9

Jet Swim Athlete

MA30-11 GB

ENGLISH

M1302313006529

PVCPlugg 2½"

122

Torx A4 FM5x2019920230Rostfritt A4Skruv MFT A4 M5x20221

M12901130065181.4404Athlete front120

Pan head Torx 4x1019922115Rostfritt A4Skruv MRT A4 M4x10819

M1297613006516Polykarbonat (PC)Insugsgaller218

M12900130065171.4404

Reglageplåt

117

Torx A4 FM5x1619920225Rostfritt A4Skruv MFT A4 M5x162416

M12902130065151.4404Spännram Athlete115

M1296713006514

EPDM Sh60

Packning 452x142x1,5114

M1296813006513

EPDM Sh60Packning självhäftande

113

ISO 6923 M5 A419930024Rostfritt A4Flänsmutter M6MF M5812

M1298113006512Mässing CW602NFlödesaxel111

M1297813006509Polykarbonat (PC)Styrplatta plast110

M127681224671.4404Startknapp19

M12769122465EPDM Sh40Bälg18

M12770122466Polykarbonat (PC)Anslutningsnippel17

M1298013006510PVCSnäckdrev16

M12979130065111.4404Flödesvred15

M12977130065081.4404

Styrplåt

14

M1297413006507Polykarbonat (PC)

