4

1. Be certain equipment (boom, sheave blocks, pen-

dants, etc.) is either lowered to the ground or

blocked securely before servicing, adjusting, or

repairing hoist.

2. Be sure personnel are clear of work area BEFORE

operating hoist.

3. Read all warning and caution tags provided for safe

operation and service of the hoist and become

familiar with the operation and function of all con-

trols before operating the hoist.

4. Inspect rigging and hoist at the beginning of each

work shift. Defects should be corrected immediate-

ly. Do not operate a hoist with defects.

5. Keep equipment in good operating condition.

Perform scheduled servicing and adjustments listed

in the “Preventive Maintenance” section of this

manual.

6. An equipment warm-up procedure is recommended

for all start-ups and essential at ambient tempera-

tures below +40°F (+4°C). Refer to “Warm-up

Procedure” listed in the “Preventive Maintenance”

section of this manual.

7. Do not exceed the maximum pressure (PSI, kPa) or

flow (GPM, lpm) stated in the hoist specifications

found in the specific sales brochure.

8. Operate hoist line speeds to match job conditions.

9. Protective gloves should be used when handling

wire rope.

10. Never attempt to handle wire rope when the hook

end is not free. Keep all parts of body and clothing

clear of cable rollers, cable entry area of fairleads,

sheaves and hoist drum.

