User Manual - Mistral M6&M8 - 04-2018 from s.n.1882761 edition

.

PARAMINA SA –Byway Evaggelistrias str. 19300 Aspropirgos, Greece, Tel: 0030 210 5575860

Fax: 0030 210 5575868, email: service@paramina.gr - website: www.paramina-compressors.com

6

If regulations dictate it, use means of individual protection.

Pay attention to labels indicating safety and risk for the unit. Strictly follow them and do not destroy them.

For any change in the operation of the unit, contact immediately the manufacturer.

Any alteration –conversion of the unit without the manufacturer’s prior written consent is not allowed.

Spare parts MUST be genuine –approved by PARAMINA.

Get accustomed to the position and use of fire extinguishing equipment that must be near the compressors.

Instructions for safe operation - risks

Check the unit on the inside and outside on a daily basis in order to make sure it is in good working condition.

Do not start the operation of the unit if you do not ensure your own safety.

Before you operate the compressor, make sure that requirements are met for the safe and smooth operation of

the unit.

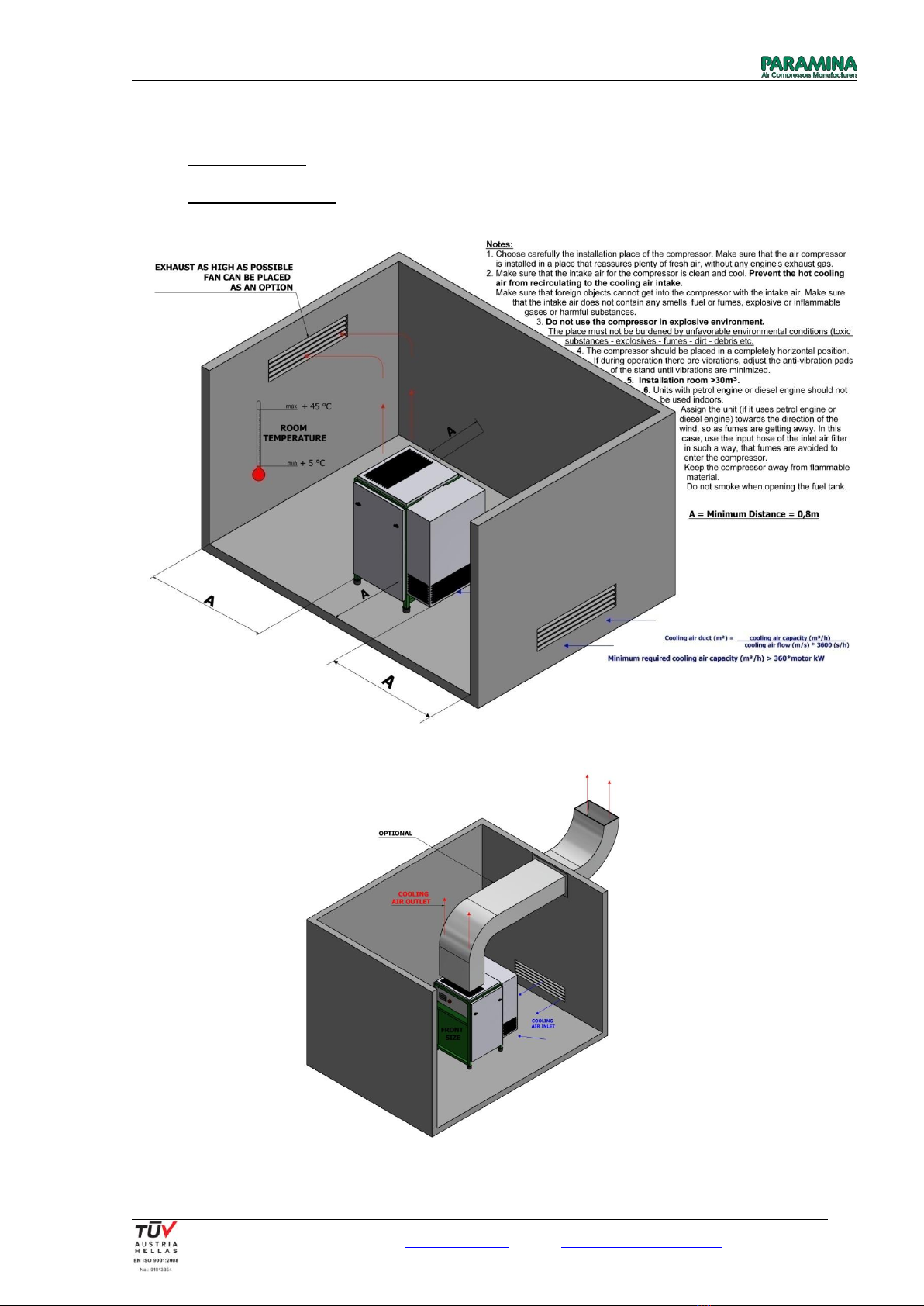

Floor must be even. Adjust the anti vibration pads, so as the unit is in horizontal position and shocks are

minimized.

Place the compressor in a well-ventilated area. Make sure that the intake air for the compressor is clean and

cool. Prevent the hot cooling air from recirculating to the cooling air intake. Make sure that foreign objects

cannot get into the compressor with the intake air. Make sure that the intake air does not contain any smells,

fuel or fumes, explosive or inflammable gases or harmful substances.

Units with petrol engine or diesel engine should not be used indoors.

Assign the unit (if it uses petrol engine or diesel engine) towards

the direction of the wind, so as fumes are getting away. In this

case, use the input hose of the inlet air filter in such a way,

that fumes are avoided to enter the compressor.

Keep the compressor away from flammable material. Do not smoke when

opening the fuel tank.

If any malfunction of the unit occurs, stop immediately its operation and check –fix the problem.

Before any maintenance or repair works, inform the users.

When replacing heavy-weight components, strap them carefully on the proper lift truck. Never walk under such

components when they are lifted.

Before any maintenance works, clean the area from out-of-use material, oils, fuel or other liquids from the unit.

Do not use corrosive materials. If you clean the unit by water or steam, make sure that neither water nor steam

comes close to the electric motor or the electric system and ensure that they will not enter open hoses. For

cleaning, use lint-free cloth.

After cleaning or repairing the unit, check all hoses for leaks, loose connections, wear or damages. Tight again

all connections and recheck every maintained safety device.

Ensure safe and environmental friendly disposal of consumable materials and old spare parts.

Special attention

Do not use the compressor in explosive environment.

Connect the compressor only to electrical systems that are compatible with its electrical characteristics and that

are within its rated capacity

Comply with the local mains supply company regulations.

Use only the recommended fuses.

A trained electrician may only execute maintenance in the electrical system.

During any maintenance work in the unit, turn off the power from the mains. It is also recommended posting a

notice warning about maintenance works on the compressor.

In case of having to execute maintenance works on an operating unit, a second person beside the electrician

must be present to handle the main safety switch. Tools to be used must be isolated.

Regularly check hoses, couplings and fittings for leaks and loose connections.

Regularly check tightening of the electrical connections.

If you replace mains cable, you must use the same type.

Decompress all hoses, filters, pressure tanks and, basically, the entire unit, before you carry out any work.

Never exceed the allowed operating pressure of the cylinders.

Immediately replace cylinders with any kind of damage.