Oz Theatre Screens can also produce custom size screens upto 6 metres wide and 2.4 metres

high in some fabrics and formats. Contact us for other formats such as 4:3 and 16:10.

Visit us online today at https://www.projectorscreens.com.au or call (07) 5546 1960

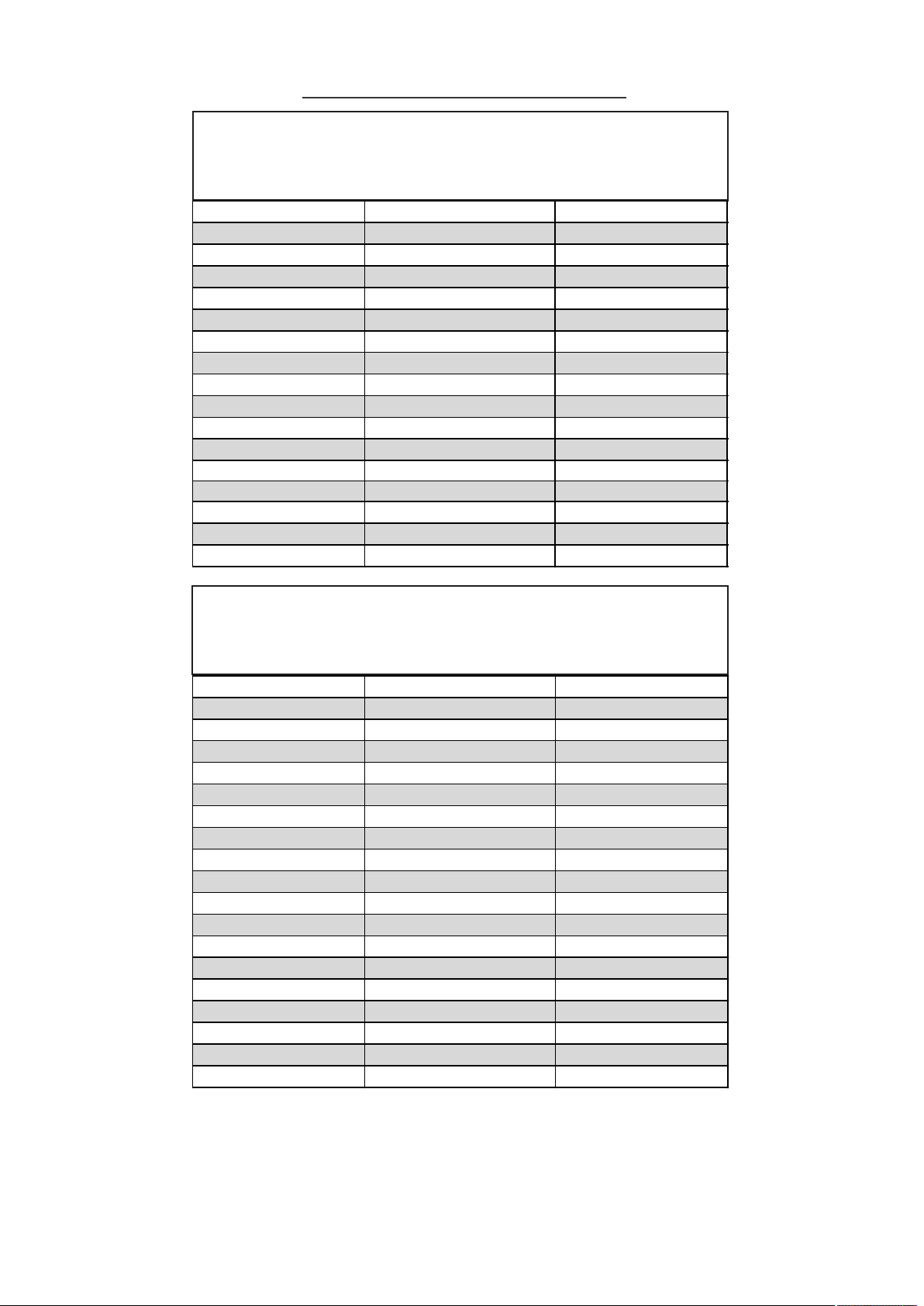

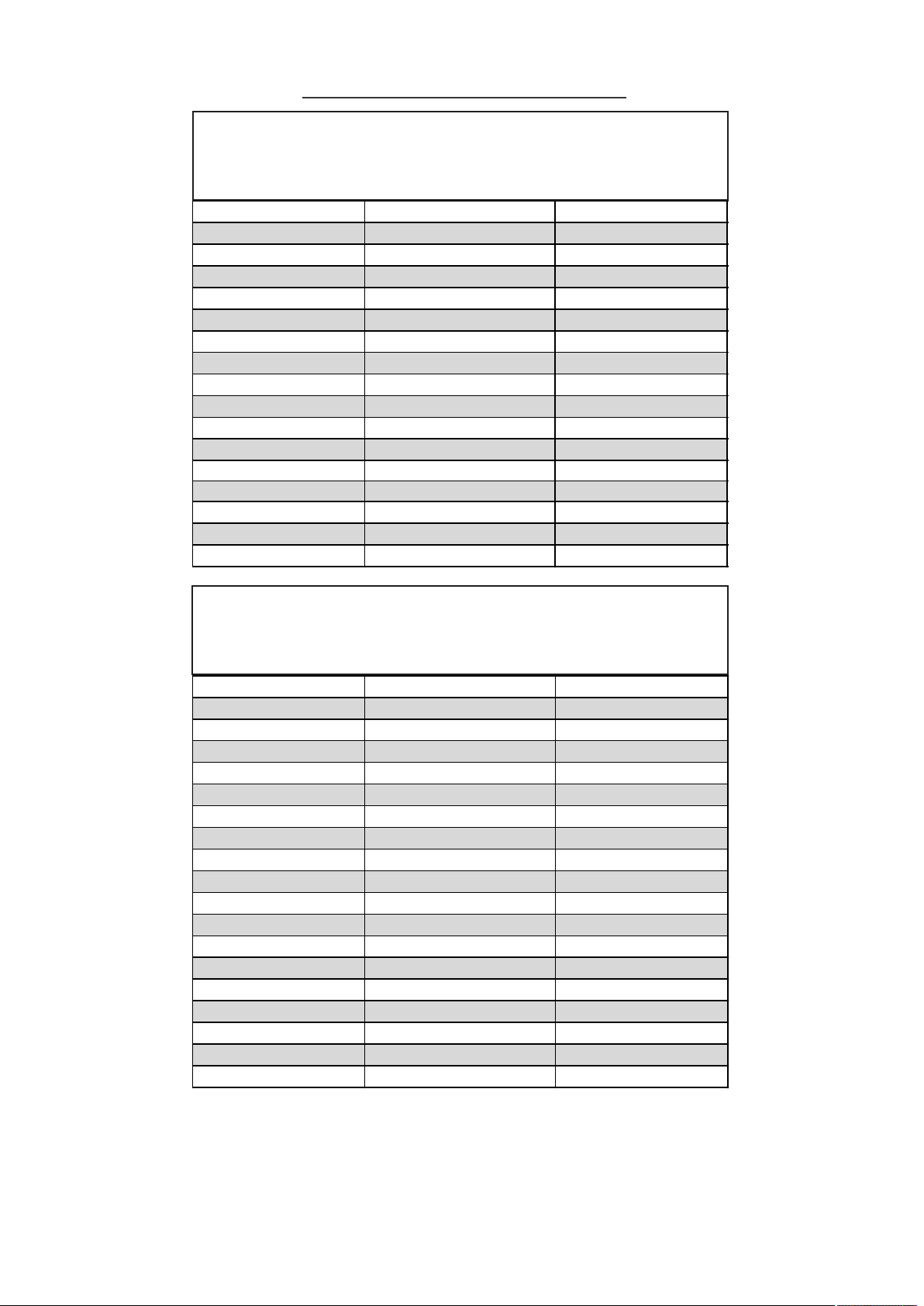

Majesc Screen Sizes

21:9 Cinemascope (2.37:1 format) Screen Dimensions

Viewing Diagonal

Inches

Overall Size Inc Frame

mm

Active Viewing Area

mm

73" 1766 X 1059 1616 X 909

82" 1980 X 1169 1812 X 1019

84" 2009 X 1195 1859 X 1045

88" 2103 X 1248 1953 X 1098

92" 2184 X 1295 2032 X 1143

96" 2271 X 1343 2121 X 1193

100" 2360 X 1393 2210 X 1243

106" 2500 X 1472 2350 X 1321

110" 2590 X 1522 2440 X 1372

115" 2693 X 1580 2543 X 1430

120" 2796 X 1638 2646 X 1488

125" 2918 X 1707 2768 X 1557

