DentalEZ Simplicity User manual

®

Installation, Operation & Care Manual

®

Simplicity

Cart

Duo

Doctor’s

Simplicity®Cart

1

Table of Contents

Section I Introduction

Specications............................................................ 2

Classications........................................................... 2

ExplanationofSymbols&Signs............................ 3

Dimensions............................................................... 3

ExplanationofPackagingSymbols ....................... 4

Packaging ................................................................... 4

Section II Pre-installation

UtilityServiceCenter ............................................ 5

PlumbingContractor'sProcedure................... 5-6

ElectricalContractor'sProcedure ...................... 6

Section III Installation

USCBase .................................................................. 7

UmbilicalConnection............................................. 7

CartLeveling ............................................................ 8

CartLid ..................................................................... 8

Assistant'sAccessories........................................... 8

FiberOptics-Electrical(Optional) .................... 9

SyringeTubing........................................................... 9

ExplanationofControlSymbols.......................... 9

Section IV Testing

DeliverySystem.....................................................10

FootControl&Handpiece ...........................10-11

Syringe .....................................................................11

FiberOptics(Optional) .......................................11

Section V Operation

DeliverySystem.................................................... 12

Handpiece .............................................................. 13

Syringe .................................................................... 14

FootControl/Chipblower................................14

FiberOptics(Optional) ......................................14

CleanWaterSystem............................................ 14

Section VI Care

Cleaning.................................................................. 15

Disinfecting ............................................................ 15

Section VII User Service

Information

DeliveryHead....................................................... 16

Handpiece ........................................................17-18

ServiceInstruction............................................... 18

DisposalofEquipment ........................................18

Section VIII Parts List / Diagrams

UtilityServiceCenter ......................................... 19

DeliveryHead/CleanWaterSystem.............. 20

Manifold.................................................................. 21

ControlBlock ....................................................... 21

CartReplacementParts ..................................... 22

FootControl ......................................................... 22

Air/WaterSyringe.............................................. 23

HVENozzle........................................................... 23

SENozzle............................................................... 23

Limited Warranty ........................................... 24

EMC Information ......................................25-28

Tubing Diagram

Simplicity®Cart

2 Installation,OperationandCareManual

Section I Introduction

This manual contains installation, operation and care

instructions and user service information for the

Simplicity®Cart Delivery Unit.

The Simplicity Cart is available in two standard con-

gurations: (1) Duo (doctor's and assistant's) instru-

mentation and (2) doctor's only instrumentation.

The Simplicity Cart Delivery Unit is intended to be

used by trained professional dental care personnel

as an interface device to connect the dental oper-

atory hand instruments to the appropriate supply

utility such as air, water, vacuum, drain and electrical.

It functions as a system management device that

provides a method of operating the hand instruments

from a single control input device.

The Simplicity cart, situated on wheels, positions

the handpieces for the optimum presentation to the

operator.

The Unit is designed to provide trouble-free service

when installed, operated and maintained according to

the procedures set forth in this manual.

To ensure correct installation, carefully read all

the procedure instructions contained in this

manual paying close attention to all notices,

notes, cautions and warnings.

Before proceeding, please review the photo below to

become familiar with the basic components of the Unit.

After the Simplicity Cart is installed, please review

the operation procedures and care guidelines with the

doctor's staff. Then leave this manual in the doc-

tor's ofce for future reference.

Utility Service

Compartment

Clean

Water

System

Doctor's

Controls

BASIC COMPONENTS

Work

Surface

Specications

Power Supply - 100-240V, 50-60 Hz., as applicable

Air Pressure - 551.6 pKa (80 PSI)

(at regulator in USC)

Water Pressure - 275.8 pKa (40 PSI)

(at regulator in USC)

Clean Water System -

Reservoir Capacity - 1.5 L

CMU Shipping Weight

Cart with transformer - 61.2 kg (135 lbs.)

Cart without transformer - 47.6 kg (105 lbs.)

Maximum Load for Cart Top - 0.453 kg (10 lbs.)

Recommended Environmental Conditions

– Environmental conditions for transport and storage:

- Relative humidity range within 0% to 95%

- Transport/storage temp. within -29ºC (-20ºF) to

74ºC (165ºF)

– Environmental conditions for operation:

- Conditioned Air

-

Atmospheric pressure range within 500 to 1050 kPa

- Operation temp. within 15ºC (59ºF) to 27ºC (80ºF)

Air and Water Inlet Temperature Range:

5ºC (41ºF) to 27ºC (80ºF)

Medical-GeneralMedicalEquipment

Certiedastoelectricalshock,re

andmechanicalhazardsonlyin

accordancewithUL60601-1,

CAN/CSA-C22.2No.601.1,

CAN/CSA-C22.2No.60601-1(2008)&

ANSI/AAMIES60601-1(2005).

Classications

0459

53HN

– Type of protection against electric shock: Class 1

Equipment

– Degree of protection against electric shock: Type B

Applied Parts. The handpiece is considered an applied part.

– Degree of protection against the ingress of water:

Ordinary

–Equipment not suitable for use in the presence of a

ammable anesthetic mixture with air or with oxygen

or nitrous oxide.

– Mode of operation: Continuous

These specications apply to model SP-A (doctor's

only instrumentation) and model SP-B (doctor's and

assistant's instrumentation).

Temperatures not within the air and water inlet

termperature range could cause damage to the unit.

CAUTION

Simplicity®Cart

3

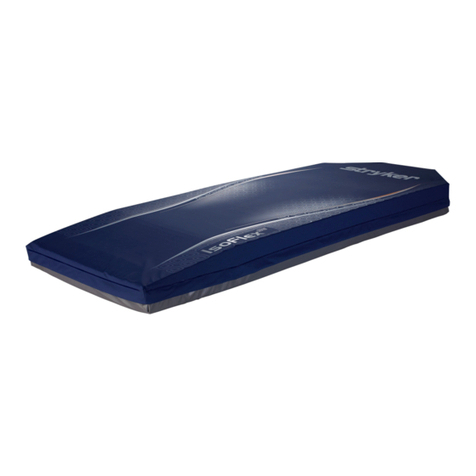

21-9/16"

14-7/8"

6-1/8"

16-5/8"

28"

19-1/4"

18-3/4"

3-5/16"

20"

Section I Introduction

Dimensions

UNIT FRONT

UNIT TOP

UNIT SIDE

TheauthorizedEuropeanrepresentativeis:

DentalEZ(GB)Ltd.,ClevelandWay

HemelHempstead,Hertfordshire,HP27DY,England

Phone:(01442)269301

Attn:Mr.JeffWhitehouse

=Caution

=Warning

=Biohazard

=WarningDangerousVoltage

=AlternatingCurrent

=DirectCurrent

=TypeBAppliedPart

=ProtectiveEarth(ground)

=GeneralMandatoryAction

=RefertoManual(followinstructions)

=EuropeanCertication

=SerialNumber

=ManufactureDate

=Manufacturer

Explanation of Symbols and Signs:

SN

●

In accordance with Part 15 of FCC rules, this

equipment was tested and complies with Class

A digital device limits. These limits are designed

to give equipment reasonable protection against

detrimental interference when operated in a

commercial environment.

●

Medical electrical equipment needs special

precautions regarding electromagnetic

compatibility (EMC) and needs to be installed

according to EMC information. (See EMC

Information, Pages 25 through 28.)

●

Mobile radio frequency (RF) communications

equipment can affect medical electrical

equipment.

