•Rotating shafts can be dangerous; you can snag clothes, skin, hair, hands, etc. This can cause serious

injury or death.

•Do not work under the vehicle when the engine is running.

•Do not work on a shaft (with or without a guard) when the engine is running.

•Do not engage or disengage driven equipment by hand from under the vehicle when the engine is

running.

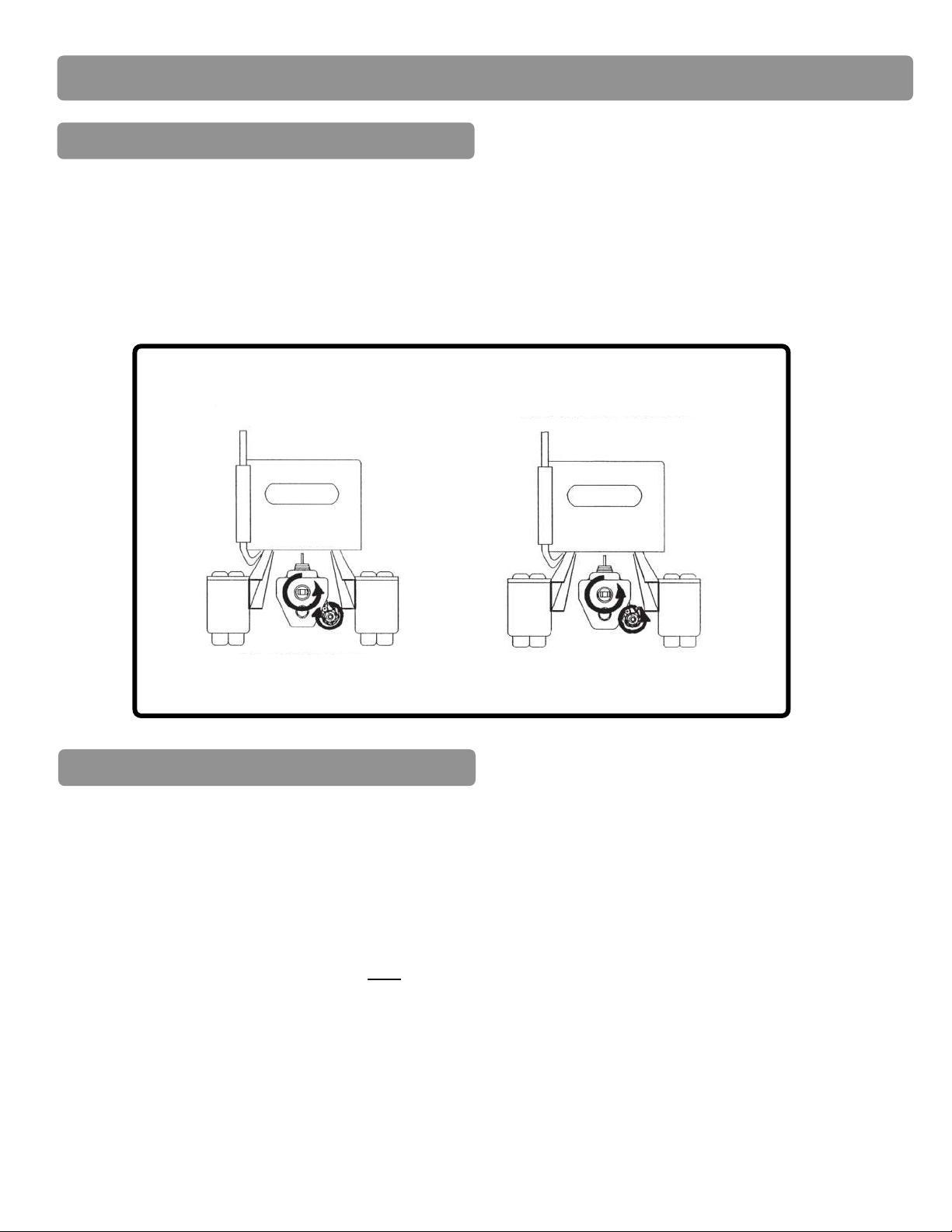

•In order to avoid becoming entangled, install the power take off and/or shaft behind the frame rail, tanks,

battery box, etc.

•If power take off and/or shaft are still exposed after installation, install a guard.

