clean and clear the zipper of debris.

5. Tear Aid patch does not stick to AIREcell.

•Make sure the area to be patched is dry and clean. Use the alcohol pad to prep the area.

Items Needed:

Towel

Type A or B Adhesive Patch

Alcohol Prep Pad

Tear Aid instruction Sheet

For most repairs, the airecell does not need to be removed completely.

1. Locate the hole in the boat and access that area of the airecell and outer skin by opening the zipper.

2. Using a towel, dry the area to be worked on.

3. Clean area to be worked on with alcohol prep pad and let the area air dry.

4. Peel backing paper off Type A or B Adhesive Patch and apply patch over punctured area.

(See Tear Aid instruction sheet for more details.)

5. Press and rub patch so that the patch seals completely and is without bubbles.

Items Needed:

Scissors or Knife

Standard Screwdriver

Roller

Stabond 2-part adhesive

Sand Paper

Popsicle Stick

Small Brush

PVC Material or Urethane Material

MEK or Alcohol Prep Pads

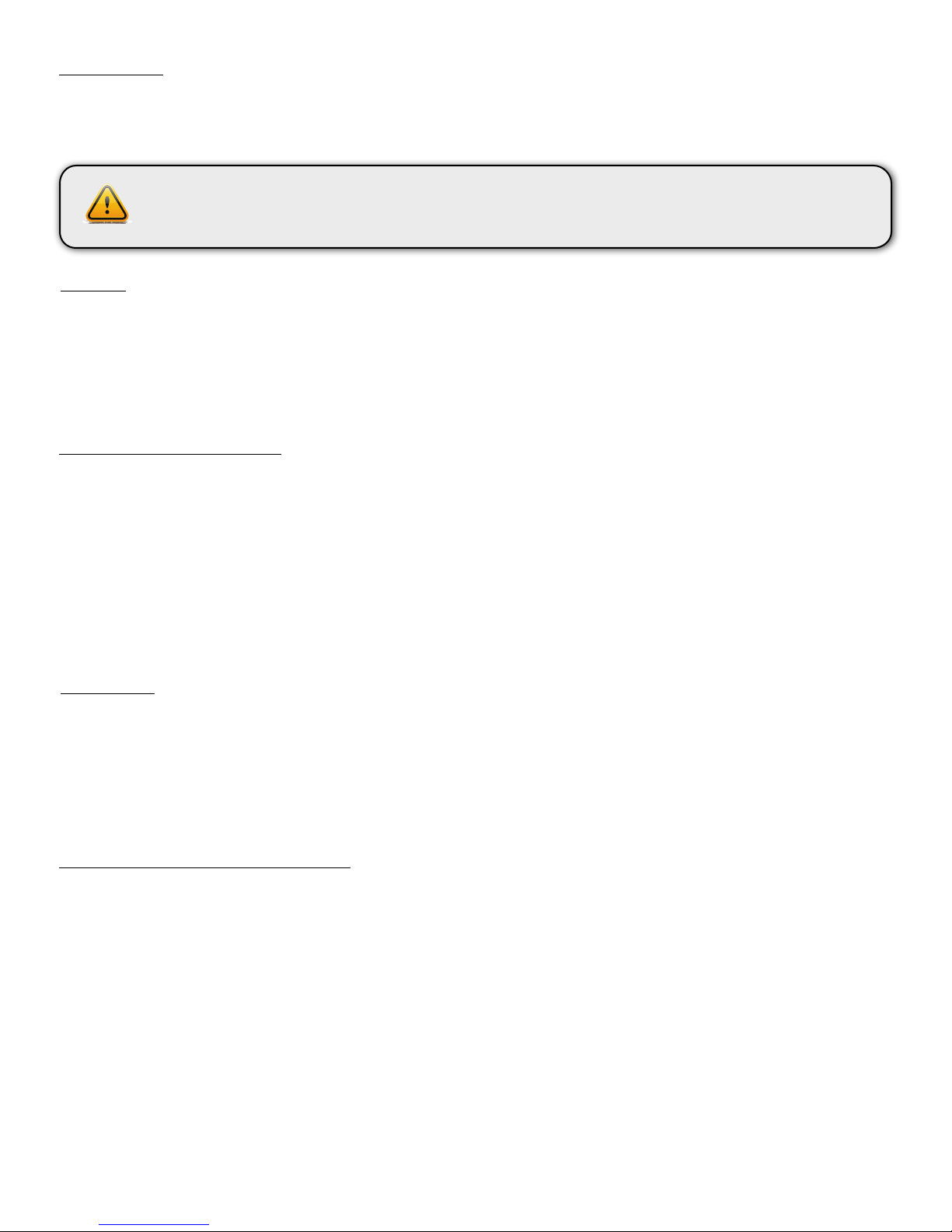

For most repairs, the airecell does not need to be removed completely. When patching the AIREcell, apply the patch to the outside of

the airecell. When patching the PVC shell, apply the patch on the inside of the PVC.

1. Locate the hole in the boat and access that area of the AIREcell and outer skin by opening the zipper.

2. Using a towel, dry the area to be worked on.

3. Cut a patch of fabric at least two inches large in length and width than the puncture, hole, or tear.

4. Clean the area to be patched (using MEK or alcohol prep pads).

5. Rough up both the patch and the area to be patched with the sand paper.

6. After opening the 2-part adhesive, prepare the Stabond glue by pouring the entire contents of the glass jar into the metal can and

stir using a popsicle stick or tongue depressor.

7. Apply an even coat of glue with a small brush to both the patch and the area to be repaired and let dry completely, approximately

10-15 minutes.

8. Apply a second coat of glue, and let dry 5 minutes or until tacky. If the glue is too dry, reactivate it with a small amount of cleaner.

9. Place the patch over the hole or tear, and press together. Using a roller or another blunt object press from the center of the patch to

the edges to seal the patch to the AIREcell or outer skin. Make sure that the patch seals completely and is without bubbles.

10. Let the glue cure at least one hour before inflating (overnight if possible is best). Do not inflate to full pressure on the same day of

the repair.