HOIST AND WIRE ROPE

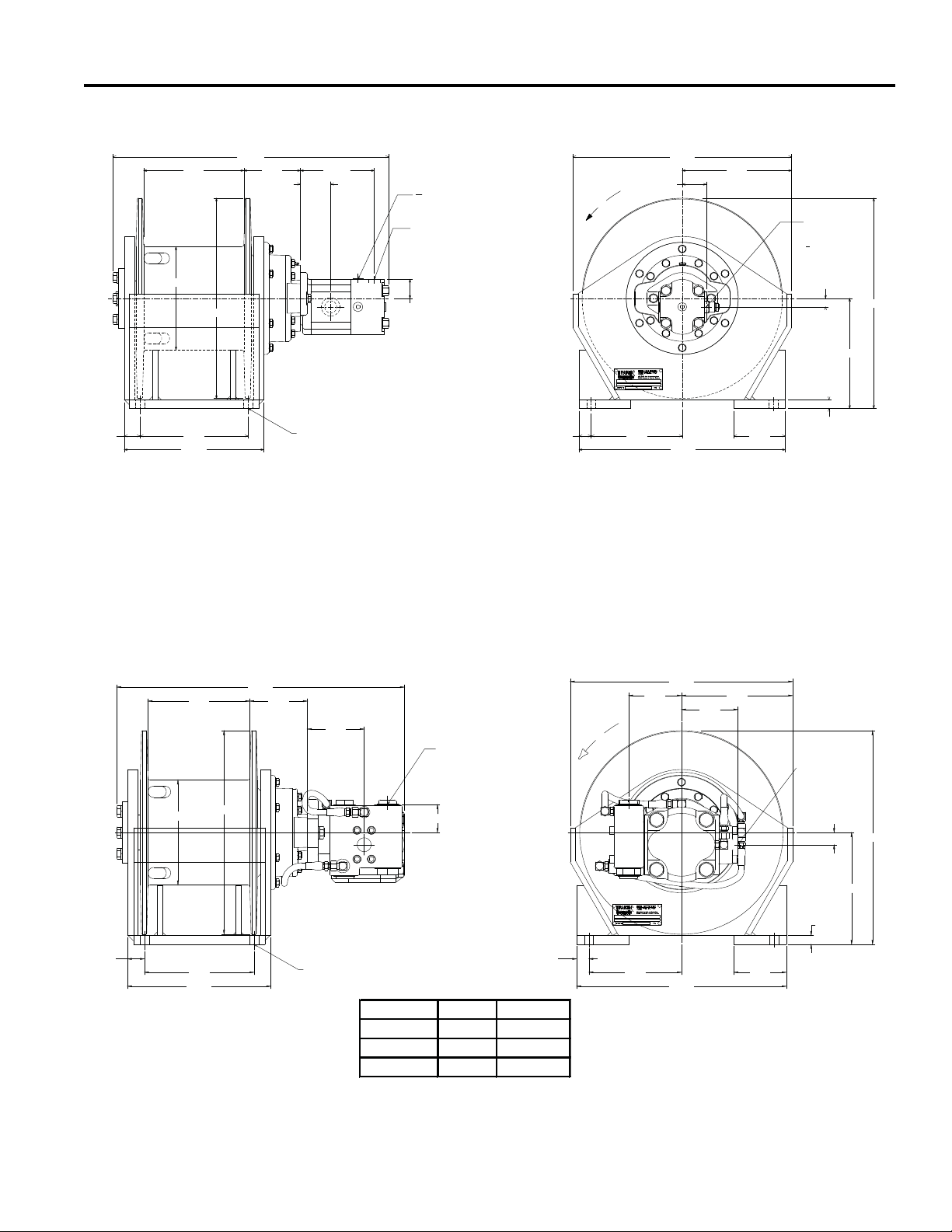

INSTALLATION

1. The hoist should be mounted with the centerline of

the cable drum in a horizontal position. The mounting

plane of the hoist may be rotated in any position

around this centerline providing the vent in the motor

adapter is above the centerline of the cable drum.

The vent should be as close to top dead center as

possible.

2. When mounting the hoist, use all four (4) mounting

holes and grade eight (8) bolts and nuts. Evenly tight-

en the nuts to the torque in the "Recommended

Torque" chart.

Refer to "Dimensional Drawing" for bolt hole size and pat-

tern.

The hoist must be mounted on a surface that will not flex

when the hoist is in use, and cause binding of the gear

train. Binding in the gear train will result in accelerated

wear and heat. Also, the mounting surface must be flat

with ± 0.020 in. (.5mm). If necessary, install shims under

the hoist mounting pads to achieve even mounting.