NOTICE

Simplicity®Cart

4 Installation,OperationandCareManual

=BoxMustRemainUpright

=

DoNotPlaceBoxOnUnlevel

Surface

=DoNotStackBox

=

BoxContentsSafeTemperature

Range

=BoxContentsSafeHumidityRange

Packaging

The Simplicity Cart Delivery Unit components are

packaged and shipped according to the shipping con-

gurations on this page.

NOTE:

Be aware that some cartons are shipped with

packing inserts that may be empty (even if optional

components are ordered).

Please verify the Simplicity Cart components packag-

ing contents against the packing list.

Simplicity Cart Unit Carton Contents:

•Cart Assembly

• Utility Service Center (USC) Box

• High-volume Evacuator (HVE) & Saliva

Ejector (SE) Components (Duo only)

• Utility Components (if ordered)

• Literature Assembly

• Utility Supply Bag:

- Elbow Fitting

- Adaptor Fitting

- 90 Deg. Valves (2)

- Adaptors (2)

- Fitting Assembly

- #10 x 1/2 Screws (4)

- Actuator Valve Assembly

• Assistant's Arm Supply Bag (Duo only):

- HVE Aseptic Sterling Tubing

- SE Sterling Tubing

- HVE Handle Valve

- SE Handle Valve

- Disposable Solid Trap Pkg. Assembly

Section I Introduction

SHIPPING CONFIGURATION

Cart

Assembly

Option Box

Insert

Foot

Control Box

USC Box

Pallet

Installation by an authorized DentalEZ dealer service

technician is recommended.

NOTICE

Do not modify the Simplicity Cart without permission

from DentalEZ.

WARNING

For any questions about an order, please

contact a DentalEZ Equipment customer service

representative at 1-866-DTE-INFO.

NOTICE

Do not position equipment so that it is difcult to

unplug the unit from the power receptacle.

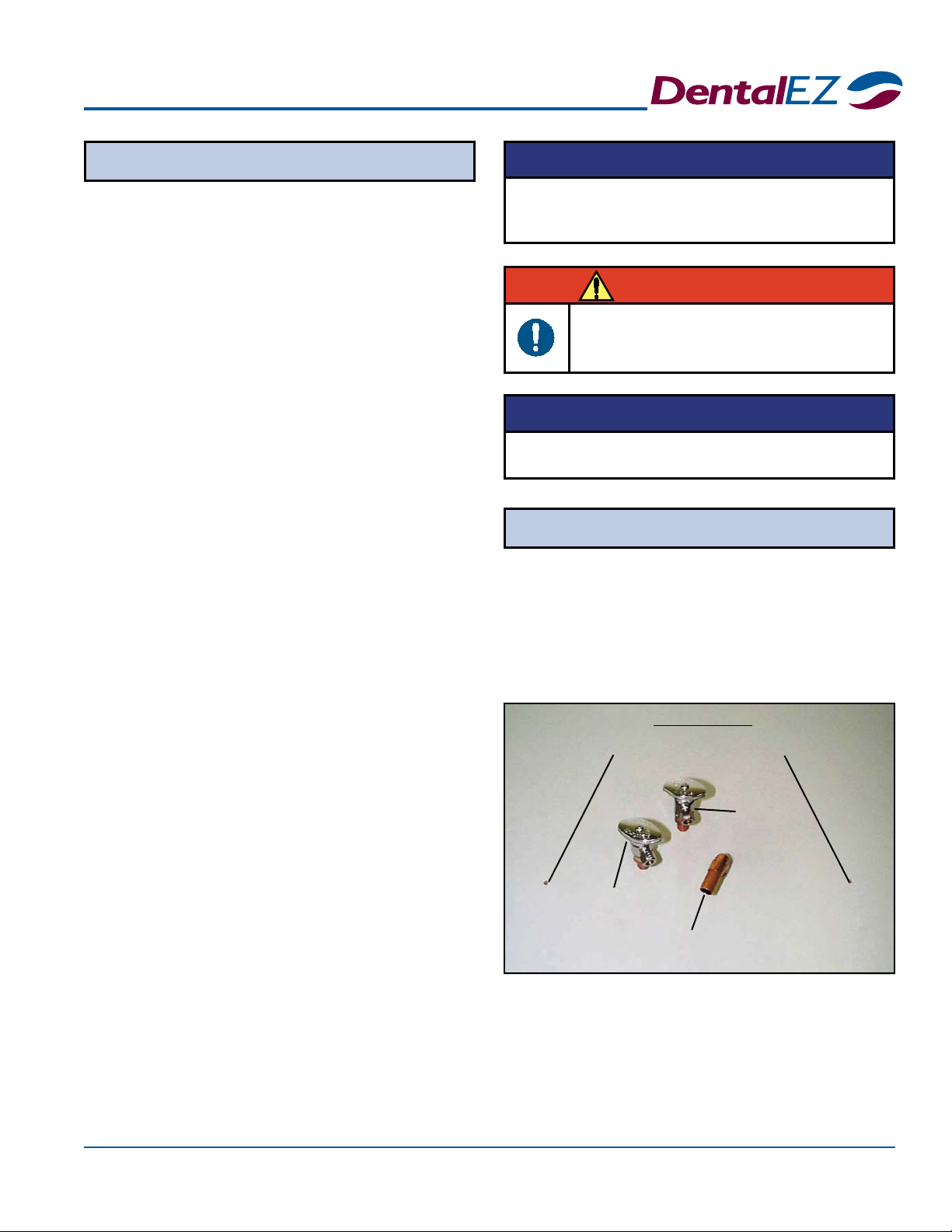

WARNING All parts supplied are necessary for proper installa-

tion, so be sure not to discard any hardware or com-

ponents until installation is complete.

-29ºC

(-20ºF)

74ºC

(165ºF)

0%

95%

-29ºC

(-20ºF)

74ºC

(165ºF)

0%

95%

-29ºC

(-20ºF)

74ºC

(165ºF)

0%

95%

-29ºC

(-20ºF)

74ºC

(165ºF)

0%

95%

-29ºC

(-20ºF)

74ºC

(165ºF)

0%

95%

Explanation of Packaging Symbols:

Simplicity®Cart

5

Section II Pre-installation

Utility Service Center

USC Carton Contents:

• Utility Service Center (USC)

•USC cover

• USC base (oor plate)

•USC Template

• Bag of supplies:

-Two #6 x 3/8" screws

-Four #10 screws

-Two adaptors

- Four plastic anchors

- 1/8" tubing barb

- Plug cap

- Two 1/8" tubing clamps

- Five 1/4" tubing clamps

-Elbow assembly

- Elbow tting

- Four 6-32 x 1/2" screws

- Four 6-32 nuts

- Pin housing, three position

- Two coupler ttings

- Air tting assembly

-Two stop valves

-Water actuator valve assembly

-Washer

NOTE: Set the USC cover aside until all installation

and testing is complete.

NOTE: For wood or metal oors, drill 5/32" holes.

For concrete, drill 1/4" holes and install plastic anchors.

USC Base Mounting Holes

Air Stop

Valve

Water

Stop

Valve Vacuum

Elbow

WALL SIDE

Plumbing Contractor's Procedure

1. Remove the full-size USC template found in

the USC Carton.

2. Position the USC template according to the

exact layout indicated, making certain correct

distance from base to chair is maintained.

3. Using the USC template, drill two mounting

holes for the USC base. But do not secure the

base to the oor at this time.

(Typical Layout)

1. Open the USC bag of supplies.

2. Using the USC template, stub the utilities

through the oor and orient as shown in the

template. (Vacuum and drain ttings not supplied.

Refer to the USC template for requirements.)

Before proceeding with plumbing

installation, comply with and maintain all

applicable utility codes and regulations.

WARNING

DO NOT DISCARD the USC template after use.

