OWL- LNS installation-90-0045-002 22/06/2011

© 2011 Owlstone Ltd Proprietary and Confidential Page 3 of 13

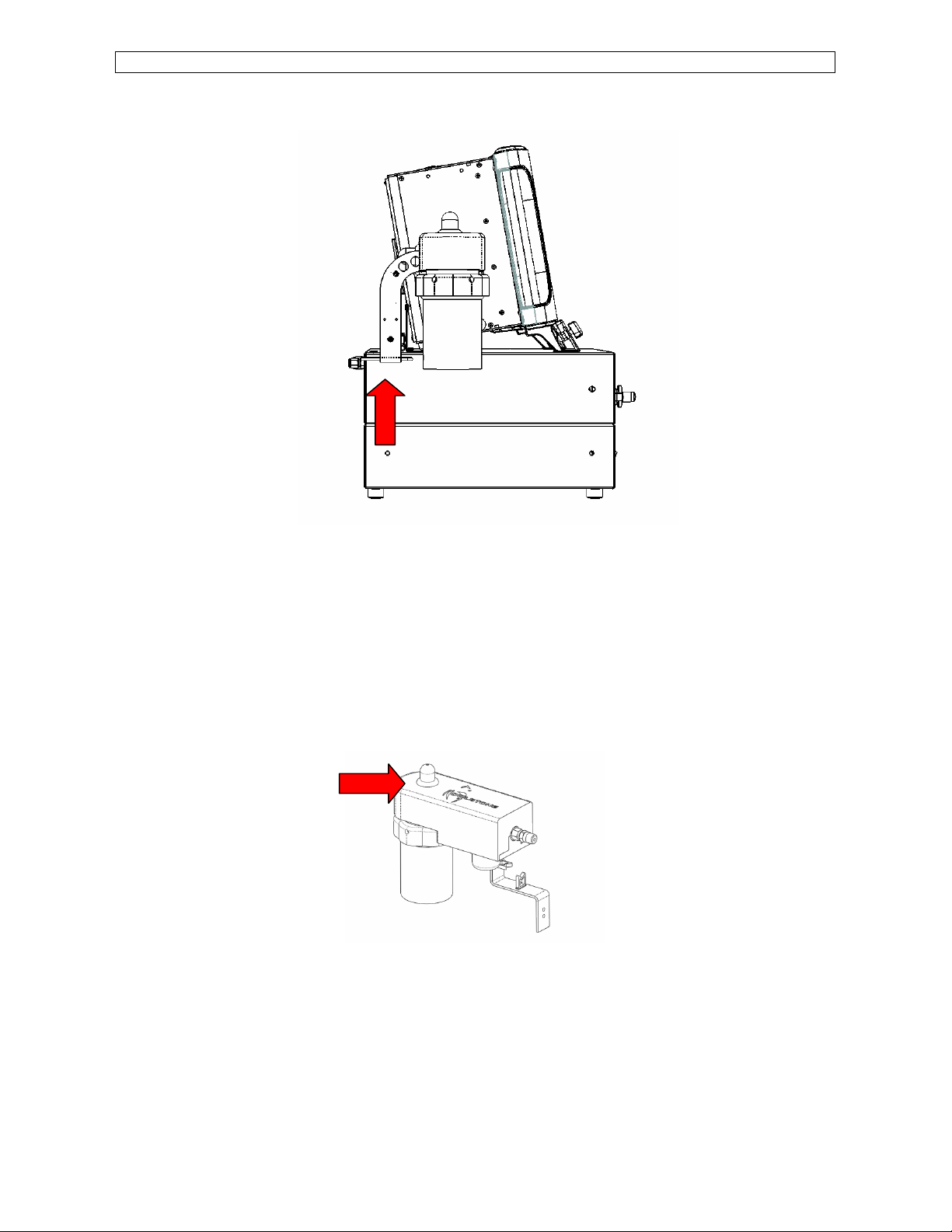

Check chemical compatibility: Materials in the flow path include PTFE, stainless steel, aluminium,

silicon, graphite, circuit board and Viton®. Ensure test atmospheres are neither corrosive nor

reactive with materials in the flow path. If in doubt please contact an OWLSTONE representative

using the contact details provided.

