2 9710 VCA 000216

ASSEMBLING THE 9710 Triple VCA W/Modulator

Before beginning assembly, go through the manual.

Look at the drawings. Feel the parts. You’re

naturally eager to plunge right in, but take a few

deep breaths first. Check the parts supplied against

the packing list on the last page of this manual.

In some cases, notes packed with the parts will

be used to call your attention to special situations.

These notes may be in the yellow "MISSING PARTS"

postcard. If parts are missing please notify PAiA at

Notice that each step in the manual is marked with

a checkoff box like this:

DESIGNATION VALUE COLOR CODE

( ) R27 100 ohm brown-black-brown

Checking off each step as you do it may seem

silly and ritualistic, but it greatly decreases the

chance of omitting a step and also provides

some gratification and reward as each step is

completed.

Numbered figures are printed in the Illustrations

Supplement in the center of this manual. These pages

may be removed for easy reference during assembly.

THE CIRCUIT BOARD

The 9710 VCA is built on a double-sided circuit

board. No special preparation or cleaning is necessary

before assembly. The "top" of the board is the side that

is printed with component designations and parts are

mounted from this side. The "bottom" of the board is

also called the solder side and is masked with a

conformal coating to lessen the chance of solder bridges.

Solder pads are tin-lead plated for ease of soldering and

assembly.

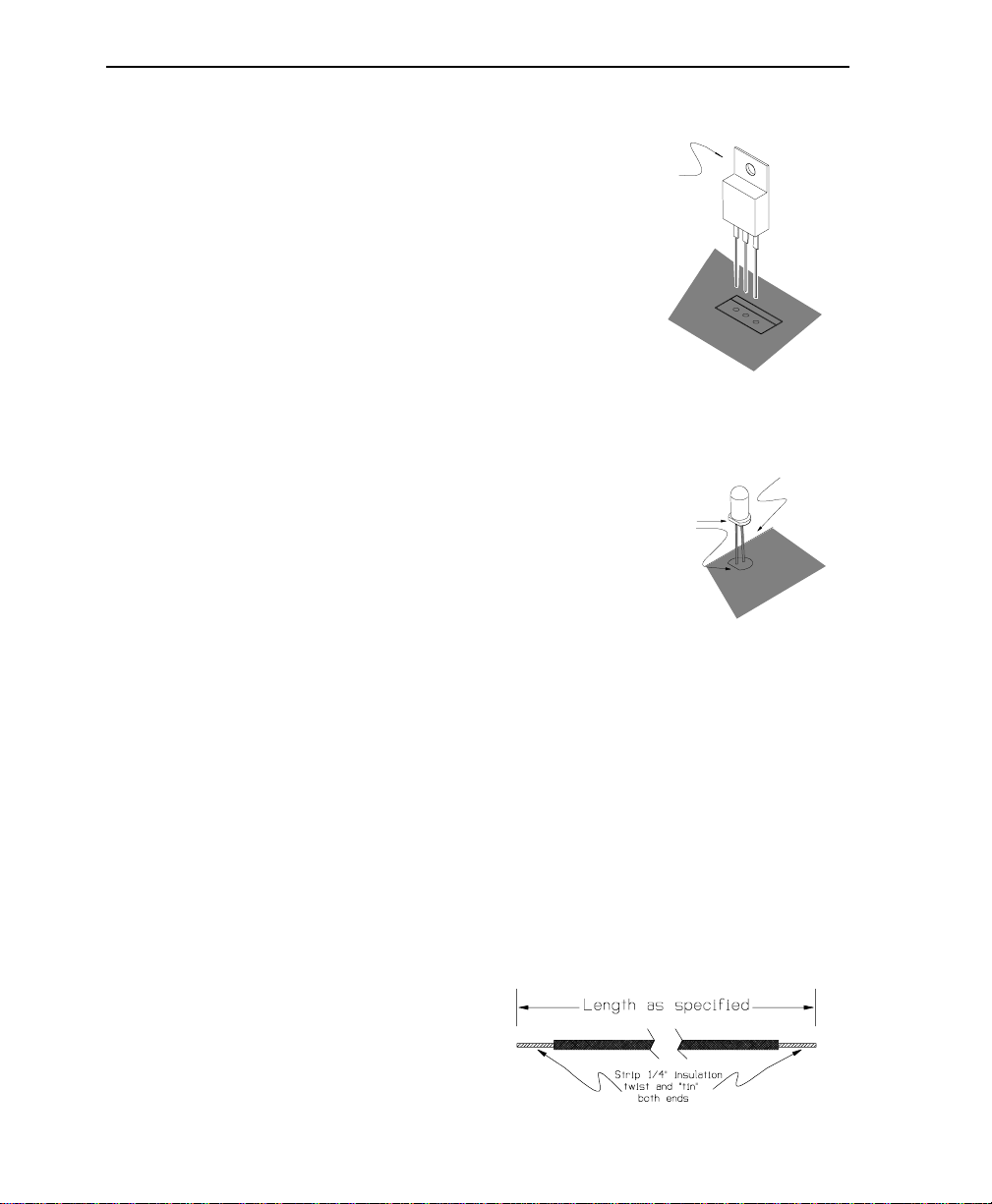

TOOLS

You’ll need a minimum of tools to assemble the kit

- a small pair of diagonal wire cutters and pliers,

screwdriver, sharp knife, ruler, soldering iron and