Panasonic DVD-RP62P User manual

Other Panasonic DVD Player manuals

Panasonic

Panasonic DVDRP82 - DIG. VIDEO DISC PLAY User manual

Panasonic

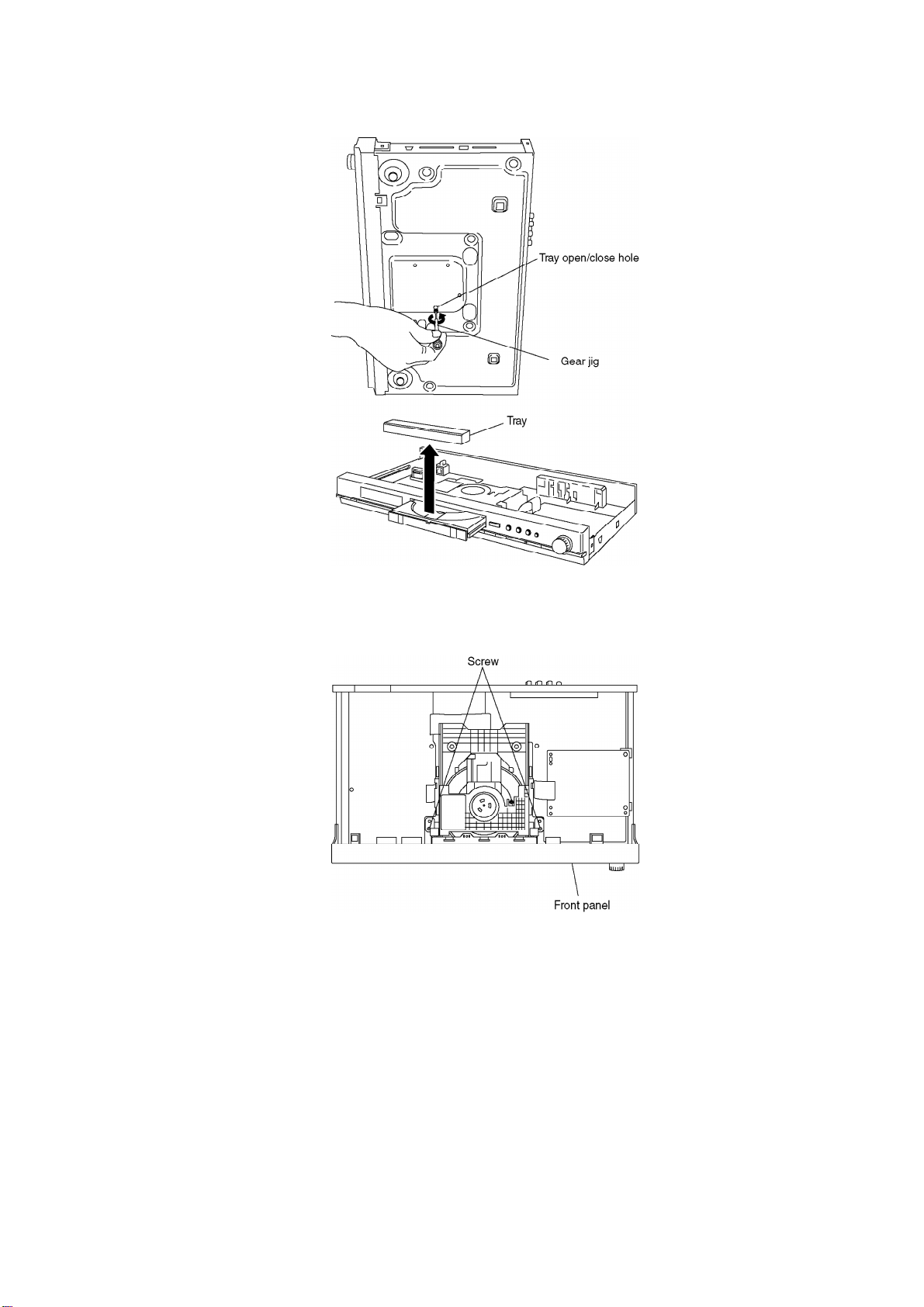

Panasonic DVD-S58PR User manual

Panasonic

Panasonic DVDRA60 - DIG. VIDEO DISCPLAYE User manual

Panasonic

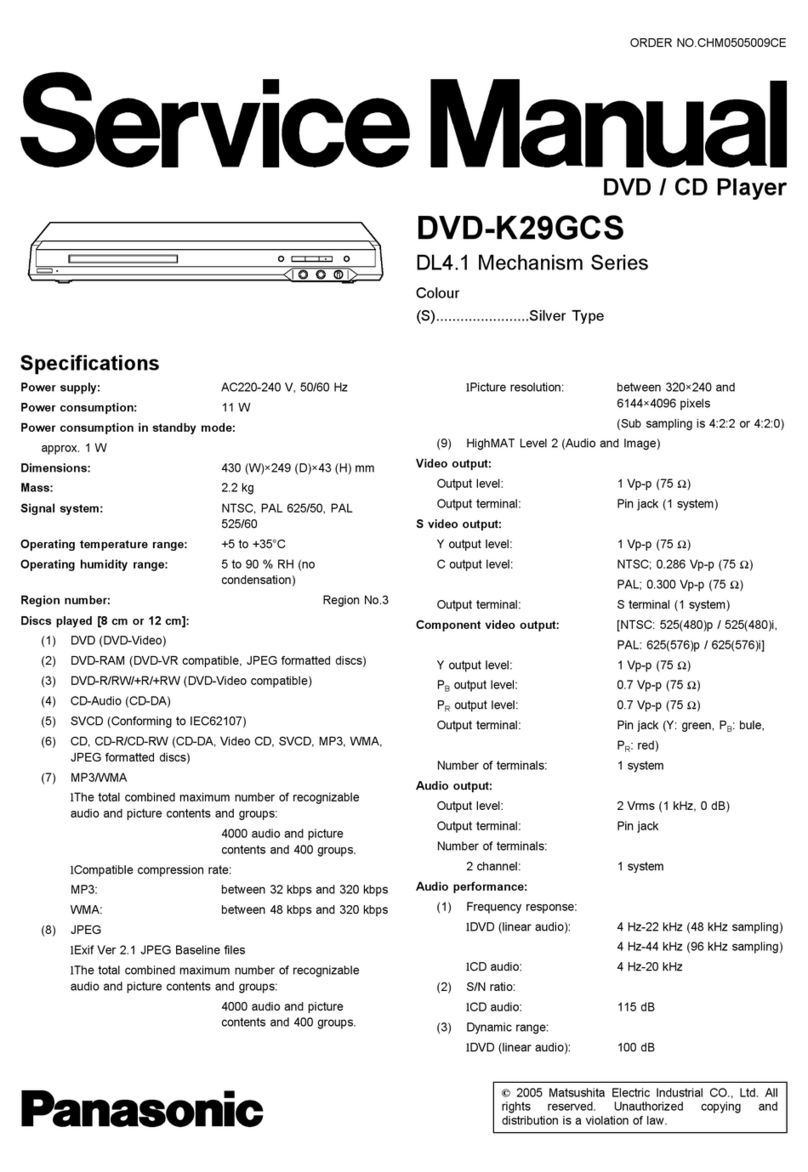

Panasonic DVD-K32 User manual

Panasonic

Panasonic DVDS43 - DIGITAL STILL CAMERA User manual

