2

CONTENTS

1GENERAL PROVISIONS ................................................................................................................. 4

2SAFETY MEASURES....................................................................................................................... 5

3THE PRODUCT PREPARATION FOR INSTALLATION.................................................................. 6

3.1 Procedure for product transportation to the installation site .................................................... 6

3.2 Rules of the unpacking of the product .................................................................................... 6

3.3 Rules of the product visual inspection .................................................................................... 6

3.4 Requirements to the product installation place ....................................................................... 7

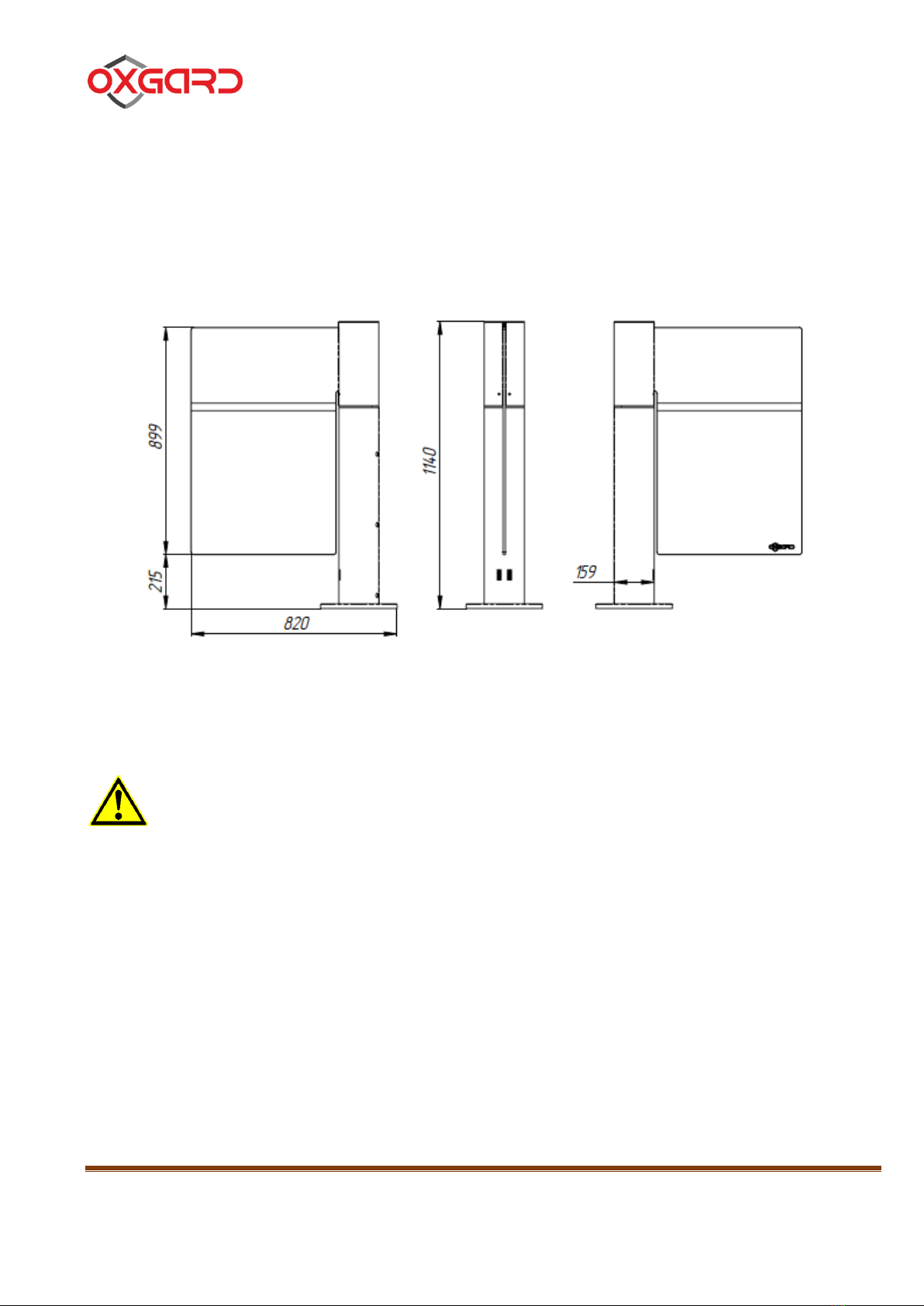

4INSTALLATION AND DE-INSTALLATION OF THE PRODUCT...................................................... 8

4.1 Required equipment............................................................................................................... 8

4.2 Product installation................................................................................................................. 8

4.3 The product dismantling ....................................................................................................... 10

5CONNECTION AND ADJUSTMENT OF THE PRODUCT.............................................................. 11

5.1 Connection of power supply ................................................................................................. 13

5.2 Connecting control panel...................................................................................................... 14

5.3 Connection of access control system (optional).................................................................... 14

6comprehensive examination........................................................................................................ 17

6.1 Visual inspection and check of the product readiness for use............................................... 17

7COMMISSIONING OF THE MOUNTED PRODUCT....................................................................... 18