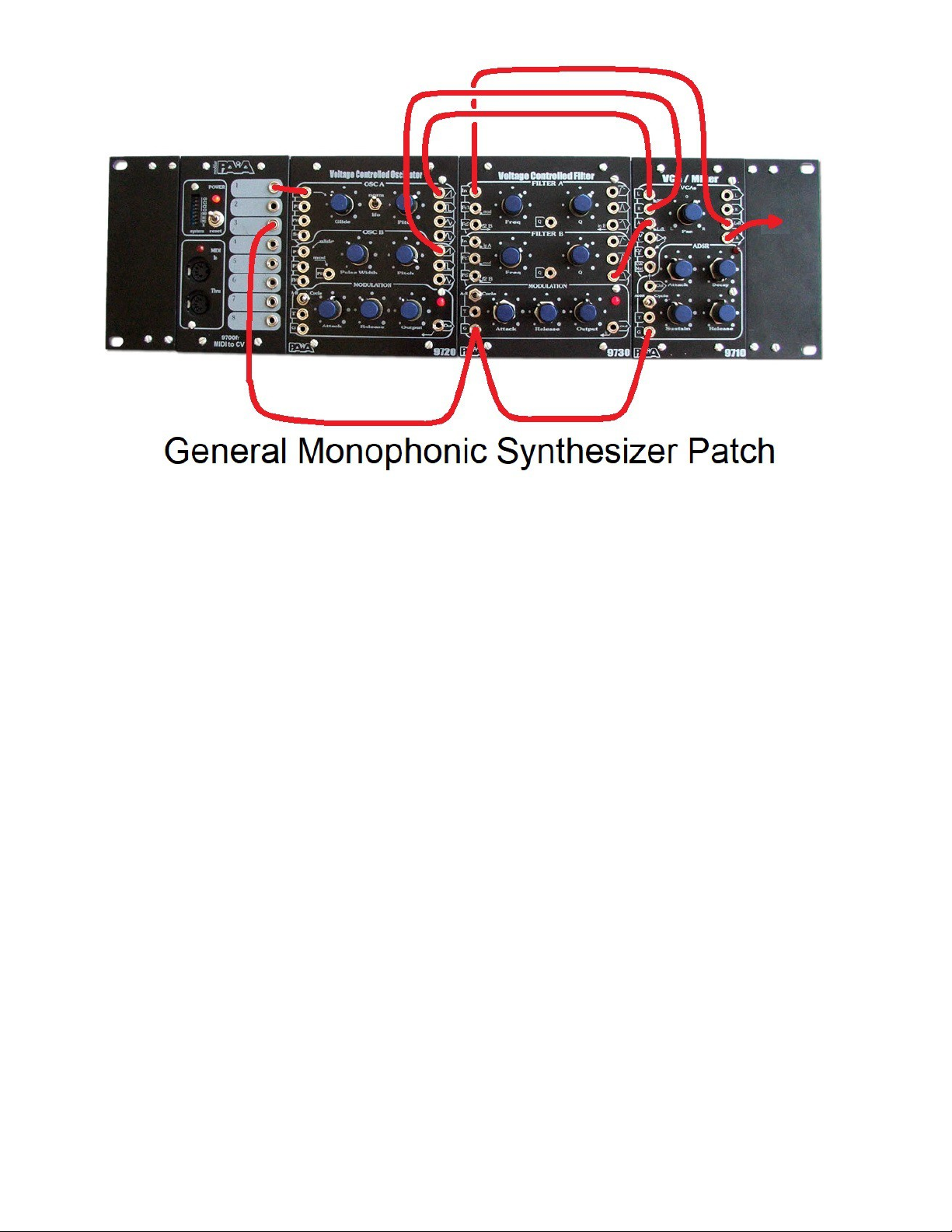

A general, monophonic synthesizer patch:

A common configuration is to start with the vc osci ators as the tone generator, to the L and R VCAs for a mix,

run through the vc fi ter for emphasis or de-emphasis of parts of that tone, and then through the vc amp ifier to

'frame' the sound. On the FatMan, two sawtooth (ramp) waves from the VCOs go to a LowPass VCF and then

to the VCA. Enve ope generators modu ate the VCF and VCA in response to the Gate trigger which indicates

the key pressed/re eased state. A Pitch CV amount according to the note pressed sets the VCO pitch.

A simp e way to imp ement this ead, mono synth patch on your P9700S is to make the fo owing connections

(patches). You may need to make some new cords a ong the way.

First, we' make the connections from the MIDI2CV8 operating in mode 1 for a mono voice comp ement of

outputs (power-up with the ow note pressed on the MIDI contro er and re ease it a coup e of seconds ater to

put the pitch cv in the best range). Use a sing e patch cord to go from the Pitch CV output on the MIDI2CV8 to

the P1 contro on VCO A. This a ows you to contro both osci ators and the G ide contro setting can be

adjusted to set the amount of time it takes for the osci ator frequency (pitch) to change for a Pitch CV change.

The Pitch contro of each osci ator can be adjusted so they are in unison or other re ationship (the rest of the

patch wi need to be made to hear this).

A 'Y' cord or one p ug with two wires and p ugs on it can be used to connect the Gate trigger output from the

MIDI2CV8 to the Gate trigger (G) inputs on the VCF and VCA modu es. This wi cause their enve ope

generator modu ators to start when a key is pressed.

Connect the two sawtooth waves from the VCOs to the L and R VCA inputs. The mix of the two waves is set

with the pan contro and the L+R output is the output of this mix and goes to VCF A In. We' take the output

from VCF B LowPass, or the bottom of the six connectors on the right-hand side with the graphic response

symbo s. Its best to keep the Q contro s at midway or so and the Frequency contro s s ight y different ti you

deve op a fee for the way the fi ter can accentuate or provide a boost on the signa . This boost can kick the

fi ter into osci ation or overdrive the VCA. The more the Q the more the boost, the ess the Q, the ess

'dramatic' the fi ter effect. The more simi ar the settings of the two series connected fi ters, the more critica the

Q setting. A cyc ic VCF modu ation is a neat effect too (instead of just an enve ope generator sweep in response

to the Gate). A Gate p us the cyc e setting gives a cyc e sync'ed to the key presses.

The VCA A section takes the VCF LowPass output with a sing e patch cord The VCA A output cou d patch to

a mixer or amp/speaker, etc.

The ADSR contro s set the dynamics of the sound as the keys are pressed and the enve ope is generated and

'opens' the VCA.

Note the VCO waveform outputs are high eve and you may need to set input eve s ower than for usua stuff,

or, a specia patch cord to attenuate the output can be made. I have one that puts a coup e of fixed resistors in

series from the tip to s eeve circuits on the p ug at 9700 end of the cab e and the signa is tapped at the junction

of the resistors for a more typica ' ine- eve '. The two resistors are a 10k and a 1k and the 10k attaches a the tip

and the 1k at the s eeve. The tap for the signa that wires on to the tip of the p ug for the mixer, amp/speaker, etc

is from the junction of the two resistors. The ground circuit is as usua --s eeve termina to s eeve termina . The

reason its needed here but not on modu e to modu e patches is that the modu es a share a ground a ready--the

power supp y ground circuit--but the synth and the externa device don't unti one connection is made between

them estab ishing a common ground.