Caution:

Incorrect equipment will cause blower failure. If you are not using

a Paragon kit, the following accessories should be installed:

Power Take Off For Transmission

•Horsepower and torque rating must be adequate for blower

RPM and pressure.

•Select ratio for required engine speed and correct blower

shaft speed.

Constant Engine Speed

•The selected engine speed must remain constant throughout

the blower discharge cycle. This requires ECM programming

or a trouble control system.

•Program ECM for max 100 RPM “ramp rate” per second.

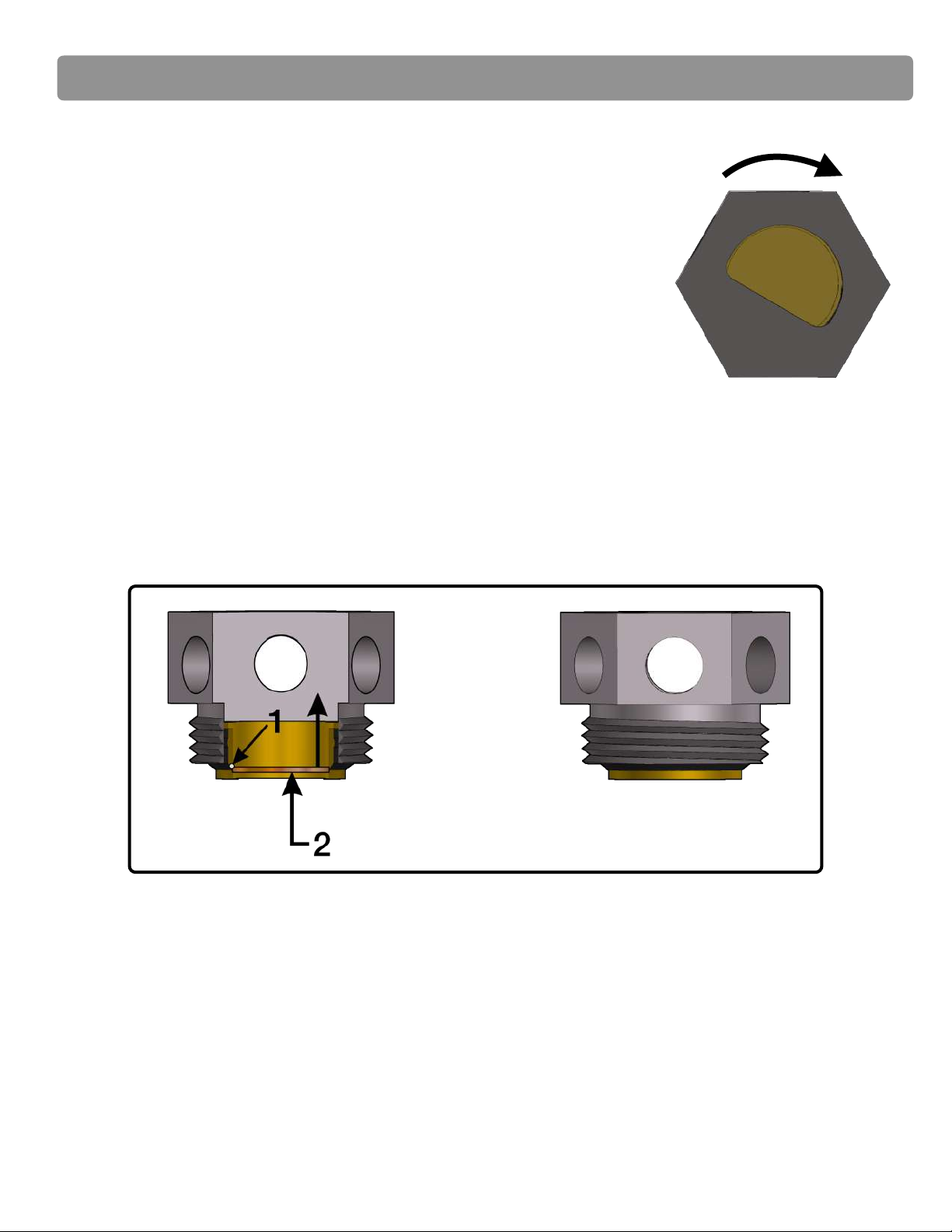

Relief Valve

•Sized for correct CFM and blower pressure rating.

•Installed on delivery side before check valve.

•Use pipe compound on male pipe thread of relief valve.

•DO NOT use thread tape.

Air Filter

•Sized for correct CFM to suit application.

Caution: An undersized filter will cause immediate

overheating of blower. The filter should not exceed 17” water

restriction. Do not mount air inlet of the filter close to truck

exhaust. This will increase the blower operating temperatures

above the maximum limits.

Suction Delivery and Pipework

•Should be free of weld beads and foreign metal.

•During vacuum applications, NEVER use rubber elbows

without internal support. Rubber elbows will collapse

under vacuum, restricting the airflow to the P858/P1057,

and causing the P858/P1057 to overheat.

