6

1.4. Equipment safety data

Safety Data R410A

Toxicity Low

In contact with skin

Skin contact with the rapidly evaporating liquid may cause tissue chilblains. In case of skin contact with the

liquid, warm the frozen tissue with water and call a doctor. Remove contaminated clothing and footwear. Wash

the clothing prior to re-use.

In contact with eyes Vapours have no effect. Liquid splashes or sprays may cause freeze burns. In these cases rinse your eyes with

running water or with a solution for eye lavages for at least 10 minutes. Immediately contact a doctor.

Ingestion In this case, burns may result. Do not attempt to make the patient vomit. If the patient is conscious, rinse the

mouth with water. Call a doctor immediately.

Inhalation

In case of inhalation, move the patient to an area with fresh air and provide oxygen if necessary. Perform

artificial respiration if the patient has stopped breathing or lacks air. In case of cardiac arrest, perform external

cardiac massage. Call a doctor immediately.

Further Medical Advice

Exposure to high concentrations can be dangerous for individuals with cardiac problems, as the presence of

catecholamines such as adrenalin in the bloodstream may lead to increased arrhythmia and possible cardiac

arrest.

Occupational exposure limits R410A: Recommended limits: 1,000 ppm v/v 8 hours TWA.

Stability Stable product

Conditions to avoid Increased pressure due to high temperatures may cause the container to explode. Keep out of the sun and do

not expose to a temperature >50°C.

Hazardous reactions Possibility of dangerous reactions in case of fire due to the presence of F and/or CI radicals

General precautions

Avoid the inhalation of high concentrations of vapours. The concentration in the atmosphere shall be kept at

the minimum value and anyway below the occupational limits. Since vapours are heavier than air and they

tend to stagnate and to build up in closed areas, any opening for ventilation shall be made at the lowest level.

Breathing protection In case of doubt about the actual concentration, wear breathing apparatus. It should be self-contained and

approved by the bodies for safety protection.

Storage Preservation Refrigerant containers shall be stored in a cool place, away from fire risk, direct sunlight and all heat sources,

such as radiators. The maximum temperature shall never exceed 50°C in the storage place.

Protection clothes Wear boots, safety gloves and glasses or masks for facial protection.

Behaviour in case of leaks or

escapes

Never forget to wear protection clothes and breathing apparatus. Isolate the source of the leakage, provided

that this operation may be performed in safety conditions. Any small quantity of refrigerant which may have

escaped in its liquid state may evaporate provided that the room is well ventilated. In case of a large leakage,

ventilate the room immediately. Stop the leakage with sand, earth or any suitable absorbing material. Prevent

the liquid refrigerant from flowing into drains, sewers, foundations or absorbing wells since its vapours may

create an asphyxiating atmosphere.

Disposal

The best procedure involves recovery and recycle. If this is not possible, the refrigerant shall be given to a

plant which is well equipped to destroy and neutralise any acid and toxic by-product which may derive from

its disposal.

Combustibility features R410A: Non-inflammable at ambient temperatures and atmospheric pressures.

Containers If they are exposed to the fire, they shall be constantly cooled down by water sprays. Containers may explode

if they are overheated.

Behaviour in case of fire In case of fire wear protection clothes and self-contained breathing apparatus.