Munstycke Athlete

13

M1297513006506EPDM Sh60Packning munstycke22

M12973130065051.4404Chassi Athlete11

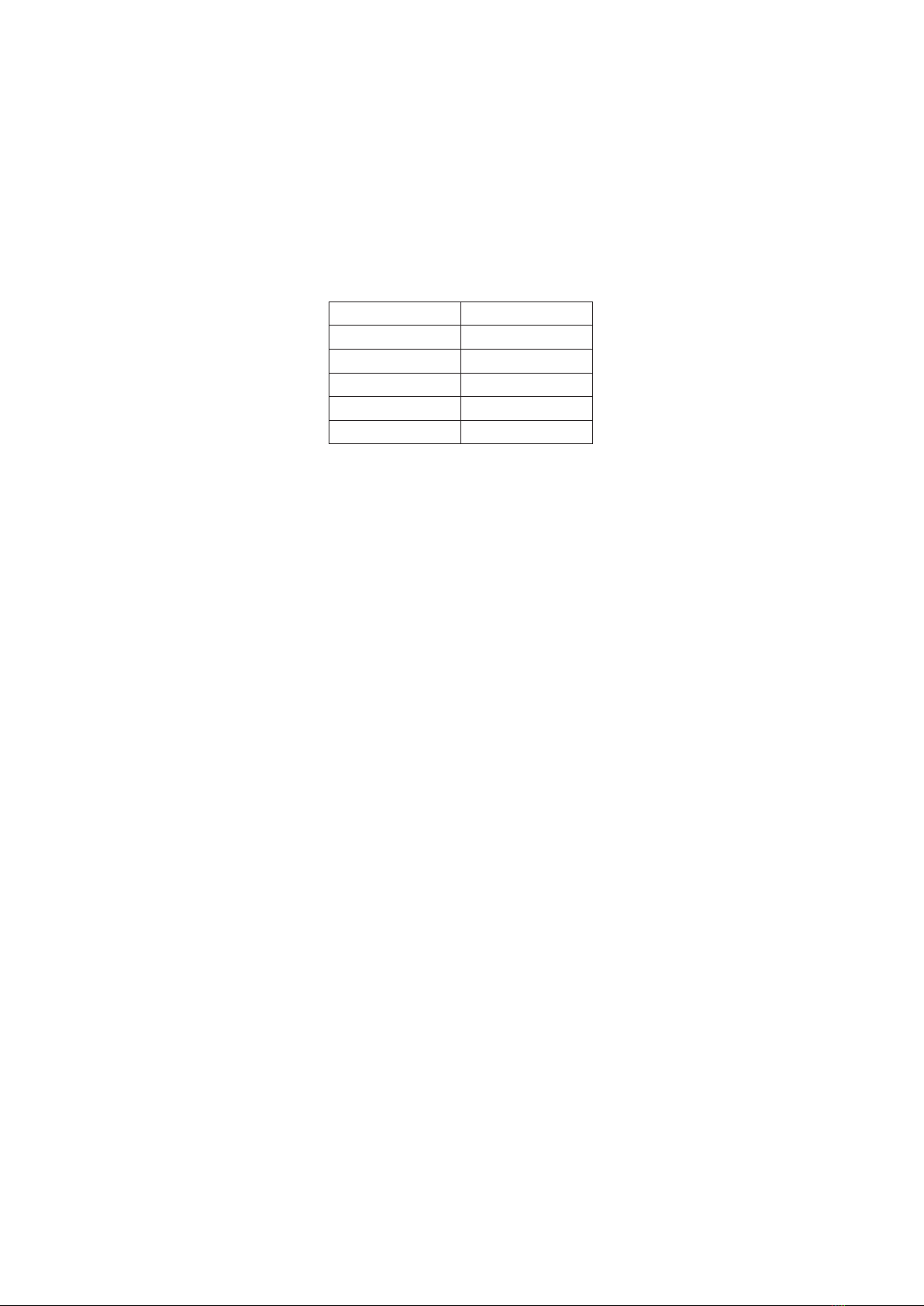

Drawing.no:Art_nrMaterialTitle/ NameQty.Item.

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-1

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

1:4

1302100

RJ 2018-12-12

Grundsats Jet Swim Athlete

M12983 1

This document and its contents are the exclusive

property of Pahléns and may not be copied,

reproduced, transmitted or communicated to a third

party, or used for any purpose without written permission.

22

1

2

3

191721 20 18

10 9

6

874

5

12

13141516

11

REV DESCRIPTION DATE APPROVED

1Bytt längd påingående skruvar 2019-03-14 RJ

This document and its contents are the exclusive

property of Pahléns and may not be copied,

reproduced, transmitted or communicated to a third

party, or used for any purpose without written permission.

