| 1

C64.65201 Issue 3

Jun 2019

Table of Contents

Document Control................................................................................................2

Cautions and Warnings in This Document..............................................................2

Introduction.........................................................................................................2

Specifications.......................................................................................................3

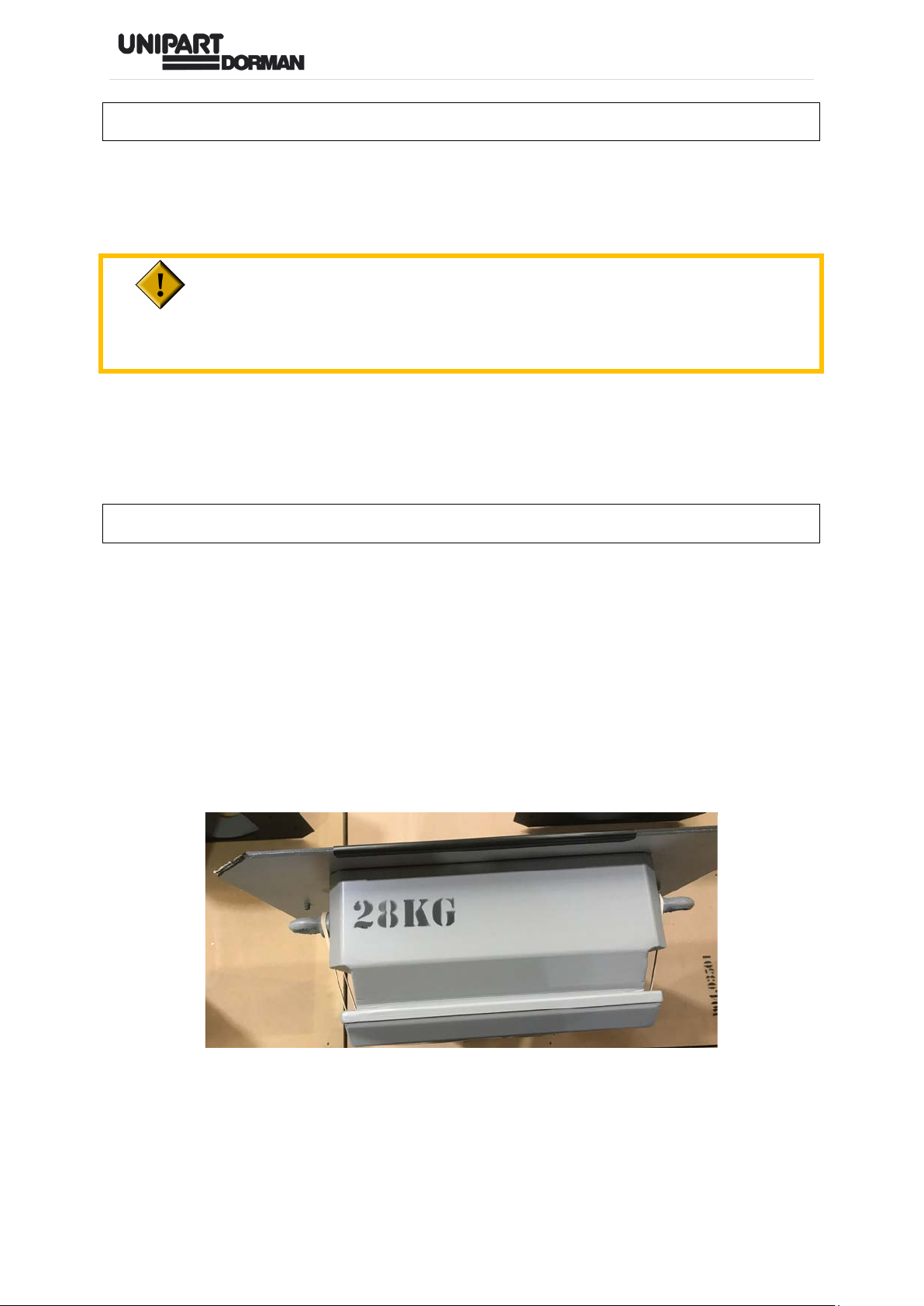

Storage ...............................................................................................................4

Safety .................................................................................................................4

Pre Installation Checks.........................................................................................5

CLS LITE Variants ................................................................................................5

