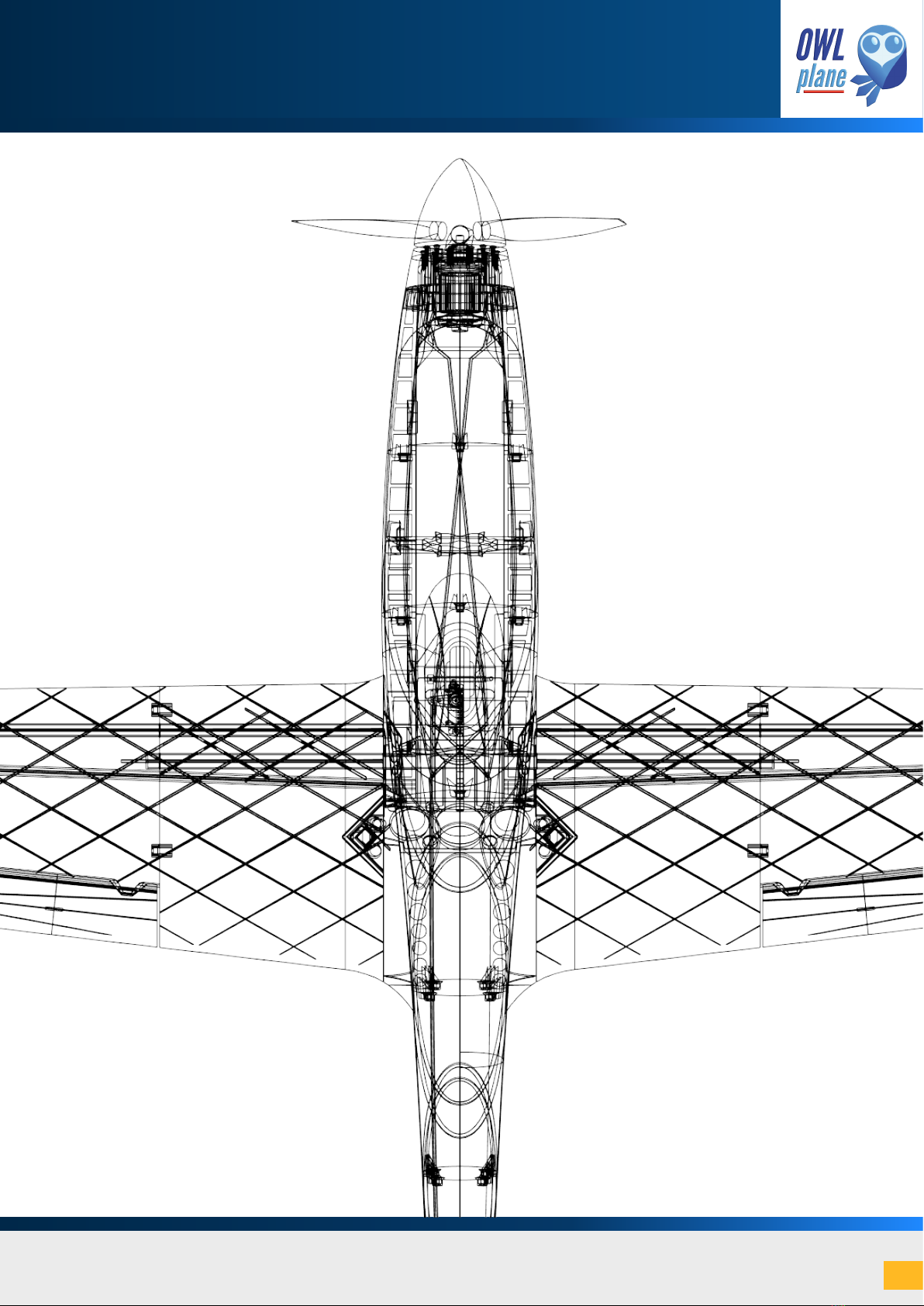

Print Your Plane As Many As You Like

Pre-Assembly Processes

OWLplane.com

Page : 2

Table of Content

Pre-Assembly Processes...............................................................................................3