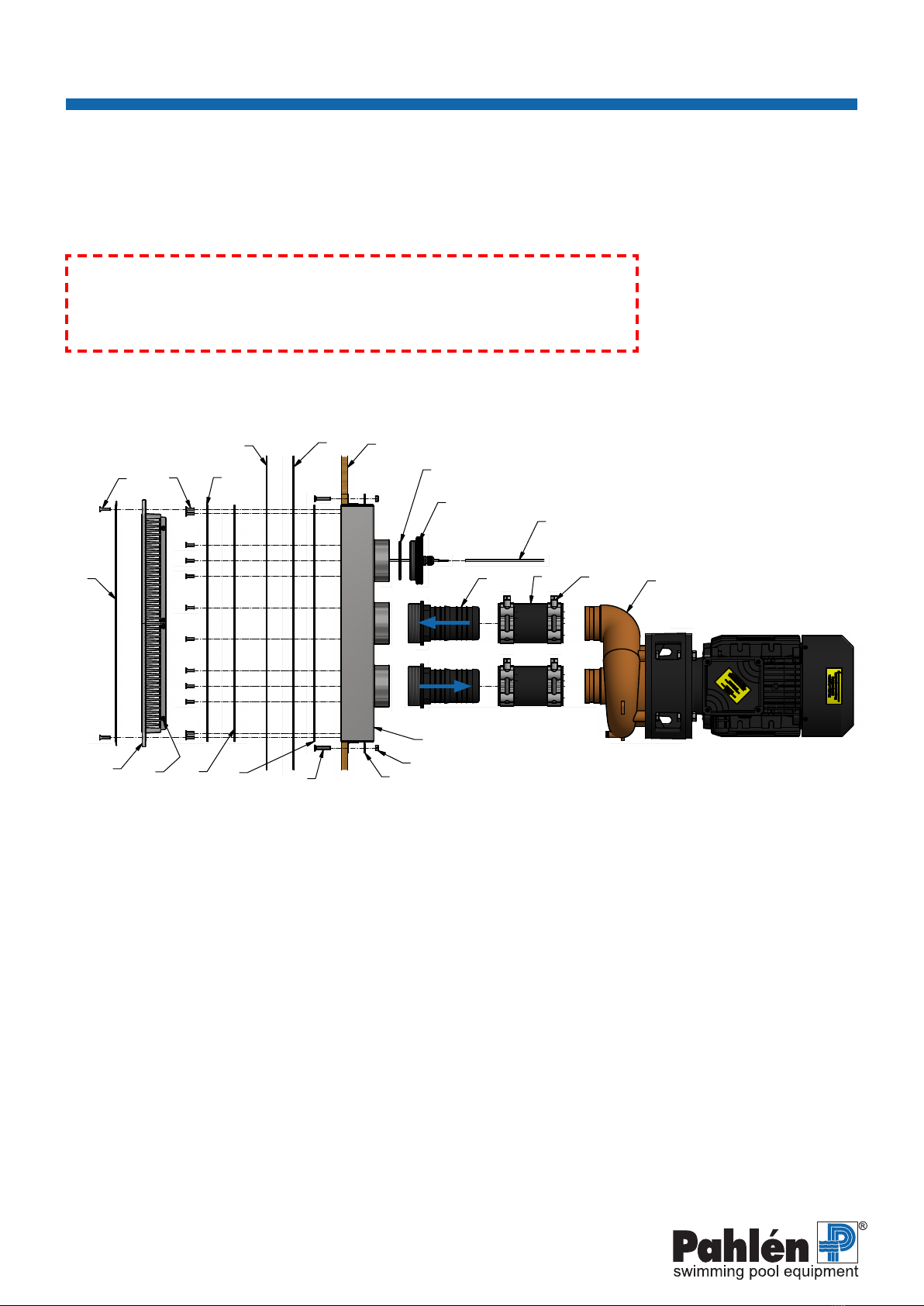

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-1

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

1302185

RJ 2019-02-11

Jet swim Athlete pump

M13021 0

This document and its contents are the exclusive

property of Pahléns and may not be copied,

reproduced, transmitted or communicated to a third

party, or used for any purpose without written permission.

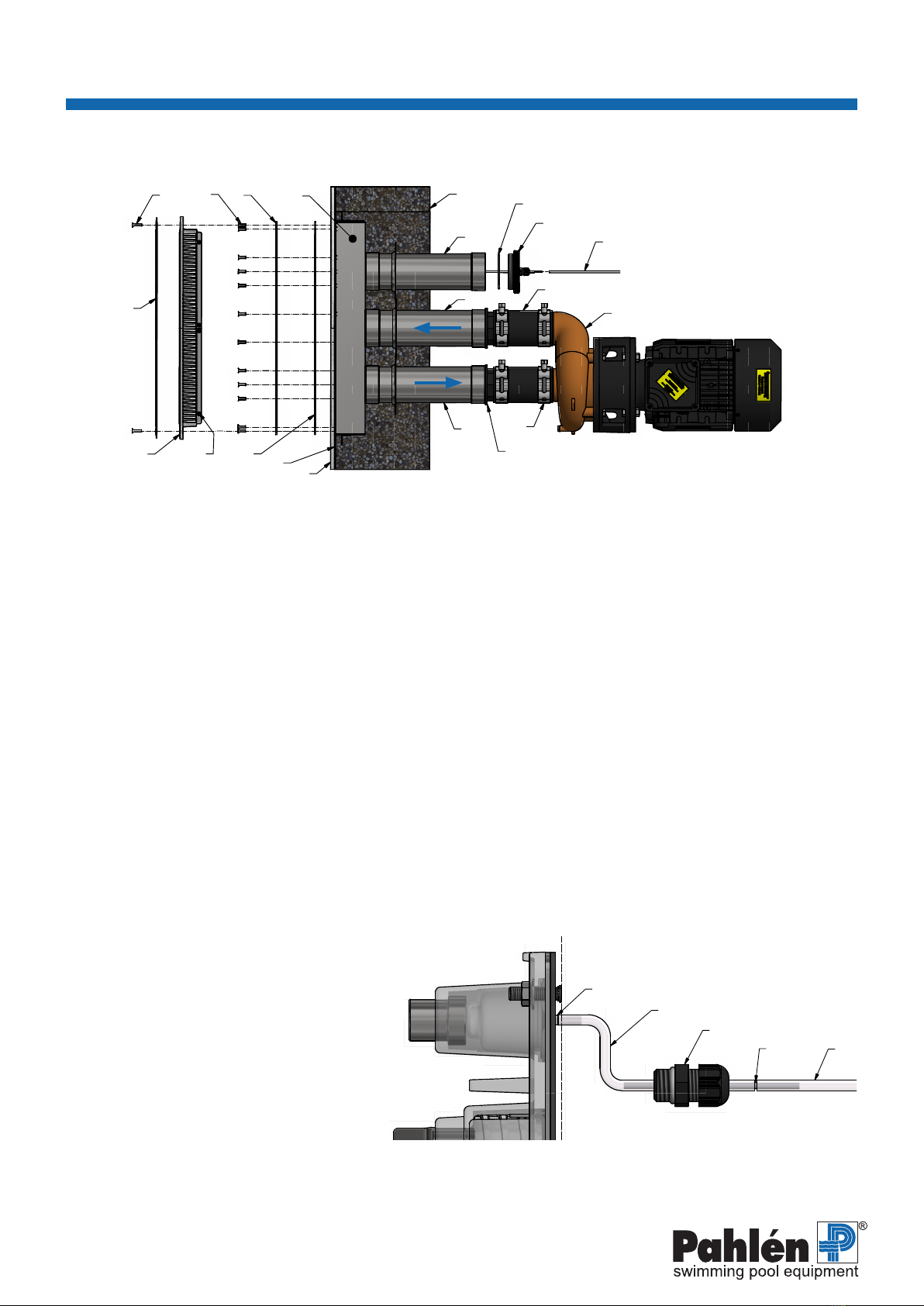

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-1

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

1:2

RJ 2019-03-25

Ingjutningsrör 2½" Athlete

M13026 0

This document and its contents are the exclusive

property of Pahléns and may not be copied,

reproduced, transmitted or communicated to a third

party, or used for any purpose without written permission.

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-1

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

1:2

RJ 2019-03-25

Ingjutningsrör 2½" Athlete

M13026 0

This document and its contents are the exclusive

property of Pahléns and may not be copied,

reproduced, transmitted or communicated to a third

party, or used for any purpose without written permission.

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-1

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

1:2

RJ 2019-03-25

Ingjutningsrör 2½" Athlete

M13026 0

It is important to read through this manual carefully in order to ensure the function and useful length of the pool equipment.

Pahlén AB is not responsible for product warranties or damages that occur as a result of faulty installation, improper use or poor

maintenance.

Product Description

The Jet Swim Athlete consists of the following parts:

Essential parts Mounting kit

(for thick pool wall)

Pump kit Control box

Technical Data

Current

Pump capacity 3 3

IP class IP55

The product is intended for the following water values:

Total chlorine content: Iron:

Chloride (salt) content: Copper:

Manganese:

Alkalinity Phosphorus:

Calcium hardness:

The product warranty does not apply outside these values.

CENELEC* members:

Note!

mental capabilities or lack of experience and knowledge, if they have been given supervision or instruction concerning use

and user maintenance shall not be made by children without supervision.

Other countries than CENELEC members (according to IEC):

Note! This appliance is not intendend for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning the

use of the appliance by a person responsible for their safety. Children should be supervised to ensure that they do not play

with the appliance.

Safety

The jet stream is powerful, which is why one should not be closer than 0.5 m from the stream outlet for a protracted period.

People with long hair should pay careful attention so that their hair does not get stuck in the inlets (the perforated openings in

the front).

Small children should not be in the pool without supervision, especially not when the Jet Swim Athlete device is in operation.

Always inform all the other bathers in the pool before starting the Jet Swim Athlete.

Always make sure that the power to the pump is turned o prior to any work, service or maintenance of the pump begins.