5

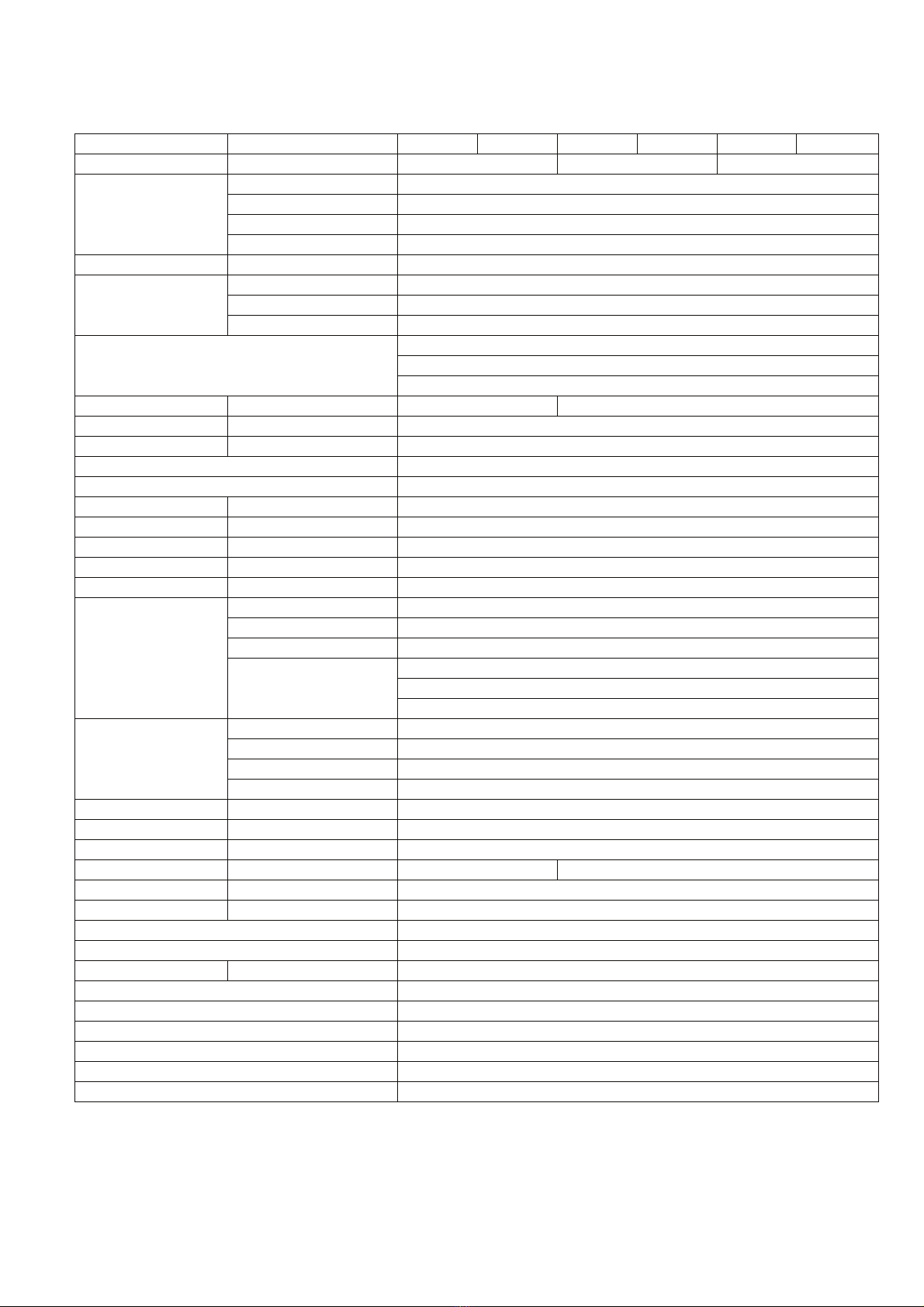

2 Specifications

*1: The amount of Ice Making Ability in 24 hours. Setting temperature, FC: 1°C, VC: 0°C, FC: -25°C.

*2: The Freezing Abilit in 24 hours. VC temperature is set to 1°C and in state of Super Freeze.

*3: Values of the Energy Consumption in year.

*4: This Measurement of Exterior Noise Emitted is measured by OFF condition of PC Fan Motor for Deodorizer.

Model NR-B32FX3 NR-B32FW3 NR-B32FX3 NR-B32FW3

NR-BG32FX3 NR-BG32FW3

Destination UK Europe except UK Germany

volume capacity

Total effective volume capacity

315L

Refrigerator compartment (PC)

179L

Vegetable compartment (VC) 46L

Freezer compartment (FC) 90L

External dimensions width/depth/height (mm) W601 ×D648 ×H1898

Internal dimensions

PC: width/depth/height (mm) W495 ×D478 ×H752.5

VC: width/depth/height (mm) W480 ×D334 ×H262

FC: width/depth/height (mm) W465 ×D267.5 ×H595

Installation size

Side: 20mm or above

Back: 50mm or above

Top: 100mm or above

Power supply plug Rating 250V/13A 250V/16A

Power supply cord Length 2.1m

Interior lamp (LED) Rating 1W

IEC protection against electric shock classes Class I

Climate Class SN-T

Refrigerator compartment sensor

Rating PCC:B=3808K±2%,R(0°C)=6.409kΩ

Freezer compartment sensor

Rating FCC:B=3850K±2%,R(-20°C)=18.9kΩ

Vegetable compartment sensor

Rating SCC:B=3808K±2%,R(-3°C)=7.490kΩ

Ambient compartment sensor

Rating ATC:B=3435K±2%,R(25°C)=10.0kΩ

Defrost temperature sensor

Rating DFC:B=3819K±2%,R(10°C)=3.899kΩ

Compressor

Type Full hermetic reciprocating system

Model ENI100E13DCH-C0EXS

Rotation speed 25/39/43/59/71(r/s)

Curled resistance cord

U-V: 5.79Ω±5%

U-W: 5.79Ω±5%

V-W: 5.79Ω±5%

Overlord relay

Model MM3-64BCX

Operation temperature without power

95 ± 5°C

Return temperature 61 ± 8°C

Operating current (A) 6.40A ± 7.5%

Fan motor Model/Rating U11P14BS1Z3/DC14V 0.19A

Electric baffle Model/Rating NSBD009ZA1/DC12V, 300p/s

VC heater Rating 230V/6914Ω/7.6W

Defrost heater Rating/Voltage

230-240V/330.6

Ω

/160-175W

220-230V/302.5Ω/160-175W

Thermal fuse Rating 250V/7A/70°C

Refrigerator oil Class/Fill S10/215 ± 5ml

Ice making ability*1 1.5kg/24h

Freezing ability*2 15.0kg/24h

Amp. Rating 1.15A

Values of the energy consumption*3 249kWh/y

Energy efficiency grade A++

Refrigerant charge R600a,70g

Measurement of exterior noise emitted*4 36db

Form polyurethane Cyclo pentane

Weight (Kg) 82kg