DDS VFO 2 Construction Manual –Issue 1 Page 3

Contents

1Introduction..............................................................................................................................................................5

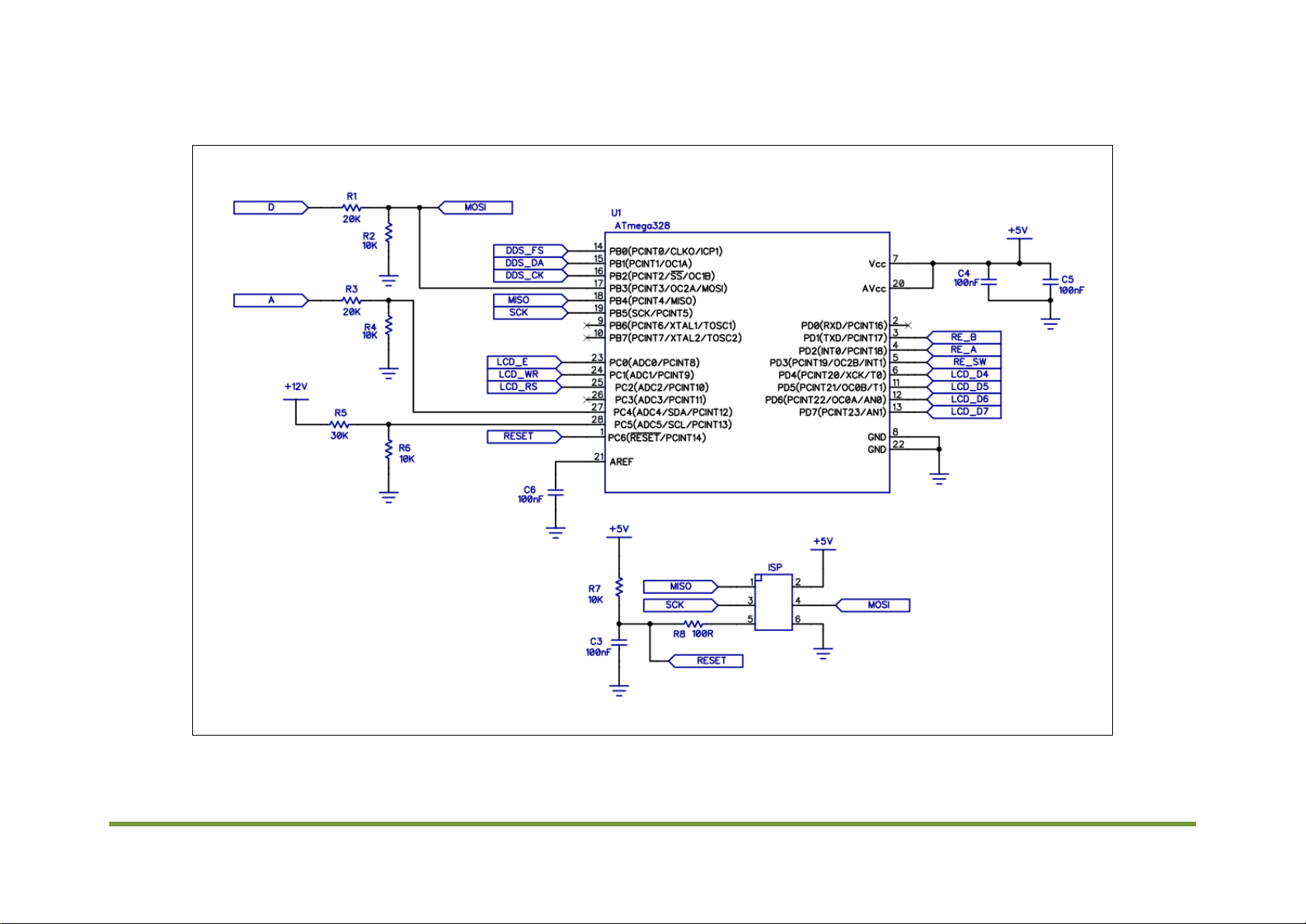

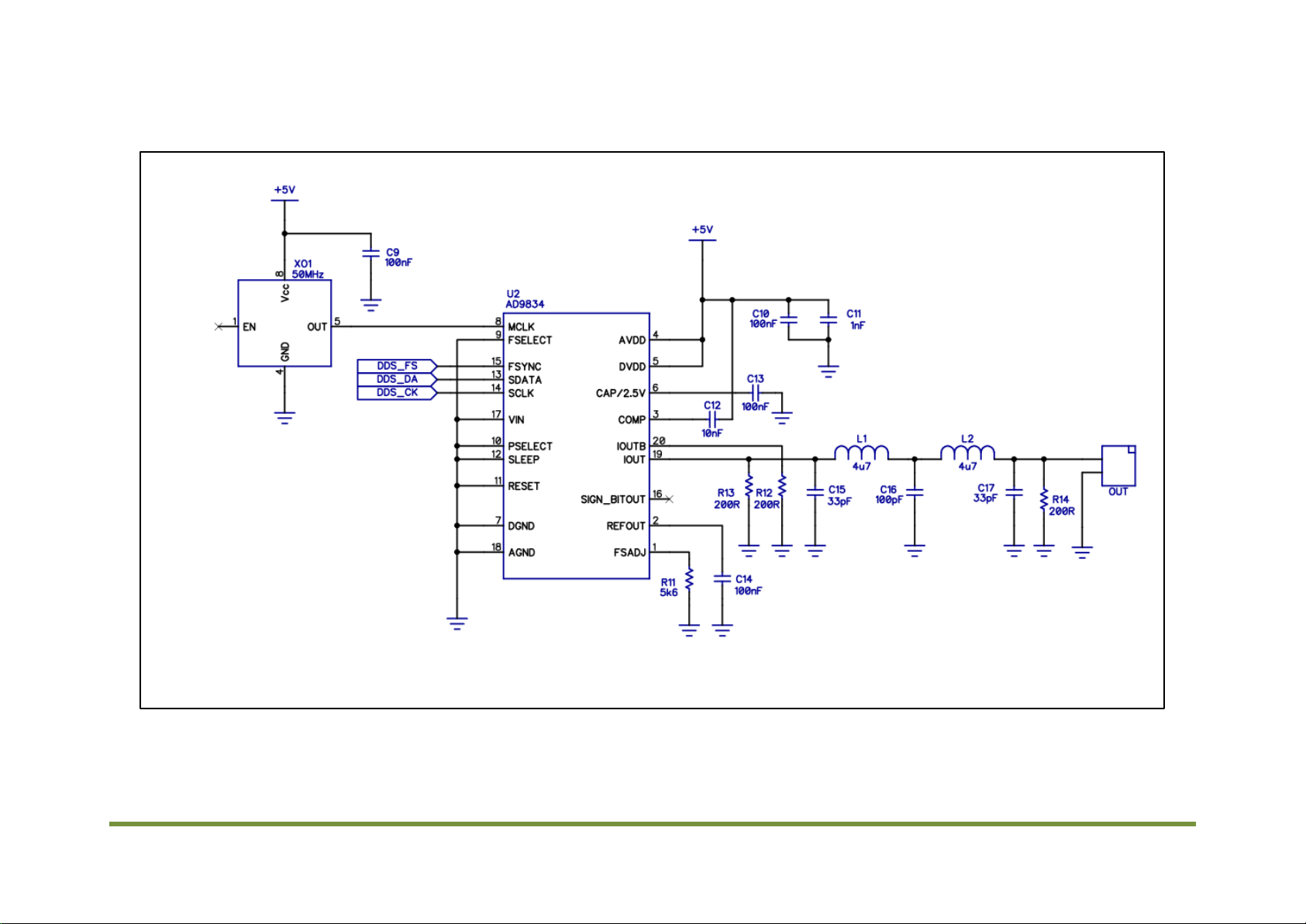

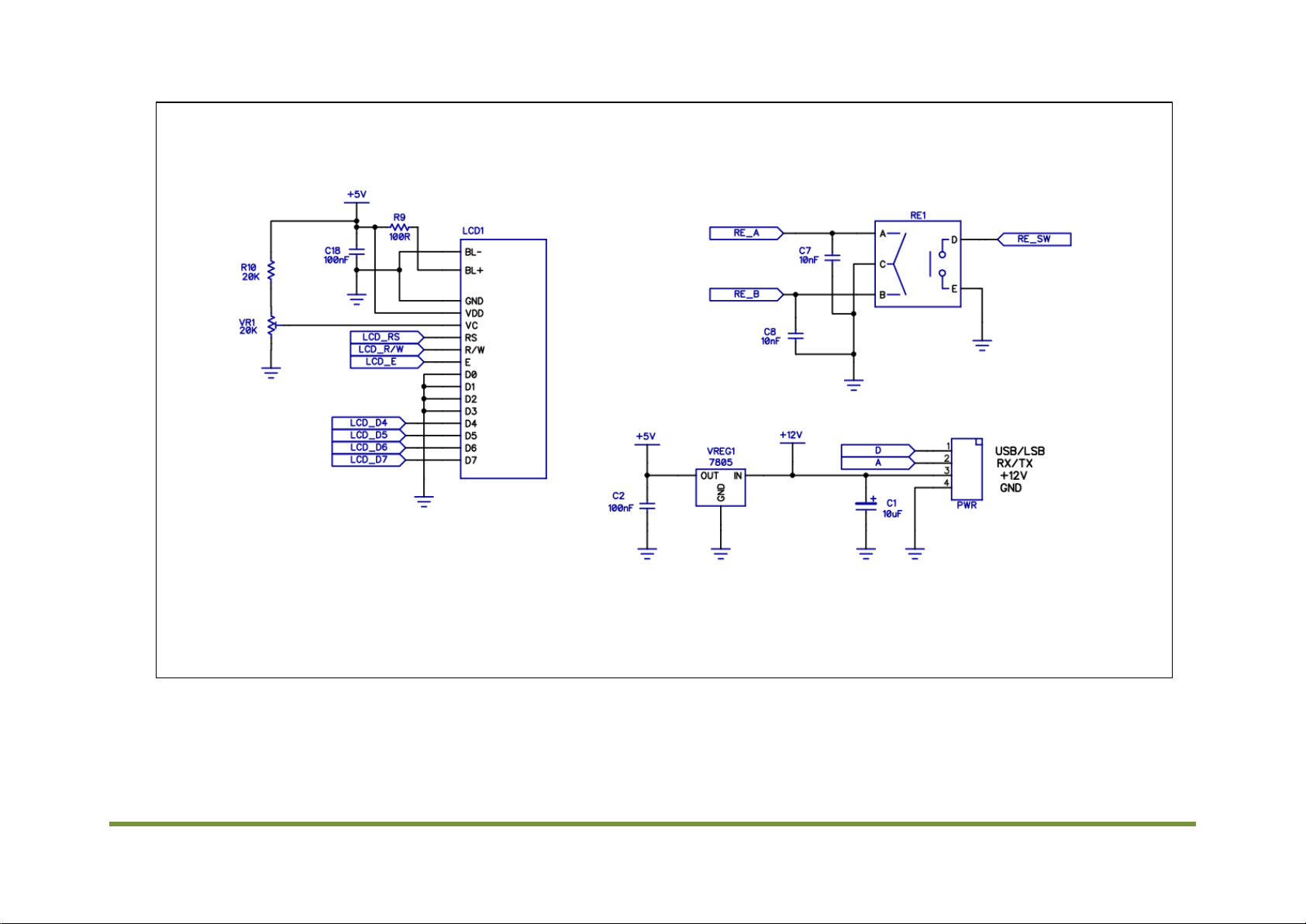

2Circuit Description .................................................................................................................................................6

3Kit Supplied Parts List........................................................................................................................................ 10

4The DDS VFO and the Superhet...................................................................................................................... 11

5Construction........................................................................................................................................................... 12

5.1 General............................................................................................................................................................ 12

5.2 Construction Steps..................................................................................................................................... 12

6First time power on............................................................................................................................................. 15

7Configuration......................................................................................................................................................... 16

7.1 Understanding options ............................................................................................................................ 16

7.2 Using the rotary encoder ........................................................................................................................ 18

7.3 Configuration Preview............................................................................................................................. 18

7.4 Entering New Values................................................................................................................................. 18

8Installing in a MST............................................................................................................................................... 20

8.1 Front Panel.................................................................................................................................................... 20

8.2 Wiring ............................................................................................................................................................. 21

8.3 Power .............................................................................................................................................................. 21

8.4 Output............................................................................................................................................................. 21

9Operation................................................................................................................................................................. 22

9.1 Power on........................................................................................................................................................ 22

9.2 Tuning............................................................................................................................................................. 22

9.3 Frequency steps.......................................................................................................................................... 22

9.4 RIT.................................................................................................................................................................... 22

9.5 Voltage Display............................................................................................................................................ 22

9.6 Frequency calibration .............................................................................................................................. 23

9.7 Voltage display calibration..................................................................................................................... 23

10 Notes ......................................................................................................................................................................... 24

10.1 Overclocking................................................................................................................................................. 24

10.2 DDS output.................................................................................................................................................... 24

10.3 Frequency range......................................................................................................................................... 24

10.4 LCD................................................................................................................................................................... 24

10.5 Firmware upgrades................................................................................................................................... 24