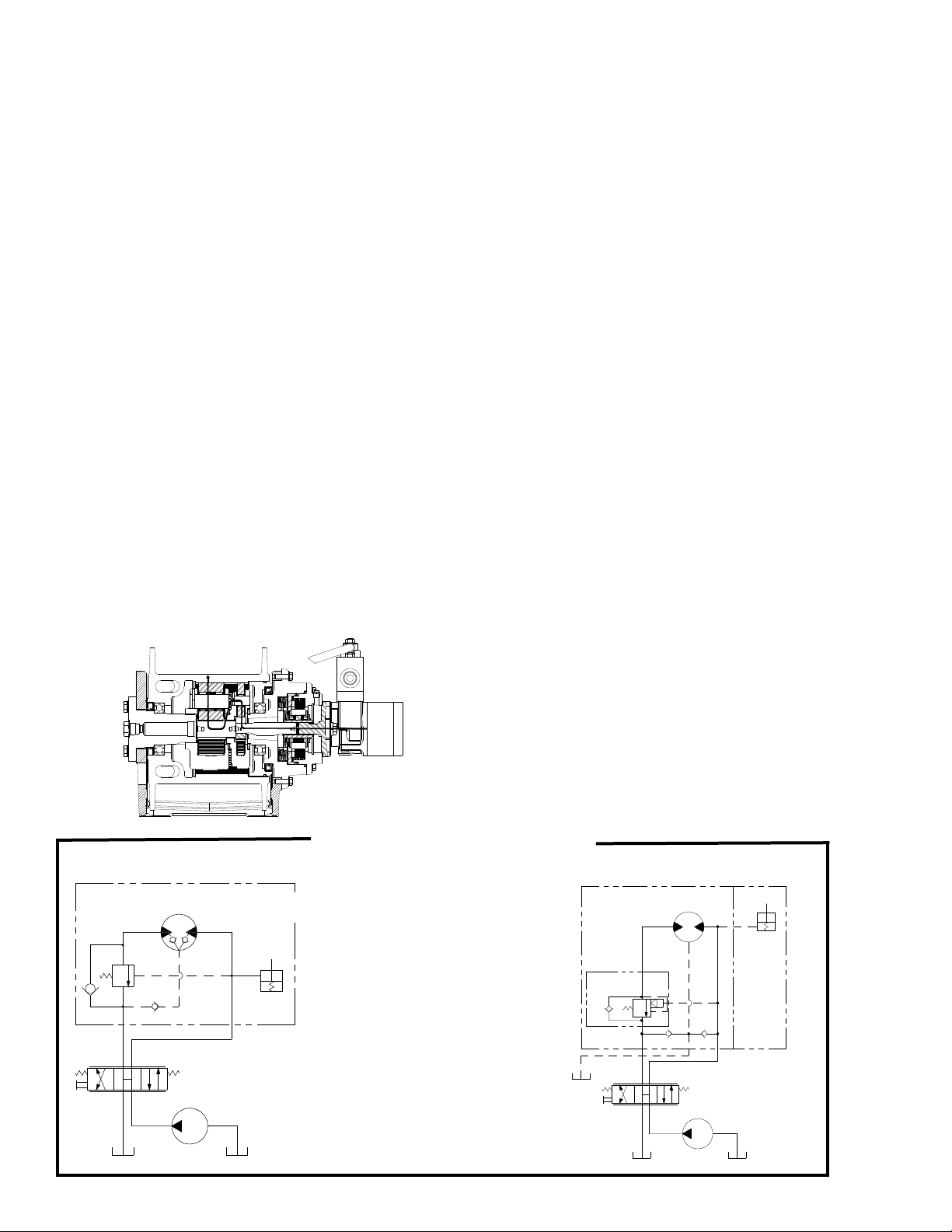

3. The hydraulic lines and components that operate the

hoist should be of adequate size to assure minimum

back pressure at the hoist. The back pressure at the

motor must not exceed 50 psi (345 kPa) to maintain

full system design braking and optimum motor seal

life.

The hoist directional control valve must be a three position

four way valve with a motor spool such that when the

valve is in the center position both work ports are open to

tank (open center, open port).

4. High quality hydraulic oil is essential for satisfactory

performance and long hydraulic system component

life.

Oil having 150 to 330 SUS viscosity at 100oF (38oC) and

viscosity index of 100 or greater will give good results

under normal temperature conditions. The use of an oil

having a high viscosity index will minimize cold start trou-

ble and reduce the length of warm-up periods. A high vis-

cosity index will minimize changes in viscosity with corre-

sponding changes in temperature.

Maximum cold weather start-up viscosity should not

exceed 5,000 SUS with a pour point at least 20oF (-7oC)

lower than the minimum ambient temperature.

