10 11

KEEP ALL SCREWS AND COVERS TIGHTLY IN PLACE: Check the

screws and covers periodically.

ADEQUATE VENTILATION: The compressor should only be used in

areas with adequate ventilation and should not be exposed to heat, or

used near inflammable substances.

NEVER USE AN AIR COMPRESSOR WHICH APPEARS DEFECTIVE

OR IS OPERATING ABNORMALLY: If the compressor operates

unusually or makes strange noises, switch o immediately and purge the

air tank. Arrange repair with an authorised service centre.

DO NOT MODIFY THE AIR COMPRESSOR: Do not attempt to modify

the air compressor, tank, fittings or attachments in any way. Doing so will

invalidate the guarantee and could result in personal injury.

DO NOT MODIFY THE TANK: Do not modify the tank or operate at

pressures or temperatures outside the limits stated in this booklet.

TURN OFF THE AIR COMPRESSOR WHEN NOT IN USE: When not in

use, turn o the air compressor by pressing the On/O switch, remove

the plug from the mains supply and slowly undo the drain valve to release

the pressure from the tank. Remember to close the drain valve before

storage and ensure it is fully tightened before use.

DO NOT TOUCH HOT SURFACES: During operation, the motor,

connections, compressor body, cylinder head and tubes may get hot,

please take care.

DO NOT DIRECT THE AIR STREAM AT THE BODY: Do not direct the

air stream at people or animals, as injury may result. Compressed air

can cause soft tissue damage and propel dirt and other particles at high

speed.

ONLY USE RECOMMENDED PARTS: To avoid the risk of bursting, only

hoses with a rated pressure of 8 bar, or more should be used. Never

attempt to repair faulty hoses.

DO NOT USE THIS COMPRESSOR TO INFLATE SMALL,

LOW-PRESSURE OBJECTS: Items such as children's toys or footballs

can explode if over-inflated.

AVOID KINKING OR TRAPPING THE AIR HOSE: Always replace faulty

hoses - never attempt a repair if a leak is detected.

DRAIN TANK: Drain the tank after each use, switch o and slowly open

the drain valve to release the air then tilt the compressor to empty

condensed water

STORE THE AIR COMPRESSOR PROPERLY: When not in use the air

compressor should be stored in a secure, dry place out of the reach of

children. Always lock up the storage area.

PROTECT YOUR HEARING: Ear protection should be worn when

operating this compressor.

MAINTAIN THE AIR COMPRESSOR WITH CARE: If the air compressor

is damaged in any way, have it repaired by a qualified service engineer.

EXTENSION LEAD: Only use extension leads that are of an

appropriate power rating and suitable for the work environment.

Extension leads must have an earth connection. Inspect the extension

lead regularly and replace if damaged.

ONLY USE PARTS AND ACCESSORIES RECOMMENDED IN THIS

MANUAL: The use of unauthorised accessories or attachments is not

permitted and may result in personal injury and damage to the air

compressor. Do not attempt to repair or modify the air compressor.

STAY ALERT: Watch what you are doing, use common sense, and do

not operate the air compressor when you are tired. The air compressor

should not be used if you are under the influence of alcohol, drugs or any

medication that makes you drowsy.

EACH USE CHECK THE AIR COMPRESSOR AND HOSE FOR

DAMAGED PARTS: Never use the air compressor if it has been

damaged in any way. Have the air compressor repaired by a qualified

service engineer. Do not use the air compressor if the On/O switch does

not operate correctly.

HANDLE THE AIR COMPRESSOR CAREFULLY: Operate the air

compressor according to the instructions contained within this

instruction booklet. This air compressor should never be operated by

children or individuals unfamiliar with its operation.

KEEP THE MOTOR AIR VENT CLEAR: Keep the motor vent clear and

free from dust, wipe regularly to maintain an adequate supply of clean air

to the air compressor.

OPERATE THE AIR COMPRESSOR AT THE CORRECT VOLTAGE: Make

sure that the mains supply voltage is the same as the voltage shown on

the rating plate.

DO NOT WIPE THE PLASTIC PARTS WITH SOLVENT: Do not use

solvents or thinners such as petrol, benzene, carbon tetrachloride or

alcohol to clean the air compressor, as these chemicals will damage the

finish. With the air compressor unplugged from the supply, use a dry

cloth to wipe over the plastic casing.

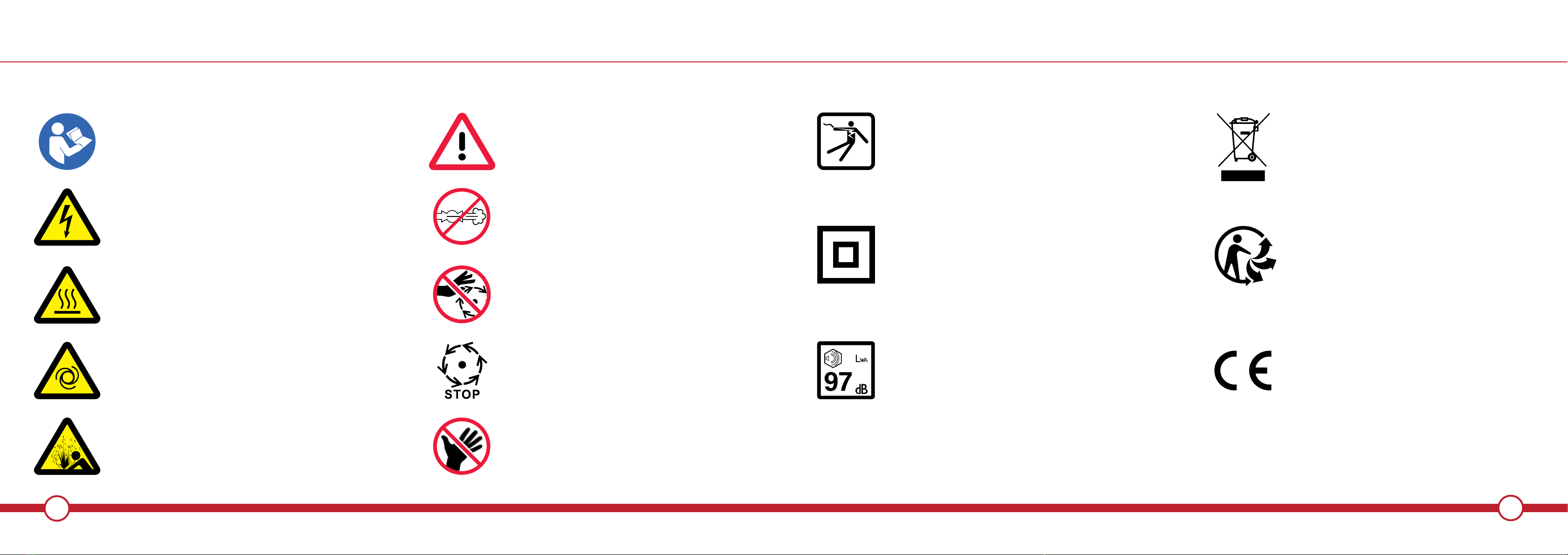

FOR SAFE OPERATION

FOR SAFE OPERATION

i

ii

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i