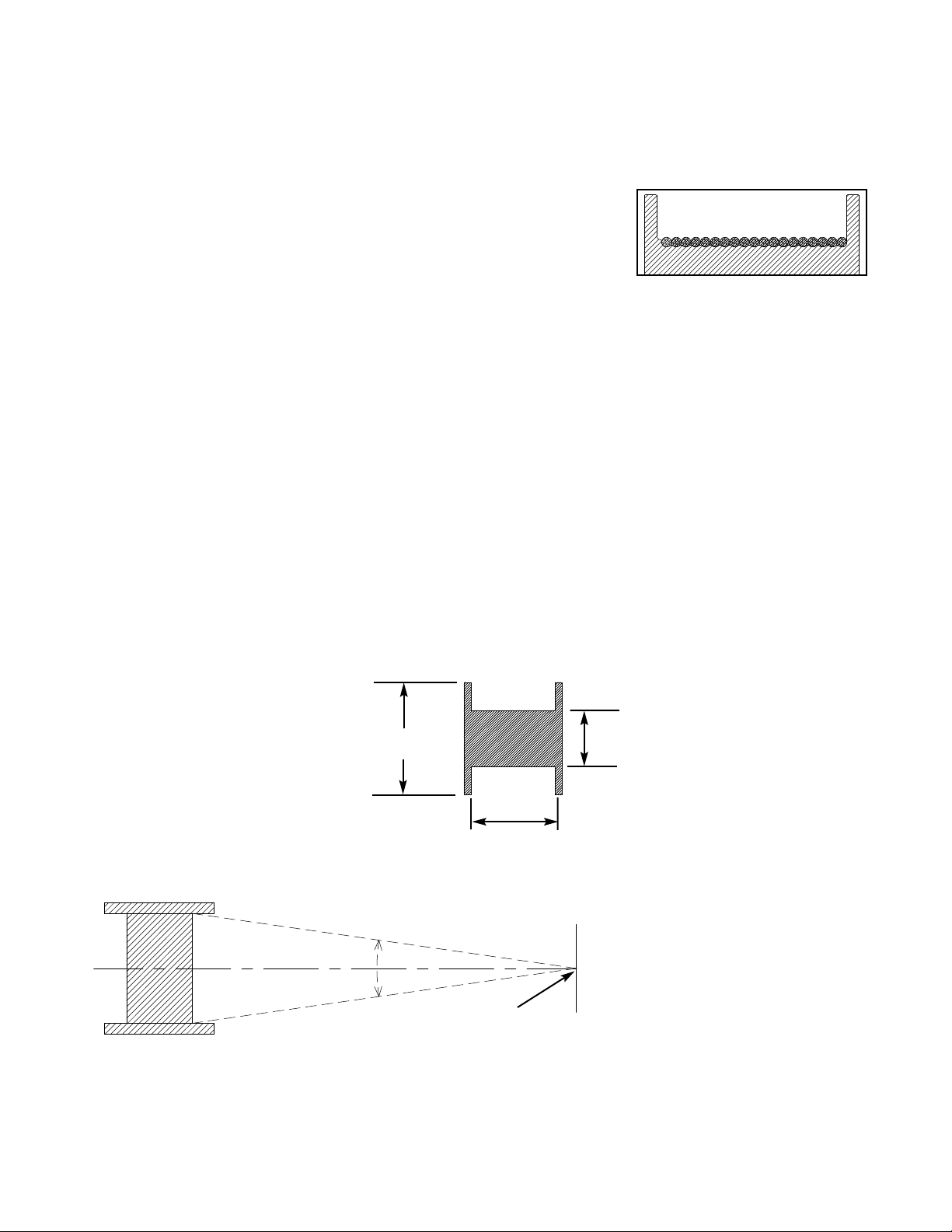

11. When winding wire rope on the hoist drum, never

attempt to maintain tension by allowing wire rope to

slip through hands. Always use “Hand-Over-Hand”

technique.

12. Never use wire rope with broken strands. Replace

wire rope that is damaged. Refer to wire rope sup-

plier manual.

13. Do not weld on any part of the hoist without

approval from PACCAR Winch Engineering.

