Overview

313221M 7

Overview

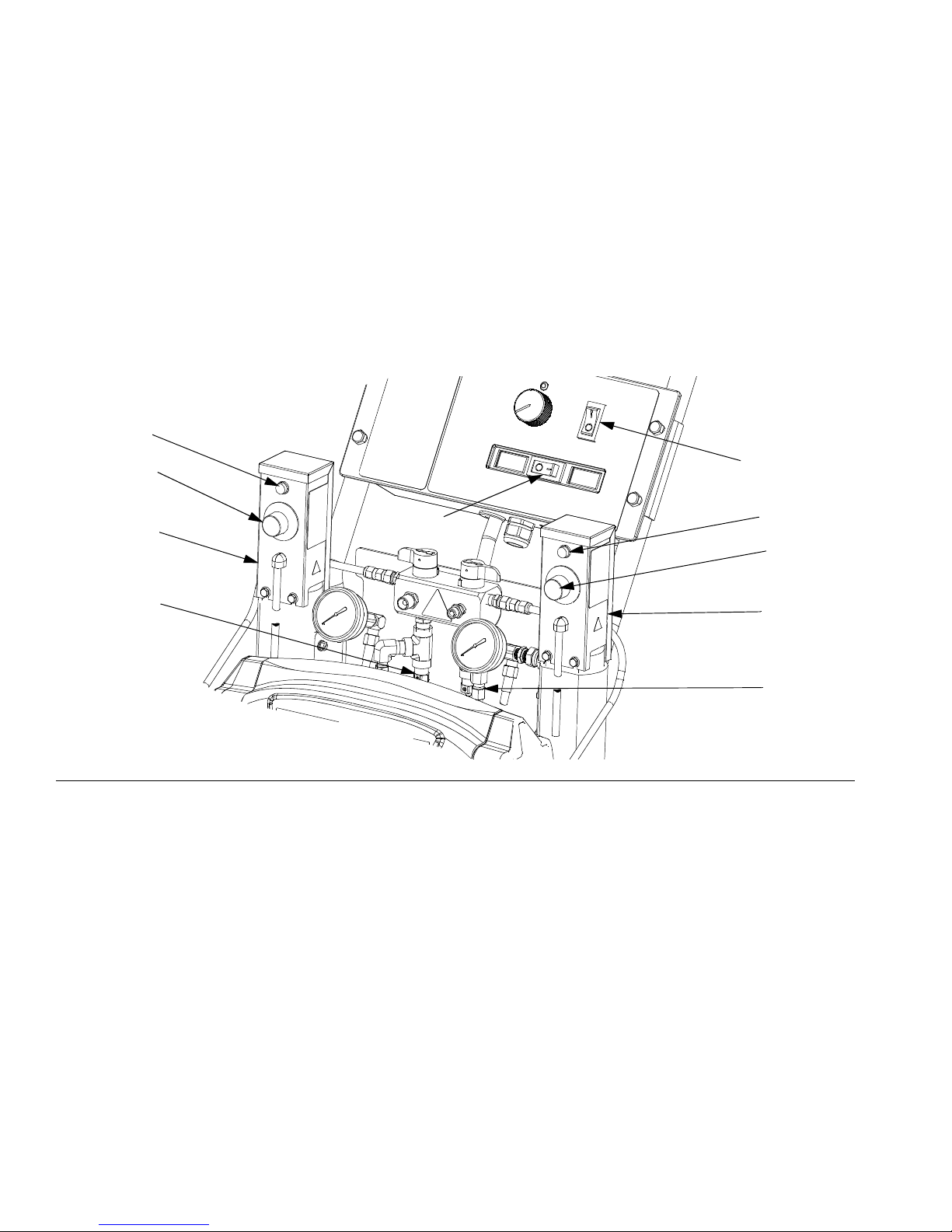

The EnergyComplete Sprayer is a portable, elec-

tric-powered, 4:1 mix ratio proportioner, for use with

EnergyComplete Air Infiltration Barrier with Flexible

Seal Technology by Owens Corning. Materials must be

self-leveling and pourable, and may be applied with

impingement mix spray guns, disposable mixer guns, or

flush-type mix manifolds.

The EnergyComplete Sprayer is siphon-fed from 5 gal-

lon pails that can be mounted on the unit.

Severe duty, positive displacement reciprocating piston

pumps meter fluid flow to the gun for mixing and apply-

ing. When set to recirculation mode, EnergyComplete

Sprayer will circulate fluids back to the 5 gallon pails.

The EnergyComplete Sprayer includes separate ther-

mostatically controlled heaters for each fluid. Digital dis-

plays show the temperatures of the two fluids.

