by the host and will set its baud rate to match that of the host. Supported baud rates include 300, 600,

1200, 2400, 4800, 9600, 19200, 38400, 57600, and 115200.

When the LRF is ready to receive commands, it will send a “:” to the host. The LRF waits in an idle state

until it receives a valid command, at which time it performs the command and returns command-specific

data (if any). The LRF will return a “?” upon receiving an invalid command.

The camera system used in the LRF Module has automatic white balance, automatic exposure, and

automatic gain control enabled by default, and will automatically adjust its image to account for sudden

changes in lighting conditions. However, the LRF works best in a controlled environment, such as indoors

with minimal changes in brightness across the frame. The LRF is also less reliable when the laser is

shining onto a bright object (for example, a white piece of paper), since the background subtraction done

during image processing could potentially “subtract” the bright laser from the already bright frame. Giving

the camera time for its automatic white balance and automatic exposure to settle helps a bit to make the

laser spot stand out. Using a red filter over the camera will also help the red laser spot become more

visible to the camera in certain situations. See the “E” command in the Command Set section below, and

Range and Accuracy, page 8, for more details.

Status Indicator

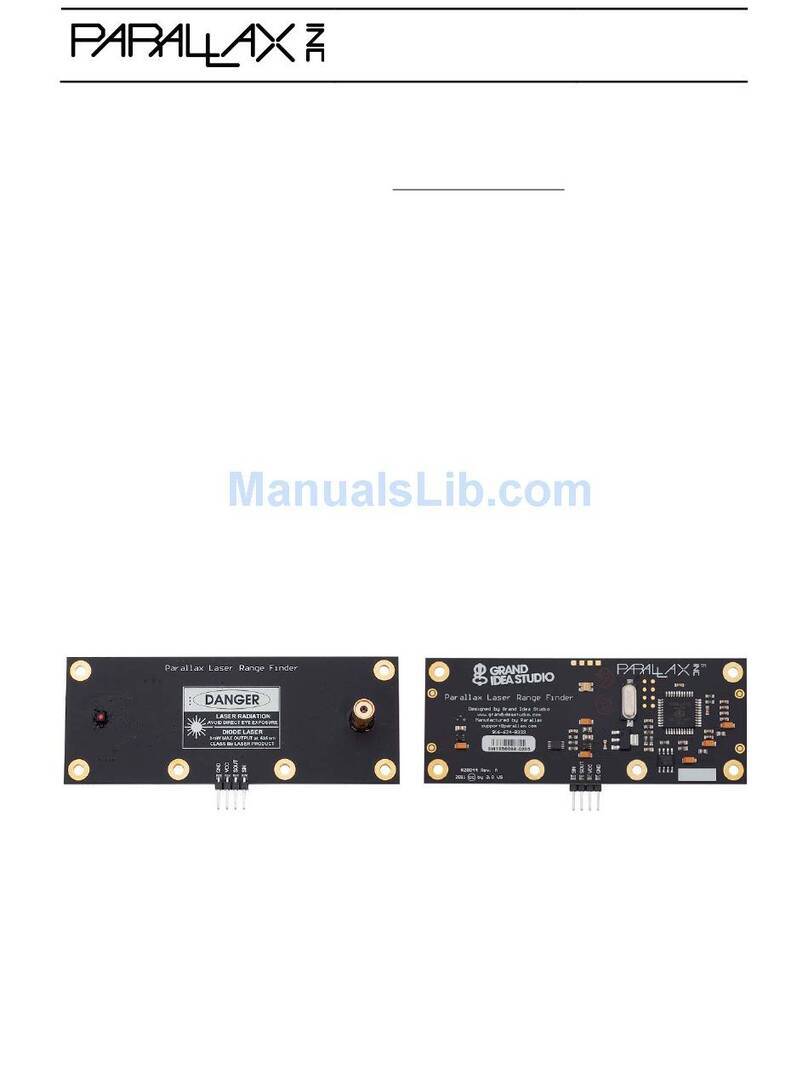

A visual indication of the LRF Module’s operating state is given with the on-board LED (Light-Emitting

Diode). The LED is located on the back side of the LRF near the center of the board. The LED denotes

four states of the Module:

1. Green: Idle state. Waiting for a valid command to be sent by the host.

2. Red: Active state. For example, performing a range calculation or capturing an image with the

camera.

3. Orange (Solid): Baud rate detection state. The LRF is waiting for a “U” character to be sent by

the host in order to automatically set the communications baud rate. Occurs on LRF power-up

only. See, Usage, page 2, for more details.

4. Orange (Blinking): Error state. The LRF has malfunctioned. A message identifying the failed

operation will be transmitted on the SOUT (Serial Out) pin. See Error Modes, page 9, for

more details.

If the LED is OFF, the LRF may not be receiving power.

Command Set

All commands are single-byte, ASCII printable values and are not case-sensitive (upper case and lower

case will both work). The basic and advanced command sets are described below.

Basic Commands

R Single range measurement (returns a 4-digit decimal value in millimeters)

B Single range measurement (returns a 4-byte binary value in millimeters)

L Repeated range measurement (any subsequent byte will stop the loop)

E Adjust camera for current lighting conditions

S Reset camera to initial settings

V Print version information

H Print list of available commands

Copyright © Parallax Inc. Parallax Laser Range Finder (#28044) v1.0 9/16/2011 Page 3 of 24