Panasonic

Panasonic DMP-UB900 Technical specifications

Panasonic

Panasonic PV-D4763SK User manual

Panasonic

Panasonic DVD-S97 User manual

Panasonic

Panasonic DVD-S25UP-S Operating User manual

Panasonic

Panasonic DVD-CP67K Operating User manual

Panasonic

Panasonic DVD Home Theatre System User manual

Panasonic

Panasonic DMP-BD10 - Blu-Ray Disc Player Installation manual

Panasonic

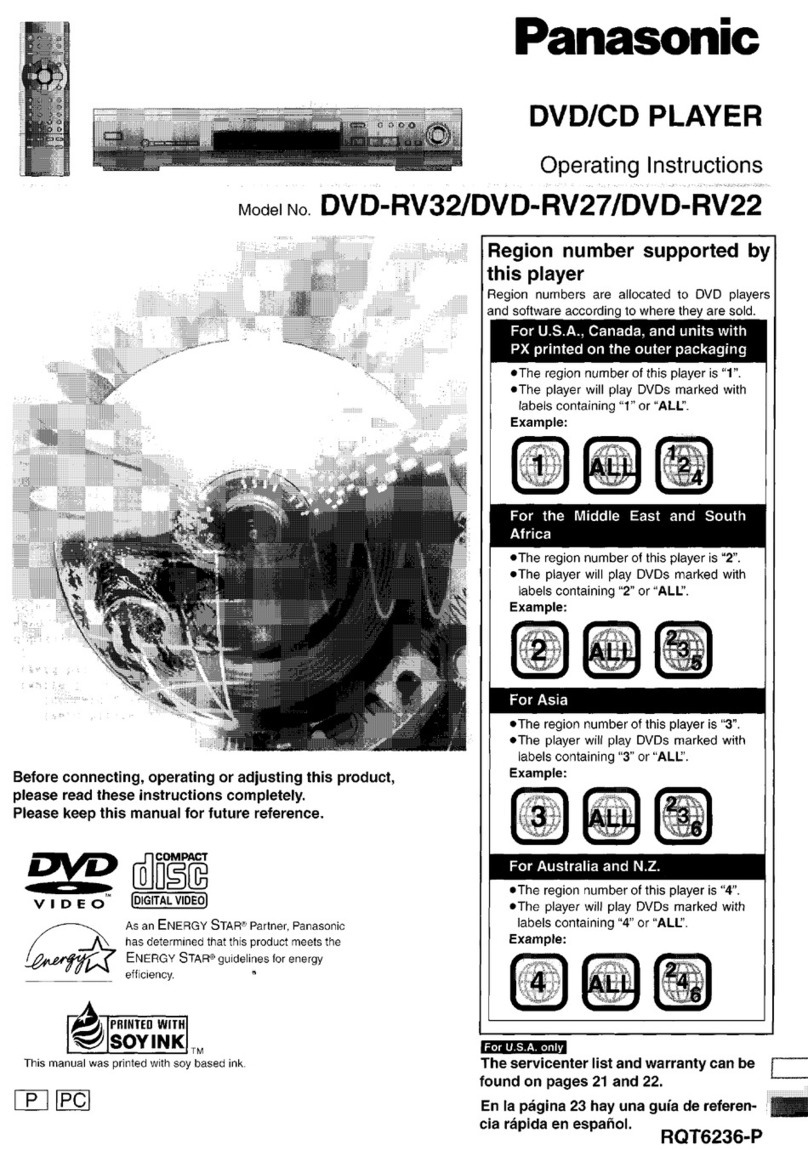