Mounting Bracket

•Strong enough to support blower weight and torque

•Allow a minimum of 1/2" clearance between the blower and

frame rail (or other non-moveable object) to prevent damage

to the blower.

Check Valve

•Sized for maximum CFM with minimal restriction.

•Should have at least (1) check valve mounted on the trailer at

the hot air hose connection.

•Must be inspected periodically for damage.

Mufflers

•Sized for maximum CFM with minimal restriction.

•Mounted downstream of the relief valve.

•Stainless steel is required for sensitive product applications

Vacuum Relief Valve (Tractor Mounted)

•Sized for correct CFM ( Not to exceed 15” of Hg ).

•This valve needs to be installed between the P858/P1057

Blower filter and the P858/P1057 inlet.

•Must be fitted with a separate filter element to prevent Blower

damage when it opens.

Note: When vacuum loading it is important that a vacuum relief

valve is installed within the system.

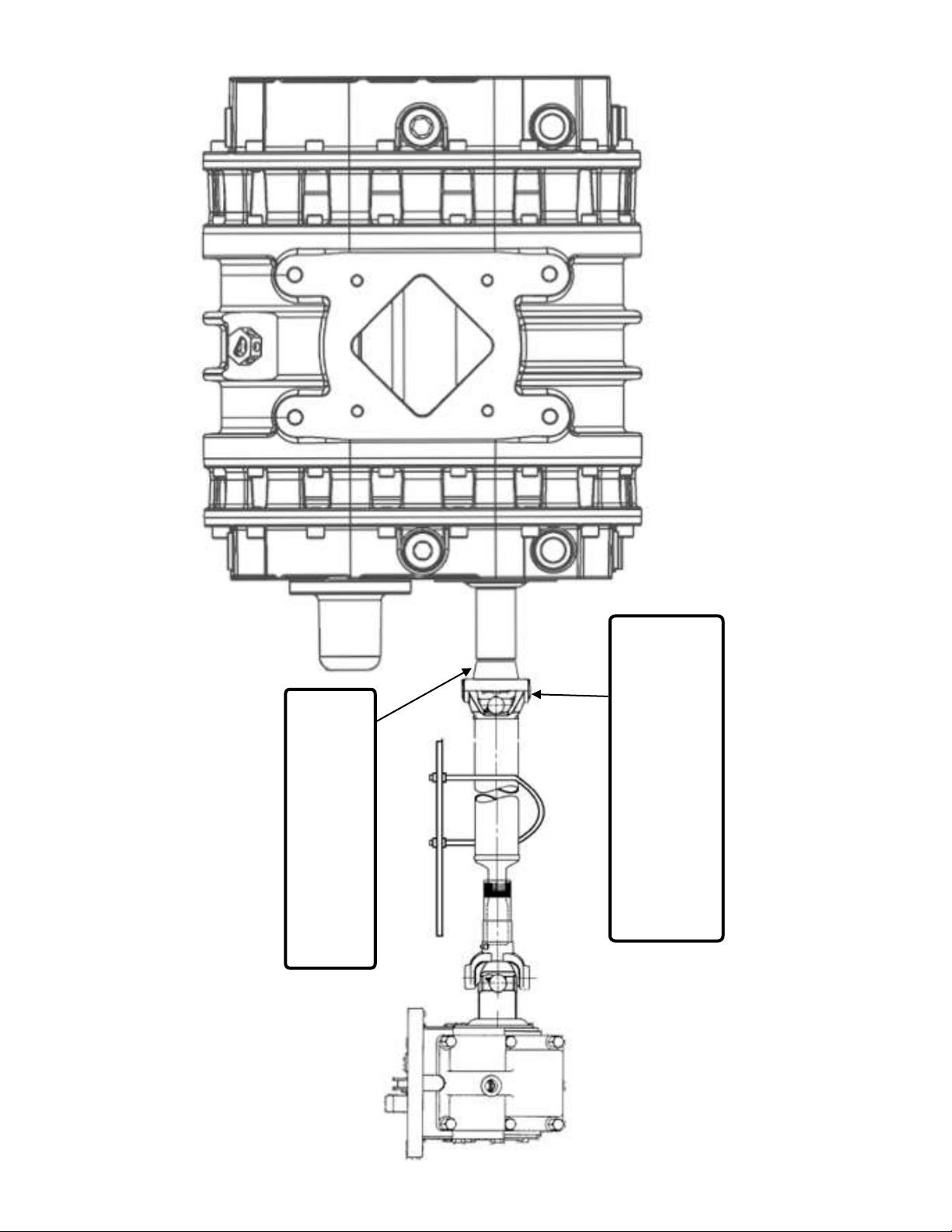

PTO Drive Shaft Single Piece

•Blower shaft must be parallel with the PTO

shaft axis within +/- 1 degree to minimize

vibration.

•Use tubular, balanced drive shaft.

•Do not force end yokes into Blower or PTO

shaft.

•Blower shaft is 1-5/8” dia. with 3/8” key.

•Maximum driveline working angle - see table

below: