www.logiquip.com |5

USER GUIDE

UNPACKING INSTRUCTIONS

INSPECTION:

1. Receiving area must meet all State and Local regulations prior to unpacking.

2. Customer must inspect skid and Table both before and after unpacking to

determine if any items were damaged during shipping.

3. All damaged items must be listed on the Bill of Lading.

4. Customer is responsible for the proper disposal of all packing materials.

The disposal of these items must meet all State and Local regulations.

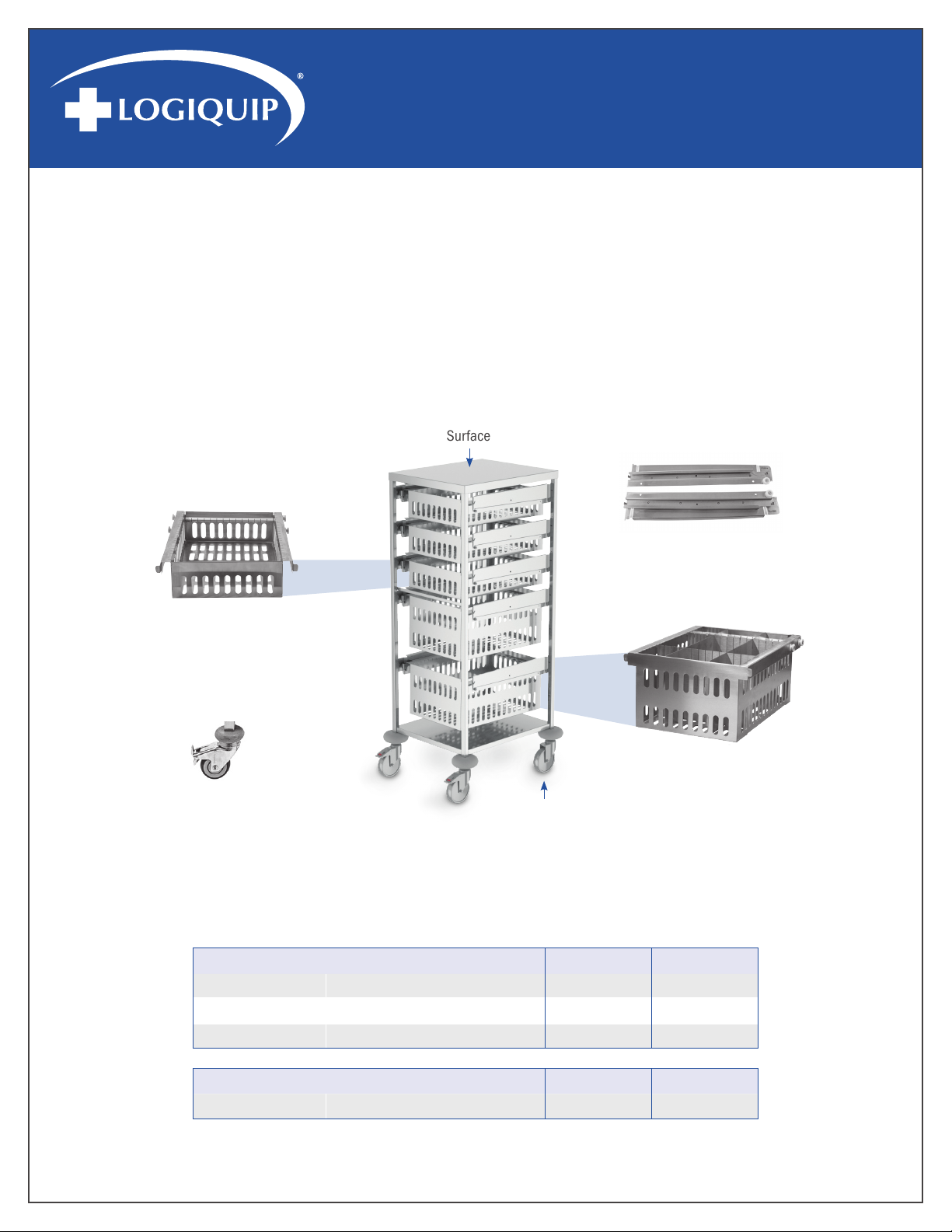

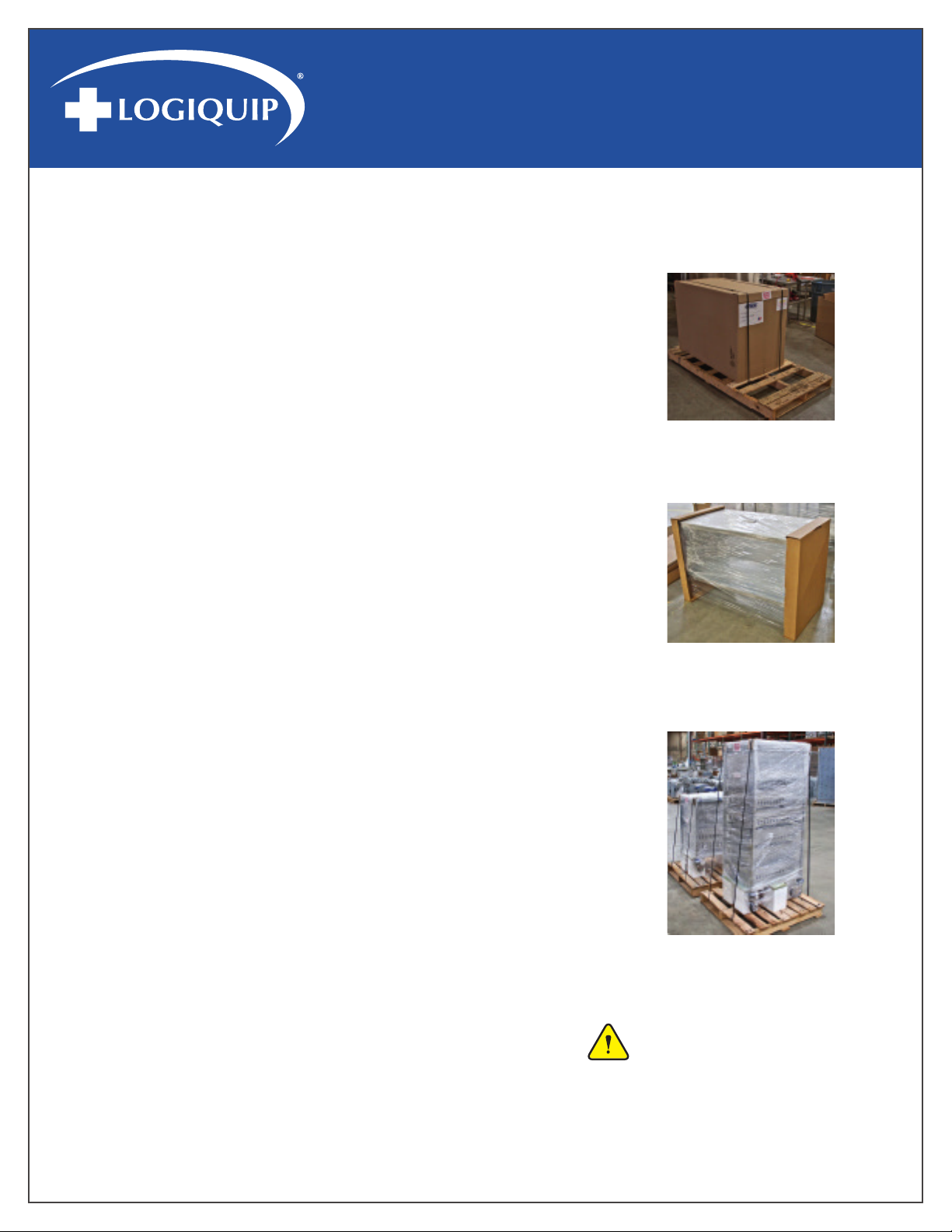

UNPACKING PHARMACY CART/WORK TABLE:

Pharmacy Carts and Work Tables are shipped on well-constructed wooden skids.

Two steel bands secure the products to the skid. The stainless steel surfaces of the

part are protected by layers of plastic wrapping. Work Tables are further protected by

heavy cardboard end caps and the entire product is contained in a heavy cardboard

box (Fig. 1 and Fig. 2).

Care must be taken while unpacking the items to avoid damage. Do not drop

tools on the items or scratch the surfaces with sharp edges.

Retain all shipping materials until the items are completely unpacked and

inspected for damage.

IMPORTANT: Wear gloves and eyewear during the unpacking operation.

UNPACKING PHARMACY WORK TABLE:

1. Use tin snips to cut the metal bands holding the box to the wooden skid (Fig. 1).

2. Remove metal staples holding one end of the packing carton together.

3. Slide out table from side of packing carton with two attached cardboard end

caps (Fig. 2).

4. Remove two (2) cardboard end caps.

5. Remove the plastic protective wrapping.

UNPACKING PHARMACY CART:

6. Use tin snips to cut the metal bands holding the box to the wooden skid.

7. Remove the plastic protective wrapping and carefully lift the cart off of the

protective foam blocks underneath the cart (Fig. 3).

8. The Pharmacy Cart/Work Table is now ready for use.

9. Discard shipping and packing materials in compliance with state and

local regulations.

10. When not in use, carts and tables must not be double stacked while in

storage. While still in their shipping cartons, carts and tables must not

be double stacked when not in use.

CAUTION: Do not use a box cutter

or any other cutting utensil to remove

the plastic wrapping around the table. These

items can scratch the protective coating on the

stain-less steel allowing the surface to rust.

Fig. 1: Boxed Work Table

Fig. 2: Wrapped Work Table

with end caps.

Fig. 3: Wrapped Pharmacy Carts