10

Palax D410 Pro+ Translation 1-2020

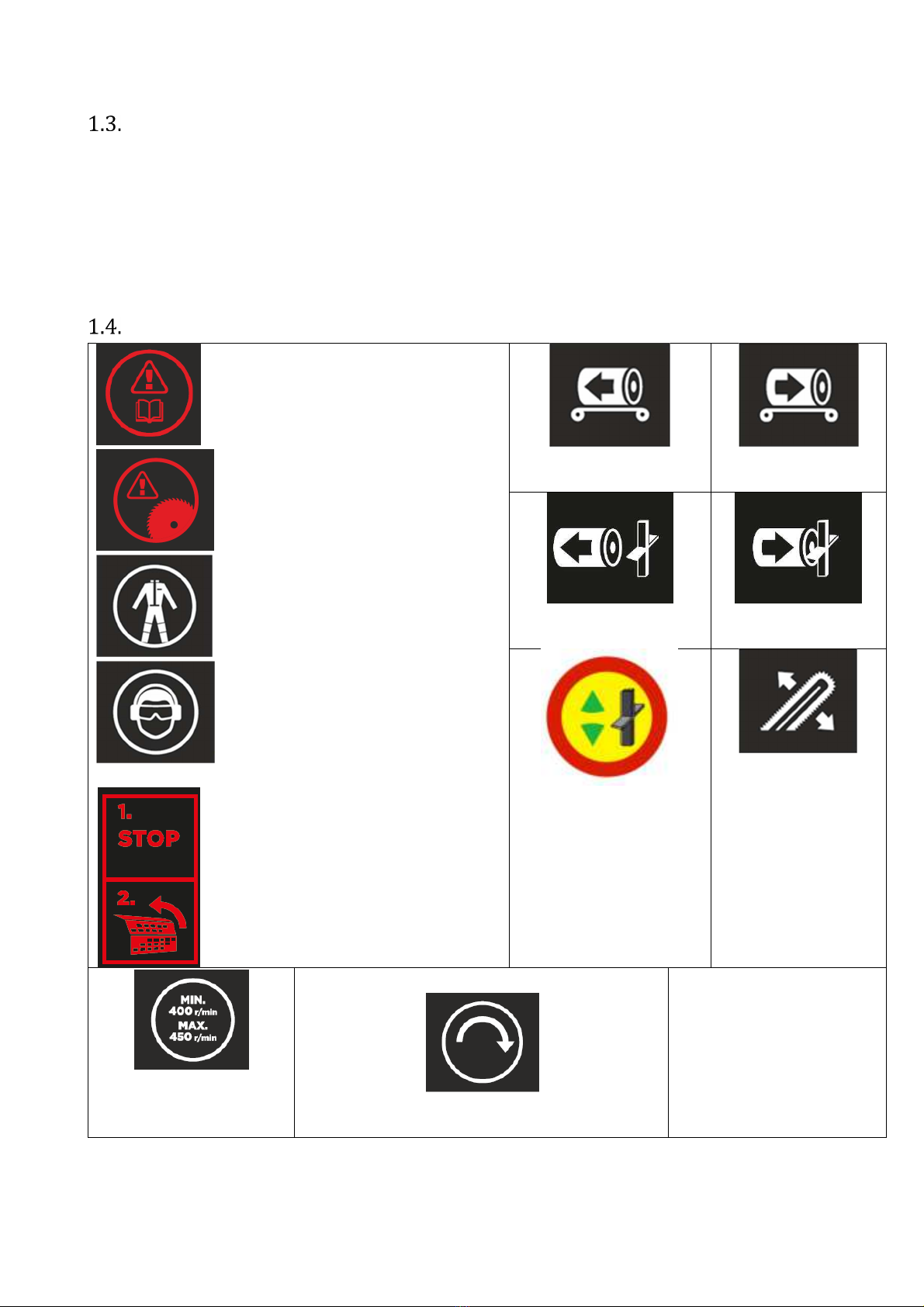

afety instructions

General reg lations and restrictions

Maximum length of the log that can be cut is 4 metres If no log-stand or log-deck is used