Panasonic DVDRV26 - DIG. VIDEO DISCPLAYE User manual

Panasonic

Panasonic PalmTheater DVD-LA95 User manual

Panasonic

Panasonic DVD-S33EE User manual

Panasonic

Panasonic DVDRP56 - DIG. VIDEO DISCPLAYE User manual

Panasonic

Panasonic DVD-F65 User manual

Panasonic

Panasonic DVD-XP50S Operating User manual

Panasonic

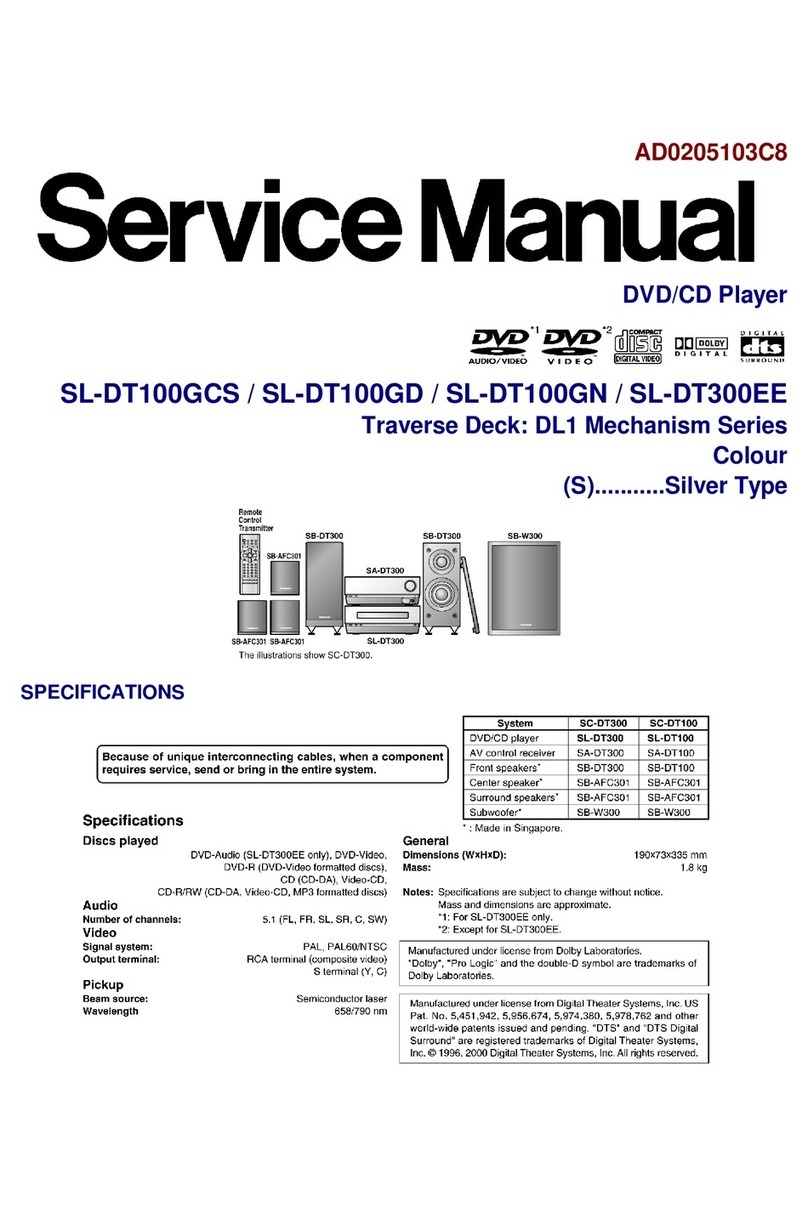

Panasonic SL-DT300EG User manual

Panasonic

Panasonic DVD-RV65 User manual