Tools Used for Cleaning and Clearing Tolerance

Cleaning and Clearing Tolerance

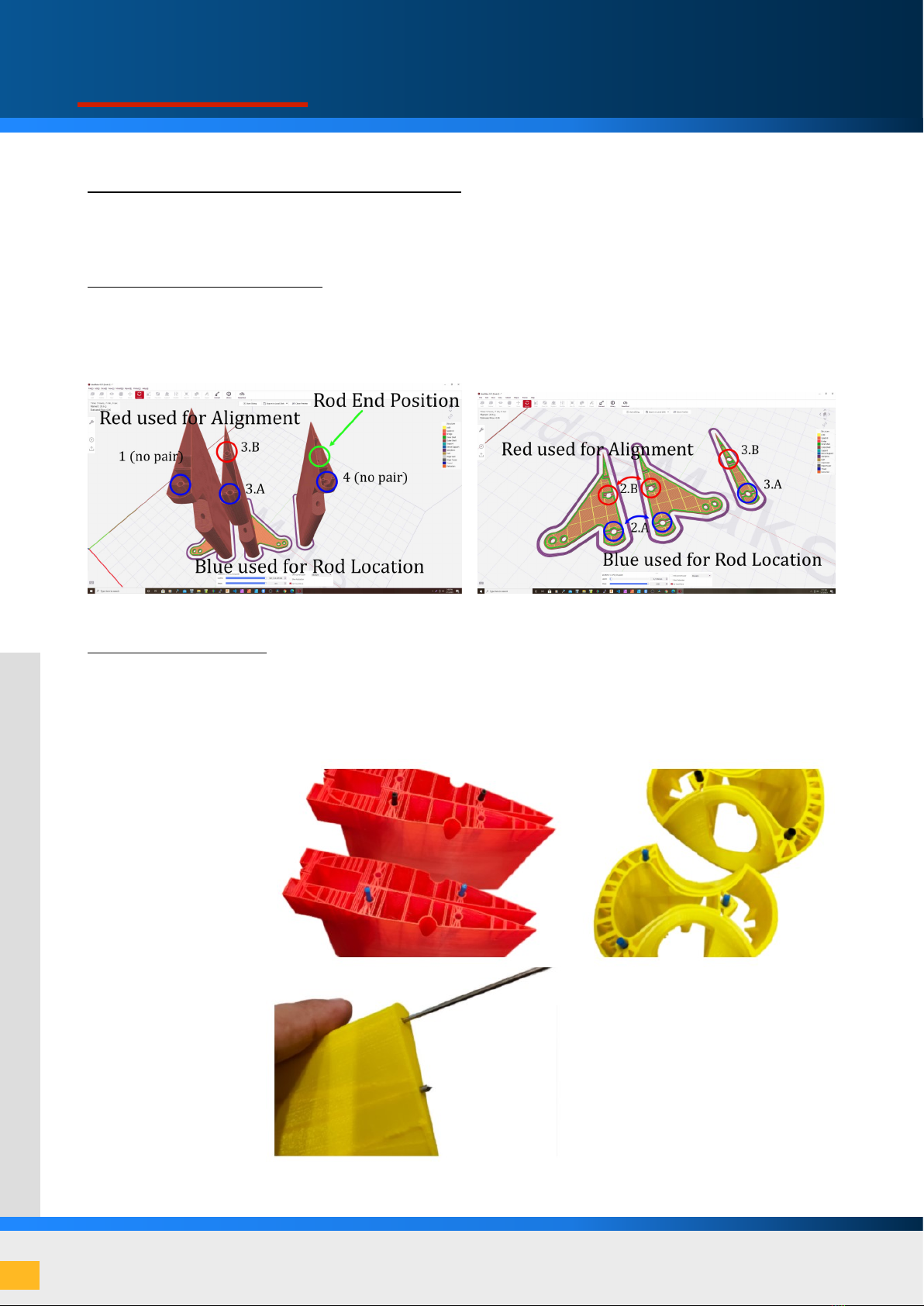

Finding and Checking Pin Position

Fuselage And Wing Assembly .....................................................................................8