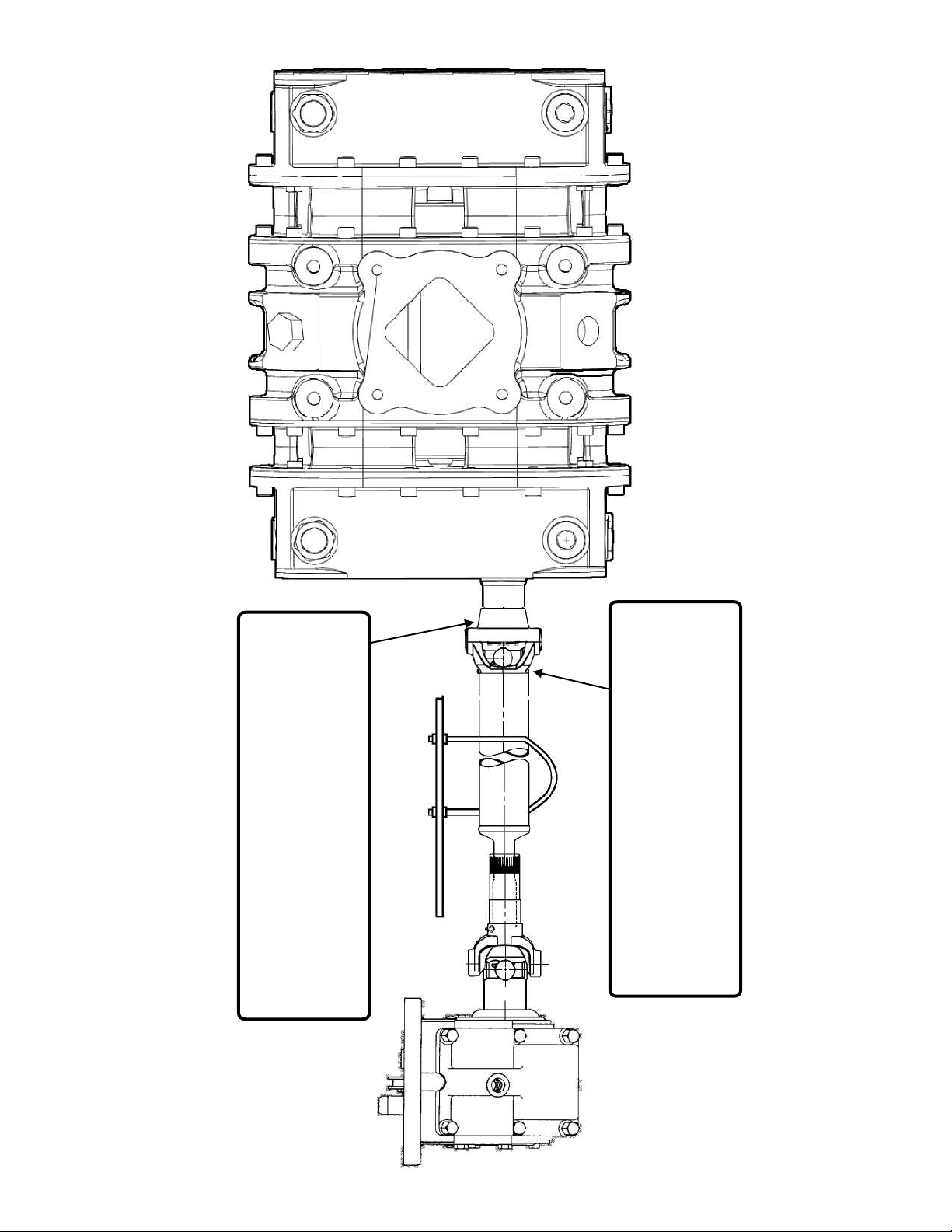

•Use provided drive shaft flange set screws and apply “Loctite® 243” or equivalent.

•Install a support strap when servicing a drive shaft to prevent personal injury.

A serious or fatal injury can occur. . .

-if you lack proper training.

-if you fail to follow proper precautions.

-if you do not use proper tools and safety equipment.

-if you assemble drive shaft components improperly.

-if you use incompatible drive shaft components.

-if you use worn-out or damaged drive shaft components.

-if you use drive shaft components in a non-approved application.

This manual contains safety instructions. Read, understand, and follow this manual.

•Get proper training.

•Learn and follow safe operating procedures.

•Use proper tools and safety equipment.

•Use proper components in good condition.