1.3 Installation and Location

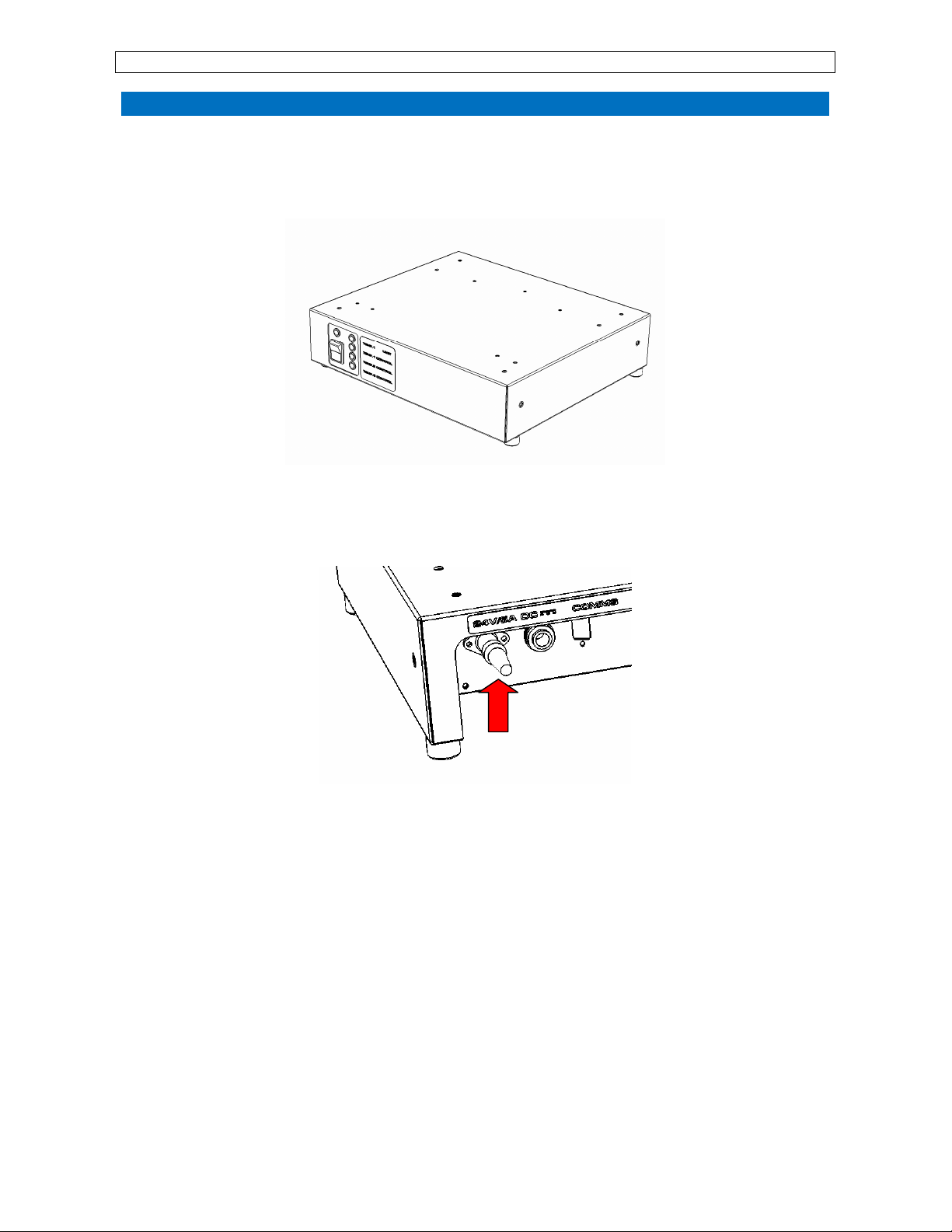

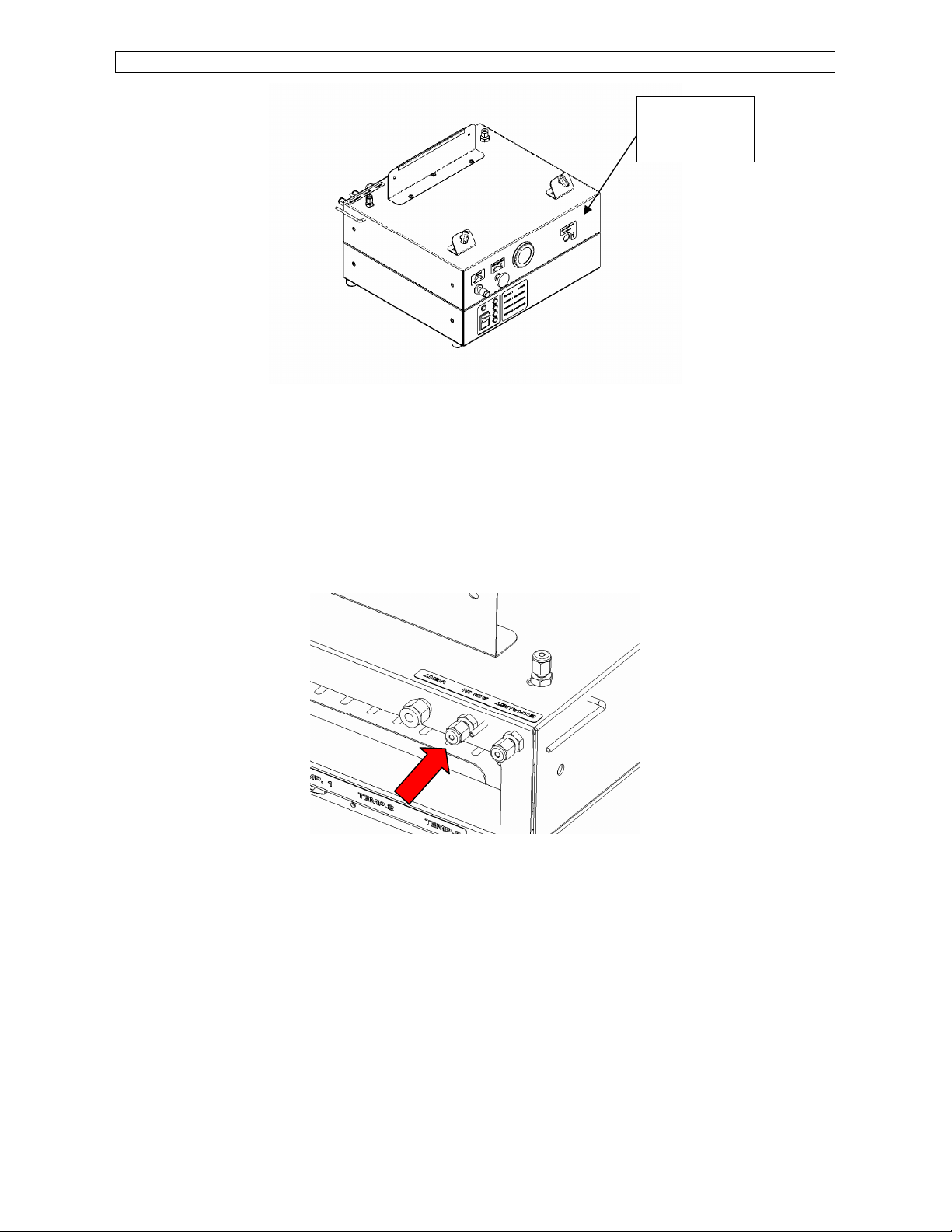