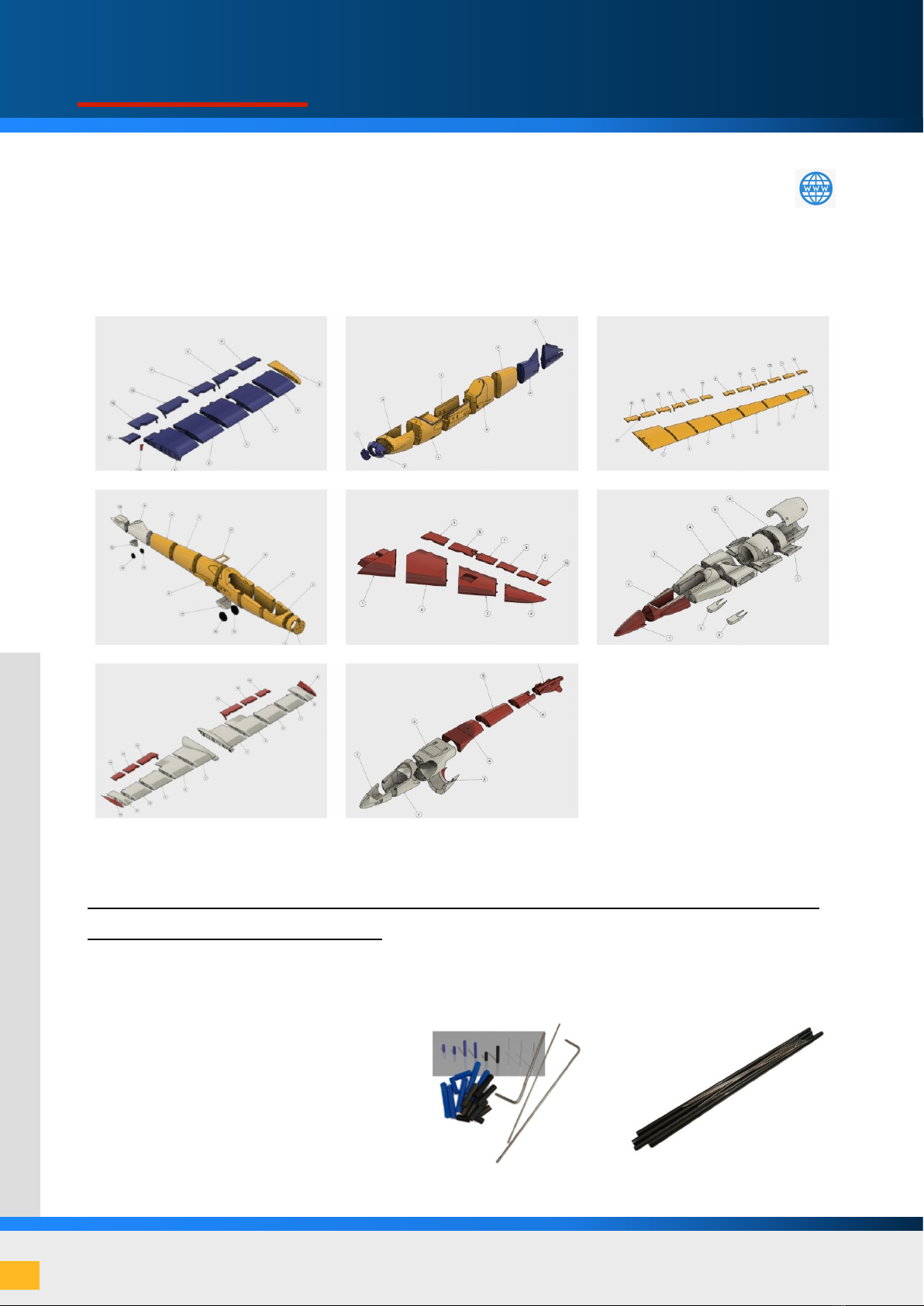

Preparing Required Hardware (Fiber Carbon Pin/3D Printed Plastic Pin and Fiber Carbon Spar)

