Panasonic TX-1413FHE User manual

Other Panasonic Monitor manuals

Panasonic

Panasonic TH-42LF8U User manual

Panasonic

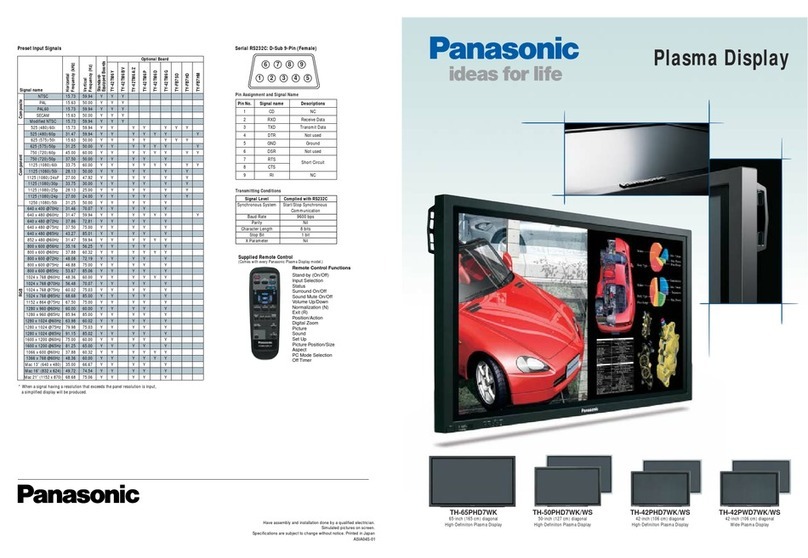

Panasonic TH-42PHD7WK/WS User manual

Panasonic

Panasonic TH-42PWD4A User manual

Panasonic

Panasonic TH-49SF1HU User manual

Panasonic

Panasonic TH-65PB1W Owner's manual

Panasonic

Panasonic TH-152UX1W User manual

Panasonic

Panasonic TH-42PW7LZ User manual

Panasonic

Panasonic TH-55LFV5U User manual

Panasonic

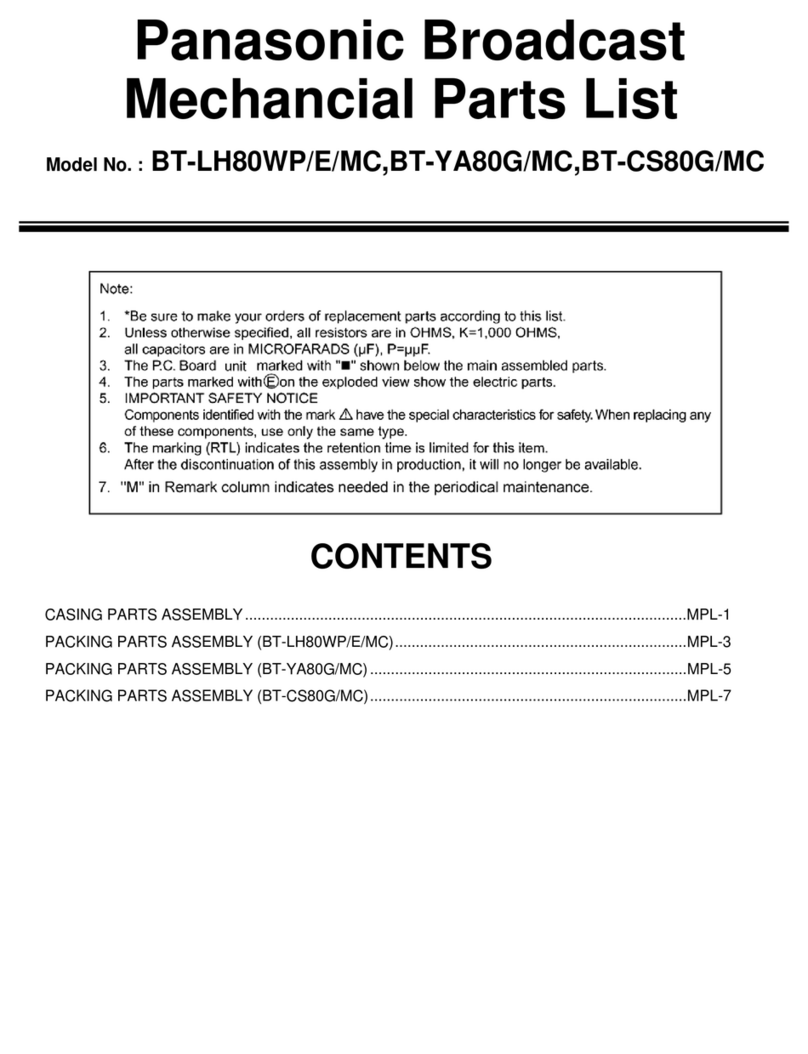

Panasonic BT-CS80G User manual

Panasonic

Panasonic TH-42PM50U User manual

Panasonic

Panasonic CFVDL02 - LCD MONITOR/ LPTP User manual

Panasonic

Panasonic PanaFlart LC40 User manual

Panasonic

Panasonic TENTATIVE TH-65VX300U User manual

Panasonic

Panasonic TH-L37U20R User manual

Panasonic

Panasonic TH-42LF6W User manual

Panasonic

Panasonic TH-49AF1U User manual

Panasonic

Panasonic Viera TH-42PW3 User manual

Panasonic

Panasonic Toughbook CF-VDW07 User manual

Panasonic

Panasonic WV-LW2200 User manual

Panasonic

Panasonic TH-75BQE1W Operating instructions