TABLE OF CONTENTS

TITLE PAGE

General Information............................................................................................................................................... 1

Use Of This Manual .................................................................................................................................... 1

Introduction ................................................................................................................................................. 2

Specifications............................................................................................................................................... 3

Product Application..................................................................................................................................... 4

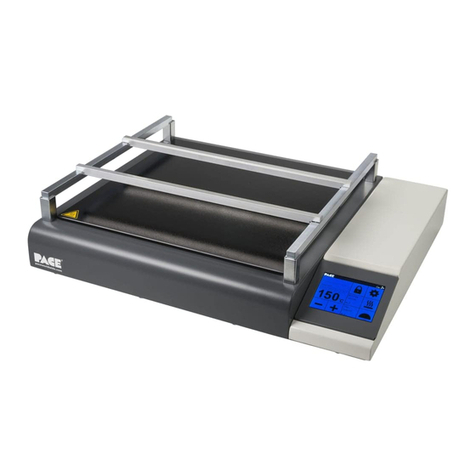

Parts Identification ...................................................................................................................................... 4

Front Panel ............................................................................................................................................. 4

Rear Panel .............................................................................................................................................. 6

ThermoFlo Handpiece............................................................................................................................ 7

Optional Accessories.............................................................................................................................. 7

Safety ...................................................................................................................................................................... 8

Heading Guidelines ..................................................................................................................................... 8

Precautions .................................................................................................................................................. 9

Set-Up ................................................................................................................................................................... 10

Electrical Requirements ............................................................................................................................ 10

System Set-Up ........................................................................................................................................... 10

Angle Bracket Kit ................................................................................................................................ 11

ThermoFlo Cubby Kit .......................................................................................................................... 12

Hose Retention Kit ............................................................................................................................... 12

QuickFit Nozzle Adapter ..................................................................................................................... 14

Optional Accessories............................................................................................................................ 14

Power Up .............................................................................................................................................. 15

Quick Start ........................................................................................................................................................... 16

Introduction ............................................................................................................................................... 16

Manual Mode Of Operation ...................................................................................................................... 16

Timed Mode Of Operation ........................................................................................................................ 18

Program Mode Of Operation..................................................................................................................... 20

Process Development ........................................................................................................................................... 22

Introduction ............................................................................................................................................... 22

Profile Development .................................................................................................................................. 22

Suggested Starting Parameters.................................................................................................................. 23

Profile Control Chart................................................................................................................................. 24

Profile Log ................................................................................................................................................. 25

General Process Guidelines.................................................................................................................................. 26

Component Preparation............................................................................................................................. 26

Component Positioning ............................................................................................................................. 26

Component Installation ............................................................................................................................. 26

Preheating.................................................................................................................................................. 29

Operation .............................................................................................................................................................. 28

Definitions ................................................................................................................................................. 28

Nozzle Selection ........................................................................................................................................ 30

ii

Table of Contents