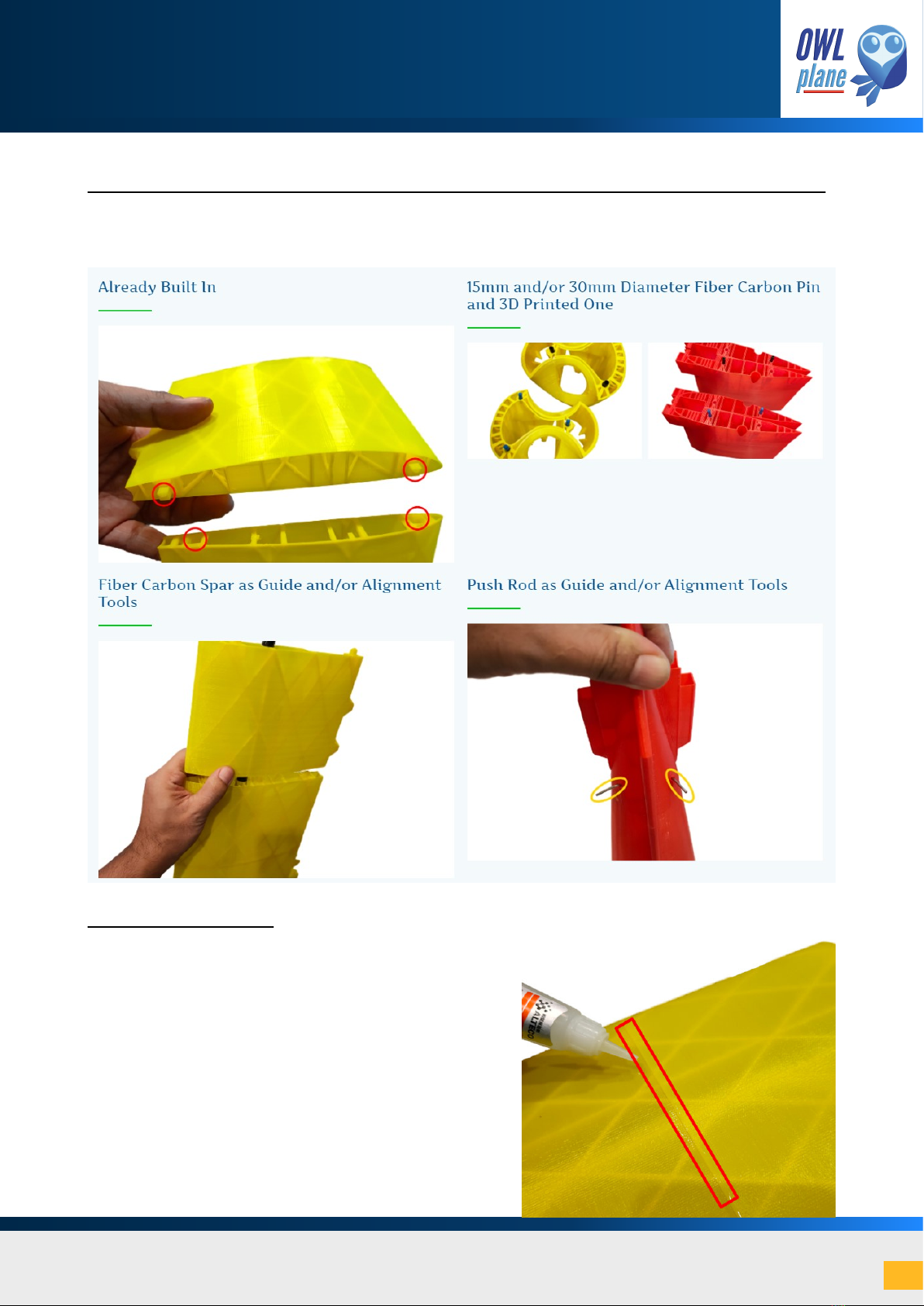

Guide and/or Alignment Tools or Mechanism for Fuselage and Wing

Gluing Two Parts

Wing And Fuselage Pin...............................................................................................10

3D Printed Plastic Pin

Screw, Nut and Washer

Stabilizer And Control Surface Assembly ...............................................................12

Preparing Pin and Rods

Guide and Alignment Tools and Mechanism

Gluing Two Parts

Canopy And Hatch Assembly ....................................................................................16

Parts, Spring and Pin

Inserting Spring and Latch

Gluing Printed Parts

Gears And Wheels Assembly .....................................................................................18

Preparing Gears and Wheels

Assembling Gears and Wheels

Placing and Locking The Battery..............................................................................20

Using Velcro Hooks and Loops

Plastic Holder for Double-Sided Hook and Loop

Servo Assembly ...........................................................................................................22

Preparing Pushrod and Parts

Installing and Assembling Servo and Push Rod using Servo Cover

Installing and Assembling Servo and Push Rod using Servo Bridge

EDF And Motor Mounting..........................................................................................26

Installing Outrunner Motor

Installing EDF Motor