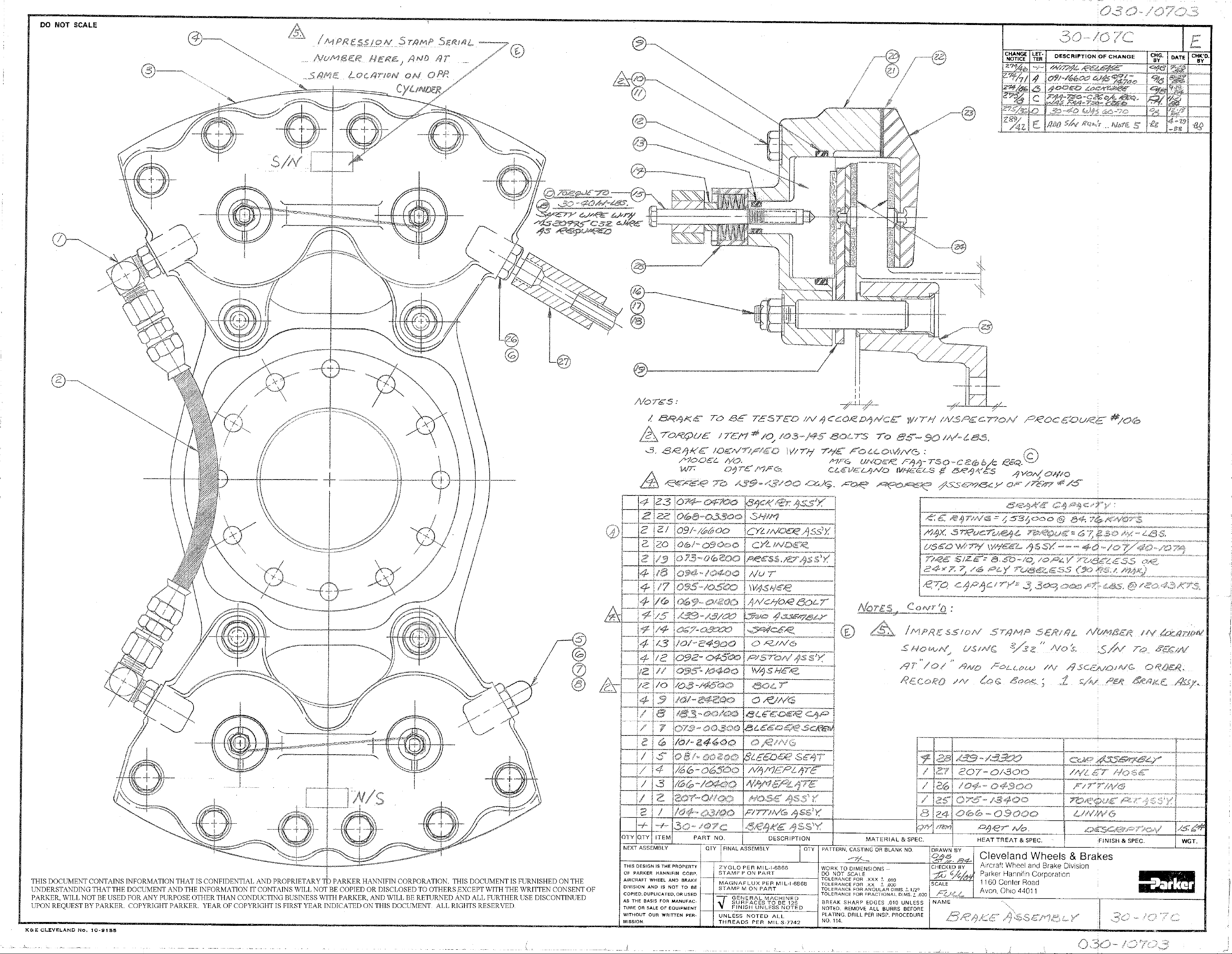

MM40-107/30-107 COMPONENT MAINTENANCE MANUAL WITH IPL

FOR MAIN WHEEL ASSEMBLY PART NO. 40-107 SERIES AND

MAIN BRAKE ASSEMBLY PART NO. 30-107 SERIES

Page LR-1/1

Feb 01/02

LIST OF REVISIONS

REV

DATE PAGE DESCRIPTION APPROVAL

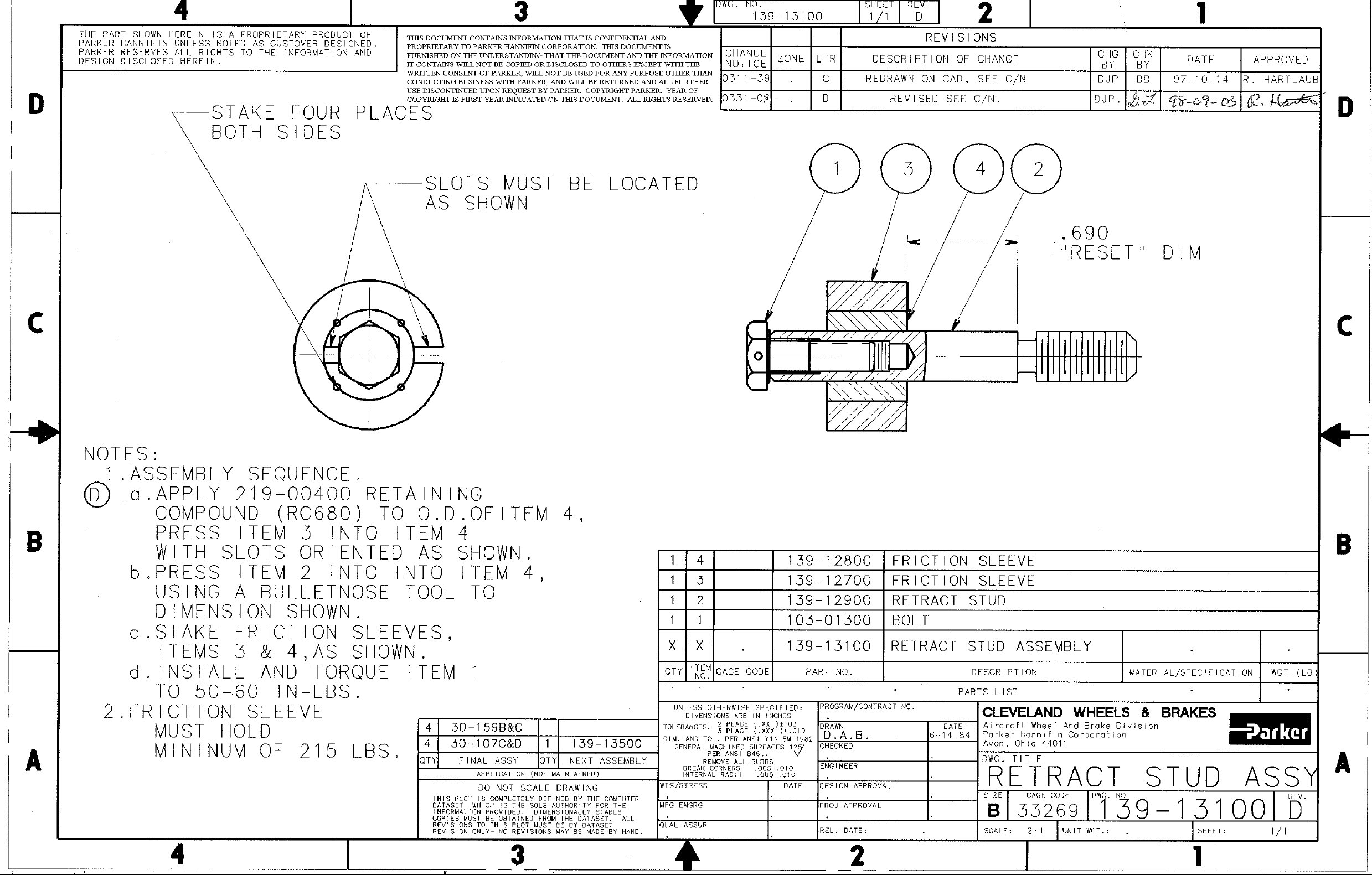

A5-5-82 7.1 B,2) & B,5)…Changed to call out removal

and installation of stud assembly from

piston instead of bolt from stud. Added

“torque stud assembly at 60-70 in-lbs.”

B.B.

7.2 …Added call out of 110-04900 stud assy.

B7-29-83 45.2.0…Changed to call out removal and

installation of center rivet. Delete appli-

cation of glue to backside of lining.