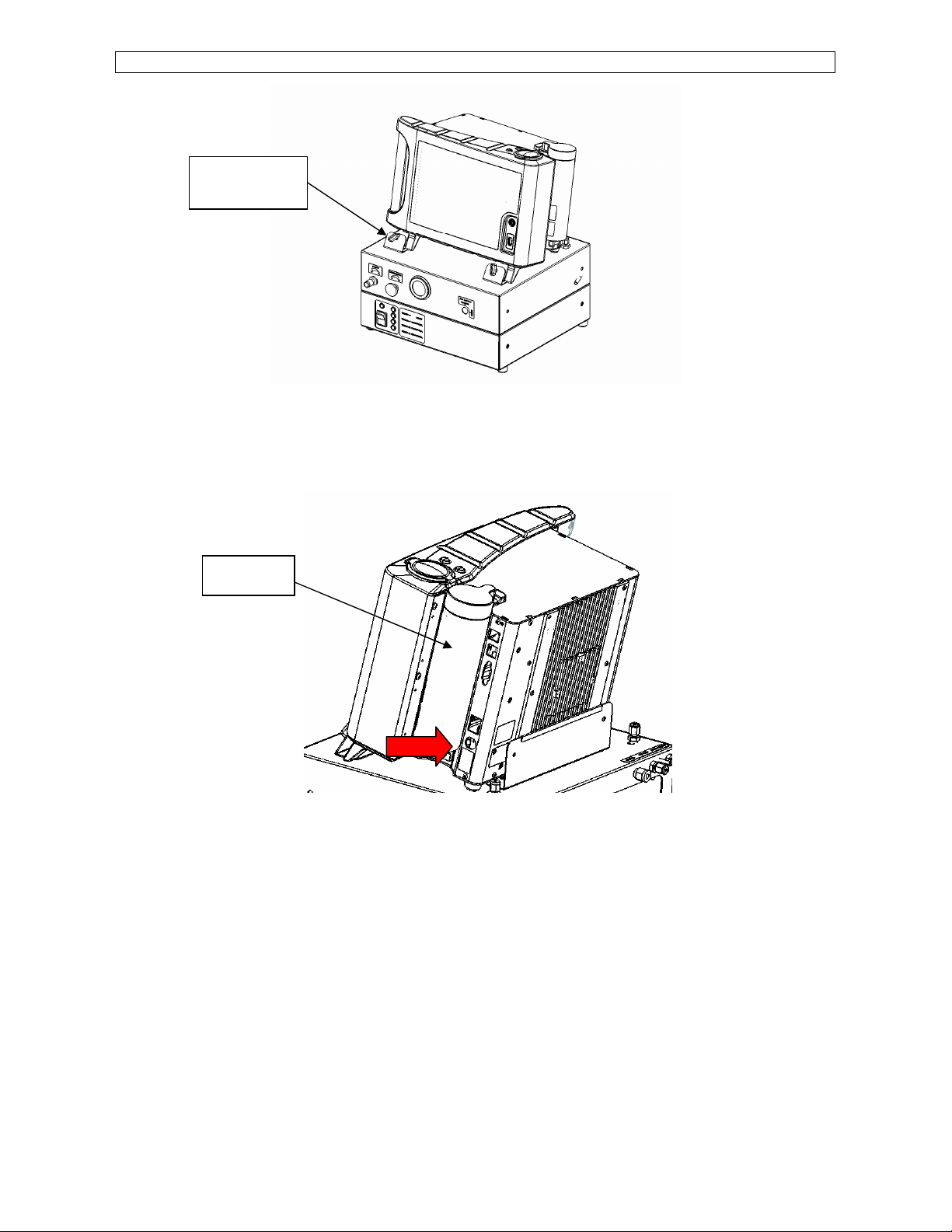

The LONESTAR and AT-LINE SAMPLING MODULE system together, unpackaged,

weighs ~20 kg; please take care in handling to avoid injury.

