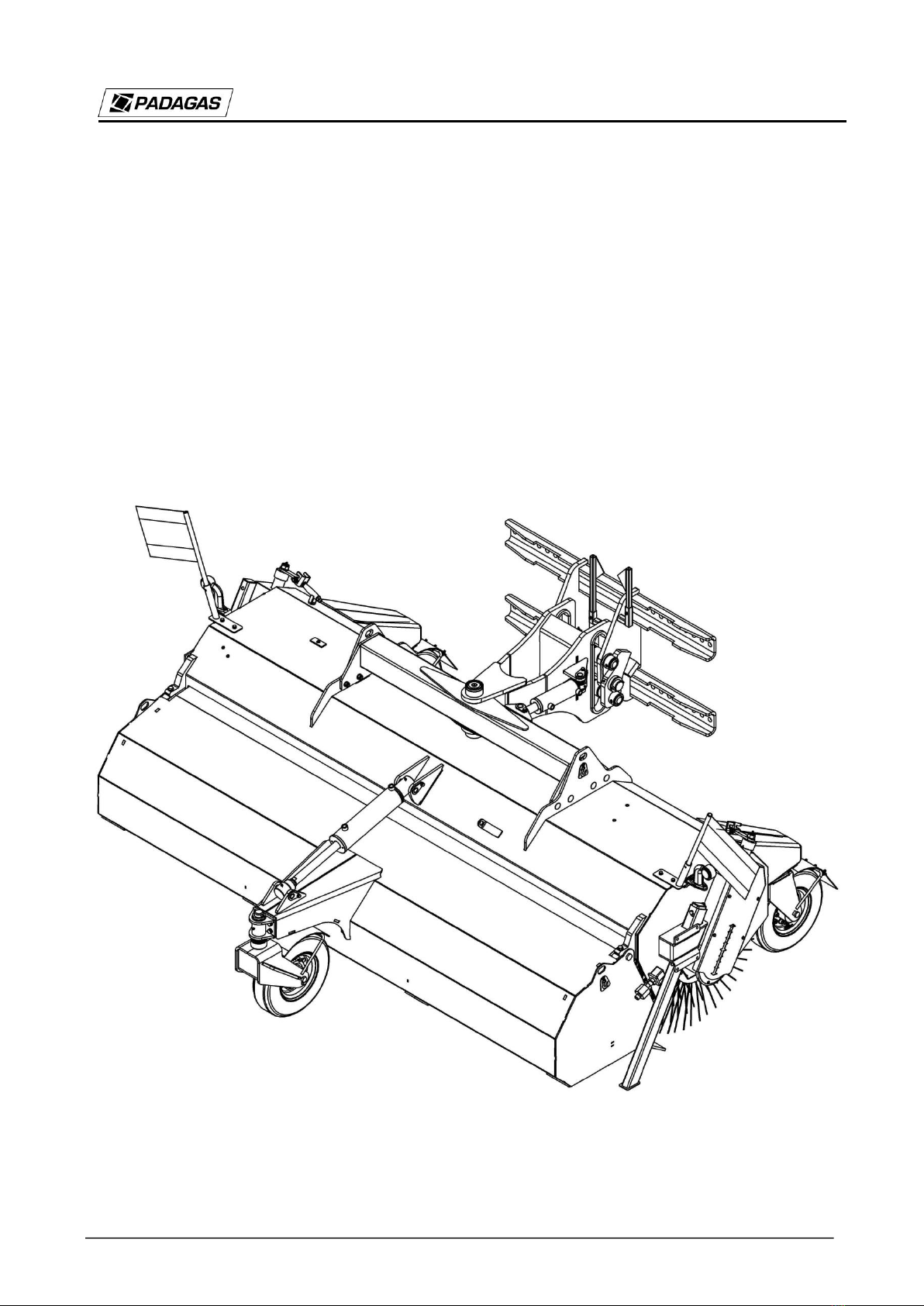

PROFI H

©V. Padagas ir ko., UAB. All rights reserved.

CONTENTS

1. INTRODUCTION ................................................................................................................................................ 6

1.1 BASIC DATA................................................................................................................................................. 6

1.2 THE INTENDED USE.................................................................................................................................... 6

2. SAFE HANDLING INSTRUCTIONS....................................................................................................................... 7

2.1 GENERAL..................................................................................................................................................... 7

2.2 PERSONNEL QUALIFICATION AND TRAINING............................................................................................. 7

2.3 POTENTIAL HAZARDS IN CASE OF BREACH OF SAFETY INSTRUCTIONS ..................................................... 7

2.4 PRINCIPLES OF SAFE OPERATION .............................................................................................................. 8

2.5 SAFETY INFORMATION FOR THE OPERATOR / USER ................................................................................ 8

2.6 SAFETY INSTRUCTIONS FOR MAINTENANCE, INSPECTION AND MOUNTING ......................................... 10

2.7 RE-MOUNTING AND REPLACING PARTS INDEPENDENTLY...................................................................... 11

2.8 INSTRUCTION AND WARNING NOTES AND SYMBOLS ON THE SWEEPING MACHINE............................. 11

3. ADDITIONAL DATA.......................................................................................................................................... 13

3.1 DOCUMENTS PROVIDED WITH THE SWEEPING MACHINE ...................................................................... 13

3.2 WARRANTY CONDITIONS ......................................................................................................................... 13

3.3 DISPOSAL OF THE SWEEPING MACHINE AT COMPLETION OF THE OPERATION...................................... 13

4. DIRECTIONS FOR USE...................................................................................................................................... 14

4.1 TECHNICAL DATA...................................................................................................................................... 14

4.2 DESCRIPTION OF THE SWEEPING MACHINE............................................................................................ 14

4.3 LIGHTS....................................................................................................................................................... 15

5. SWEEPING MACHINE OPERATION.................................................................................................................. 15

5.1 CONNECTING THE SWEEPER TO THE TRACTOR ....................................................................................... 15

5.2 CONNECTION OF THE SWEEPING MACHINE TO THE HYDRAULIC SYSTEM .............................................. 16

5.3 TEST OPERATION ..................................................................................................................................... 16

5.4 OPERATING THE SWEEPING MACHINE..................................................................................................... 16

5.5 HYDRAULIC UNIT ...................................................................................................................................... 18

5.6 LUBRICATION SCHEME ............................................................................................................................. 19

6. SWEEPER EQUIPMENT.................................................................................................................................... 20

6.1 ADDITIONAL EQUIPMENT......................................................................................................................... 20

6.2 PAKABU RĖMAS........................................................................................................................................ 20

6.3 HIDRAULINIAI KOMPONENTAI IR PAPILDOMOS OPCIJOS........................................................................ 20

6.4 ELEKTRINIAI KOMPONENTAI .................................................................................................................... 21