Under continuous operating conditions the temperature of

the oil at any point in the system must not exceed 180ºF

(82oC). 120oF (49oC) to 140oF (60oC) is generally consid-

ered optimum.

In general terms:

For continuous operation at ambient temperatures

between 50oF (10oC) and 110oF (43oC), use SAE 20W;

for continuous operation between 10oF (-12oC) and 90oF

(32oC), use 10W; for applications colder than 10oF (-

12oC), contact the BRADEN Service Department. The

use of multi-viscosity oils is generally not recommended.

5. The hydraulic oil filter should have a 10 micron nomi-

nal rating and be full flow type; or one in accordance

with recommendations of the pump manufacturer.

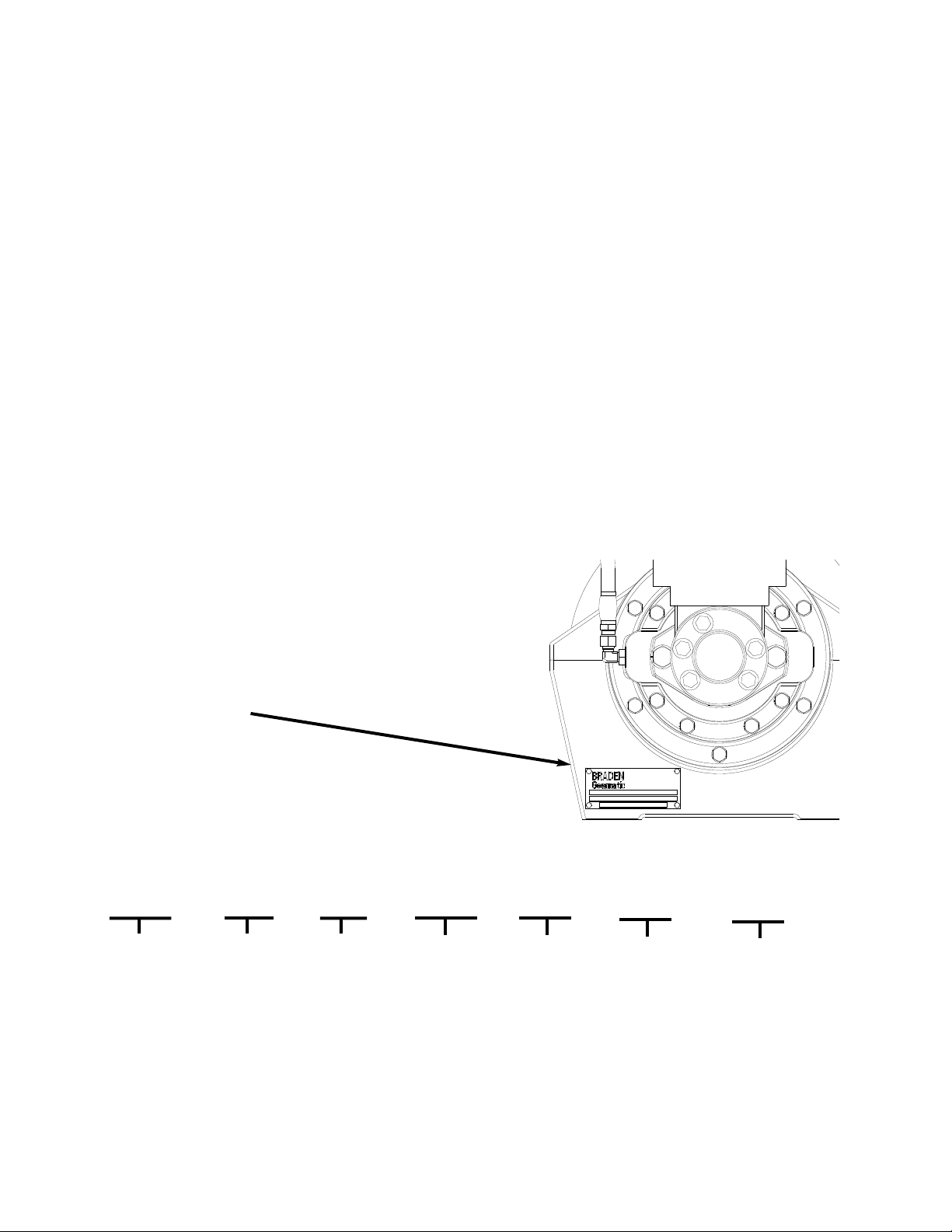

6. The vent plug in the motor adapter must be located

close to top dead center as possible. If the hoist is

mounted on a pivoting surface, the vent plug must

remain above the centerline of the cable drum to pre-

vent gear oil leakage.