Maximum diameter of the log that can be split is 40 cm

The machine is exclusively intended for the production of firewood

The machine may be operated by one person only

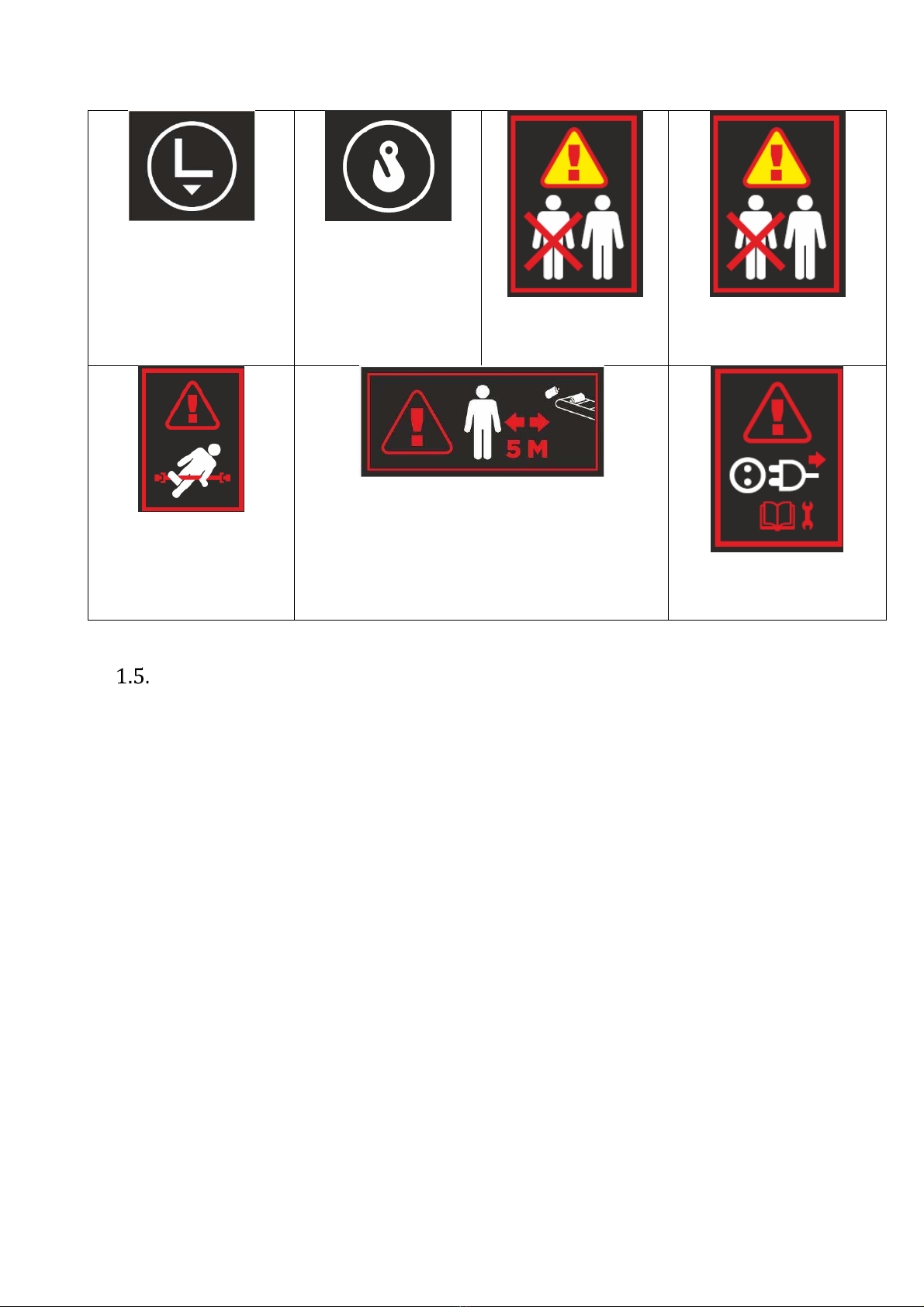

The danger zone around the conveyor is 5 metres to the sides and away from the conveyor

The machine must be equipped with additional lights for transport on public roads

The in-feed deck and the discharge conveyor must always be lifted up and locked in the transport

position for transport

Only persons over 18 years of age are allowed to operate the machine

Never remove any safety-related devices from the machine

The operator

Every person operating the machine, must thoroughly study the entire user manual

Always use eye guards and hearing protectors

Always wear protective shoes

Always wear work gloves

Do not wear loosely-fitting clothing

Before se

Always carry out the required preparations on both the machine and the conveyor before

starting the machine

Make sure that all other people stay outside the work area

Only use a fault-free PTO shaft and attach the chain for the shaft-guard The permissible

revolutions range of the PTO shaft is 400–450 r p m

Operate the machine on a sufficiently firm and level surface

Only operate the machine in an adequately lit space

Keep the tractor-powered machine connected to one of the drawbars Ensure that sufficient

space is provided for the PTO shaft and its guard

Always check that all the covers are intact and properly fastened

Always ensure that the saw-chain is in perfect condition

Always ensure that the electric conductors are intact

Always check that all the operating controls are operational

Always check the oil level and make sure that the hydraulic hoses and components are free of

damage

Before starting the work, make sure that the machine stands firmly in position

D ring operation

Carelessness during the cut-off operation constitutes a major hazard!

During the cut-off operation, make sure that the log is always supported on the in-feed belt at

the cutting point: danger of rolling over!

Exercise particular caution when cutting knotty or crooked logs, as faulty cutting might roll the

log over or twist the saw-bar with enough force to break it

Keep the work area clean and clear of foreign objects

Always stop the machine and disconnect the power supply cable or the PTO shaft before

servicing