B.B.

7.1 …”SERIES” was “/30-107A”

…Added line B,2A) B,5)…Added “(or bolt

and spring guide, if used).” Added “(or

bolt P/N 103-15300, is used).”

7.2 …Added footnote *

…Added footnote **

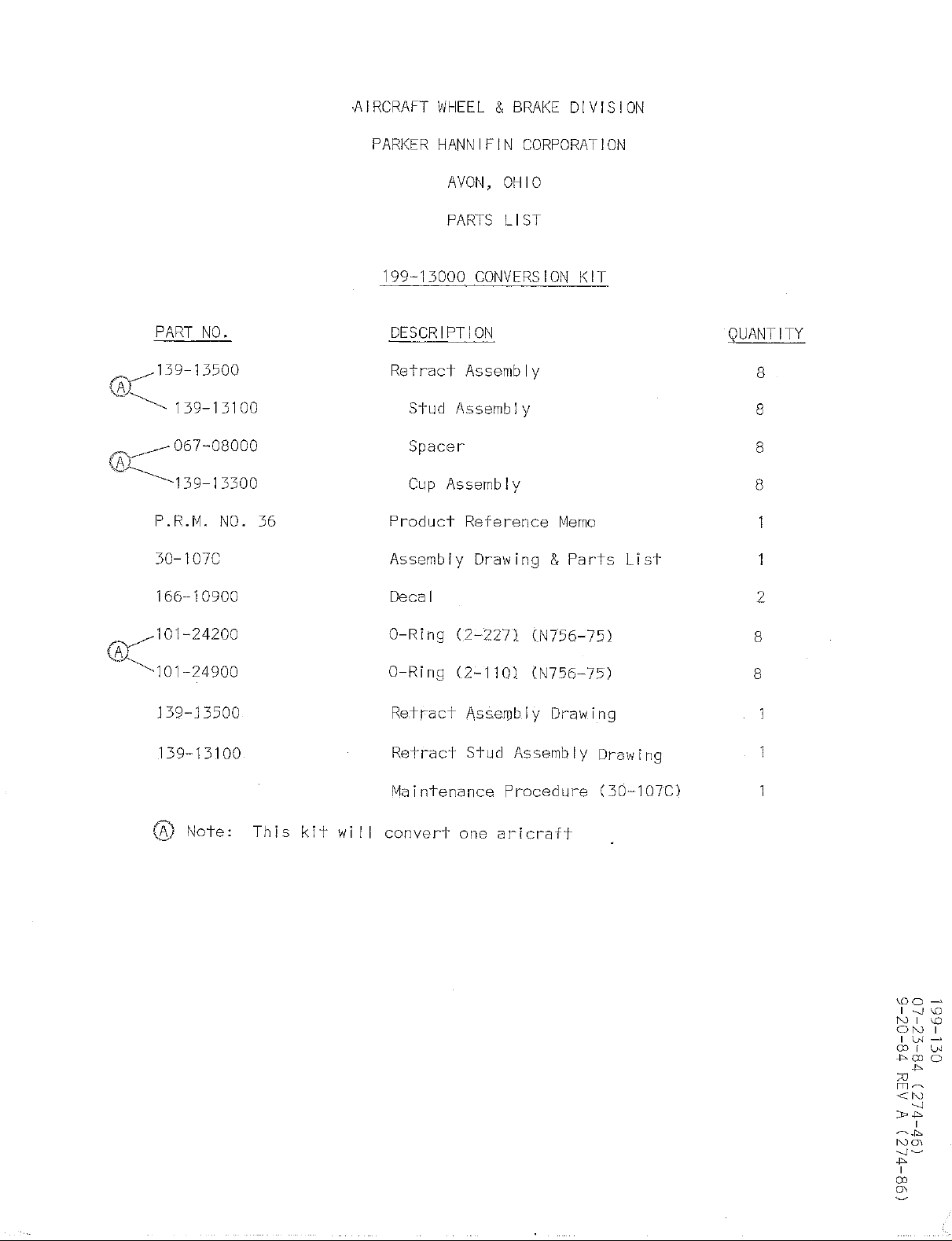

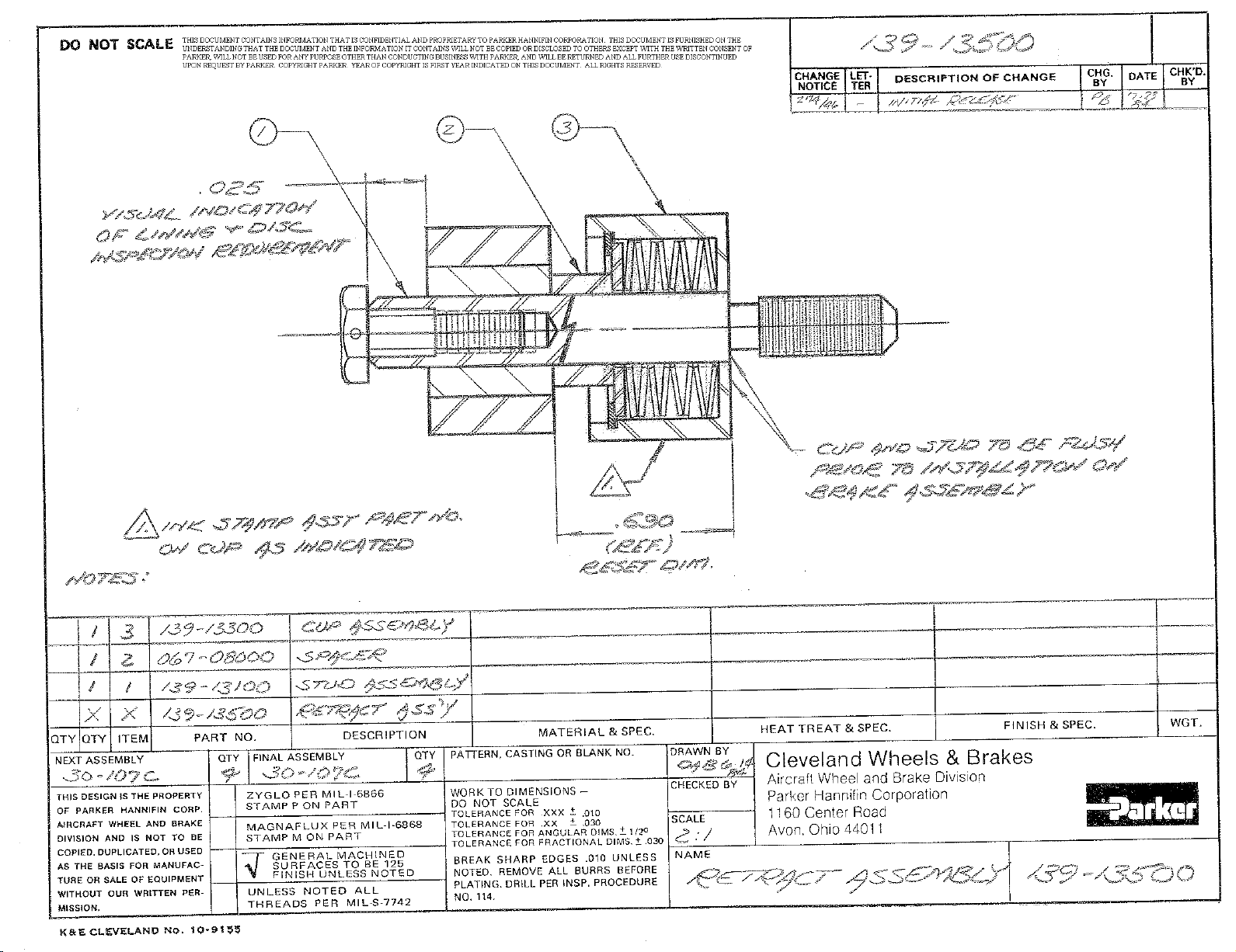

C9/27/84 7.3 …Added Section 7.3, Maintenance

Instructions, 30-107C Brake Assembly B.B.

D12/10/84 7.3 …Added 30-107D

Para. 7.3, 1.: Added “199-13001” and

“38”.

Para. 7.2, 1.< 16): “30-40” was “60-70”.

B.B.

E3/18/87 6“.492” was “:.502” B.B.

F1/10/89 2Sec. 3.1.2 Add “…300 in-lb.” B.B.

G02/01/02 ALL Add instructions for 30-107E and Update

formatting B.B.