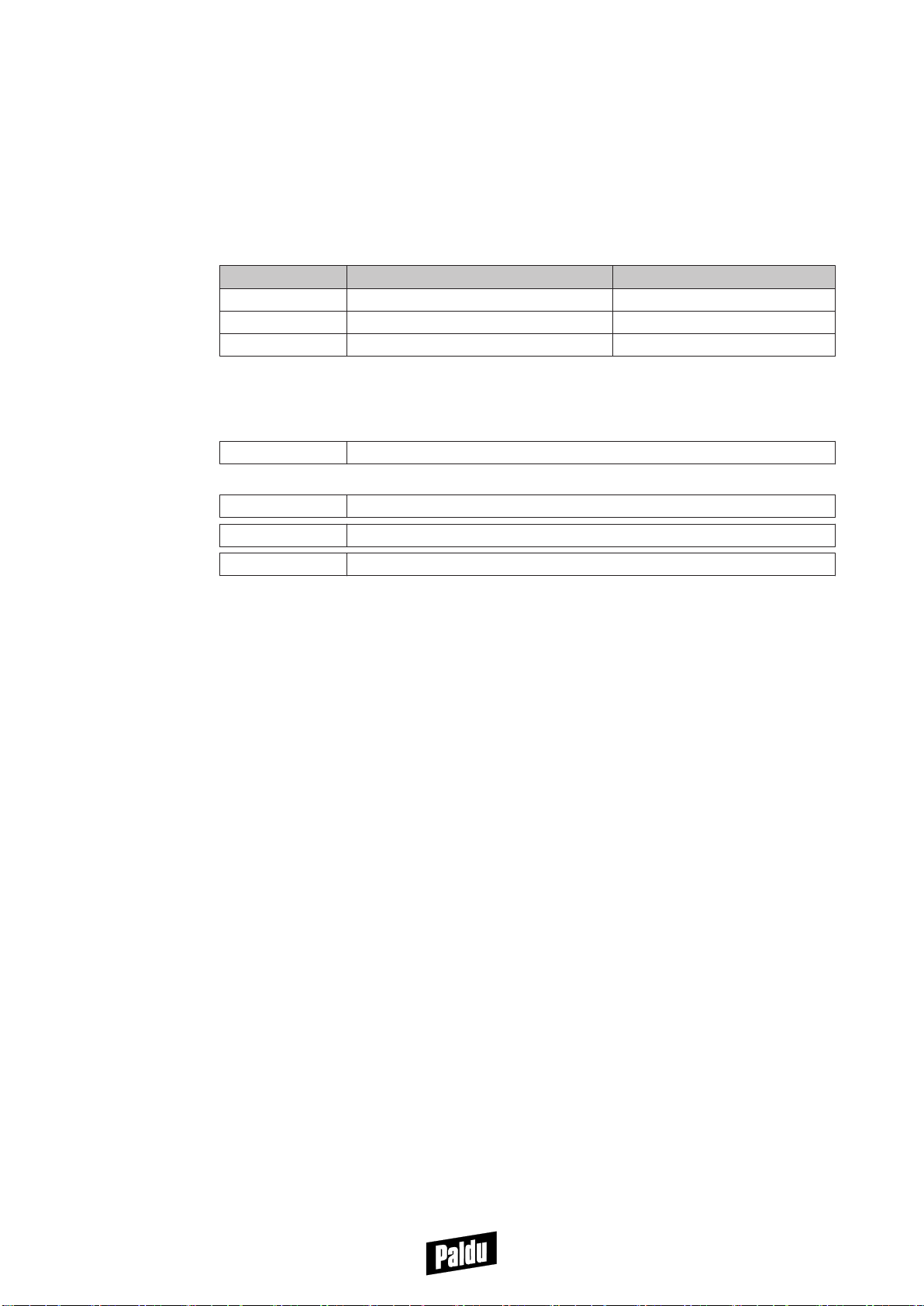

Further information

Symbol for further information relating to a bought-in part.

Information

Action-related information.

General safety information

The machine may only be operated by persons who are familiar with the machine’s

operation and hazards and with the user manual.

▪ It is the operator’s responsibility to provide appropriate staff training.

Persons under the influence of alcohol, drugs or pharmaceutical products that impair

responsiveness must not operate the machine or carry out maintenance work on it.

The machine may only be operated if it is in perfect working condition.

If faults occur on the machine, work must be stopped immediately.

Ensure the machine is stable before starting it.

Minimum age of operative: 18 years.

Only one person may operate the machine at a time.

Take regular breaks to ensure concentration.

Ensure that your workplace is adequately illuminated as poor lighting can significantly

increase the risk of injury.

Never work without the protective guards in place.

Only carry out repair, set-up, maintenance and cleaning work when the drive is switched off

and the tool is stationary.

▪ If the machine has a PTO drive, the universal joint shaft must be removed from the

tractor.

▪ The electric motor must be switched off and the power cable disconnected.

Never leave the machine running unattended.

Switch off the machine's drive unit before carrying out any adjustments.

Only use original - Paldu - spare parts.

Do not modify or tamper with the machine.

Work on electrical equipment must only be carried out by qualified electricians.

Never use damaged cables.

Machines with electric motors must not be used in the rain as this can lead to a malfunction

of the switch or the motor.

Safety instructions for log splitter

Do not hold the log with your hand while splitting.

Do not reach into the splitting area.

Wear safety shoes and close-fitting clothes when working with this device.

Only use the machine outdoors.

2.2

2.3

Safety information

8