Neatly refold it and place it in the back of this

manual.

NOTICE

For reference, a color-coded tubing diagram is

included with this manual.

NOTICE

Simplicity®Cart

6 Installation,OperationandCareManual

Section II Pre-installation

The electrical contractor is to provide a covered

115/220 VAC receptacle which meets all applicable

utility codes and regulations.

For the recommended location of the 115/220 VAC

receptacle, see the USC template.

NOTE: If the recommended location is not met, the

USC base may interfere with the 115/220 VAC

receptacle.

Air Fitting

Assembly

Water Actuator

Valve

Assembly

Electrical Contractor's Procedure

NOTE: Pay close attention to the orientation of the

template to the wall.

3. Sweat the valve adaptors to the air and water

stubs.

4. Apply the appropriate thread sealant to the

valve adaptors and install the stop valves.

5. Sweat the vacuum elbow to the stubs.

6. Sweat the hose connectors to the elbows

as applicable and orient as shown in the

template.

7. Flush the air and water lines to remove trash

and debris from the lines.

8. Connect the water actuator valve assembly to

the water stop valve as shown in the template.

Using a 5/8" open-end wrench, tighten the

nut securely.

9. Connect the air tting assembly to the air

stop valve as shown in the template. Using

a 5/8" open-end wrench, tighten the nut

securely.

(Typical Layout)

Before proceeding with electrical installation,

all wiring must be in accordance with NEC

and local electrical codes.

WARNING

Electrical contractor's parts are not supplied.

NOTICE

Rating of main circuit breakers should be 20 Amp

maximum.

CAUTION

WARNING

To avoid the risk of electrical shock, this

equipment must only be connected to a

supply mains with protective earth.

WARNING

Isolating the unit from the supply mains is

accomplished by unplugging the unit from the power

receptacle.

NOTICE

Do not connect items that are not part of the system

to the cart.

WARNING

Only use power supplies that are supplied by

DentalEZ as part of the Simplicity Cart.

Simplicity®Cart

7

Section III Installation

USC Base

Umbilical Connection

1. Position the USC base over the two mounting

holes that were drilled during pre-installation.

2. Secure the base using two #10 screws.

1. Attach the red incoming air pressure line to

the air tting assembly using the compression

tting supplied.

3. Trim the 5/8" vacuum line. Then install the

5/8" vacuum line on the vacuum elbow.

4. Slide a 1/8" tubing clamp onto the yellow

signal air line from the umbilical. Connect

this line to the water valve/actuator.

5. Open the air stop valve and check for leaks.

2. Slide a 1/4" tubing clamp onto the red air

line from the umbilical. Connect this line to

the remaining 1/4" barb on the air regulator

assembly.

5/8"

Vacuum

Line

Incoming Green Water Line

Green Line

Marked "W"

Water

Regulator

●

Before making tubing connections, use soap to

lubricate all in-line barbs and lines.

● After making each connection, secure by sliding

an appropriate size tubing clamp over the barb/

tube connection.

NOTICE

If the city water option was ordered, follow the

instructions included with the kit.

NOTICE

(Typical Layout)

Red Incoming Air

Pressure Line

Yellow

Signal

Air Line

Red Air Line from Umbilical

Water

Stop

Valve

Air

Stop

Valve

Water Valve/

Actuator

(Typical Layout)

Simplicity®Cart

8 Installation,OperationandCareManual

Section III Installation

Cart Leveling

1. Make sure the cart is on a level oor (Move the

cart to a level location if necessary.)

2.

Close the top cover of the cart. Then check the

side to side and front to back level of the top.

3. If leveling is necessary, loosen the four

mounting (3/8-16) screws and turn the

appropriate leveling set (1/4-20) screw.

4. When the top is level, re-tighten each mount-

ing screw.

Cart Lid

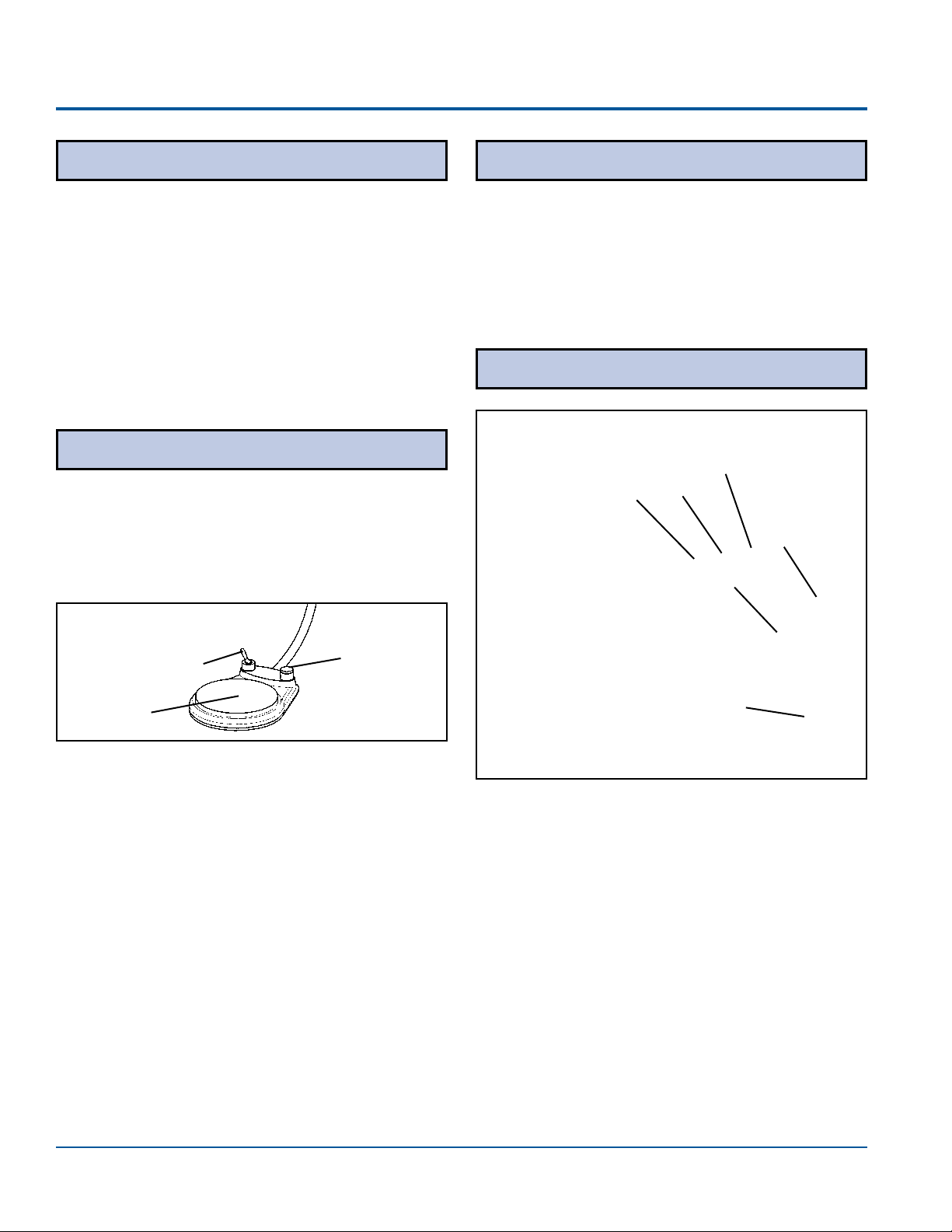

Saliva Ejector(SE)

1. Connect the SE

valve to the 5/16"

O.D. tubing.

Closed

1/2" Port

5/16" O.D.