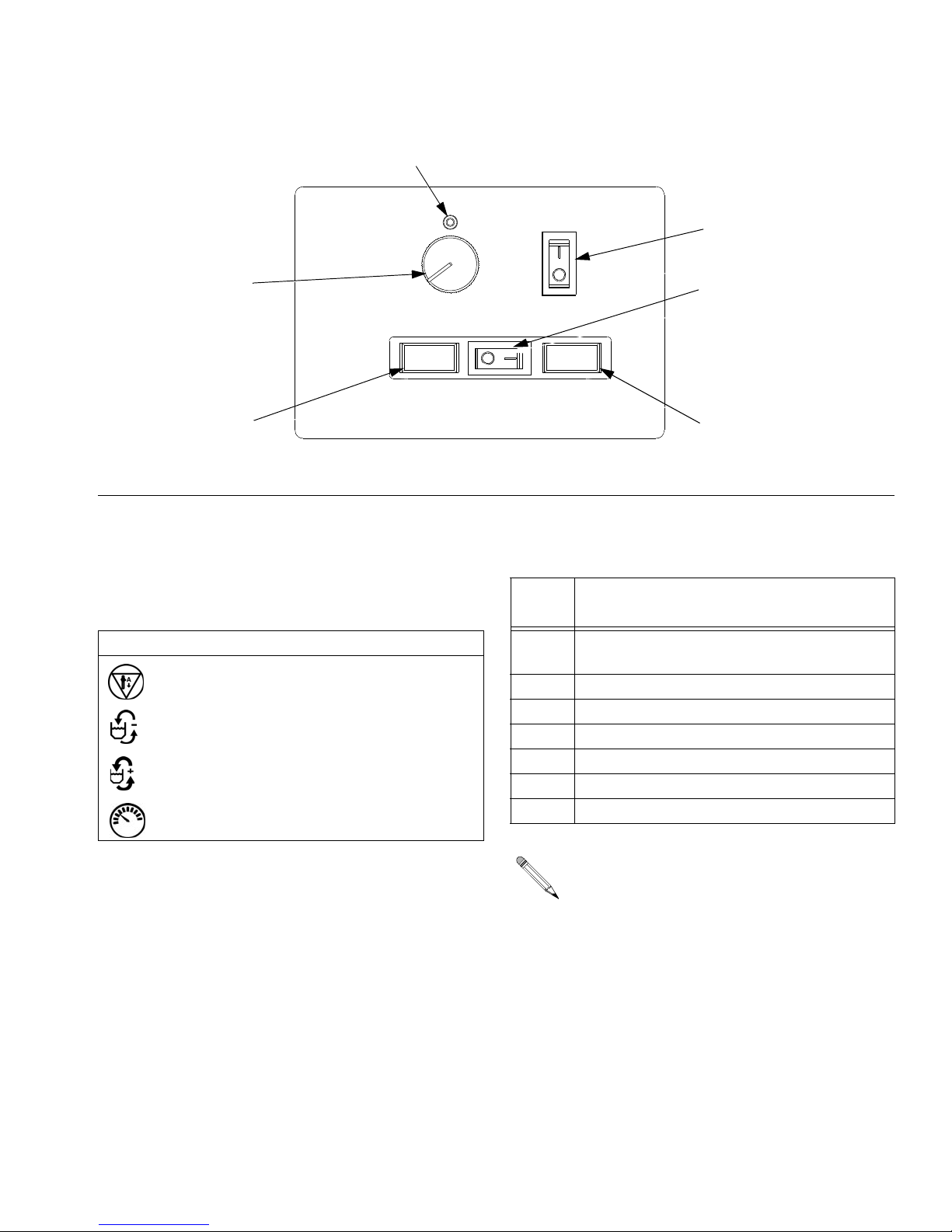

An electronic processor controls the motor, monitors

fluid pressures, and alerts the operator if errors occur.

See STATUS Indicator, page 9, for further information.

For models with a compressor: An air compressor pro-

vides and regulates air pressure for the spray gun.

The EnergyComplete Sprayer has two recirculation

speeds, slow and fast, and an adjustable pressure out-

put.

Slow Recirculation

• Slow circulation results in a higher temperature

transfer in the heater, so hoses and gun heat up

quicker.

• Good for touchup or low flow spraying, up to moder-

ate temperature.

• Not used to circulate full pails up to temperature.

Fast Recirculation

• Use to support higher flow rates or higher tempera-

tures by preheating the pails.

• Agitates fluid within pails, to avoid heating only the

fluid at the top of the pail.

• Use for flushing.

Pressure Adjust

Automatically maintains selected pressure output for

dispensing or spraying.

Keep Components A and

B Separate

Compatible Solvents

Use the following solvents for cleaning and flushing A

and B fluid.

EnergyComplete Air

Infiltration Barrier

Temperature

Requirements

Material Storage

EnergyComplete Air Infiltration Barrier A and B fluid

should always be stored between 40-110°F

(4.4-43.3°C). The A side fluid (white) will freeze below

32°F (0°C).

If the A side fluid freezes, stir until the temperature is

between 40-110°F (4.4-43.3°C).

Application

Ensure the temperature of the EnergyComplete Air

Infiltration Barrier A and B fluid is between 70-110°F

(4.4-43.3°C).

Note: Use EnergyComplete pail insulators when spray-

ing below 40°F (4.4°C).

Post Application

Ensure that the ambient air temperature where Energy-

Complete Air Infiltration Barrier has been sprayed

remains above 20°F (-6.66°C) for 1 hour after spraying.

Lower temperatures and higher humidities slow the cur-

ing process. The foam will not be resilient until it cures.

The foam will fully cure once warmer temperatures and

lower humidity levels return.

CAUTION

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A (white

fluid) and component B (red fluid) parts.

A and B Fluid Compatible Solvent

A side (white) Water

B side (red) Owens Corning B-Side Cleaner