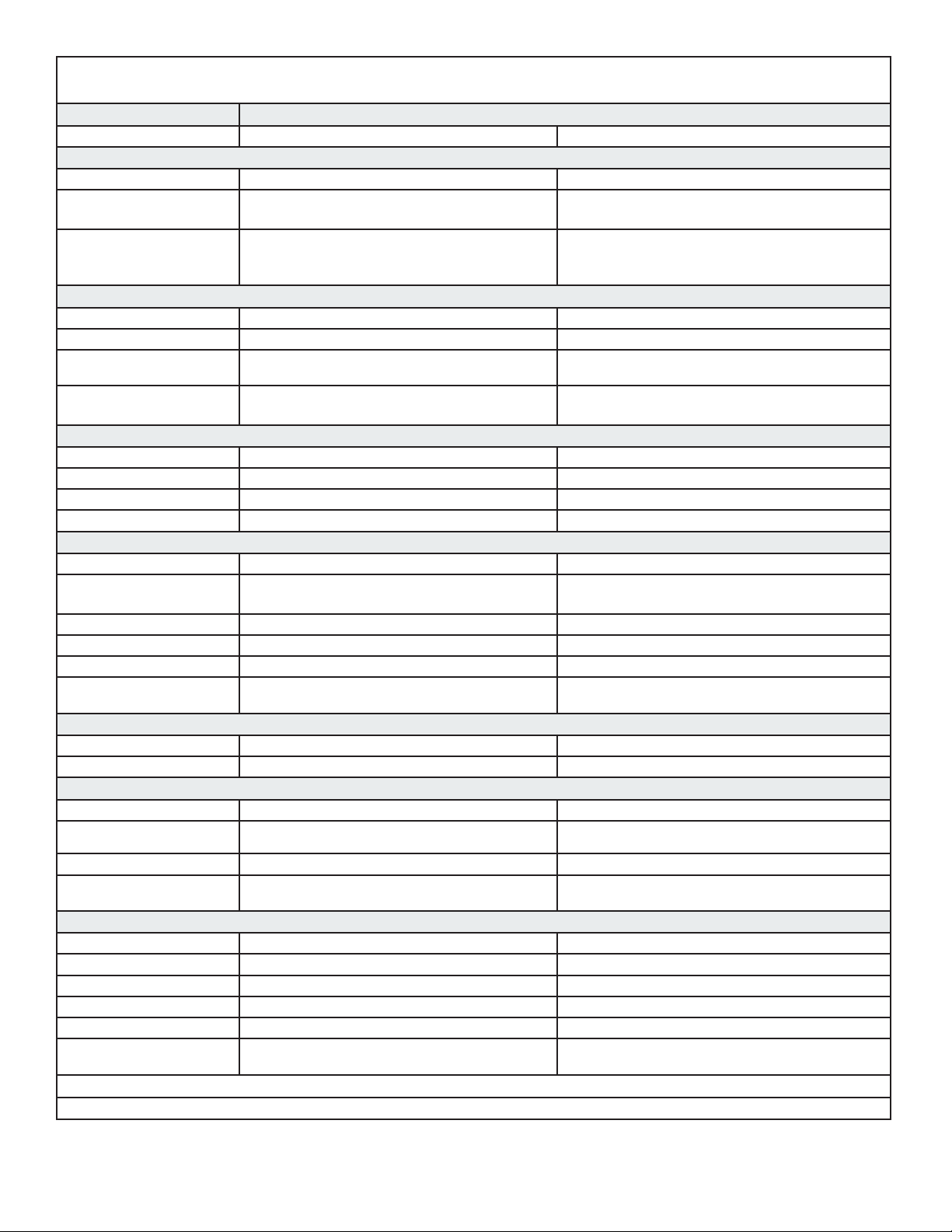

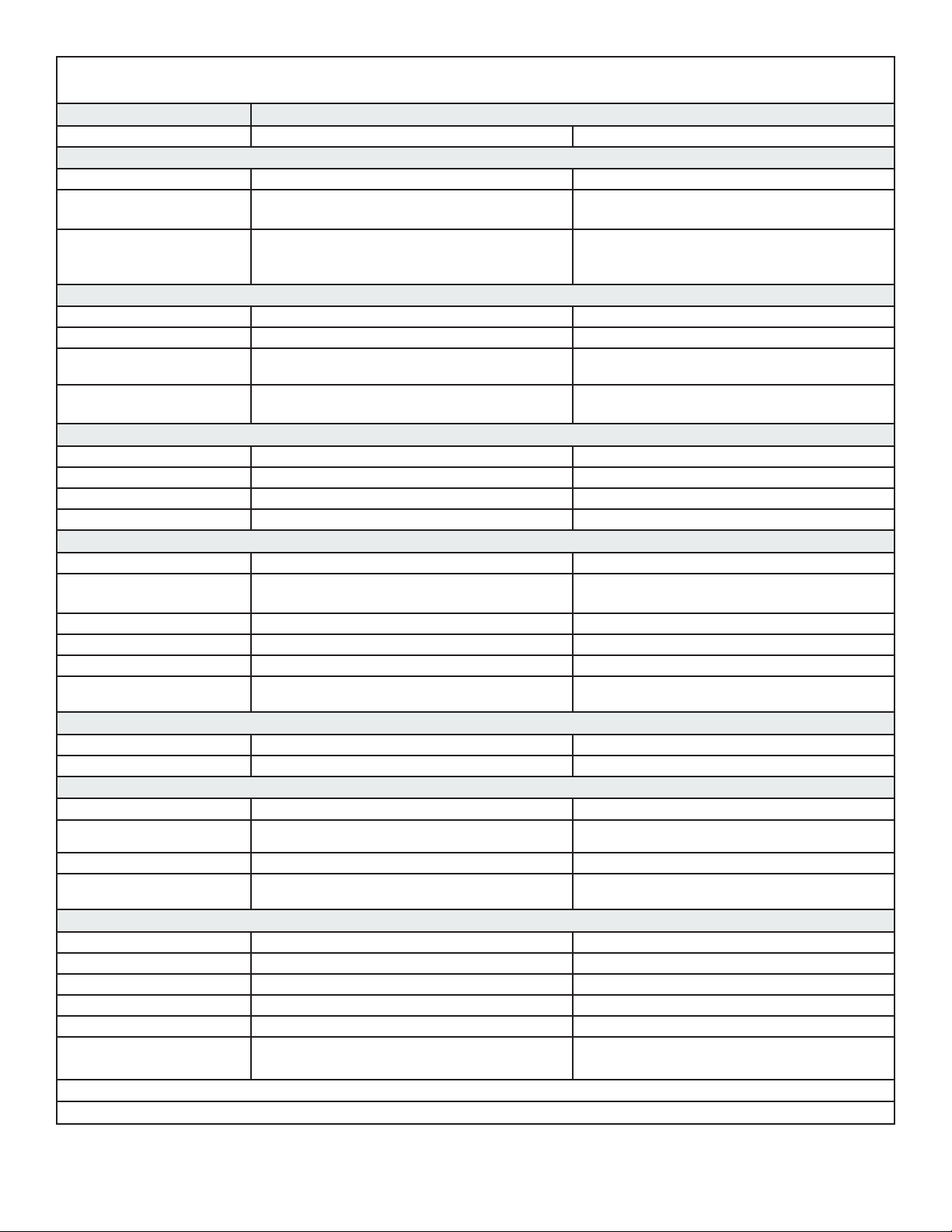

TABLE OF CONTENTSTABLE OF CONTENTS

SAFETY INFORMATION ���������������������������������������������������������������������������������������������������������������������������������������������������1

UNPACKING THE MACHINE �������������������������������������������������������������������������������������������������������������������������������������������2

TRANSPORTING THE MACHINE �����������������������������������������������������������������������������������������������������������������������������������3

BATTERIES ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������4

SELECTION ..................................................................................................................................................................4

INSTALLATION ...........................................................................................................................................................4

SERVICING LEAD ACID BATTERIES (NON-HYDROLINK® MODELS) ..............................................................5

SERVICING LEAD ACID BATTERIES WITH HYDROLINK® ..............................................................................6

WATERING SYSTEM ..................................................................................................................................................6

BATTERYSHIELD® AUTOMATED WET BATTERY PROTECTION SYSTEM......................................................7

CHARGING ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������9

ON-BOARD CHARGER ..............................................................................................................................................9

OFF-BOARD CHARGER ........................................................................................................................................... 11

PRE-USE SETUP�����������������������������������������������������������������������������������������������������������������������������������������������������������������12

ORBITAL PADS & CHEMICAL-FREE FINISH REMOVAL (CFR) ........................................................................16

DISK MACHINE PAD DRIVERS & BRUSHES .......................................................................................................17

SQUEEGEE SYSTEM ................................................................................................................................................19

RECOMMENDED MAINTENANCE�������������������������������������������������������������������������������������������������������������������������������22

RECOMMENDED SERVICE PARTS ������������������������������������������������������������������������������������������������������������������������������23

TROUBLESHOOTING GUIDE ����������������������������������������������������������������������������������������������������������������������������������������26

PARTS DIAGRAMS������������������������������������������������������������������������������������������������������������������������������������������������������������28

