- 3 -

Safety Precautions

1. NEVER touch the display with a hot soldering iron or other hot tools.

2. Wait one hour after unpacking the device to allow any condensation built up during transport to

dissipate.

3. Do not expose the device to water or other moisture.

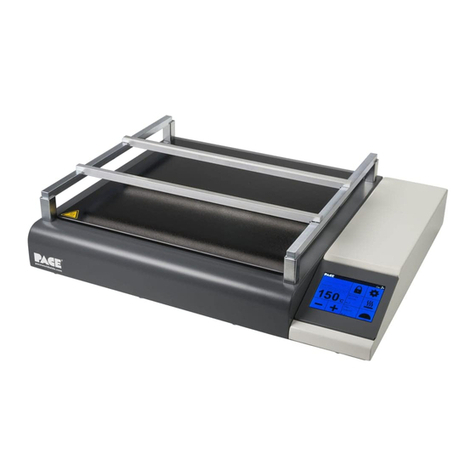

4. The PH 100 Preheater must only be used indoors near a suitable power source. Avoid using extension

cords. When not in use, store unit in a clean, dry place.

5. Place the PH 100 Preheater device on a solid, hard, dry, stable surface with good ventilation. Do not

place the device on damaged or heat-sensitive surfaces. Leave space around the device and

underneath (min. 20 cm) for proper ventilation.

6. WARNING: ALWAYS let the PCB cool down before touching it after heating. After Power Off, the device

will take up to 30 minutes to cool down. Wait for the device to cool down before touching the glass-

ceramic heating plate. Always turn off the system and verify it has cooled down before leaving it

unattended. The heating plate is hot and may cause burn injuries. ALWAYS use heat-insulated gloves.

7. The PH 100 MUST ONLY be used for preheating PCBs for soldering and rework operations.

8. DO NOT use the device if the glass-ceramic heating plate is cracked, or otherwise damaged or broken.

9. DO NOT place PCB’s (or anything else) directly onto the glass-ceramic heating plate.

10. ALWAYS mount the PCB to be preheated onto the PCB holder.

11. PH 100 Preheater should only be used by trained personnel.

12. DO NOT use the device near flammable materials. DO NOT store flammable materials near the device.

ALWAYS consult the MSDS (Material Safety Data Sheet) of materials to check their flammability.

13. DO NOT attempt to modify or repair the device yourself. If a fault develops, contact us at

support@paceworldwide.com (USA) or sales@paceworldwide.com (Europe). The case is sealed by a

hologram label. If this is damaged, the warranty is automatically voided.

14. ALWAYS check that the power cable is not damaged before every use.

15. PH 100 Preheater MUST ONLY be connected to a properly grounded (earthed) power supply of the

proper voltage and frequency (PH 100 120VAC, 50/60 Hz; PH 100E 230VAC 50/60 Hz). Always check

that the ground (earth) is working correctly.

16. Minimum/Maximum ambient temperatures: Min = +5°C (41°F); Max = +40°C (104°F)

17. Humidity Limits: Up to 80% relative humidity at 31°C, which decreases linearly between 31°C and 40°C,

to a maximum of 50% relative humidity. Maximum operating altitude above sea-level 2000m (6562 ft.).

18. During soldering and rework processes, toxic/noxious fume emissions may be released. ALWAYS use

Fume Extraction or exhaust ventilation as specified in the MSDS of the solder, flux and solvent materials

being used. As with all soldering devices, particularly in industrial use, it may be necessary to measure

the emissions, which should be done by an expert.

19. DO NOT place the magnetic PCB holder rails or magnetic feet on a hot surface as they may become

demagnetized.

20. The power outlet MUST be easily reachable to cut off the power in case of emergency. The power can

only be cut by unplugging the device from the power outlet or unplugging the cord from the unit. Even

after you have turned off the device using the ON/OFF switch, it is still connected to live power.