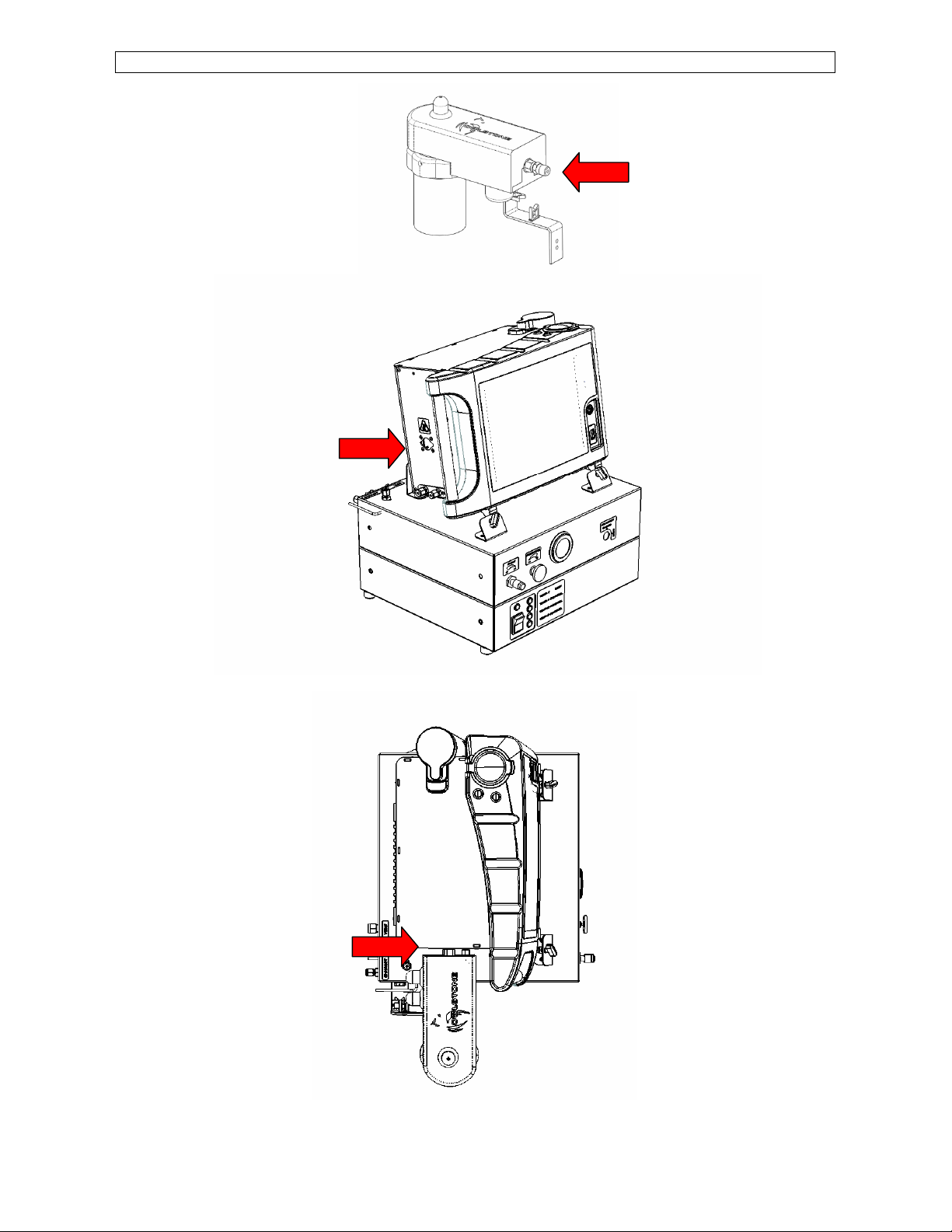

Before using the system, ensure that all power cables are intact with no

damaged insulation or frays.

•Ensure that the LONESTAR instrument and AT-LINE SAMPLING MODULE are placed on a

solid, level surface, which is able to support their weight

•Only use the OWLSTONE supplied power supply

•Ensure cabling is routed behind the system, at bench level, posing no risk of tripping.

Ensure all cables are detached from the LONESTAR instrument before attempting to move

the unit

•The LONESTAR instrument gets warm during operation. Handle with care and ensure there

is adequate ventilation around the system

•Do not place in space that is poorly ventilated or confined. Allow at least 50cm clearance

from walls and free flow of air around the system

•Do not place near flammable materials