14. Use recommended hydraulic oil and gear lubricant.

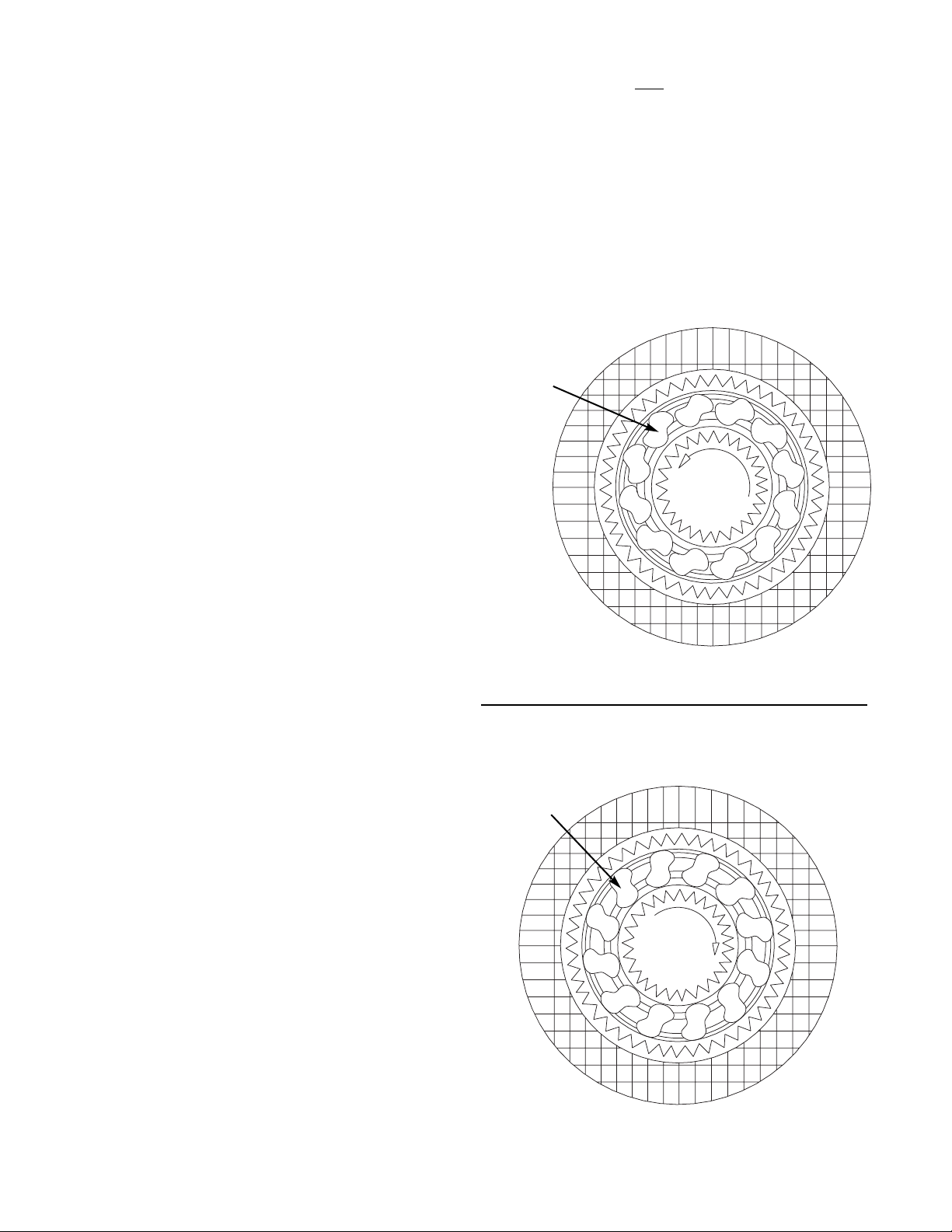

15. Keep hydraulic system clean and free from contam-

ination at all times.

16. Use correct anchor for wire rope and pocket in

drum.

17. Do not use knots to secure or attach wire rope.

18. The BRADEN designed wire rope anchors are not

intended to support the rated load. ALWAYS main-

tain a minimum of five (5) wraps of wire rope on the

drum. It is recommended that the last five (5) wraps

of wire rope be painted bright red to serve as a visu-

al reminder.

19. Never attempt to clean, oil or perform any mainte-

nance on a machine with the engine or prime mover

running, unless instructed to do so in this manual.

20. Never operate hoist controls unless you are proper-

ly positioned at the operators station and you are

sure personnel are clear of the work area.

21. Assure that personnel who are responsible for hand

signals are clearly visible and that the signals to be

used are thoroughly understood by everyone.

22. Ground personnel should stay in view of the opera-

tor and clear of the hoist drum. Do not allow ground

personnel near wire rope under tension. A safe dis-

tance of 1½times the working length of the wire

rope should be maintained.

23. Install guarding to prevent personnel from getting

any part of body or clothing caught at a point where

the cable is wrapped onto the drum or drawn

through guide rollers or potential “pinch points”.

24. Install switches or valves that will shut off power to

the hoist, in locations where they can be reached by

anyone entangled in the wire rope before being

drawn into the hoist or any “pinch point”.

25. “Deadman” controls, which automatically shut off

power to the hoist whenever the operator leaves his

station or releases the hoist control lever, should be

installed whenever practical.

26. Never allow anyone to position any part of body

under a suspended load.

27. Avoid sudden “shock” loads or attempting to “jerk” a

load free. This type of operation may cause heavy

loads, in excess of rated capacity, which may result

in failure of wire rope, hoist or crane structure.

28. Whenever possible, install the hoist in a location

that is not immediately adjacent to a “normal” oper-

ator’s station.

29. All hoist controls shall be located within easy reach

of the operator. The controls shall be installed in

such a location that the operator is removed from

the electrical path to ground if the load, rigging, or

wire rope come in contact with or within proximity to

an electrically energized conductor.

GENERAL SAFETY RECOMMENDATIONS

Safety for operators and ground personnel is of prime concern. Always take the necessary precautions to ensure

safety to others as well as yourself. To ensure safety, the prime mover and hoist must be operated with care and

concern for the equipment and a thorough knowledge of the machine’s performance capabilities. The following

recommendations are offered as a general safety guide. Local rules and regulations will also apply.