7. Refer to "Dimensional Drawing" for relationship

between drum rotation and which port is pressurized.

WIRE ROPE INSTALLATION

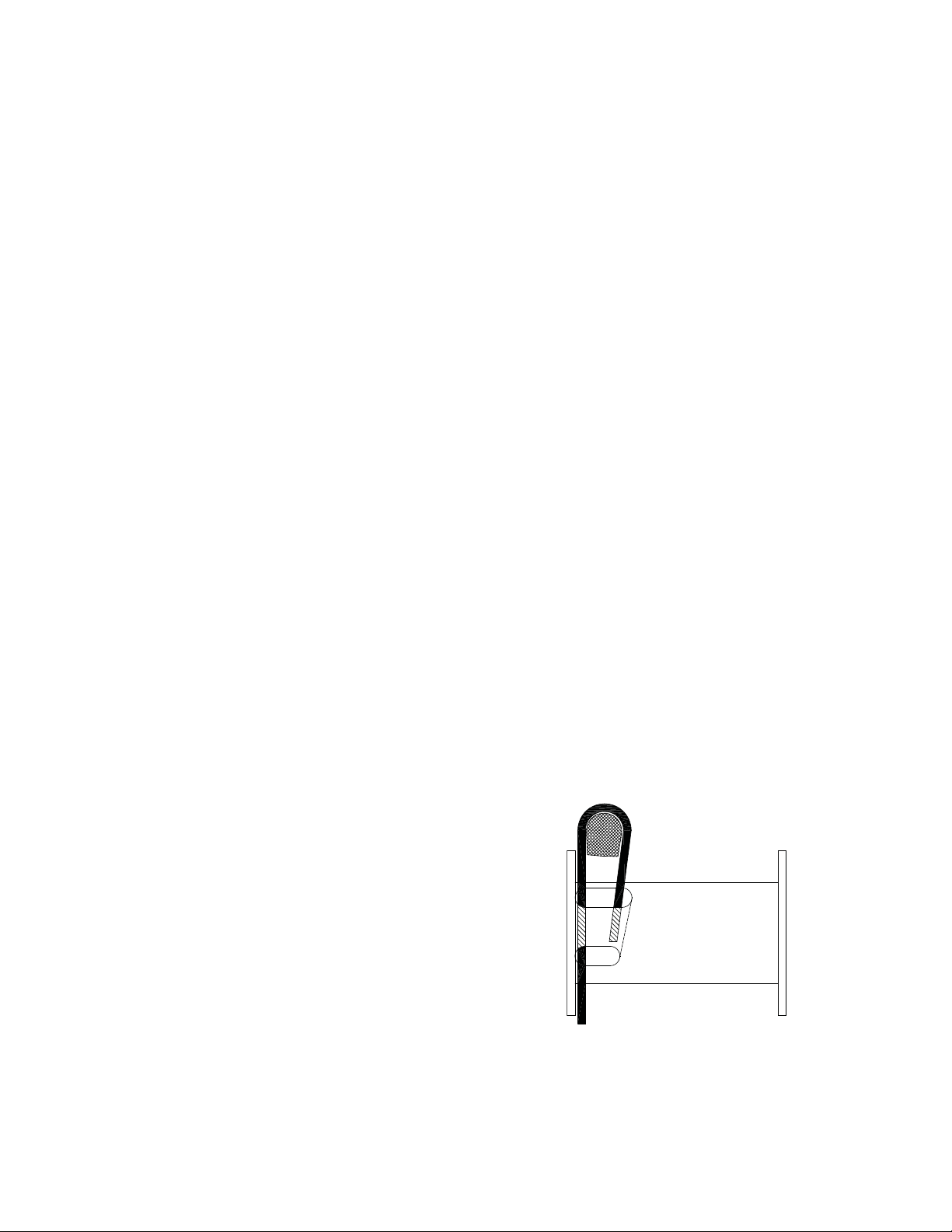

Since the static brake on this hoist is "effective both direc-

tions", cable can be wound onto the drum in either direc-

tion without any modifications to the hoist. The cable

drum has two anchor pockets to accommodate this. Take

the free end of the wire rope and insert it through the small

opening of the anchor pocket you are going to use. Loop

the wire rope and push the free end about three-fourths of

the way back through the pocket. Install the cable anchor

with the small end toward the drum, then pull the slack out

of the wire rope. The cable anchor will slip into the pock-

et and secure the wire rope to the drum. A minimum of

five (5) wraps of wire rope should remain on the cable

drum at all times. Refer to "General Safety

Recommendations" for additional information.

The standard cable anchor wedge supplied with the hoist

is intended for 5/16 to ½in. (8 to 13 mm) wire rope.

8