SE Tubing

Connects

Here

Instrument

Holder

High-Volume Evacuator (HVE)

1. Connect the

HVE valve

to the 5/8"

O.D. tubing.

2. Hang the HVE valve in the instrument holder.

3.

Connect the tubing to an open 1/2" port under

the solids collector located under the cart.

4. If an optional second HVE valve is used, do

the following:

a. Insert a sharp, pointy object into the

closed 1/2" port under the solids

collector and create a smooth opening.

b. Repeat Steps 1 through 3.

Air / Water Syringe(Optional)

NOTE: Connections for the optional air / water

syringe are factory installed.

2. Hang the SE valve in the instrument holder.

3.

Connect the tubing to the open 1/4" port

under the solids collector in the assistant's arm.

Leveling

Set Screw

Mounting

Screw

Assistant's Accessories

1. To open the cart lid, unscrew the lid screw

located under the cart's chassis.

2. The lid is now free to open and close.

3. When the lid is closed, screw in the lid screw.

Lid

Screw

SE Valve

HVE Valve

5/16" O.D.

Tubing

5/8" O.D.

Tubing

5/8" O.D.

HVE

Tubing

Connects

Here

5/8"

Vacuum

Line

Connects

Here

Simplicity®Cart

9

Fiber Optics - Electrical(Optional)

Syringe Tubing

Section III Installation

1. Hang the syringe in the holder.

2. Connect the air and water lines to the

appropriate male and female connectors in the

delivery head chassis.

NOTE: If the optional ber optics were included in

the original order, electrical connections have been made

inside the delivery head at the factory. Plug the ber

optic transformer into the outlet and the harness from the

cart umbilical.

=ON(Power)

=Standby(Power)

=Water

=NoWater

=Flush

=ChipAir

=WaterBottle

=CityWater

=HandpieceDrive(Air)

=CoolantAir

=CoolantWater

=Variability

Explanation of Control Symbols:

Simplicity®Cart

10 Installation,OperationandCareManual

1. Pull the locking knob and turn the adjustment

knob on each regulator until the correct

pressure reading is reached.

2. When nished, push the locking knob down.

Section IV Testing

Coolant Water Lines

Utility Service Compartment

1. Turn on all services supplying the USC.

2. Open the air and water manual stop valves by

turning the knobs counterclockwise.

3. Inspect all joints and connections for leaks.

4. Plug the power cord from the ber optics into

an electrical outlet.

5. Turn the master switch ON.

6. Inspect for leaks in the service console and

delivery head.

Air and Water Filter/Regulators

If the regulators are not set at 551.6 pKa (80 PSI) for

air and 275.8 pKa (40 PSI) for water, do the following

adjustment process:

Delivery System

Foot Control & Handpiece

WET/DRY

Toggle Valve

Wet

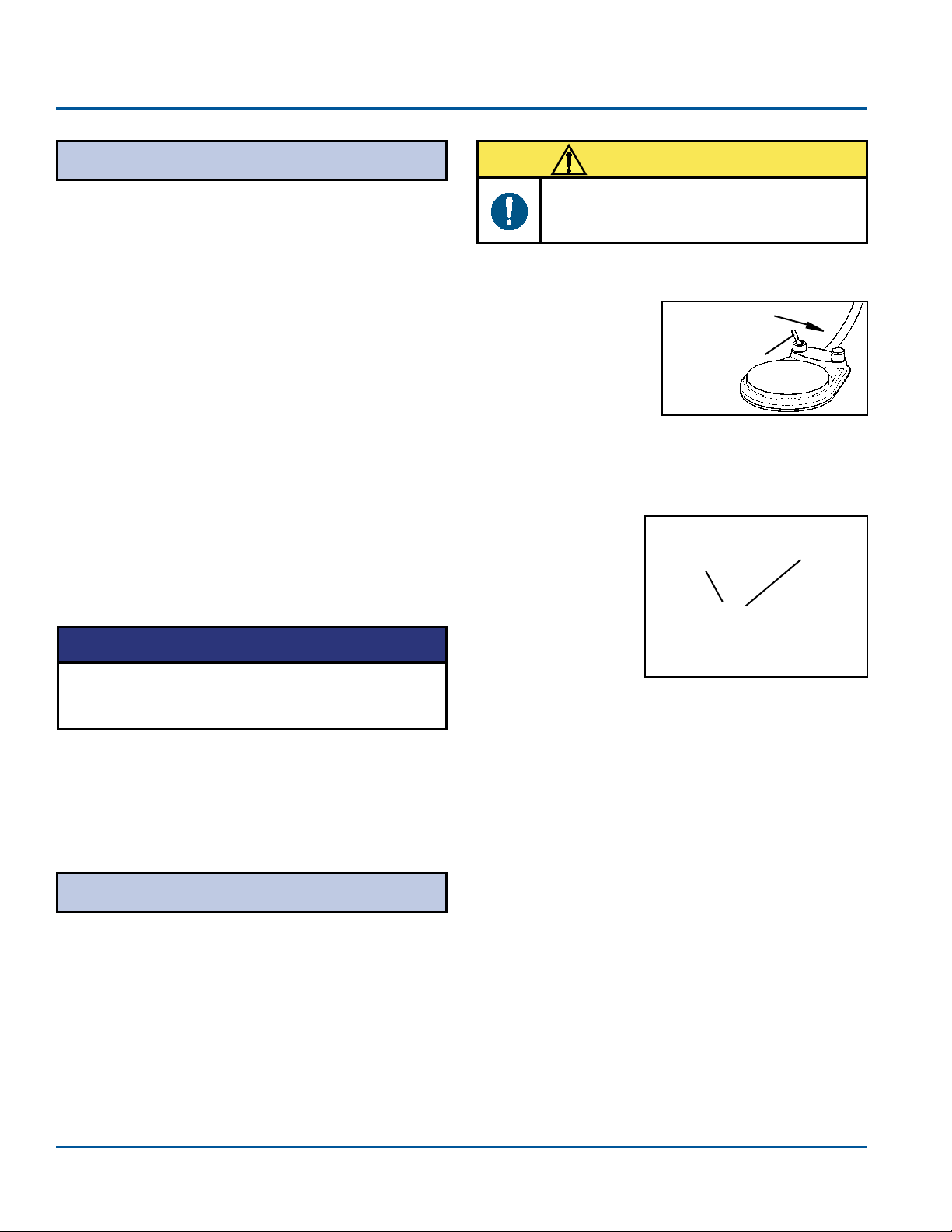

1. At the foot

control, ip the

toggle valve to

WET.

2. Purge air from the coolant water lines for each

handpiece as follows:

a. Make sure master switch is in ON

position.

b. Open

the water

coolant

valve to

the full,

open

position.

c. Pick up a handpiece tubing and lay the

end into a sink or cuspidor bowl.

d. Simultaneously depress the foot control

disc and hold the ush valve, located in

the back of the delivery head, in the ush

position. Let water ow until all air has

escaped.

e. Return the handpiece tubing to its holder.

f. Repeat steps c. through e. for each

additional handpiece tubing.

Water

Coolant

Valve

Master

Switch

Chipblower

If the handpiece utilizes coolant air, a burst of air

should be delivered to the handpiece when the chip

air valve on the foot control is depressed.

Before utilizing handpieces, all air must be

purged from the coolant water lines to allow

the system to function properly.

CAUTION

The air regulator is factory preset to deliver 551.6

pKa (80 PSI). The water regulator is preset to deliver

275.8 pKa (40 PSI).

NOTICE

Simplicity®Cart

11

Section IV Testing

Air Pressure

1. Flip the toggle valve to DRY at the foot

control.