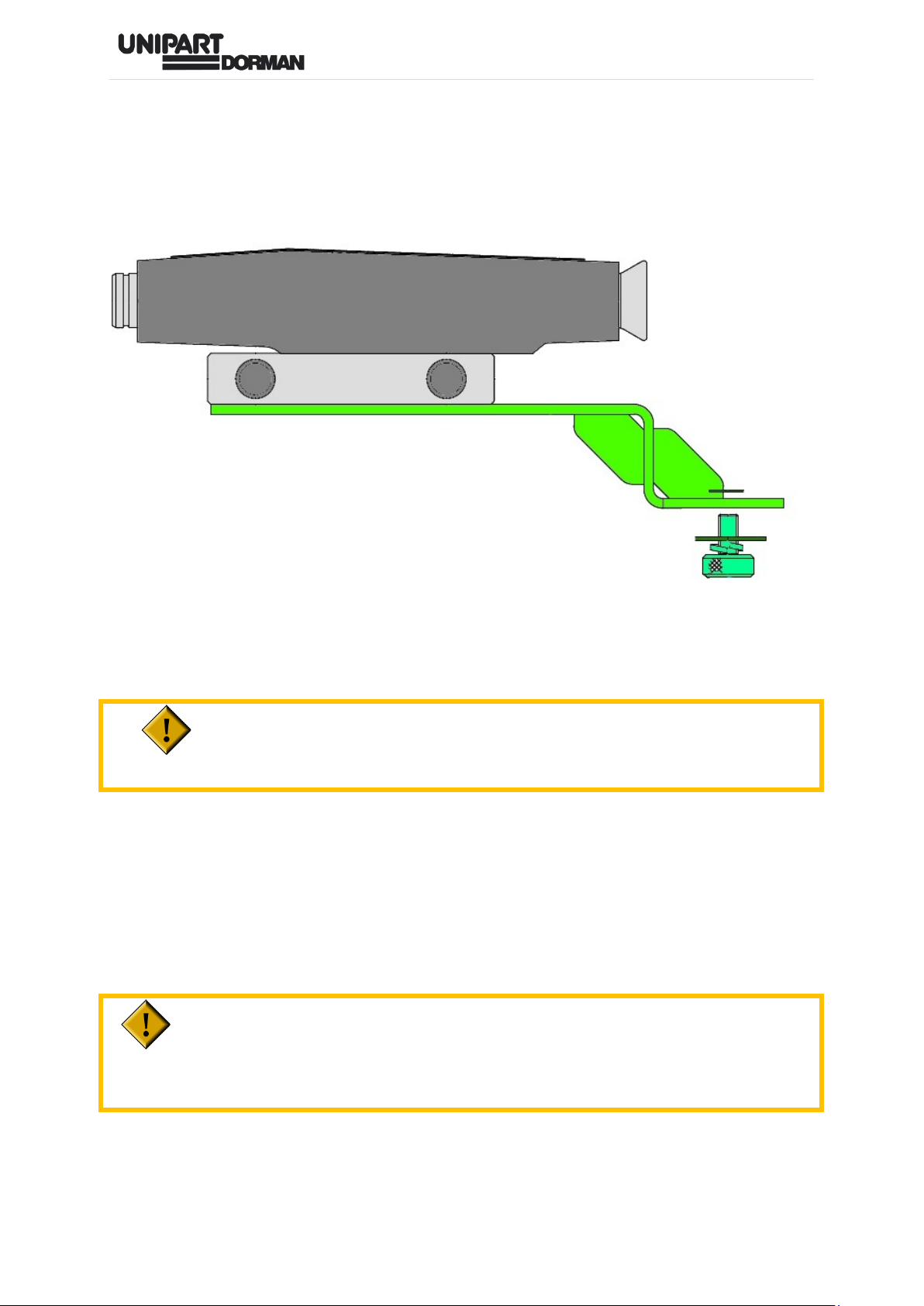

Detachable Alignment Scope ................................................................................6

