- 1 -

ZVP-PC-0151-00-R1

1.0 GENERAL INFORMATION

1.1 Panblast Notice to Purchasers and Users

1.1.1 All products and equipment designed and

manufactured by PanBlast are intended for use

by experienced users of abrasive blasting

equipment and its associated operations and

abrasive blasting media.

1.1.2 It is the responsibility of the user to:

-Determine if the equipment and abrasive

media is suitable for the users' intended

use and application.

-Familiarize themselves with any

appropriate laws, regulations and safe

work practices, which may apply within

the users' working environment.

-Provide appropriate operator training and

a safe working environment including

operator protective equipment (PPE) such

as, but not limited to, blasting suit, safety

footwear, protective eyewear and hearing

protection.

1.1.3 PanBlast Standard Terms and Conditions of Sale

apply. Contact your local PanBlast office or

distributor should you require any further

information or assistance.

1.2 ! WARNING ! – READ THIS SECTION

CAREFULLY BEFORE USING THIS

EQUIPMENT/APPARATUS.

1.2.1 Heavy metal paint, asbestos and other toxic

material dusts will cause serious lung disease

or death without the use of properly designed

and approved air supplied respiratory

equipment (SAR) by blast operators and all

personnel within the work site area.

1.2.2 The compressor must have adequate output

and the plumbing between the compressor and

the point of attaching the air supply hose must

have sufficient capacity to supply the volume of

air at the pressure required.

1.3 Standard Safety Precautions

1.3.1 Approved safety eyewear, hearing and footwear

protection should be worn at all times by the

operator(s) and anyone else in the immediate

area that may be exposed to any hazards

generated by the abrasive blasting process.

1.3.2 Suitably approved respiratory protection should

also be worn when handling abrasive media,

abrasive refuse dust and when carrying out any

service/maintenance work where any dust may

be present.

1.3.3 Any work performed on electrical wiring or

components must only be carried out by

suitably qualified and registered electrical

trades’ personnel.

1.3.4 Under no circumstances should any safety

interlocks / lock-outs or features be altered or

disabled in any way.

1.3.5 All equipment must be isolated from the

compressed air supply and electrical power

source prior to any service or maintenance

work being carried out.

1.3.6 All care must be taken by the operator(s) when

lifting or moving equipment or components in

order to prevent injury. Pressure Blast Pots

must always be emptied of abrasive media

before any attempt is made to move them.

1.3.7 Any modification of the equipment or use of

non genuine PanBlast™ replacement parts will

void warranty.

1.3.8 Always check the Material Safety Data Sheet

(MSDS) on the abrasive media being used to

ensure that it is free of harmful substances, in

particular, free silica, cyanide, arsenic or lead.

1.3.9 Test the surface to be blasted for harmful

substances, taking the appropriate measures

and precautions to ensure the safety of the

operator and all personnel.

1.3.10 The operator should carry out a daily inspection

before start up of all wearing and safety items

to ensure that they are in correct operating

order. In particular check all blast hose

couplings and nozzle holders, ensuring that all

couplings have engaged correctly and the

safety locking pins are fitted and in good

condition. Always install safety whip check

cables at every connection. Ensure that the

blast nozzle has been securely screwed into the

nozzle holder and the nozzle holder has been

secured to the blast hose correctly and that all

screws are engaged.

2.0 INTRODUCTION

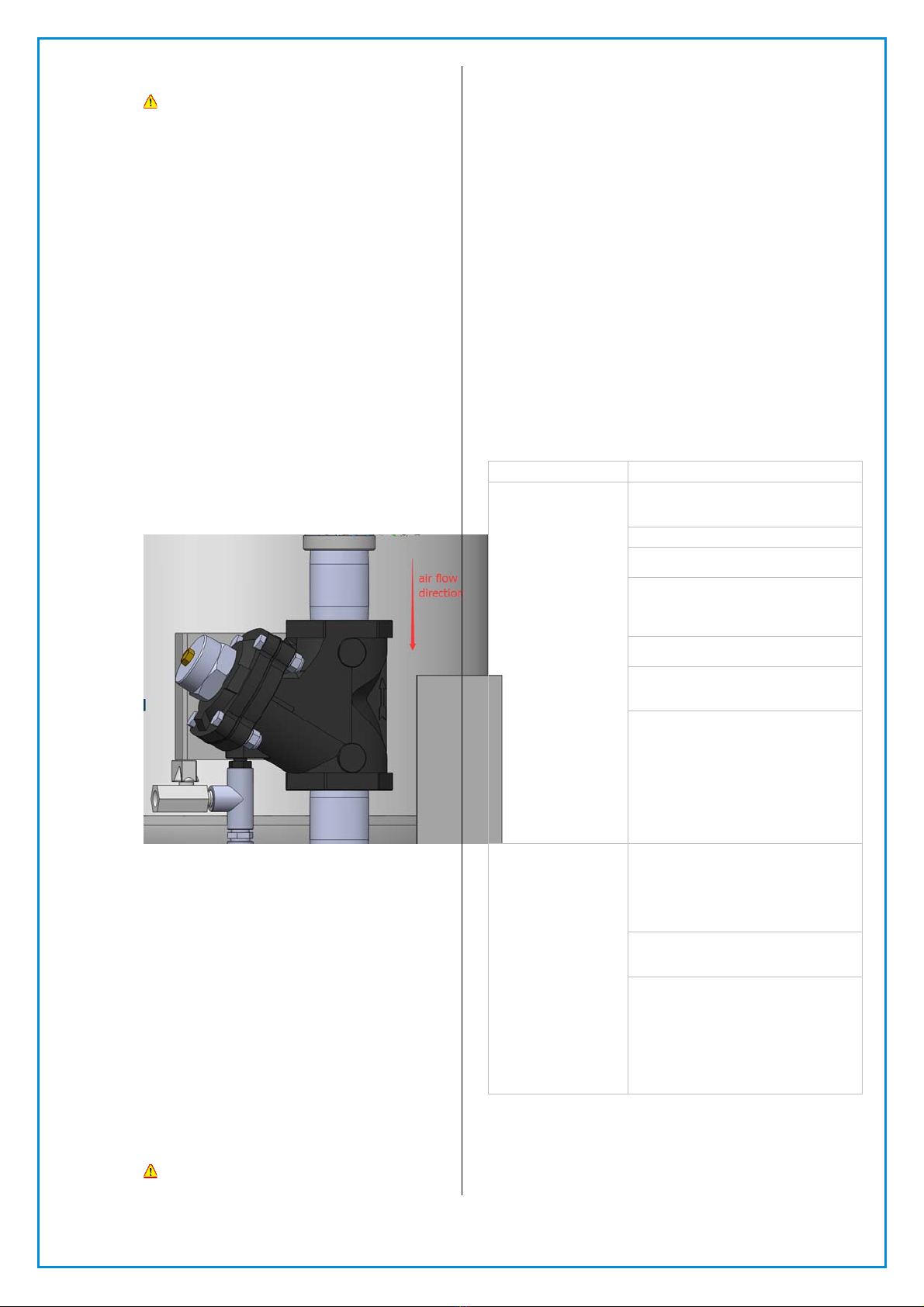

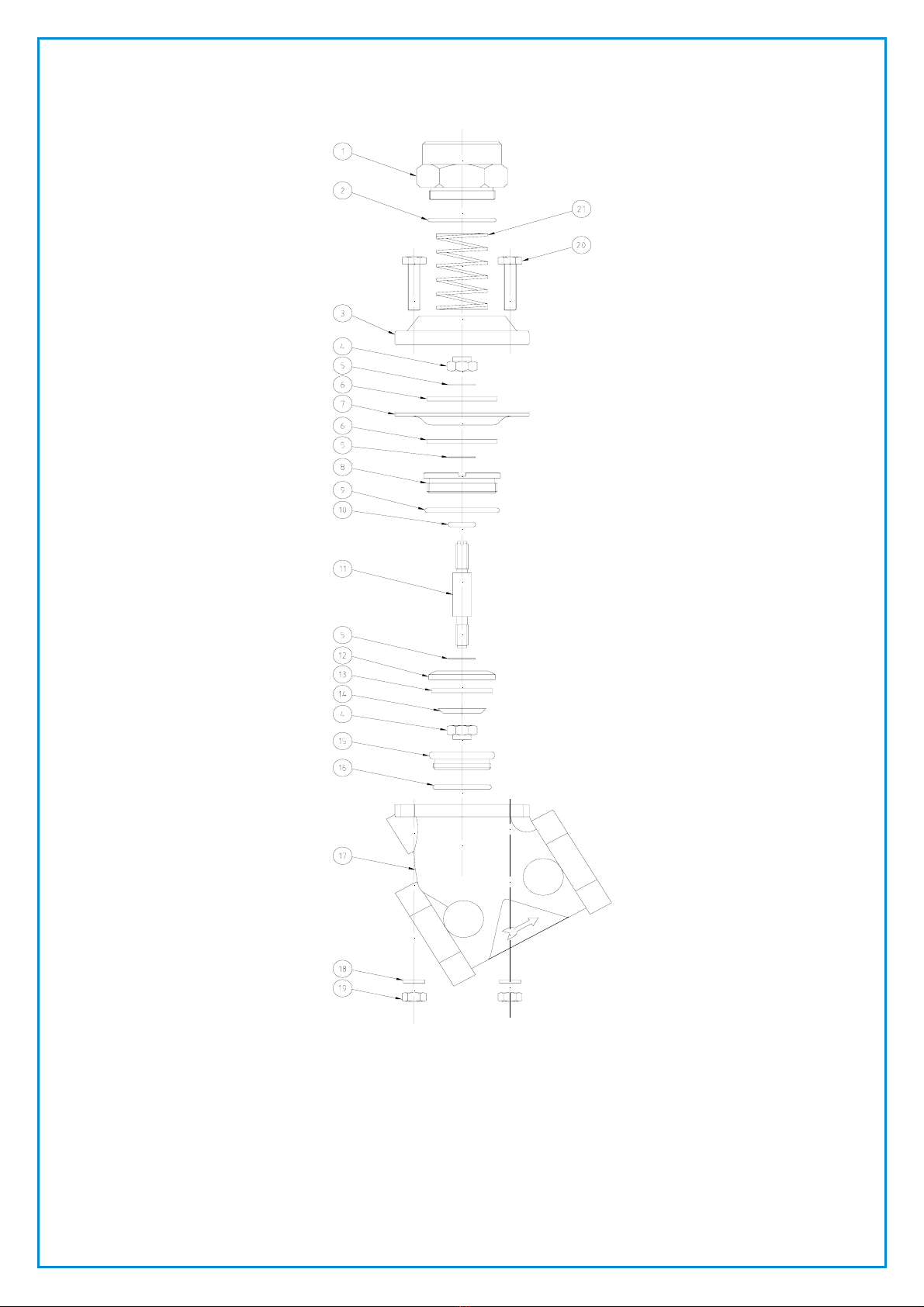

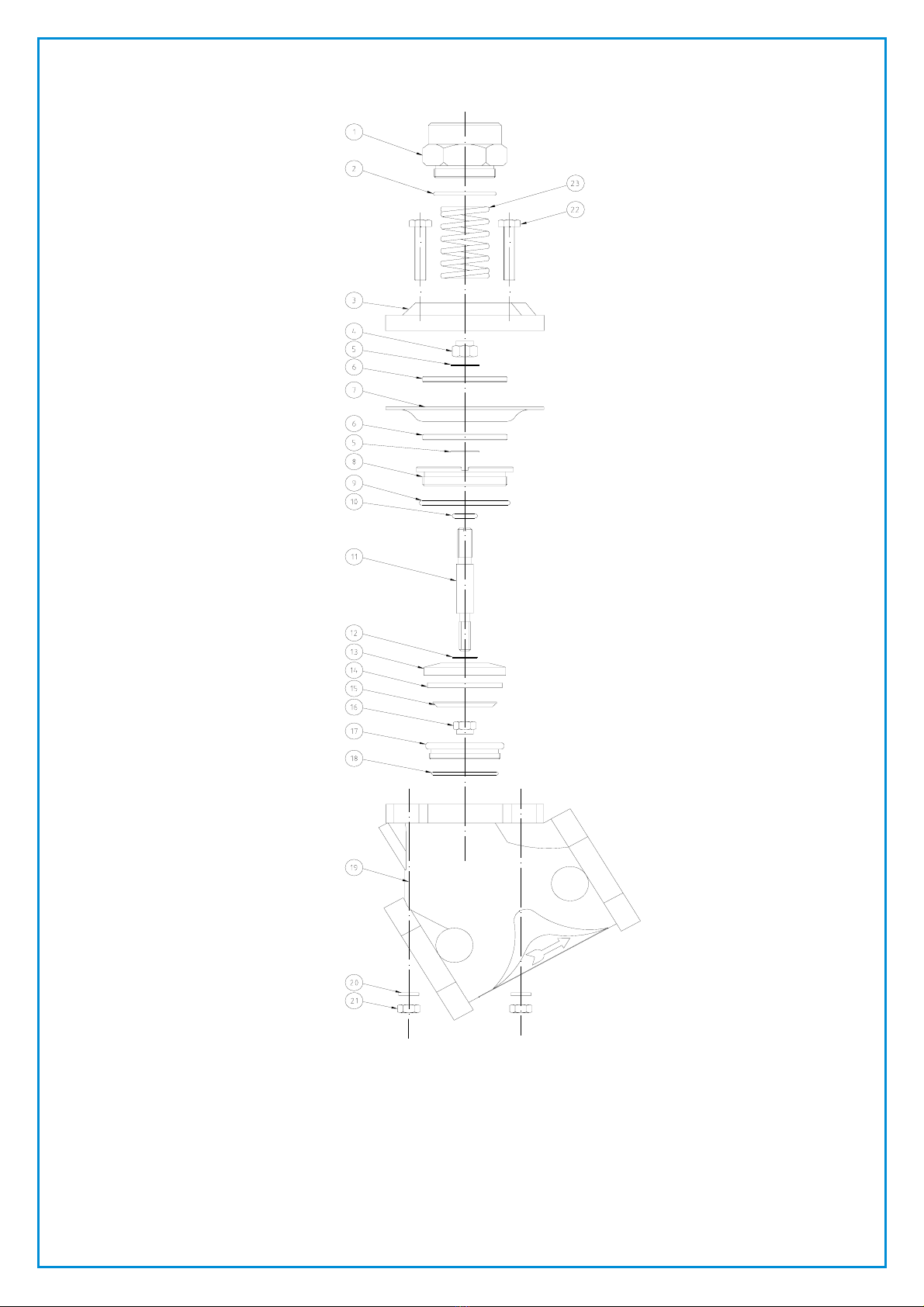

2.1 These instructions cover the operation and

maintenance of PanBlast™ Tandem Remote

Control Inlet Valve models as follows:

-BAC-RC-PB-0274 Tandem Valve 3/4"

-BAC-RC-PB-0275 Tandem Valve 1"

-BAC-RC-PB-0276 Tandem Valve 1-1/4"

-BAC-RC-PB-0277 Tandem Valve 1-1/2"

2.2 The PanBlast™ Tandem Remote Control Inlet

Valve is a diaphragm driven spring type remote

control inlet valve. The PanBlast™ Tandem

Remote Control Inlet Valve is ideally suited for

blast pots with plumbing configurations of 3/4"

through to 1-1/2" with an operating pressure

not exceeding 1034kPa (150psi).

2.3 The PanBlast™ Tandem Remote Control Inlet

Valve is generally used in conjunction with a

separate remote exhaust valve on pressure

release blast pots and Corsa II Abrasive

Metering Valves on pressure hold type blast

pots. PanBlast recommends that the Tandem

Remote Control Inlet Valves are operated and

activated by either AirStop or AirStop II Remote

Control Deadman Handles.

NOTE: UNDER OSHA 1915:34(c)(1)(iv) DEAD

MAN CONTROL. A DEADMAN CONTROL

DEVICE SHALL BE PROVIDED AT THE NOZZLE

END OF THE BLAST HOSE EITHER TO

PROVIDE DIRECT CUTOFF OR TO SIGNAL THE

POT TENDER BY MEANS OF A VISUAL AND

AUDIBLE SIGNAL TO CUT OFF THE FLOW, IN

THE EVENT THE BLASTER LOSES CONTROL

OF THE HOSE. THE POT TENDER SHALL BE

AVAILABLE AT ALL TIMES TO RESPOND

IMMEDIATELY TO THE SIGNAL.