Instruction Manual

DPH 220 - DPH 460

5.2. Authorized use :

The unit is built according to state of the art technology and established safety technical regulations. Nevertheless, its use can cause

danger to life and limb of the operator or third parties or damage to the machine and other equipment. Operate the unit only in

technically perfect condition in accordance with regulations and safety danger notices detailed in the instruction manual. The

manufacturer/supplier is not responsible for damage resulting from a wrong utilisation of the machine. The user alone is responsible for

this risk. The compressor is built to produce top quality breathing air according to DIN EN 12021 rules.

5.3. Safety notices for operation

:

- Ensure that only trained personnel work with the machine.

- Filling hoses must be in satisfactory condition and threads undamaged.

- Ensure intake air is free from noxious gas, exhaust fumes and solvent vapour.

- The use of petrol and diesel compressors is forbidden in indoor place.

- Check the unit externally for damage and faults periodically. Inform the department/person responsible immediately if anything is not

as is should be (including operation). If necessary, shut the machine down immediately and make it safe.

Observe switching on and off processes and monitoring indications according to the instructions manual.

- Use only DINO PAOLI SRL original parts and equipments.

- Drain the valve regularly if manual drain valve. Check every 10 minutes the valve if automatic drain valve.

- Switch off the machine when do not use it.

- Clean oil, fuel or care products from, the machine, in particular the connections and screw joints, before carrying out

maintenance/repair work. Do not use aggressive cleaning fluid. Use a fibre-free cleaning cloth.

- Completely remove all covers/seals after cleaning.

- Use only original fuses with specified current rating. If there is a failure in the electric energy supply, shut the machine/unit down

immediately.

- Work on electric units or operating equipment may only carried out by a qualified electrician or by a person under the instruction and

supervision of qualified electrician according to electric technical regulations.

- The electrical equipment of a unit must be regularly checked.

- When working in small rooms, observe any national regulations.

- Depressurize system and pressure lines before commencing repair work.

- With regard to oil, grease and other chemical substances, observe the relevant safety rules for the product.

- When switching on the machine, check the arrow to ensure correct direction of rotation of the drive motor.

- The cooling fan of the compressor must have a minimum clearance of 50 cm.

5.4. Electrical installation:

For electrical installation must follow these steps:

Do check by an electrician that the plant complies with regulations and bear the maximum absorption of the compressor.

Check that power is coming to the voltage required by the compressor and the power cord used is not undersized.

WARNING: if the motor is three-phase, make sure that the fan of the compressor turns in the right direction of the arrow. To reverse

the rotation enough to reverse up by trained two of the three phases of the power plug.

Make sure the grounding is connected firmly on the plug and on the electrical system.

If you change the power cord make sure it is appropriately sized.

6. OPERAZIONI PER L’AVVIAMENTO:

6.1 Preparation for operation.

WARNING: this machine is built to produce breathing air. It is not suitable for compression of oxygen. Explosion occurs if an oil

lubricated compressor is operated with pure oxygen or gases with oxygen content of more than 21%!

All compressor units are tested prior to delivery to the customer, so after correct installation of the unit there should be no problem

putting it into operation, observing the following points:

Prior to first operation read Instruction Manual carefully. Make sure that all persons handling the compressor and the filling station are

familiar with the function of all controls and monitors.

Immediately after switching on the system for the first time check the direction of rotation of the motor for compliance with the arrow

on the unit. If motor turns in the wrong direction, the phases are not connected properly. Shut down unit immediately and interchange

two of the three phase leads in the switch box. Never change leads at the motor terminal board.