130" 3030 X 1770 2880 X 1620

135" 3140 X 1831 2990 X 1681

140" 3250 X 1894 3100 X 1744

145" 3360 X 1956 3210 X 1806

150" 3470 X 2018 3320 X 1868

16:9 HDTV (1.78:1 format) Screen Dimensions

Viewing Diagonal

Inches

Overall Size Inc Frame

mm

Active Viewing Area

mm

92" 2306 X 1060 2156 X 910

100" 2506 X 1144 2356 X 994

110" 2726 X 1237 2576 X 1087

115" 2841 X 1285 2691 X 1135

120" 2956 X 1334 2806 X 1184

125" 3071 x 1382 2921 x 1232

130" 3186 X 1431 3036 X 1281

135" 3302 x 1480 3152 x 1330

140" 3416 X 1528 3266 X 1378

145" 3530 X 1576 3380 X 1426

150" 3646 X 1625 3496 X 1475

155" 3760 X 1673 3610 X 1523

160" 3873 X 1721 3723 X 1571

165" 3995 X 1773 3845 X 1623

170" 4117 X 1824 3967 X 1674

175" 4241 X 1876 4091 X 1726

180" 4361 X 1927 4211 X 1777

185" 4480 X 1977 4330 X 1827

190" 4596 X 2026 4446 X 1876

1