DESCRIPTION OF WINCH

The winch has three basic assemblies:

1. Hydraulic motor assembly and brake valve

2. Cable drum assembly

3. Brake cylinder and motor adapter

The hydraulic motor is bolted to the motor adapter

which in turn is bolted to the brake cylinder and the

winch base. The cable drum assembly is supported

by antifriction bearings which are located by the brake

housing at one end and the bearing support at the other

end. The ring gear for both planetary sets is machined

on the inside surface of the cable drum.

PLANETARY GEAR TRAIN

The hydraulic motor shaft is directly coupled to the

inner brake hub which is connected to the input shaft

which acts as the sun gear for the primary planetary

set. When driven by the input shaft, the primary planet

gears walk around the ring gear machined in the cable

drum and drive the primary planet carrier.

The primary planet carrier drives the output sun gear

which drives the output planet gears. The output planet

carrier is splined to the bearing support and cannot

rotate. As the output planet gears are driven by the

output sun gear, they drive the ring gear/cable drum.

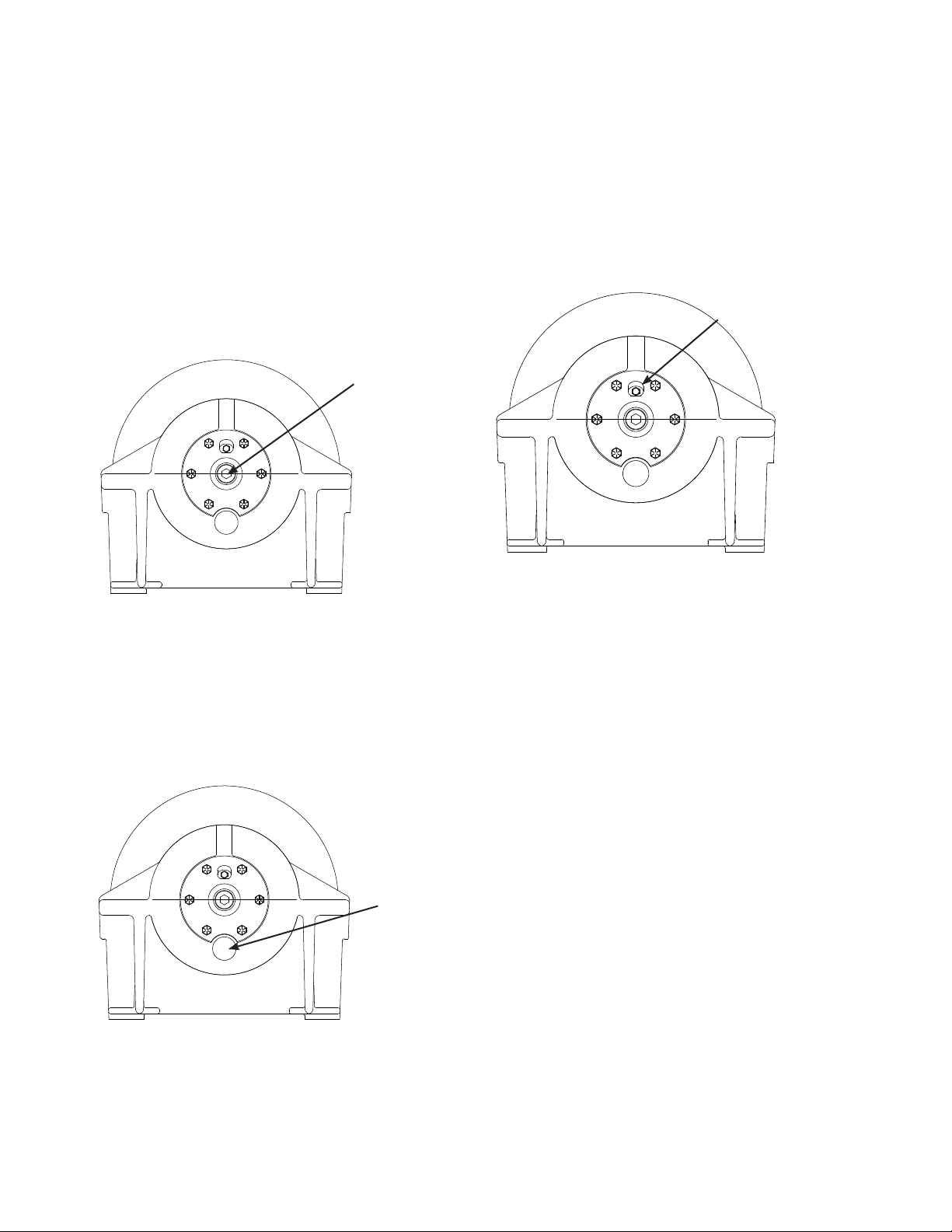

DUAL BRAKE SYSTEM

The dual brake system consists of a dynamic brake

system and a static brake system.

The dynamic brake system has two operating compo-

nents:

1. Brake valve assembly

2. Hydraulic motor

The brake valve is basically a counterbalance valve.

The counterbalance valve is mounted to the hoist port

of the motor on units with 020, 029 and 039 motors.

Units with the 071 motor use a counterbalance valve

cartridge in the brake valve block which is bolted to

the motor. The operational theory of both systems is

the same. A check valve allows free flow of oil to the

motor in the haul-in direction and a pilot operated,

spring-loaded spool valve blocks the flow of oil out of

the motor when the control valve is placed in neutral.

When the control valve is placed in the pay-out posi-

tion, the spool valve remains closed until sufficient pilot

pressure is applied to the end of the spool to shift it

against spring pressure and open a passage. After the

spool valve cracks open, the pilot pressure becomes

flow-dependent and modulates the spool valve opening

which controls the pay-out speed. .

The static brake system has three operating compo-

nents:

1. Spring-applied, multiple friction-disc brake pack

2. Overrunning brake clutch assembly

3. Hydraulic brake cylinder and spring plate

The static brake consists of alternately stacked fric-

tion and steel brake discs. The steel brake discs are

externally splined to the motor adapter and cannot

rotate. The friction discs are internally splined to the

outer brake hub of the overrunning brake clutch. When

compressed by spring force, the brake pack locks the

overrunning brake clutch outer brake hub to the motor

adapter.

The static brake is released by the pilot pressure at a

pressure lower than that required to open the pilot oper-

ated brake valve. This sequence assures that dynamic

braking takes place in the brake valve and that little, if

any, heat is absorbed by the friction brake.

The friction brake is primarily a load holding brake and

will provide dynamic braking only during extremely slow

operation when there is insufficient flow to open the

brake valve.

The sprag type overrunning brake clutch is installed

between the inner brake race and the outer brake hub.

The overrunning brake clutch, allows the inner brake

race and input shaft to turn freely in the direction to haul

in cable and locks up to force the friction brake discs to

turn with the inner brake race and input shaft to pay out

cable. The brake pack remains fully applied when haul-

ing in cable and must be released by pilot pressure to

allow the brake discs to turn freely and pay-out cable.

THEORY OF OPERATION

4

Power Flow

(hoisting)