BATTERIES, BATTERYSHIELD® & HYDROLINK® .............................................................................................28

OPTIONAL ONBOARD CHARGER .........................................................................................................................29

CONTROLS .................................................................................................................................................................30

ELECTRONICS ...........................................................................................................................................................37

FRAME ASSEMBLY ..................................................................................................................................................41

HEAD LIFT ASSEMBLY ............................................................................................................................................42

SOLUTION TANK ......................................................................................................................................................43

RECOVERY TANK AND VACUUM .........................................................................................................................44

OPTIONAL CHEMICAL INJECTION .......................................................................................................................46

35” SQUEEGEE ASSEMBLY .....................................................................................................................................47

40” SQUEEGEE ASSEMBLY .....................................................................................................................................48

45” SQUEEGEE ASSEMBLY .....................................................................................................................................49

SQUEEGEE LINK.......................................................................................................................................................50

SCRUB HEADS ..........................................................................................................................................................52

WIRING DIAGRAMS ��������������������������������������������������������������������������������������������������������������������������������������������������������64

S-24 WIRING DIAGRAM ..........................................................................................................................................64

S-28 (DISK) & S-32 WIRING DIAGRAM .................................................................................................................66

S-28 ORBITAL WIRING DIAGRAM ........................................................................................................................68

BATTERYSHIELD® (OPTIONAL) WIRING DIAGRAM ........................................................................................70

OPTIONAL CHEMICAL INJECTION WIRING DIAGRAM ...................................................................................71