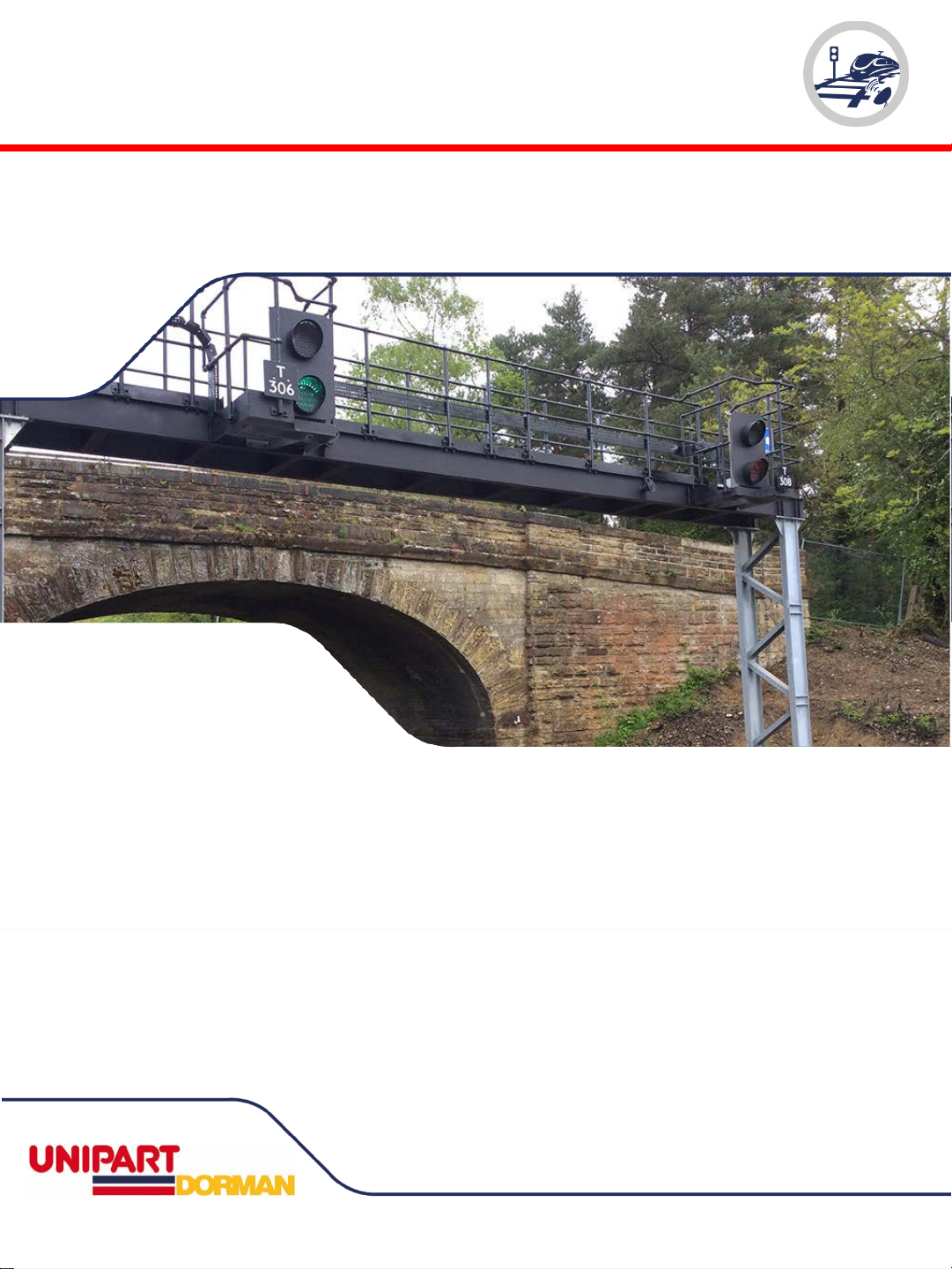

INSTALLATION AND ALIGNMENT OF CLS LITE HEADS ON ALL STRUCTURES EXCEPT

THE UNIPART DORMAN ASSISTED LIFT TRUNNION ..............................................8

Preparing and Mounting the Signal Head...............................................................9

Backboard Arrangement.......................................................................................9

Signal Alignment................................................................................................11

INSTALLATION AND ALIGNMENT OF CLS LITE HEADS USING THE UNIPART

DORMAN ASSISTED LIFT TRUNNION..................................................................18

Preparing and Mounting the Signal Head.............................................................20

Backboard Arrangement.....................................................................................23

Alignment at the ALT .........................................................................................25

INSTRUCTIONS COMMON TO BOTH VARIANTS...................................................27

Electrical Connection..........................................................................................27

Changing the Door Opening Side ........................................................................30

Door Preparation................................................................................................31

Frame Preparation .............................................................................................33

Refitting the Door ..............................................................................................34

Maintenance Activity ..........................................................................................34

Signal Husbandry...............................................................................................35

Service and Repair.............................................................................................35

Module Replacement..........................................................................................35

End of Life Disposal............................................................................................37

Contact Us.........................................................................................................38

Document Reference C64.65201 Issue 3 Apr 2019