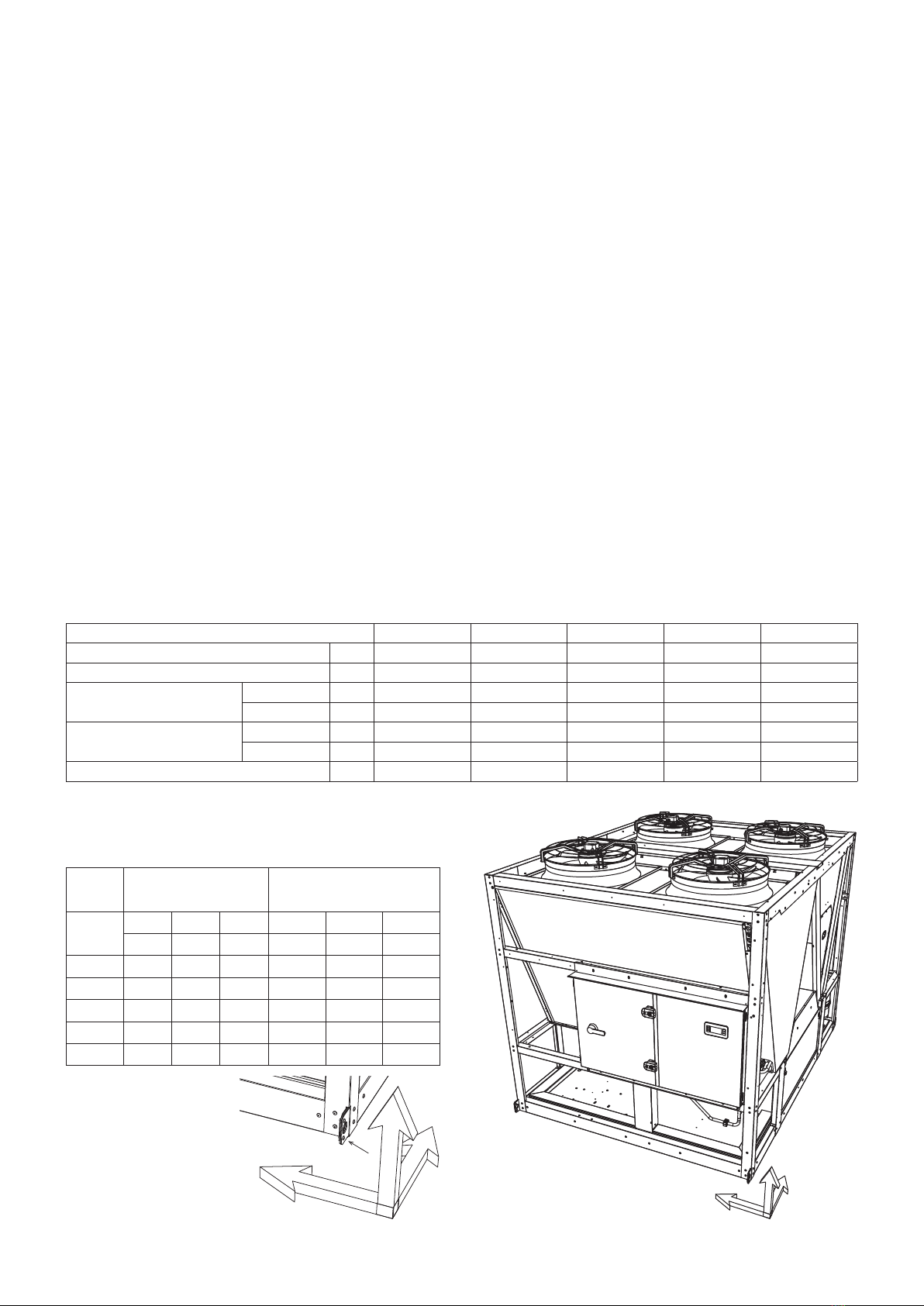

2. Inspection and storage

At the time of receiving the equipment carefully cross check all the elements against the shipping documents in order to ensure

that all the crates and boxes have been received. Inspect all the units for any visible or hidden damage.

In the event of shipping damage, write precise details of the damage on the shipper’s delivery note and send

immediately a registered letter to the shipper within 48 hours, clearly stating the damage caused. Forward a copy of

this letter to the manufacturer or his representative.

Never store or transport the unit upside down. It must be stored indoors, completely protected from rain, snow etc. The unit

must not be damaged by changes in the weather (high and low temperatures). Excessively high temperatures (above 60°C)

can harm certain plastic materials and cause permanent damage. Moreover, the performance of certain electrical or electronic

components can be impaired.