1. GENERAL

The manual is a part of the scope of supply and serves to ensure proper handling and

optimum functioning of the instrument. For this reason, the manual must be read before

start-up.

In addition, the manual is for all personnel who require knowledge concerning transport,

setup, operation, maintenance and repair.

The manual must not be used for the purpose of competition without a written consent

from Pall and must also not be forwarded to third parties.

Copies for personal use are permitted.

All information, technical data and illustrations contained in these instructions are based

on information available at the time of publication.

1.1 Symbol assertion

This symbol indicates a safety instruction.

These safety instructions should always be followed carefully.

By not following these instructions injuries of persons or material damage

could happen.

Pall does not accept liability in the event of these

safety instructions being ignored.

This symbol indicates a note.

These notes should be observed to achieve optimum functioning

of the equipment.

1.2 Safety instructions

General Safety Instructions

• Excessive mechanical loads and incorrect usage should always

be avoided.

• In general, work on live components should be avoided and

when absolutely necessary should be performed by qualified

personnel only.

• Installation, electrical connection, maintenance and commissioning

should be performed by qualified personnel only.

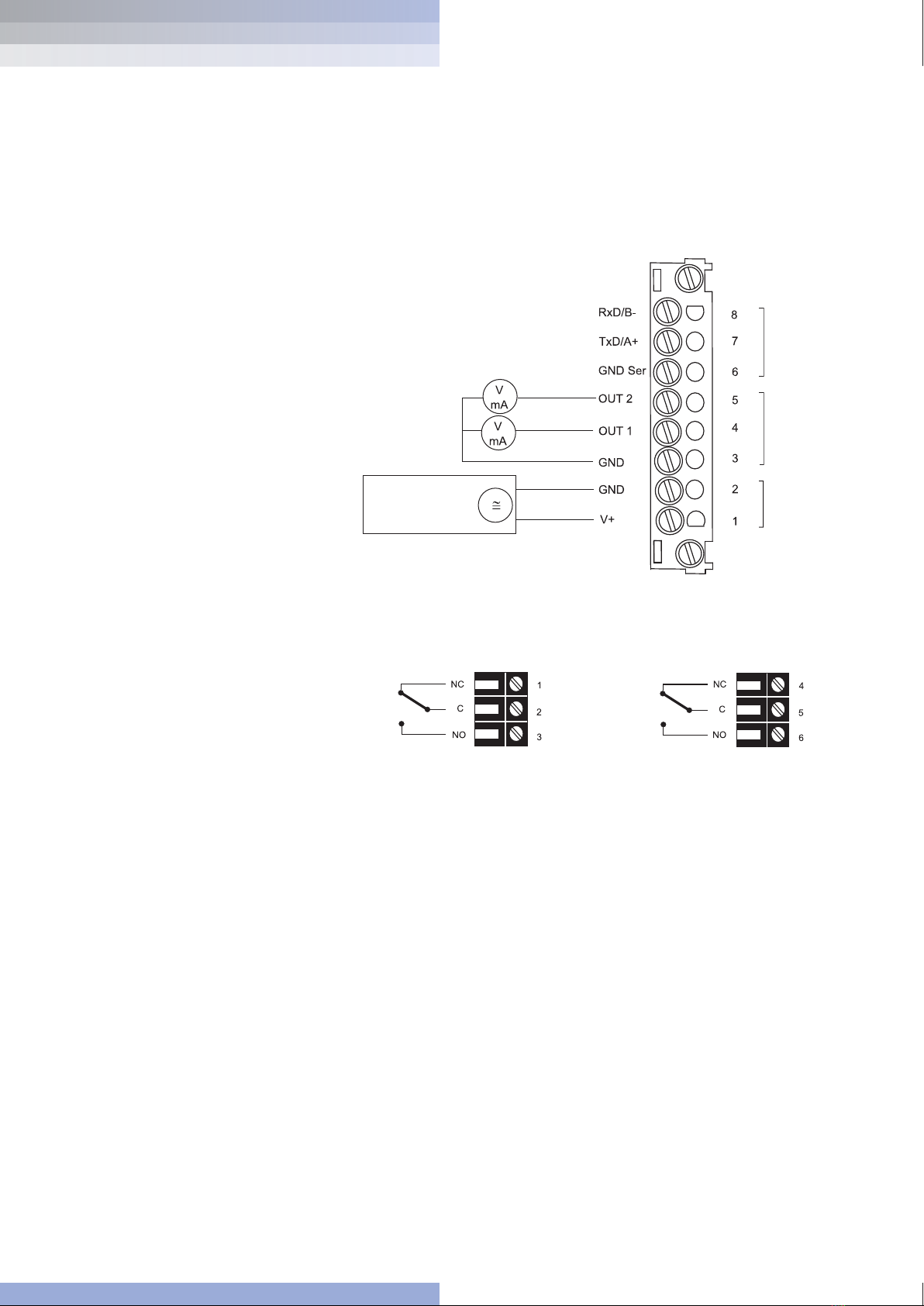

Safety instructions for use of the alarm module

with voltages >50V

• To insulate the optional relay connections from the low-voltage side of

the water sensor, the partition provided for this purpose must be fitted

in the lower section.

• During operation of the instrument the modular housing must be

completely closed.

• The protection class of an opened housing corresponds to IP00 and

direct contact with components carrying dangerous voltages is therefore

possible. In general, work on live components should be avoided and

when absolutely necessary, should be performed by qualified personnel

only.

1.3 Disposal of Equipment

At the end of its life, the Water Sensor should be dismantled and disposed

of in accordance with all applicable local waste disposal laws and bylaws.

Where facilities exist, component parts of the unit may be recycled.

Details of the materials of construction are given on the product installation

drawing and if required, more detailed information regarding specific

items may be obtained from Pall or an approved agent.

If component parts of the equipment were previously contaminated with

the service fluid, an appropriate Manufacturer’s Safety Data Sheet (MSDS)

for the fluid should be obtained and read to ensure that contaminated

component parts are disposed of safely. Pall Europe Ltd., will meet it’s

obligations under the EU Directive on Waste Electrical and Electronic

Equipment (WEEE).

Hardware 4

instruction booklet

Pall WS08 Series

Water Sensor