2. To adjust the individual handpiece drive air

pressure to the manufacturer's specications

do the following procedure:

a. Remove the handpiece from its holder.

b. Hold the handpiece, fully depress the

foot control and observe the amount of

air pressure delivered to the handpiece

indicated on the drive air pressure gauge

located on the side of the cart.

c. Locate the air pressure adjustment screws

on the bottom of the delivery head

chassis.

If the unit is equipped with a syringe, rst depress the

air button and then the water button to test the ow.

Syringe

Air Pressure

Adjustment

Screws

d. Turn the air pressure adjustment screw

on the control valve of the appropriate

handpiece (counterclockwise to increase

pressure, clockwise to decrease pressure) until

the handpiece manufacturer's correct

specication registers on the pressure

gauge.

3. Repeat a. through d. in Step 2 to set the

pressure for each handpiece.

NOTE: If a low-speed handpiece is required, slide the

pinch clamp over the appropriate water line going through

the pinch valve.

Follow the test procedures outlined in the instructions

included in each ber optic handpiece package.

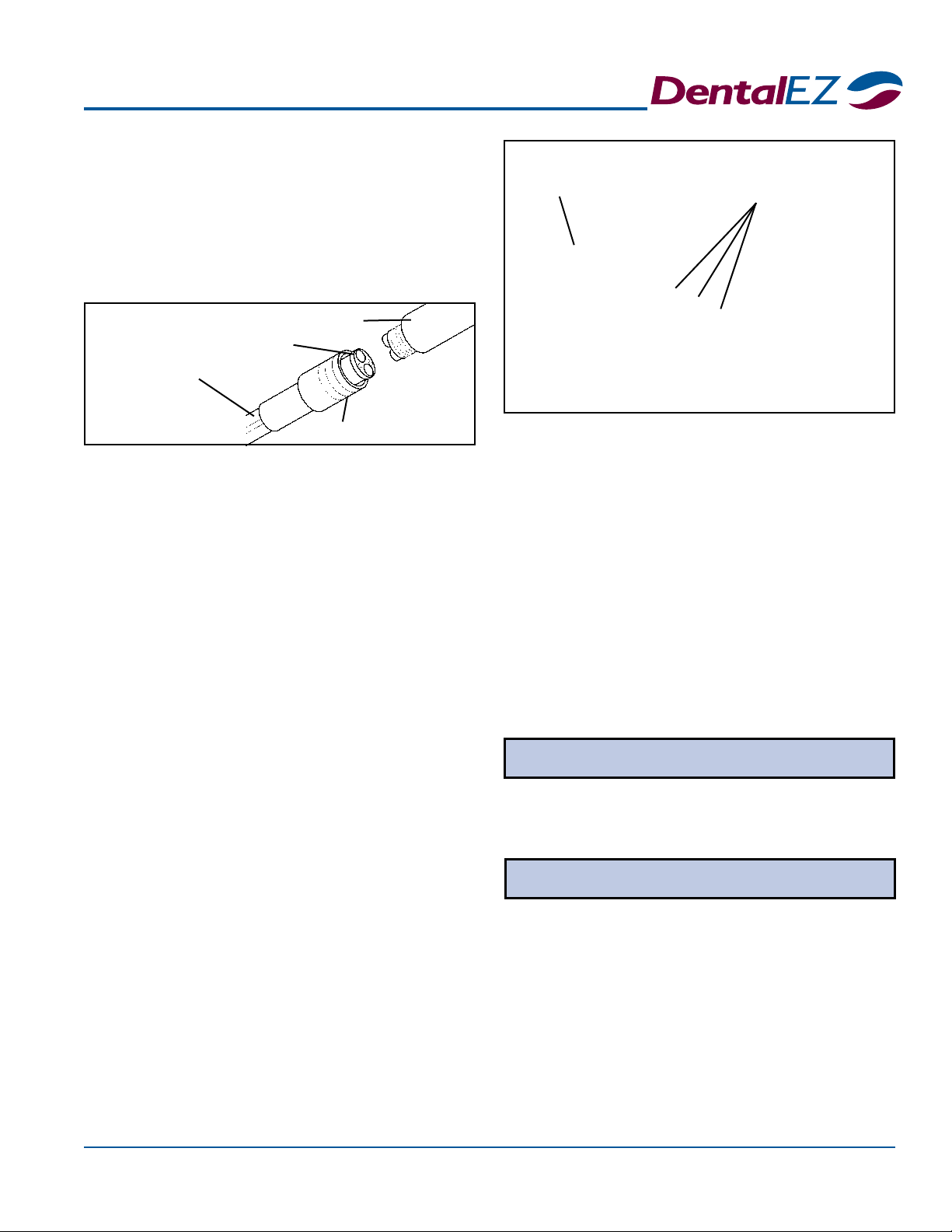

Fiber Optics(Optional)

Tubing

Adaptor

Handpiece

Nut

Drive Air

Pressure

Gauge

3. Attach the handpiece to the tubing as follows:

a. Slide the connector nut down along the

tubing to expose the handpiece adaptor.

b. Carefully align and insert the handpiece

base into the adaptor. Then replace and

tighten the connector nut.

Simplicity®Cart

12 Installation,OperationandCareManual

Section V Operation

Instrument Hanger

•An automatic CUT OFF, can be demonstrated

by placing tubing in the hanger and disabling

operation for that position.

Some of the Simplicity Cart Delivery Unit design

features:

•Operation of three handpieces and a syringe.

•Drive air may be adjusted individually for each

handpiece.

•

An automatic cut-off valve in each handpiece

holder section disables operation for that position.

•

Foot control toggle valve allows wet or dry cutting.

•Master switch turns entire unit ON and OFF.

Delivery System

Master Switch

Oil Collector/

Filter Cover

Screws

• Each handpiece holder angle can be adjusted by

using an Allen wrench to loosen two set screws

in the back of each section and rotating it to the

desired angle; then re-tightening the screws.

• An oil collector/lter is designed to collect oil

from the handpiece exhaust air. Once a week,

check the lter for cleaning or replacement by

removing the two screws that secure the lter

cover.

Hanger

Bar

Handpiece

Holder Section

Automatic

Cut Off

Valve

Master Switch

The master switch controls the ON/OFF function

of air, water and electricity to the entire unit. Flip the

master switch to turn ON the unit.

Drive Air

Water Adjustment

Water Outlet

Air Outlet

VERY IMPORTANT: At the end of each work day

and anytime the unit is unattended, make sure the

master switch is in the OFF position.

CAUTION

To prevent possible injury because of accidental

operation, do not leave young children unattended.

WARNING

Simplicity®Cart

13

Section V Operation

Handpiece

Coolant Water Adjustment

•Coolant water spray to all the handpieces can

be turned ON or OFF using the toggle switch

located on the foot control.

• The coolant spray volume is regulated for each

handpiece by using the coolant water adjustment

valve located on the side of the delivery head.

• While operating a handpiece, turn the coolant

water adjustment valve counterclockwise (while

looking directly into valve) to increase the volume of

coolant water spray. To decrease volume, turn

the valve clockwise.

Air Pressure

Air pressure to each handpiece can be adjusted to

the manufacturer's specications by following the air

pressure instructions in Section IV Testing under the

heading Air Pressure on Page 11.

NOTE: These procedures must be done while:

•The master switch is in the ON position,

•The handpiece is out of its holder and

•The foot control is fully depressed.

NOTE: When making necessary air pressure

adjustments, refer to the air pressure gauge located at the side

of the cart to check the approximate amount of air pressure

delivered to the handpiece.

