4

WARNING!!! Use of the powered paraglider is at your own risk.

Table of Contents

WARNING!!! ................................................................................................ 2

PRE-FLIGHT CHECKS ..................................................................................... 5

FLIGHT SAFETY PRECAUTIONS ...................................................................... 6

SOME GOLDEN RULES !!! ............................................................................. 7

PRE-ASSEMBLY CHECK ................................................................................. 8

List of Components......................................................................................................... 8

FITTING THE RADIATOR ............................................................................... 9

F ll ng the rad ator. .................................................................................... 14

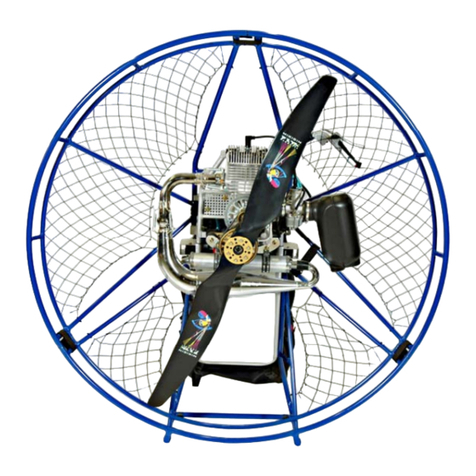

FITTING THE PROPELLER BLADES ............................................................... 16

ASSEMBLING THE 3-PIECE PROPELLER GUARD ........................................... 17

Charg ng the Cyclone L Po battery: ............................................................ 18

REDUCTION BELT ADJUSTMENT ................................................................. 19

FITTING THE WEIGHT-SHIFT HARNESS ....................................................... 20

ADJUSTING THE WEIGHT SHIFT HARNESS........................................................ 21

MIXING FUEL AND OIL ............................................................................... 22

Caution!..................................................................................................................... 23

PRIOR TO STARTING THE ENGINE .............................................................. 24

Warning!!! - Stay Clear of this Area !!! ..................................................................... 24

STARTING THE ENGINE AND ENGINE TEMPERATURE ................................. 25

STOPPING THE ENGINE........................................................................................... 28

RE-STARTING THE ENGINE.................................................................................... 28

ENGINE TEMPERATURE.......................................................................................... 29

CARBURETOR ADJUSTMENT ...................................................................... 30

ENGINE RUNNING IN PROCEDURE ............................................................. 31

MAINTENANCE SCHEDULE ......................................................................... 33

EVERY 5 HOURS........................................................................................................ 33

EVERY 10 HOURS...................................................................................................... 34

EVERY 50 HOURS...................................................................................................... 34

TROUBLE SHOOTING .................................................................................. 34

STORAGE FOR A LONG PERIOD AND USE THEREAFTER .............................. 35