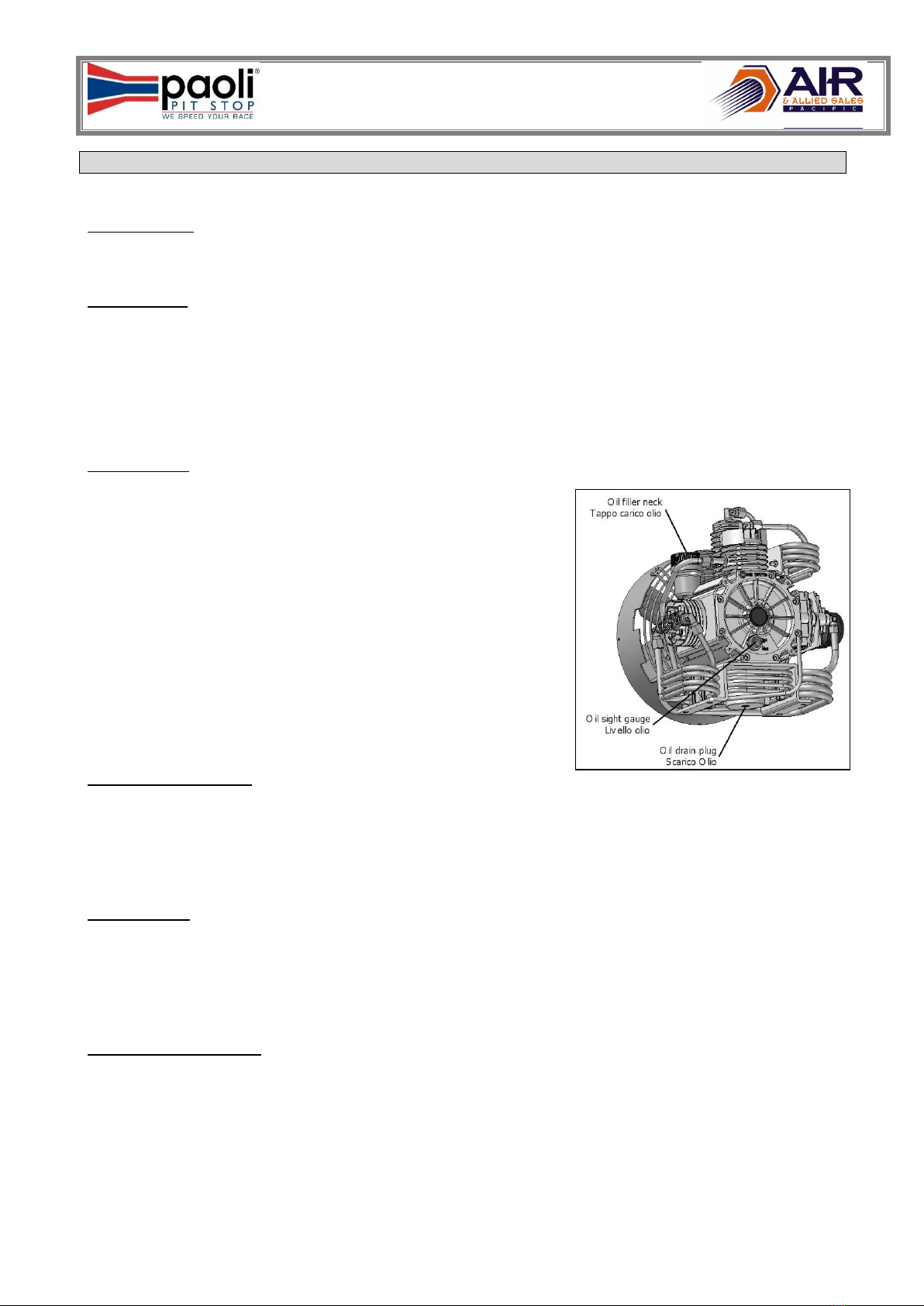

Prior to each operation check the oil level. Only for petrol unit: - check engine oil level according to manufacturer’s instruction manual -

check fuel tank. Top up if necessary - open fuel shut-off valve.

Every time the unit is started up check all systems for proper operation. If any malfunction is observed stop unit immediately and find

the cause of the fault or call the service department.

www.air-allied.com.au

Page 3

Air & Allied Sales (Pacific) Pty Ltd