Coolant Water

Adjustment Valve

Air Pressure

Adjustment

Screws

Air Pressure

Gauge

Flush System

It is recommended that the tubing of each handpiece

used be ushed after each patient.

1. Hold the handpiece tubing over a sink,

cuspidor or open vacuum line.

2. Move the FLUSH valve located on the side

of the delivery head to the right and hold it

there for 20 seconds.

NOTE: Flushing the water line in the handpiece can be

done by operating the FLUSH valve while either fully

depressing or not depressing the foot control.

Flush

Valve

Simplicity®Cart

14 Installation,OperationandCareManual

Clean Water System

•To operate the clean water system, the master

switch must be ON.

• Flip the bottle toggle switch (A) to the ON po-

sition.

• Adjust the regulator valve (B) to 275.8 pKa (40

PSI). This will be shown on gauge (C).

• If optional city water is in use, ip the supply

toggle switch (*D) to change from city to bot-

tled water.

• To remove the bottle, ip switch (A) to the OFF

position, then unscrew it from the assembly.

A

B

*D (Optional)

Water

Bottle

C

Section V Operation

Foot Control / Chipblower

Syringe

Chipblower

Valve

Button

WET/DRY

Toggle

Valve

Disc

• Full pressure on the disc causes the handpiece to

operate at full speed.

NOTE: The coolant water spray ON/OFF function

is also controlled by using the toggle valve on the foot control

as described above.

The speed of the handpiece is controlled by depressing the disc

located on the foot control.

• A light pressure on the foot control disc causes a

slow speed.

Fiber Optics (Optional)

If the handpiece utilizes coolant air, the chipblower

feature is used to blow debris away from the cutting

site by creating an air blast through the handpiece

without causing the burr to rotate. To operate the

chipblower, depress and hold down the valve button

on the upper right of the foot control.

The syringe is designed to deliver air or water, or a

mixture of air and water, as required.

•To deliver water only, press the button on the

syringe marked with a water drop symbol.

• For air only, press the button on the syringe with

no marking.

• To get a spray mixture of air and water, press

both buttons simultaneously.

The ber optics control is automatically activated by

operating the handpiece using the foot control.

NOTE: When the foot control is released, the ber optics

light will stay on for approximately ten seconds to allow

inspection of the cutting site.

Flush

Simplicity®Cart

15

Section VI Care

Cleaning Disinfecting

The Simplicity Cart Delivery Unit should be cleaned

as follows:

•Wipe frequently with a damp, lint-free cloth.

• Use a mild detergent to clean stains.

• At the end of the day, ip the master switch to

the OFF position and clean the instrumentation.

• Each morning, ip the master switch to the ON

position and check the air and water system for

proper operation using the three-way syringe.

Liquid disinfectants are recommended for use on all

external surfaces and should be applied using a soft,

clean cloth.

Use extreme caution when selecting the proper

chemical disinfectant for the delivery unit.

NOTE: *Cavicide™is the recommended disinfectant for

use on all external surfaces.

*Cavicide™ is a trademark of Micro Aseptic Products, Inc.

Avoid using disinfectants in spray containers

because they may cause premature staining,

discoloration and/or damage to the Simplicity Cart

Delivery Unit.

CAUTION

SlugBusterTM solution and cleaning brushes for

assistant's instrumentation can be ordered through

DentalEZ dealers.

NOTICE

Do not use abrasive cleaning agents.

CAUTION

CAUTION

Do not use disinfectants that contain any of the

following:

• Iodophors • Glutaraldehydes

• Phenols • Sodium Hypochlorites

• Alcohol on plastic surfaces

Clean outside surfaces of tubing with a non-alcohol

based cleaner/disinfectant only. Use of an alcohol

based cleaner/disinfectant will discolor tubing.

CAUTION

Simplicity®Cart

16 Installation,OperationandCareManual

Section VII User Service Information

A full-color tubing diagram of the Simplicity Cart

Delivery Unit system is located at the end of this manual.

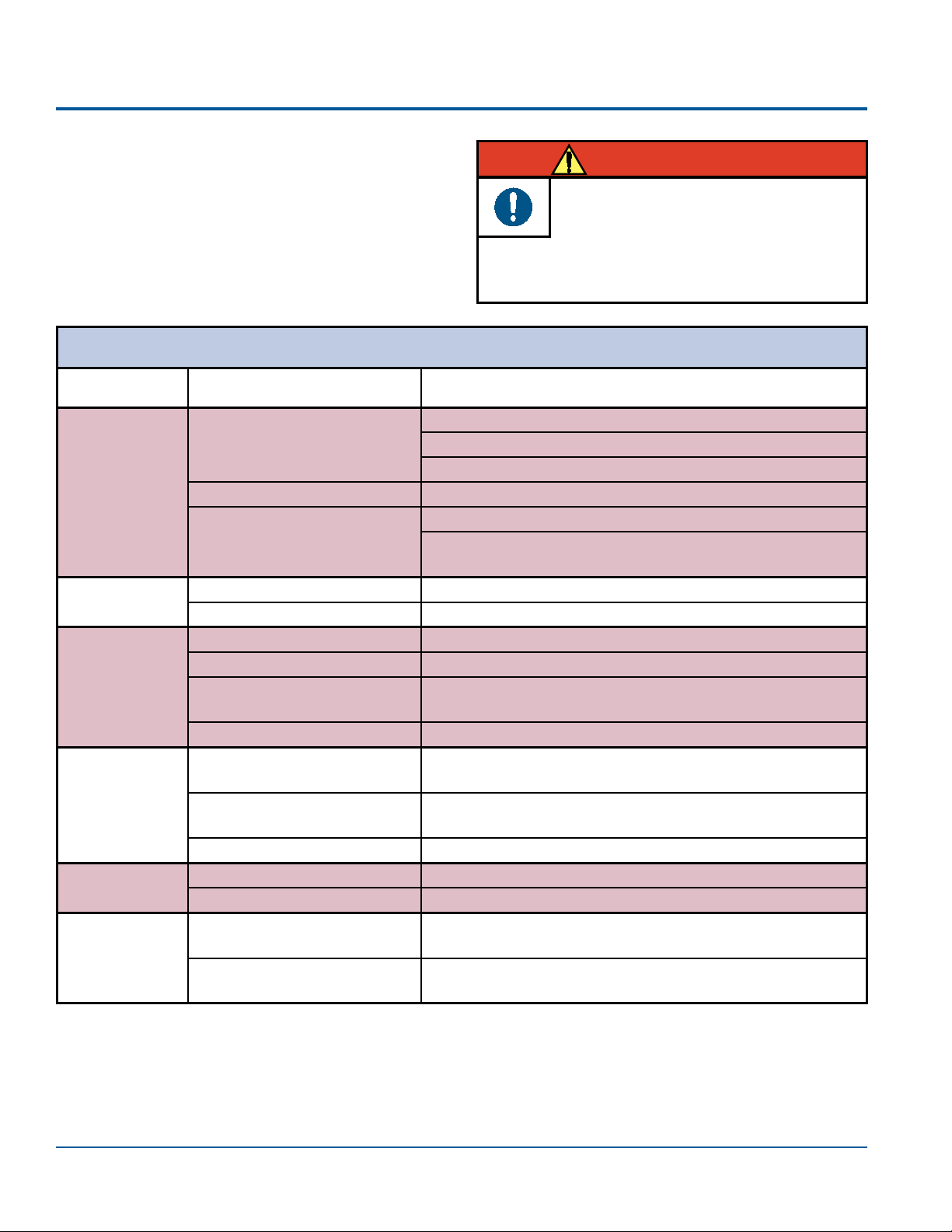

The following charts should be used when trouble-

shooting operational problems. If these suggested

troubleshooting procedures do not resolve the

problem, see the Service Instruction on Page 18.

Exercise extreme caution when

troubleshooting the electrical components

of the deliver unit. When testing, always

WARNING

disconnect the external power. When electrical

power is required, safety precautions must be

followed.

Delivery Head

Symptom Possible Cause(s) Solution

Unit will not

turn on. No air to master switch Open stop valve in oor utility box.

Open and adjust air regulator to 80 PSI.

Check for pinched red 1/8" tubing in umbilical.

Faulty master switch Turn switch to ON position and verify air ow.

Faulty air pilot valve Verify an air supply to top tting of valve.

If air is present at top tting of valve, verify air to foot

control tubing. If no air at tubing, valve is defective.

Unit has no

electric power No building power Check main circuit supply or contact electrician.

Improper outlet voltage Verify proper outlet voltage in USC.

Unit has no air Unit is not turned on. Ensure master switch is in ON position.

Air stop valve is closed. Turn stop valve ON and verify 80 PSI is on air gauge.

Pinched air line Check for pinched or restricted 1/4" red tubing from oor

utility box to cart.

Faulty air pilot valve Check barbs for blockage. If none, replace valve.

No water

(handpiece &

syringe)

Master switch is in OFF

position. Turn switch to ON position.

Pressure regulator is not

adjusted. Ensure clean water system gauge reads 40 PSI.

Slide clamp is clamping line. Move clamp to allow water ow through line.

Air in coolant

water Unit has not been purged. Purge water lines.

Faulty water control valve If unit was purged, replace water control valve.

Water ush

fails to operate. Water toggle is in OFF

position. Place toggle in ON position.

Faulty water ush toggle

valve If water is present at valve, but not owing, replace valve.

Simplicity®Cart

17

Section VII User Service Information

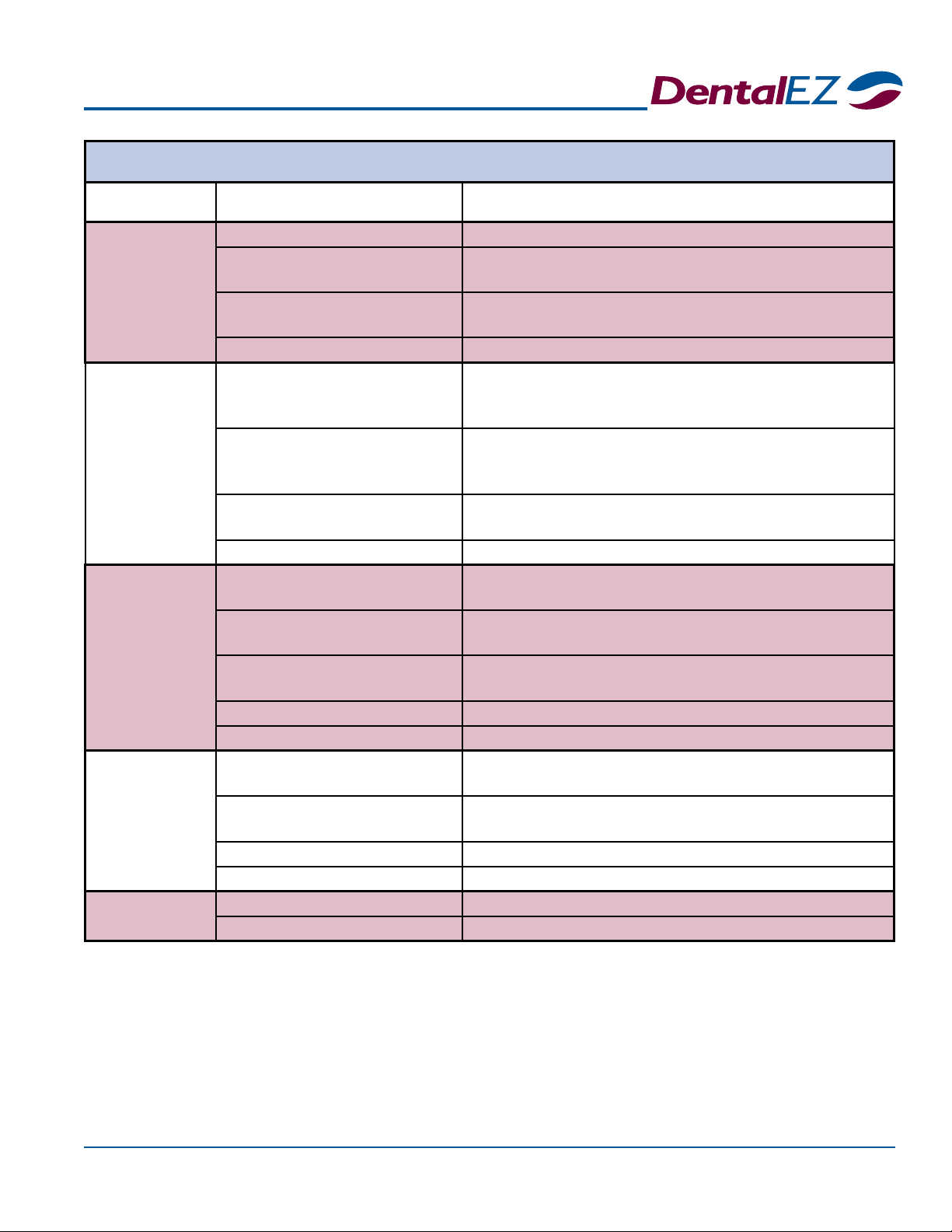

Handpiece

Symptom Possible Cause(s) Solution

Water dribbles

from handpiece

while in holder.

Faulty handpiece holder Repair or replace holder.

Pinched or restricted tubing to

holder Straighten or replace tubing.

Pinch valve diaphragm is

leaking Replace diaphragm.

Low air pressure Ensure air regulator gauge in oor box reads 80 PSI.

Water dribbles

from handpiece

after foot

control is

released.

Faulty water control valve Depress foot control, then release Remove black

tubing from water control valve. If dribble continues,

replace valve.

Faulty water relay in foot

control Turn unit OFF. Open foot control and inspect water re-

lay block. If piston is not damaged and is moving freely,

stretch the spring. Reassemble and retry foot control.

Pinched or restricted tubing

from foot control Straighten or replace tubing.

Low air pressure Ensure air regulator gauge in oor box reads 80 PSI.

No ber optic

light at

handpiece

Power transformer is not

plugged in. Plug transformer into designated receptacle in USC.

Internal wires in control head

and/or USC are not connected Check connections in control head and/or USC.

No signal air to ber optic

lamp control Check for pinched or restricted tubing.

Faulty transformer Check output for 9V.

Faulty bulb Replace bulb.

No coolant

water at any

handpiece

Coolant water adjustment

valves are closed. Turn valve counterclockwise to open valve.

Water toggle on foot control is

in the OFF position. Flip toggle to the right for the ON position.

Slide clamp is clamping line. Move clamp to allow water ow through line.

Pinched or restricted tubing Straighten or replace tubing.

No coolant air

to handpiece Slide clamp is clamping line. Move clamp to allow air ow through line.

Pinched or restricted tubing Straighten or replace tubing.

Simplicity®Cart

18 Installation,OperationandCareManual

Section VII User Service Information

Service Instruction

If the problem is not addressed or cannot be iso-

lated by performing the suggested troubleshooting

procedures, contact your local DentalEZ full-service

dealership. (See Limited Warranty, Page 24.) Be prepared

to supply the following product information:

•Model Name

•Model Number

•Serial Number

(The serial number label is located on the underside of

the cart.)

•Date of Installation

Disposal of Equipment

Before servicing, always disconnect the

external power by unplugging the unit from

the power receptacle.

WARNING

The DentalEZ Technical Service Department is

available to supply service personnel with any

additional information or instructions needed to

repair or maintain the dental delivery system.

NOTICE

Disposal and Decommissioning of

DentalEZ products:

Note: All local regulatory requirements

for disposal and decommissioning of

equipment apply.

Electrical Salvage: Remove ber optic

controller and transformer.

Metal Salvage: Remove all aluminum and

steel components for recycle as metal

salvage.

Plastic Salvage: Remove all plastic

components for recycle as plastic salvage.

Biologically Contaminated Salvage: Oral

extraction lines should be handled with

precaution and disposed of appropriately.

Non-Salvage Components: All other

material unsuitable for recycling should

be disposed of properly.

Handpiece(continued)

Symptom Possible Cause(s) Solution

No drive air Drive air ow adjustments on

pinch valves are closed. Using a screw driver, turn adjustment screw counter-

clockwise to adjust drive air pressure. Set to

manufacturer's recommended pressure.

Faulty handpiece holder valve If pinch valve does not release with handpiece out of

holder and tubing to holder is not restricted, replace

hanger valve.

Faulty foot control Depress foot control. If no air is present, repair or

replace foot control

Pinched or restricted tubing Straighten or replace tubing.

Simplicity®Cart

19

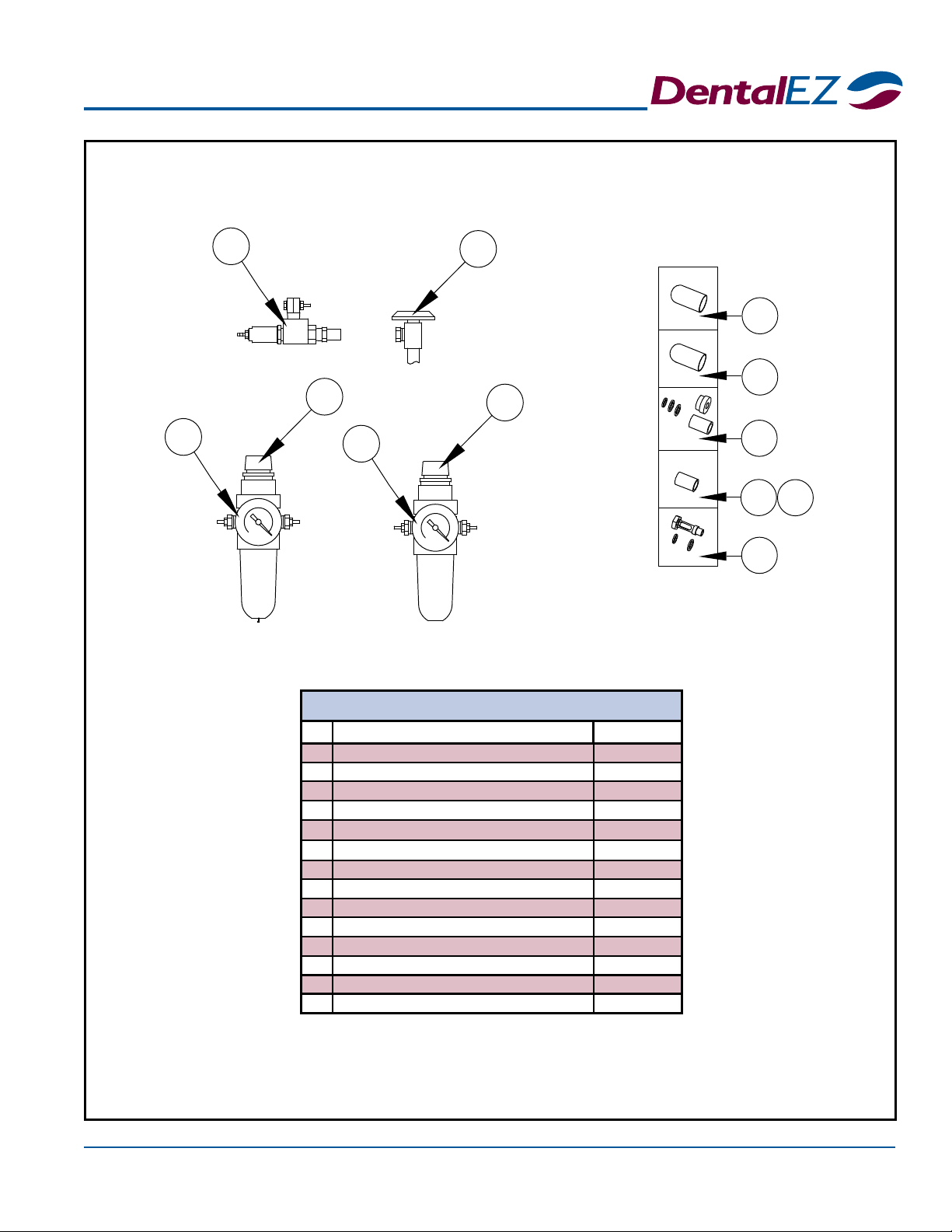

Section VIII Parts List/Diagrams

60 0

160 0

*5

2*1

4

3

*6

*10

7

*8

*9

12

11

*OptionalEquipment

# Part/Kit Name Part/Kit No.

*1 Water Actuator Valve 3801-637

2 Stop Valve 3800-960

3 Air Regulator 3801-638

4Air Pressure Gauge 3800-534

*5 Water Regulator 3802-107

*6 Water Pressure Gauge 3800-533

7 Air Regulator Bowl - Watts 3802-267

*8 Water Regulator Bowl - Watts 3802-268

*9 Water & Air Regulator Repair Kit - Watts 3802-273

*10 Water Regulator Filter - Watts 3802-270

11 Air Regulator Filter - Watts 3802-271

12 Regulator Retainer - Watts 3802-272

*Water Regulator Gauge Repl. Kit - Watts 3802-269

Air Regulator Gauge Repl. Kit - Watts 3802-266

Utility Service Center

Other manuals for Simplicity

1

This manual suits for next models

1

Table of contents

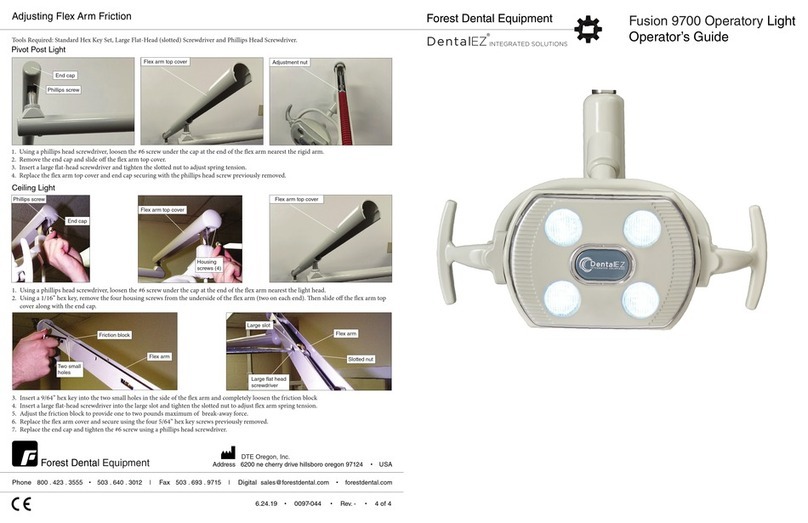

Other DentalEZ Medical Equipment manuals